Method for designing gear forging die by three-order non-uniform rational B-splines

A non-uniform and rational gear technology, applied in the direction of wheels, vehicle parts, metal processing equipment, etc., can solve the problems of long production cycle and high production cost, and achieve the effects of reducing production man-hours, saving forging die costs and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

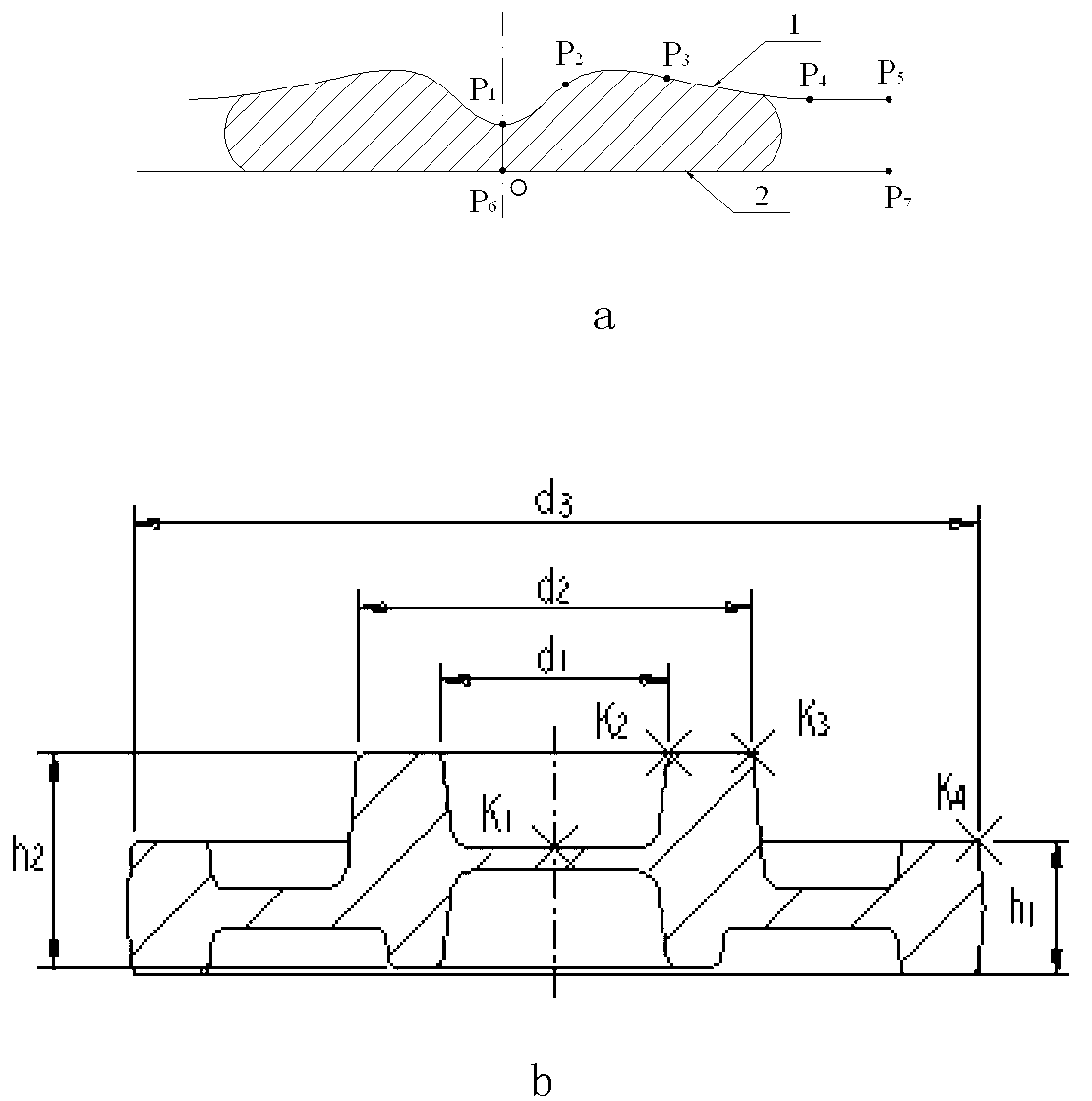

[0029] This embodiment is a method for designing a forging die of a gear forging by using a third-order non-uniform rational B-spline. The gear forging die is used to produce figure 1 (b) Gear forging shown. The gear forging is a typical short-shaft forging, which is composed of three parts: the hub, the spoke plate and the rim. According to the diameter and height of the gear forging hub and rim, the type value point of the third-order non-uniform rational B-spline curve is determined. Through This type of value point establishes a third-order non-uniform rational B-spline curve.

[0030] The gear forging die described in this embodiment includes a final forging die chamber and a forming and upset die chamber. The specific design process includes the following steps:

[0031] Step 1 Design the final forging die cavity. According to the design method of the final forging die chamber in the forging manual, design the final forging die chamber according to the gear forging. ...

Embodiment 2

[0051] This embodiment is a method for designing a forging die of a gear forging by using a third-order non-uniform rational B-spline. The gear forging die is used to produce figure 1 (b) Gear forging shown. The gear forging is a typical short-shaft forging, which is composed of three parts: the hub, the spoke plate and the rim. According to the diameter and height of the gear forging hub and rim, the type value point of the third-order non-uniform rational B-spline curve is determined. Through This type of value point establishes a third-order non-uniform rational B-spline curve.

[0052] The gear forging die described in this embodiment includes a final forging die chamber and a forming and upset die chamber. The specific design process includes the following steps:

[0053] Step 1 Design the final forging die cavity. According to the design method of the final forging die chamber in the forging manual, design the final forging die chamber according to the gear forging. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com