Unmanned aerial vehicle with night flight LED lamp

A technology for LED lamps and LED lamp sockets, which is applied in the field of aircraft, can solve the problems of increasing difficulty in the design of mold structures and demolding mechanisms, complex structural design of plastic parts, and complex structures, so as to reduce the maintenance cost of the mold, and achieve a compact structure. Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

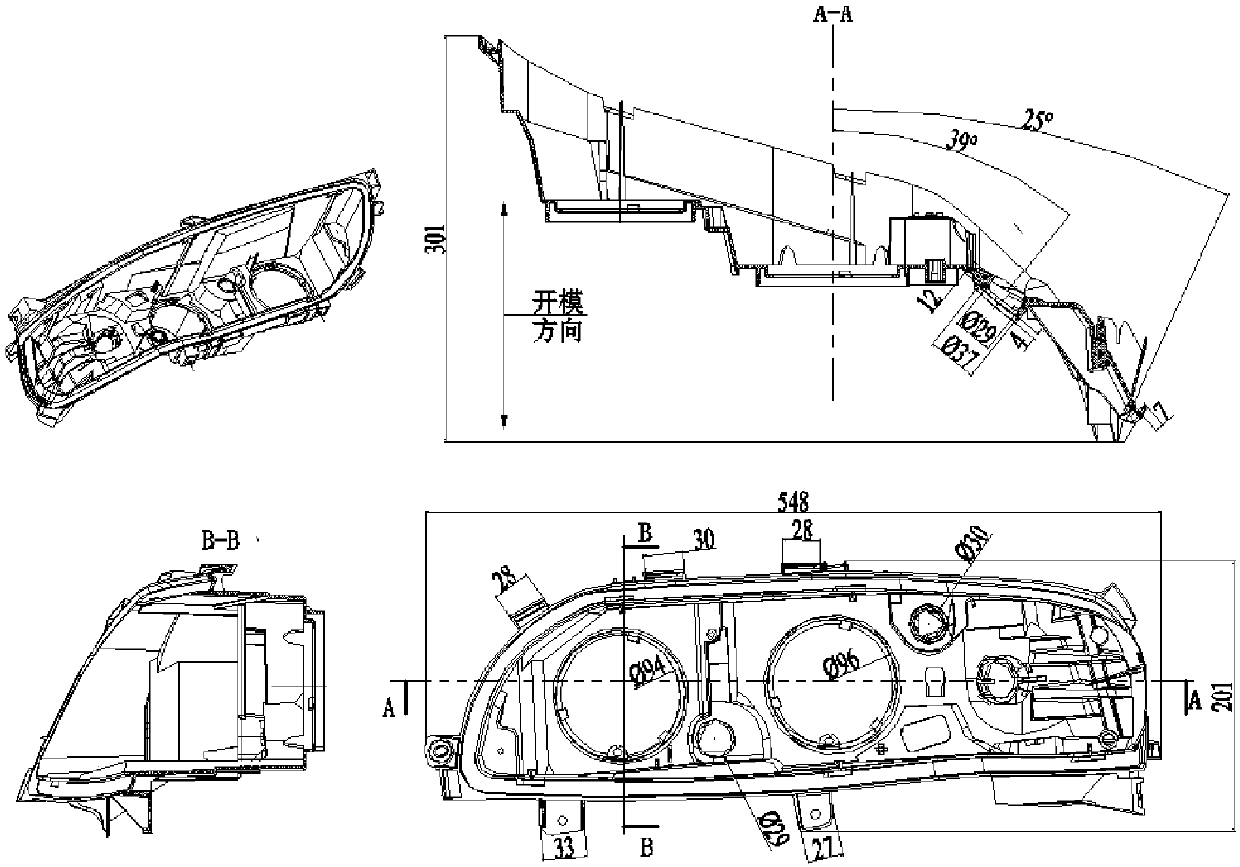

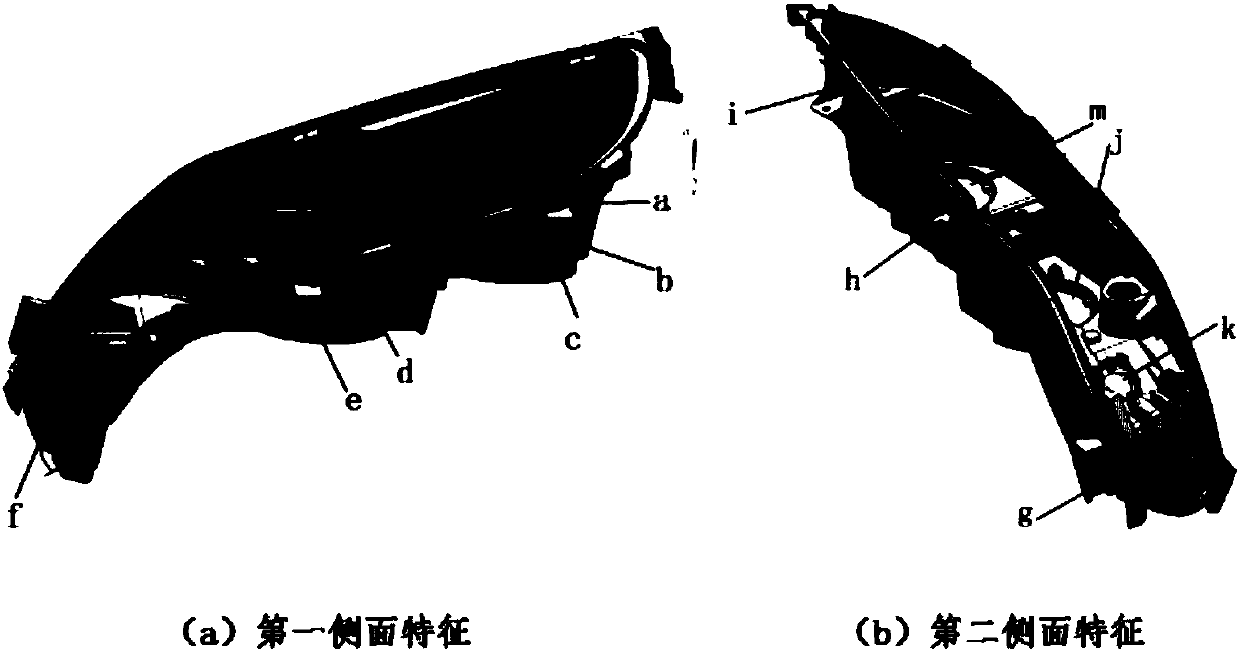

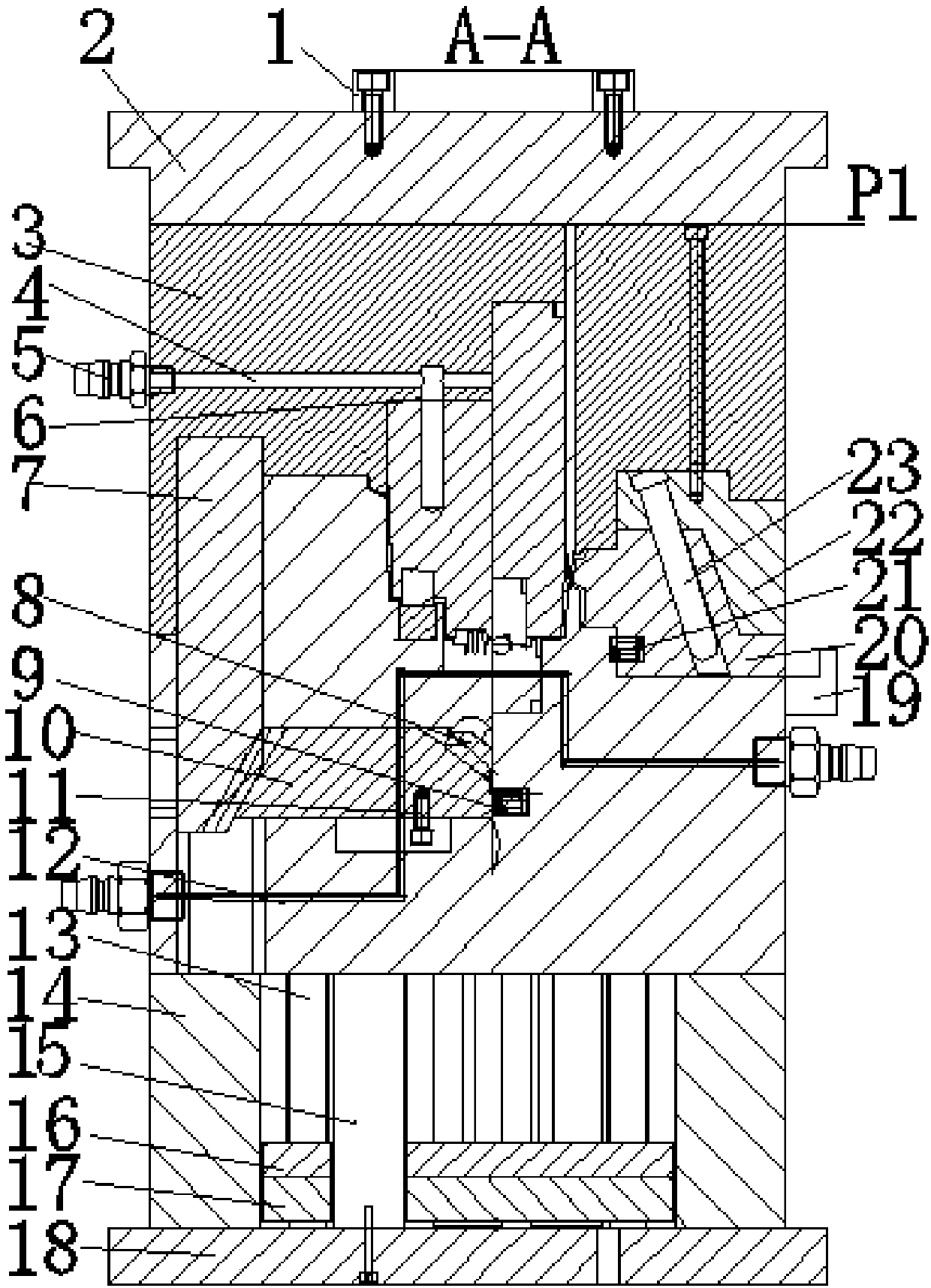

[0028] Figure 1-9 Shown is the relevant explanatory diagram of the present invention; the product structure targeted by this mold is as follows figure 1 , figure 2 As shown; when the product is injection molded, when the molded part is designed, the parting design is as follows figure 1 When designing the mold opening direction shown in the A-A section in the middle, the following difficulties need to be solved in the design of the mold: 1) The shape is irregular and there are many ribs. Potential cracks are generated, so the gate position and the design of the gating system must be selected reasonably; 2) The wall thickness of the product is uneven, and there are many internal holes, and shrinkage warpage is easy to occur after injection molding; 3) Narrow holes, walls, etc. There are many features, and the corresponding cavity and core inserts are difficult to design and process; 4) The shape is irregular, so the cooling water channel cannot effectively follow the shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com