Mechanism assisting in oblique ejection of centre through injection mold

A technology of injection molds and thimbles, which is applied in the field of mechanisms for auxiliary thimble ejection of injection molds, which can solve the problems of high mold manufacturing costs, low product production efficiency, and the inability of molds to be made into one mold with multiple cavities, so as to improve production efficiency , The structure is simple and reliable, and the effect of reducing the cost of mold opening and injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

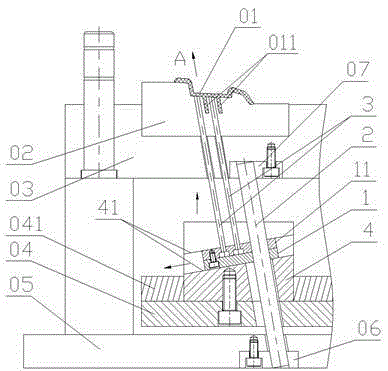

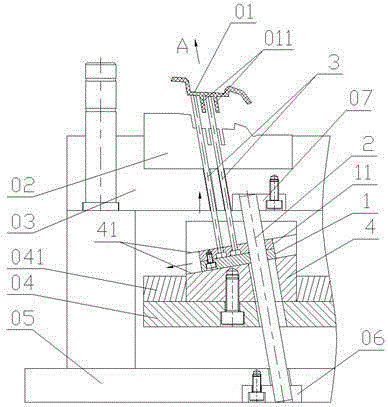

[0010] Figure 1-2 Shown is an explanatory diagram related to the present invention; a mechanism for an injection mold auxiliary thimble ejecting obliquely, including a sliding plate 1, a sliding pressure plate 11, a guide rod 2, an ejector rod 3, and a sliding seat 4.

[0011] The sliding plate 1 is fixed together with the sliding pressure plate 11, and can slide obliquely in the sliding seat 4, such as figure 1 shown.

[0012] The upper section of the guide rod 2 is fixed in the upper fixed block 07, the middle is in the sliding plate 1, and the lower end is fixed in the lower fixed block 06, as figure 1 shown.

[0013] The oblique angle of the ejector rod 3 is consistent with the oblique rib position 011, the upper end of the ejector rod 3 is in the movable mold core 02, and is in contact with the product 01, and the lower end of the ejector rod 3 is fixed on the slide plate 1 and the slide platen 11 between, such as figure 1 shown.

[0014] Described sliding seat 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com