Particle damping rubber vibration isolator of engine

A rubber vibration isolator and particle damping technology, which is applied in the direction of non-rotational vibration suppression, can solve the problems of difficult design and manufacture, high cost, and complex structure of liquid resistance rubber vibration isolators, and achieve simple and reliable structure, low cost, Create a convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

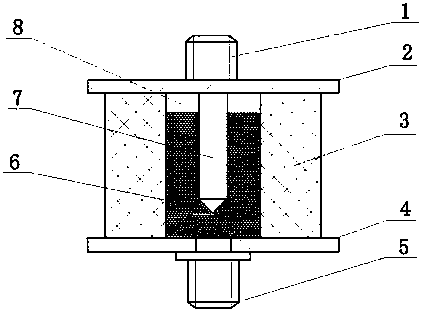

[0021] A particle damping rubber vibration isolator for an engine. The particle damping rubber vibration isolator is as figure 1 As shown, it consists of upper connecting bolt 1, upper connecting plate 2, vibration isolation rubber 3, lower connecting plate 4, lower connecting bolt 5, granular damping material 6 and damping rod 7. The upper end surface and the lower end surface of the vibration isolation rubber 3 are vulcanized and bonded to the corresponding upper connecting plate 2 and lower connecting plate 4, the lower plane of the lower connecting plate 4 is fixed with the lower connecting bolt 5, and the upper plane of the upper connecting plate 2 is fixed with an upper The connecting bolt 1 and the lower plane of the upper connecting plate 2 are fixed with a damping rod 7 . The upper connecting bolt 1, the upper connecting plate 2, the vibration isolation rubber 3, the lower connecting plate 4, the lower connecting bolt 5 and the damping rod 7 are connected with the sa...

Embodiment 2

[0029] A particle damping rubber vibration isolator for an engine. Except following technical parameter, all the other are with embodiment 1.

[0030] The loading amount of the granular damping material 6 is 60-75% of the volume of the damping chamber 8 .

[0031] The material of the vibration-isolation rubber 3 is nitrile rubber.

[0032] The shape of the upper connecting plate 2 is oval, and the shape of the lower connecting plate 4 is the same as that of the upper connecting plate 2 .

[0033] The length of the damping rod 7 is 0.7-0.8 times the height of the vibration-isolation rubber 3, and the cone angle of the free end of the damping rod 7 is 70-100°.

[0034] The shape of the granular damping material 6 is a sphere with a diameter of 0.5-1mm. The particle damping material 6 is made of lead.

[0035] The hollow cylinder is an elliptical cylinder with a central hole, and the central hole is an elliptical hole.

Embodiment 3

[0037] A particle damping rubber vibration isolator for an engine. Except following technical parameter, all the other are with embodiment 1.

[0038] The loading amount of the granular damping material 6 is 70-85% of the volume of the damping chamber 8 .

[0039] The material of the vibration-isolation rubber 3 is neoprene.

[0040] The shape of the upper connecting plate 2 is polygonal, and the shape of the lower connecting plate 4 is the same as that of the upper connecting plate 2 .

[0041] The length of the damping rod 7 is 0.7-0.8 times the height of the vibration-isolation rubber 3, and the cone angle of the free end of the damping rod 7 is 50-80°.

[0042] The shape of the granular damping material 6 is a sphere with a diameter of 1-5mm. The particle damping material 6 is made of copper.

[0043] The hollow cylinder is a prism with a central hole, and the central hole is a polygonal hole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com