Technics for manufacturing plastic products based on ejection principle and device thereof

A technology for plastics and products, applied in the field of product manufacturing technology, can solve the problems of huge equipment investment, increased mold opening costs, and inability to manufacture, and achieve the effect of reducing mold opening costs and injection molding costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

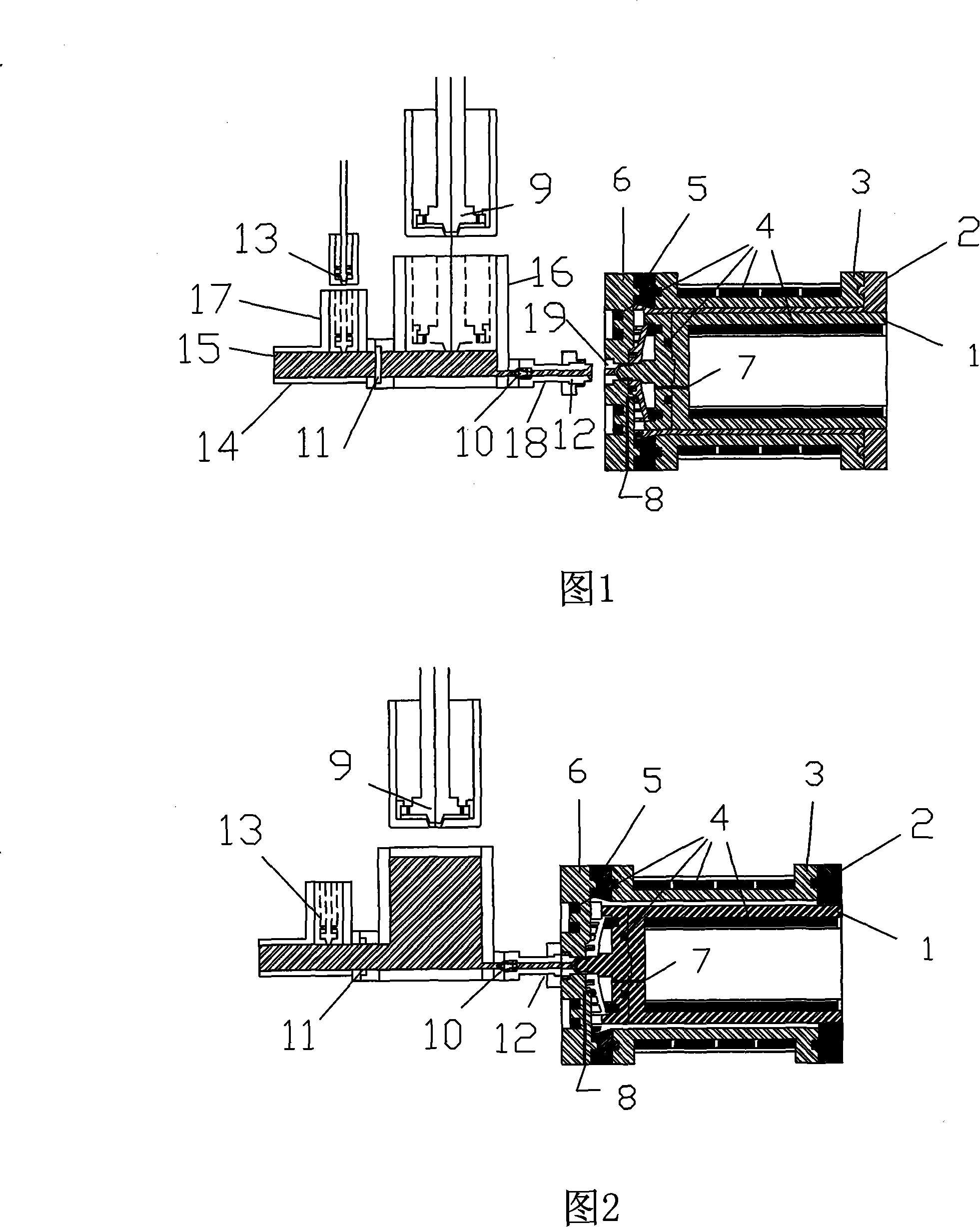

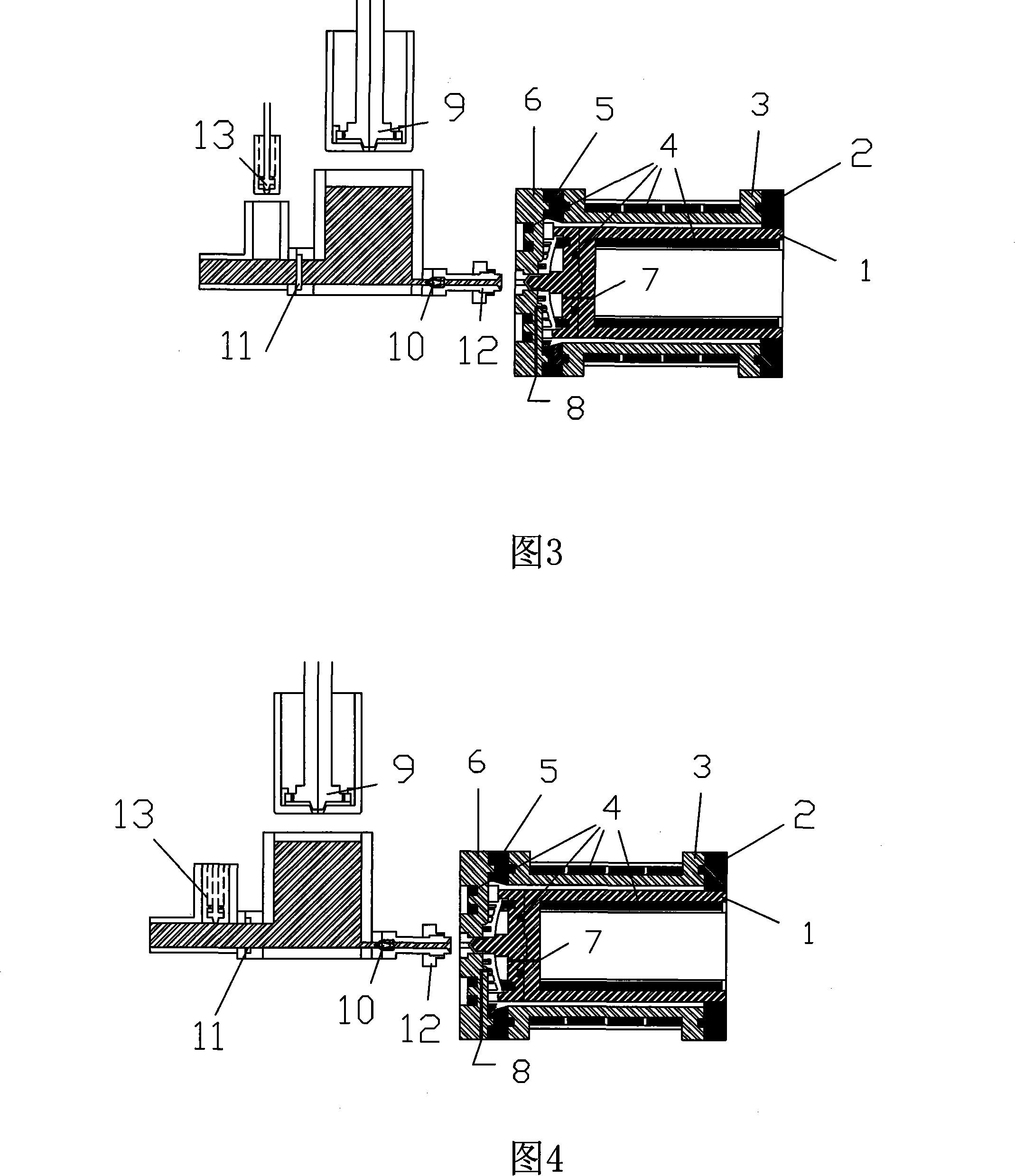

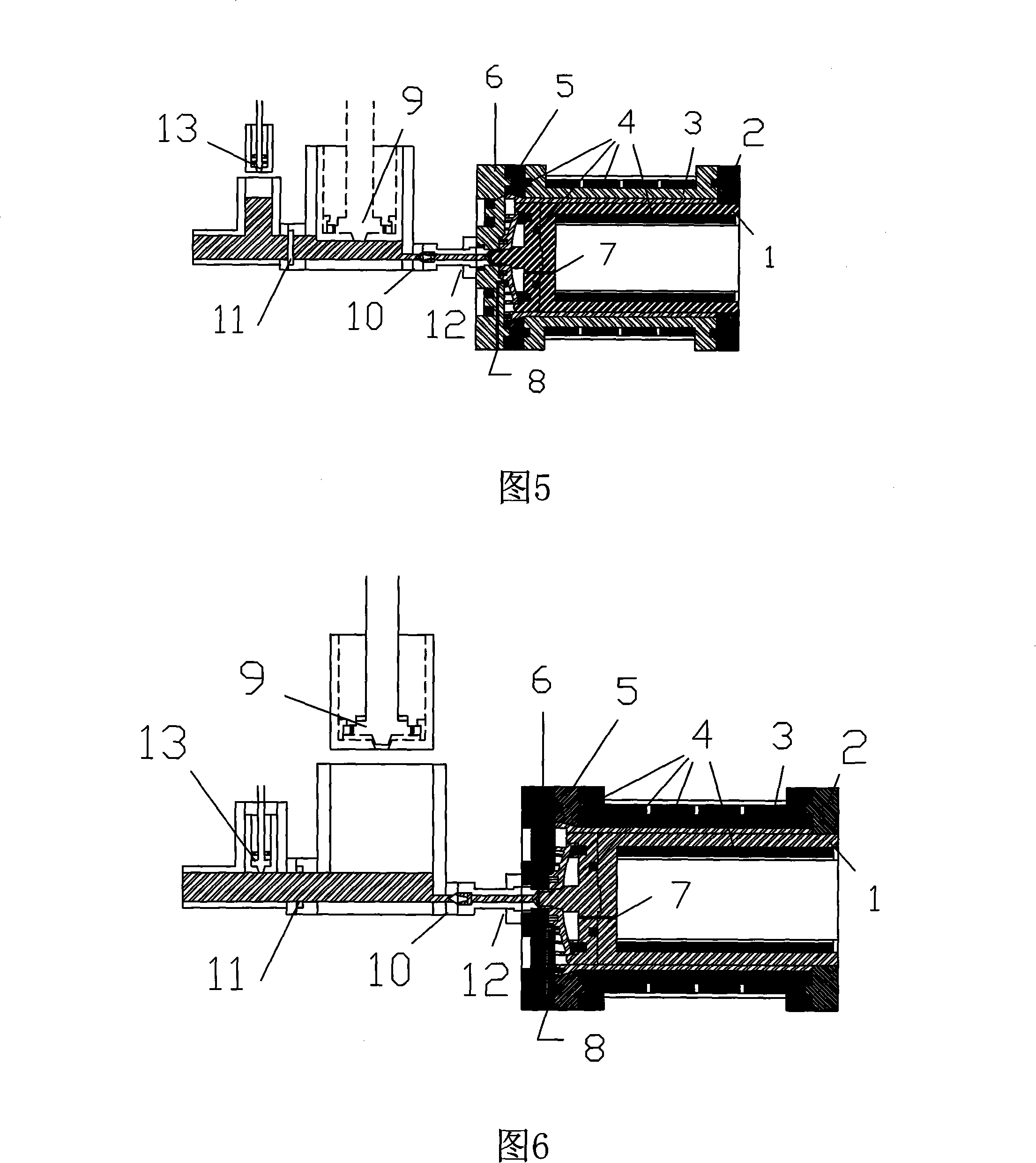

[0016] 1, the present invention discloses a device for manufacturing plastic products with overweight or complex structure based on the principle of injection. The device includes an extruder 14 and a mold. The extruder 14 is provided with a feed channel 15 along the feed channel 15 There is an extrusion storage barrel 16 and a storage storage barrel 17, of course, multiple storage storage barrels 17 can also be provided. The extrusion storage barrel 16 and the storage storage barrel 17 are equipped with hydraulic devices 9 and 13, respectively. A control valve 11 is installed between the extrusion storage barrel 16 and the storage storage barrel 17; The discharging pipe 18 butted with the mold is equipped with a valve, and the end of the discharging pipe is provided with a locking screw 12. The valve can be a check valve 10 or other valves that are in operation.

[0017] As shown in the figure, the mold consists of a male mold core 1, a female mold 3 mounted on the male mold core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com