Patents

Literature

31results about How to "Change wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

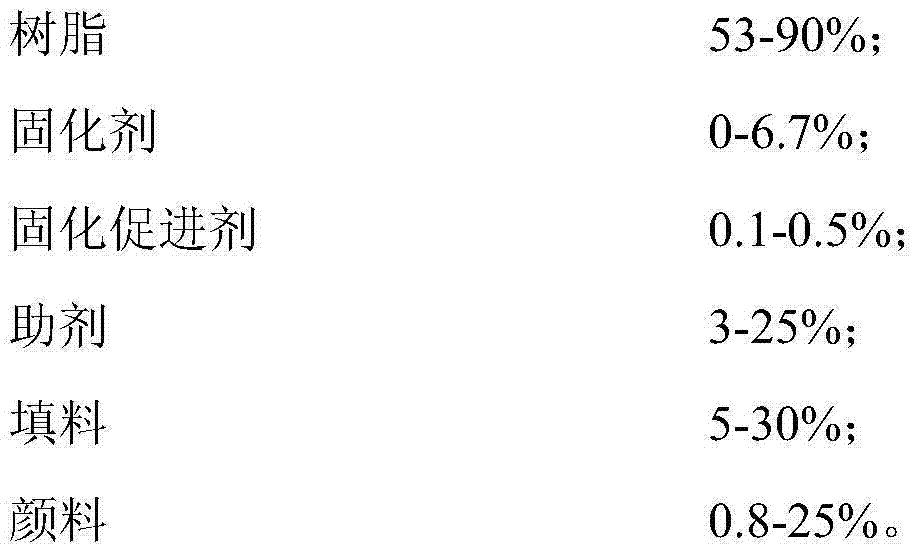

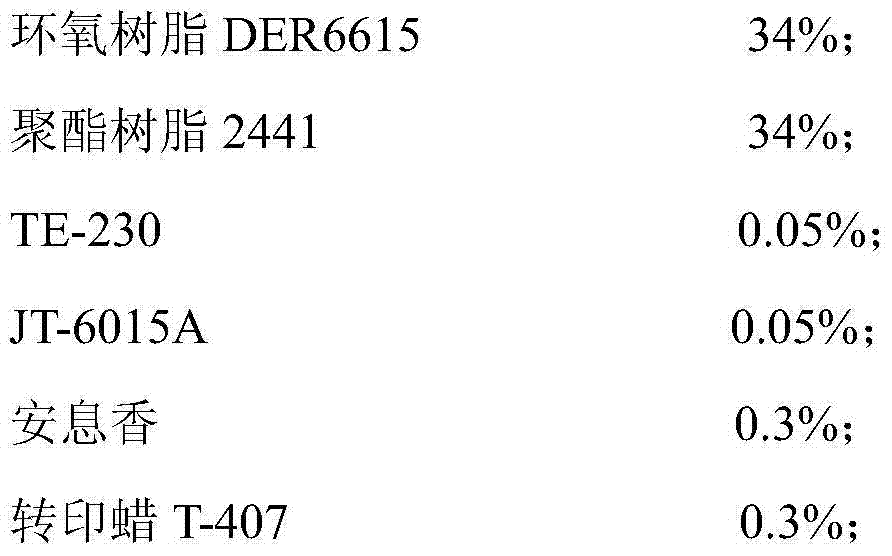

Powder coating for MDF transfer printing and application method of powder coating

PendingCN104497808AImprove texture clarityEasy to tear offDuplicating/marking methodsPowdery paintsWeather resistanceWear resistance

The invention relates to powder coating and particularly relates to powder coating for MDF transfer printing and an application method of the powder coating. The powder coating is prepared from the following raw materials in percentage by weight: 53-90% of resin, 0-6.7% of a curing agent, 0.1-0.5% of a curing accelerant, 3-25% of auxiliaries, 5-30% of filler and 0.8-25% of pigment. After the powder coating is used for transfer printing, the texture is clear, the penetration is deep, the third dimension is strong, the transfer printing paper can be easily uncovered, the thermal transfer printing product is durable in use, and the patterns are not dropped, cracked or faded; moreover, the thermal transfer printing only achieves a surface decoration effect without changing the characteristics of the original glossiness, the wear resistance, the weather resistance, the acid and alkali resistance, and the like of the product. The invention also provides an application method of the powder coating.

Owner:山东朗法博粉末涂装科技有限公司

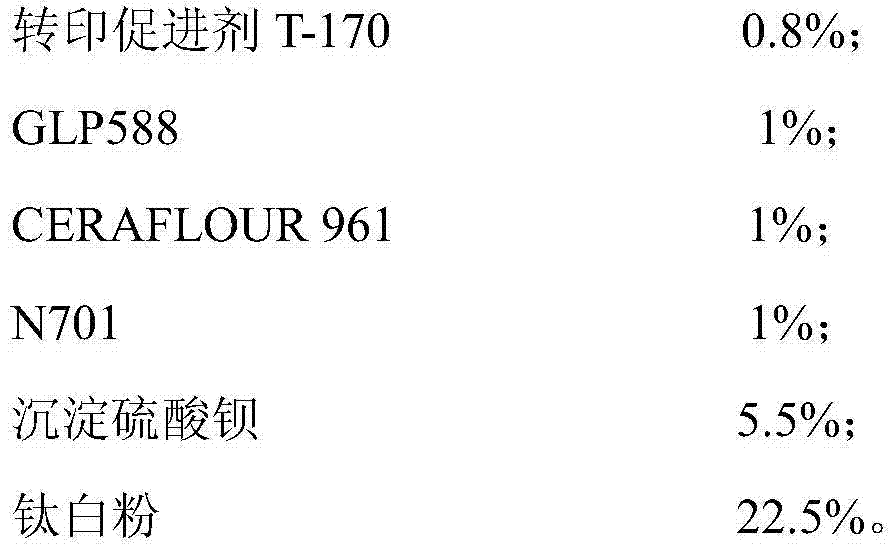

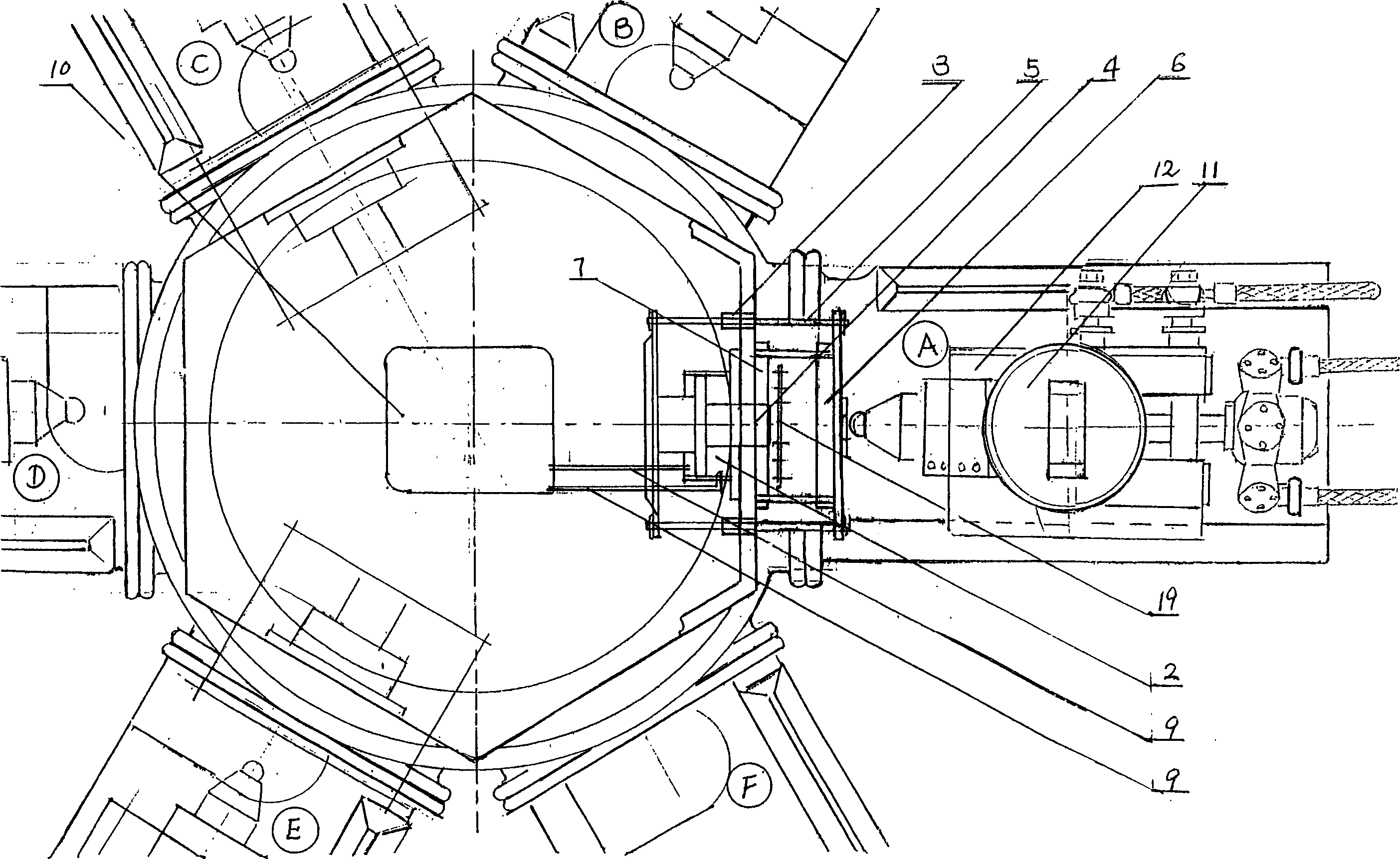

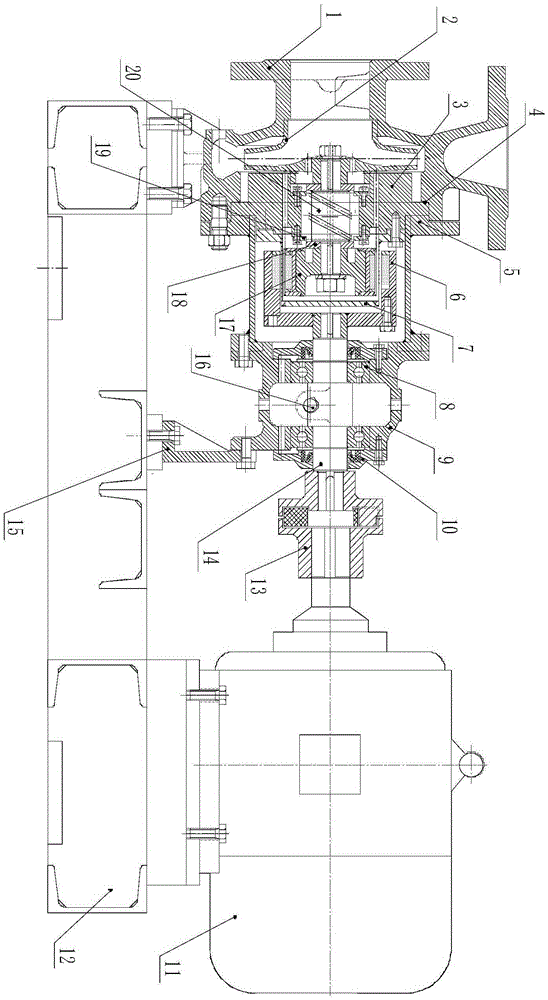

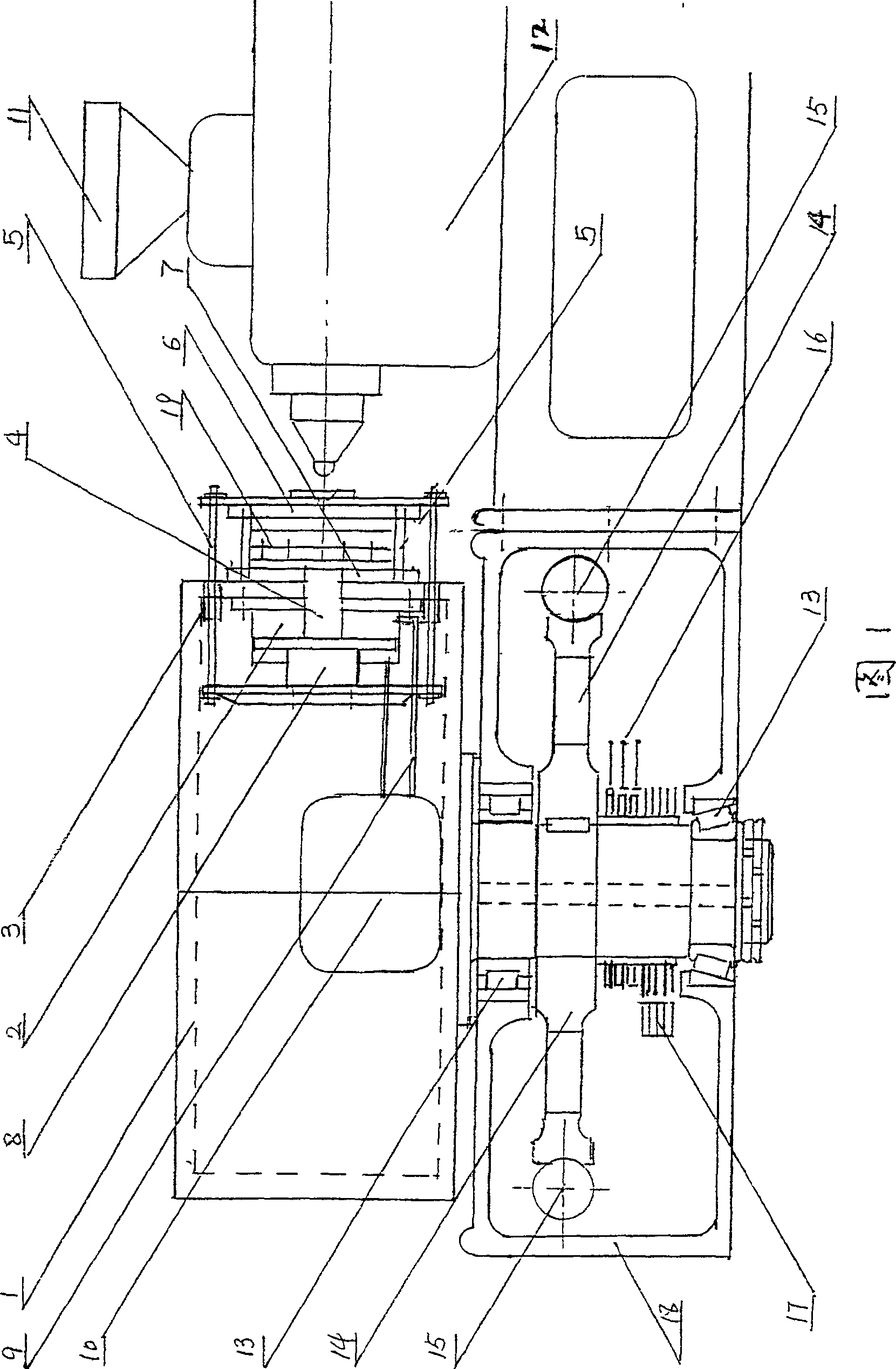

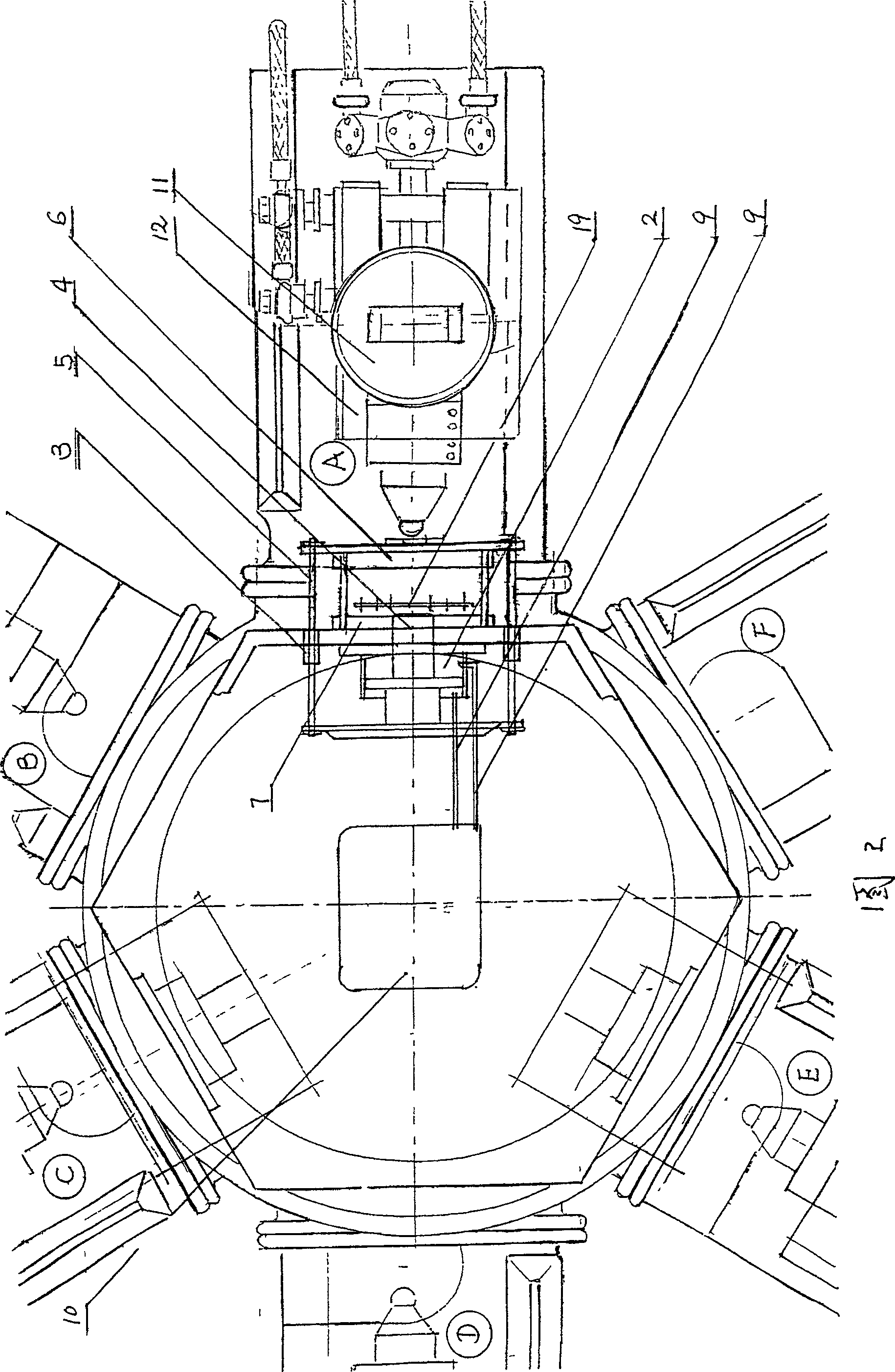

Multifunctional plastic jetting-molding machine

A multifunctional injection moulding machine is composed of a rotary bench with multiple work positions for moulds consisting upper and lower die plates and driven by motor via drive mechanism, and injection moulding unit, a mould closing unit, which is a pressure-holding high-pressure mould locking structure consisting of guide sleeve, beating rod, guide rod and upper and lower die plates, and a hydraulic system consisting of high-pressure cylinder and the booster installed in the center of said rotary bench.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Novel high-resilience foamable rubber shoe sole material and preparation method thereof

The invention discloses a novel high-resilience foamable rubber shoe sole material and a preparation method thereof. The material is characterized of being prepared from, by mass, 10-15% of chloroprene rubber, 8-12% of natural rubber, 10-15% of ethylene-vinyl acetate copolymer, 20-25% of butadiene rubber, 6-12% of butadiene styrene rubber, 5-10% of ethylene propylene diene monome, 5-12% of white carbon black, 3-6% of naphthenic oil, 0.5-1.5% of resin, 1-3% of an active agent, 1-3% of a foaming agent, 1-3% of a modified flowable agent and 0.5-1.5% of a bridging agent. The preparation method comprises the steps of material compounding, banburying, mixing, open milling, stamping and vulcanization, so that a finished product is obtained. According to the novel high-resilience foamable rubber shoe sole material and the preparation method thereof, the characteristics that compatible and complementary elements exist among all types of rubber raw materials are utilized, the novel foamable rubber shoe sole material having the mechanical properties such as high resilience, high abrasion resistance and low weight is obtained, and the material is widely applied to the field of rubber shoe sole manufacturing.

Owner:JINJIANG XINQIDA SHOES MATERIALS CO LTD

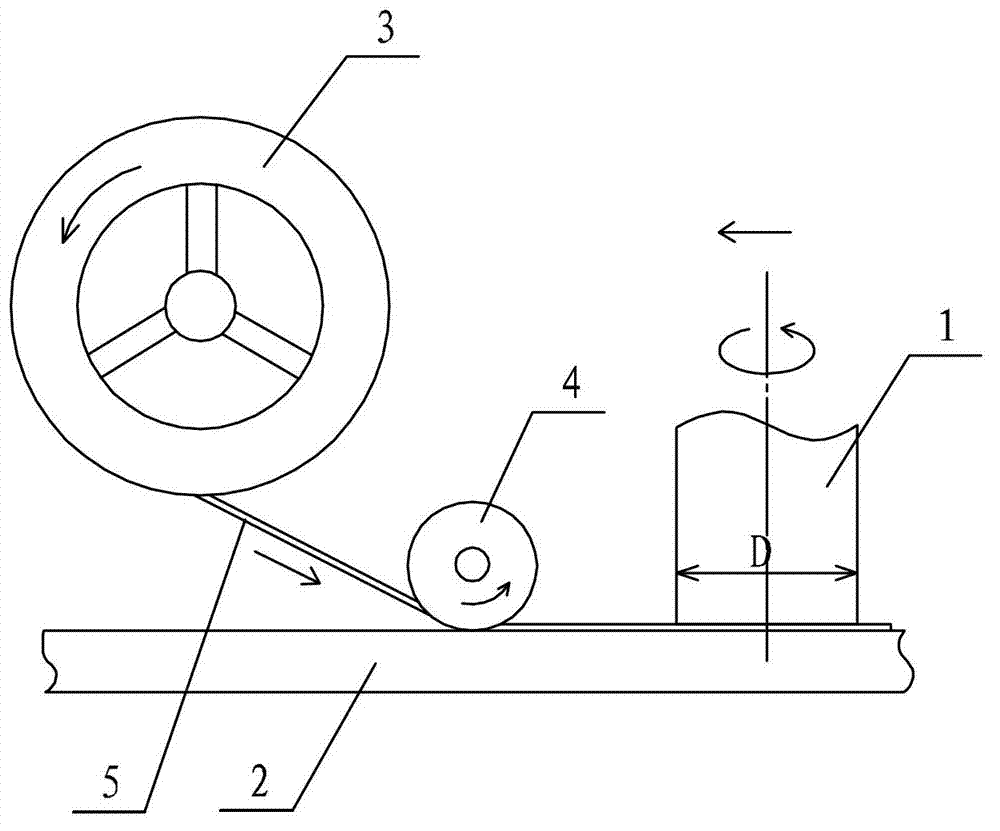

Epoxy resin-based composite wear-resistant coating material and preparation method thereof

InactiveCN107384117AImprove toughnessImprove wear resistancePolyurea/polyurethane coatingsEpoxy resin coatingsEpoxySilanes

The invention discloses an epoxy resin-based composite wear-resistant coating material and a preparation method thereof, and belongs to the technical field of a composite material. The preparation method comprises the following steps: stripping a molybdenum disulfide crystal in a surfactant aqueous solution according to an ultrasonic auxiliary stripping method to prepare two-dimensional layered structure molybdenum disulfide; modifying with silane hydrolysate; preparing polyurethane prepolymer by taking diisocyanate and polyether glycolas raw materials; finally, compounding epoxy resin, the polyurethane prepolymer, silicon carbide, the molybdenum disulfide and the like to prepare the epoxy resin-based composite wear-resistant coating material. The prepared two-dimensional layered structure molybdenum disulfide is used for forming a low-shear-stress film on the friction surface, so that the friction coefficient is reduced, and filling and repairing effects on the friction surface are achieved; under the synergism of the wear-resistant filler, the wear resistance of the epoxy resin is improved. The epoxy resin-based composite wear-resistant coating material prepared by the method has high tensile strength and high shear strength, has high adhesion property with a base layer, and can meet the requirements of the domestic market.

Owner:常州聚盛节能工程有限公司

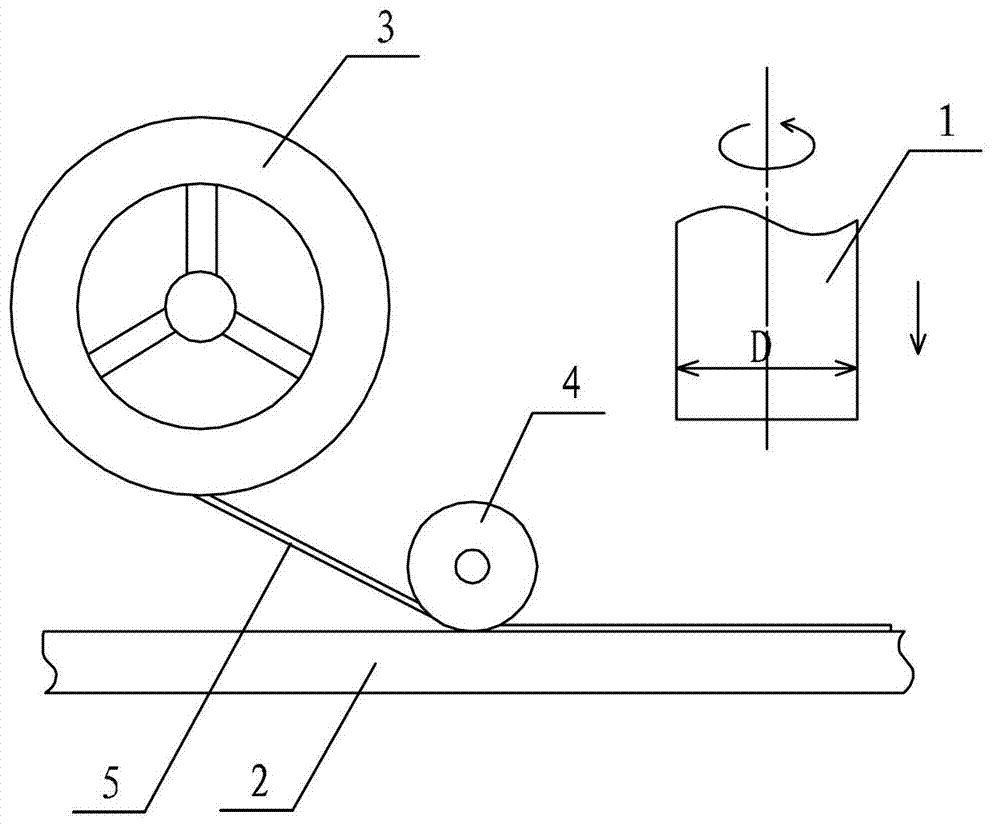

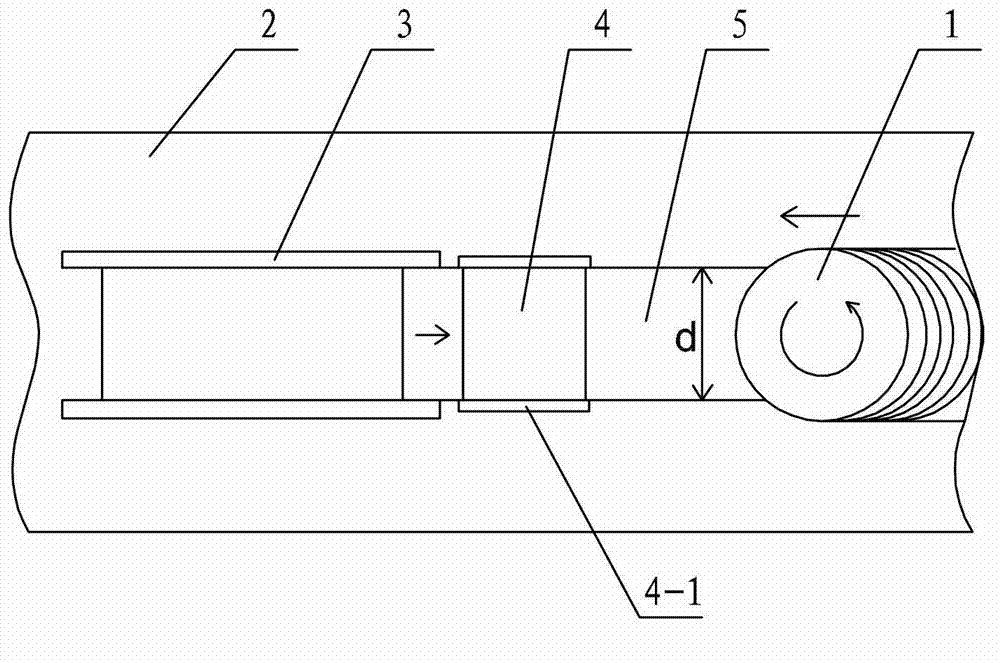

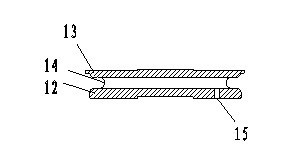

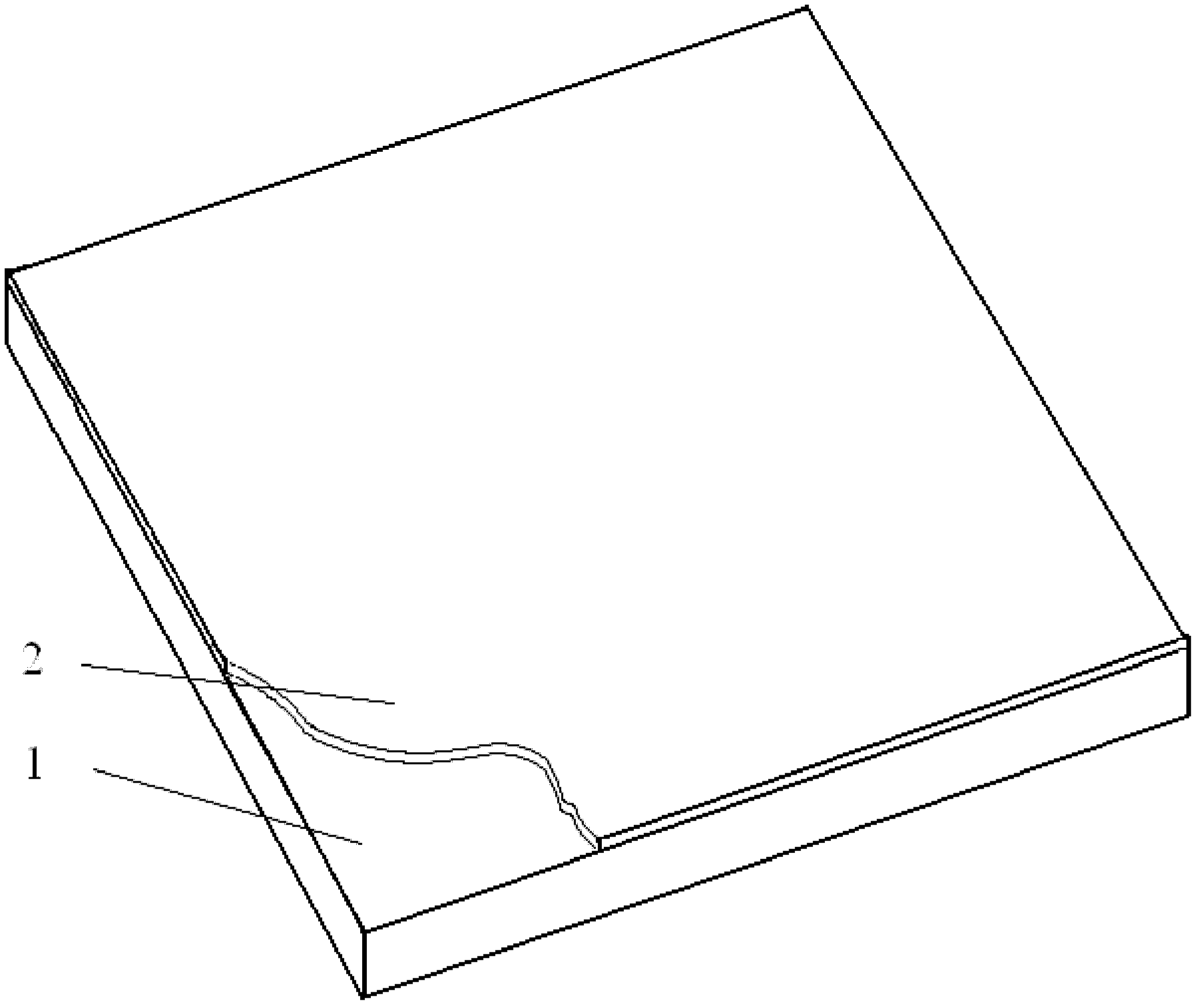

Strap-shaped welding wire filling-in type stirring friction treatment method

InactiveCN103170726ALow dilution rateChange surface propertiesNon-electric welding apparatusBand shapeEngineering

The invention relates to a strap-shaped welding wire filling-in type stirring friction treatment method, relates to a filling-in type stirring friction treatment method, and aims at solving the problem that generally high-energy beam powder bead welding can only be conducted under gas protection or even under vacuum condition. The method comprises the following steps of: firstly, pretreatment preparation, namely, a wire feeding wheel and a positioning guide wheel are fixed on a main shaft of a welding machine, a material to be treated is clamped, a strap-shaped welding wire is put under the positioning guide wheel, the positioning guide wheel is tightly adhered to the surface of the material to be treated, the strap-shaped welding wire is fixed on the surface of the material to be treated, and the end part of the strap-shaped welding wire is put just below a needleless welding tool; secondly, stirring friction treatment, namely, the welding machine is started, the needleless welding tool starts to vertically feed downwards, the shaft shoulder of the needleless welding tool is contacted with the end part of the strap-shaped welding wire and is gradually compressed into the upper surface of the material to be treated, and the strap-shaped welding wire is subjected to bead welding on the surface of the material to be treated by using the stirring and fogging and pressing functions of the shaft shoulder; and thirdly, after-welding settlement, namely, the welding wire is cut off by using a pair of cutting nippers, the residual welding material and overlap are removed by using a steel wire brush. The method is applied to stirring friction treatment.

Owner:HARBIN INST OF TECH

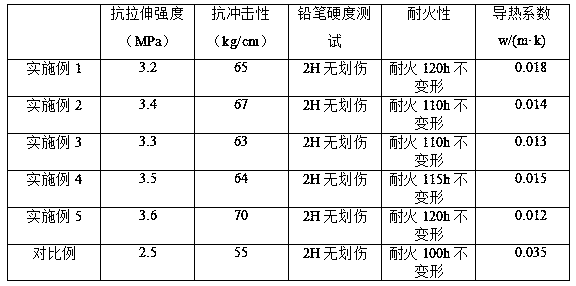

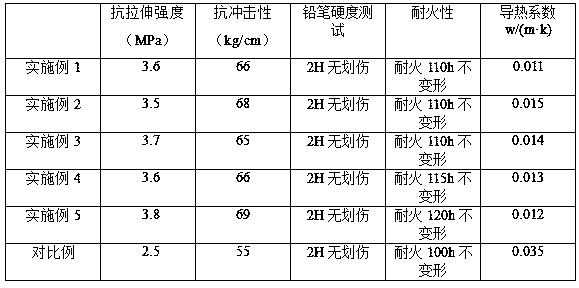

Coating for fire-fighting apparel fabric and preparation method thereof

The invention discloses a coating for a fire-fighting apparel fabric. The coating includes, by weight parts, 20-30 parts of styrene-acrylic emulsion, 15-25 parts of epoxy emulsion, 10-20 parts of polyurethane emulsion, 7-11 parts of terpene resin, 6-14 parts of acrylic resin, 6-9 parts of modified talc powder, 4-7 parts of attapulgite, 3-6 parts of polyvinylidene fluoride, 4-8 parts of hollow floating beads, 2-5 parts of polyvinyl alcohol, 4-9 parts of modified nano-expanded vermiculite, 2-3 parts of ethyl cellulose, 3-6 parts of reinforcing fiber, 2-4 parts of calcium stearate, 2-3 parts of thickener, 3-4 parts of flame retardant and 1-2 parts of nano silver ion bactericide. The coating for the fire-fighting apparel fabric has good waterproof performance, heat insulation performance and fireproof performance, has high use safety, has good wear resistance, and is soft and light and convenient to operate.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

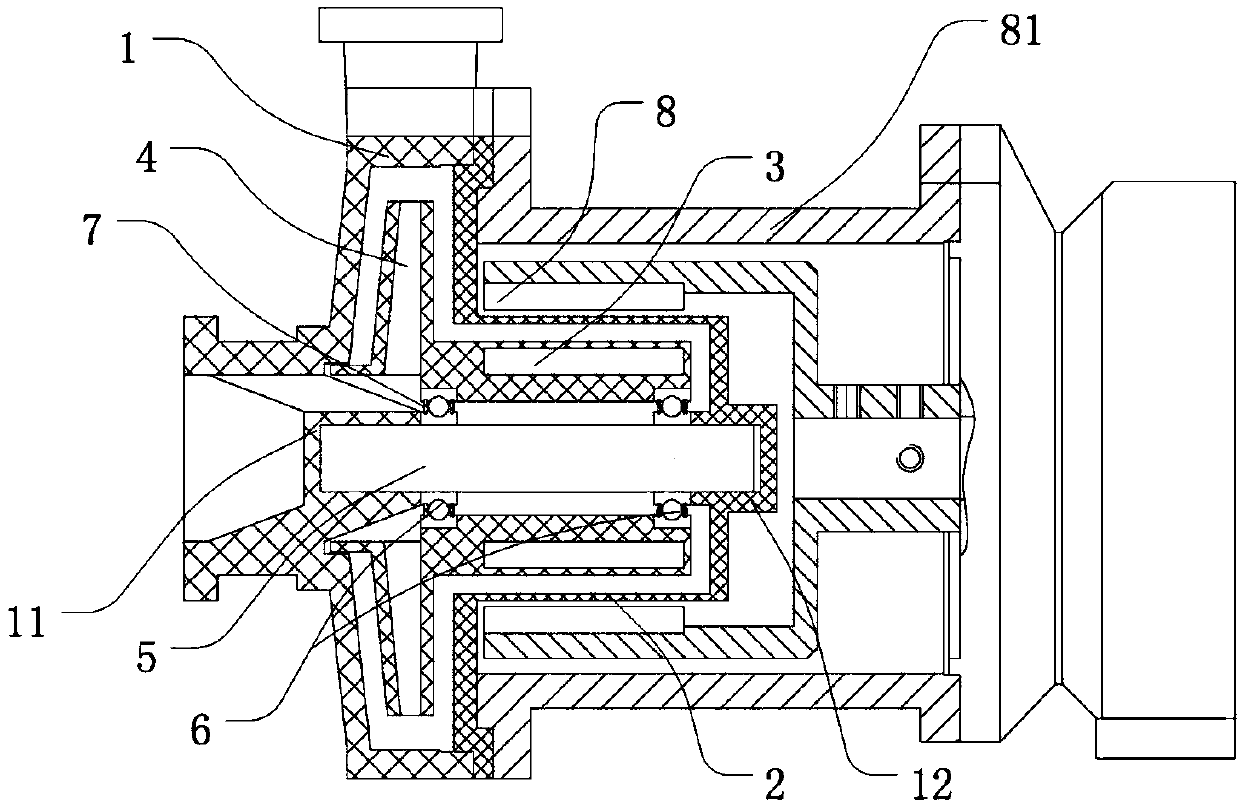

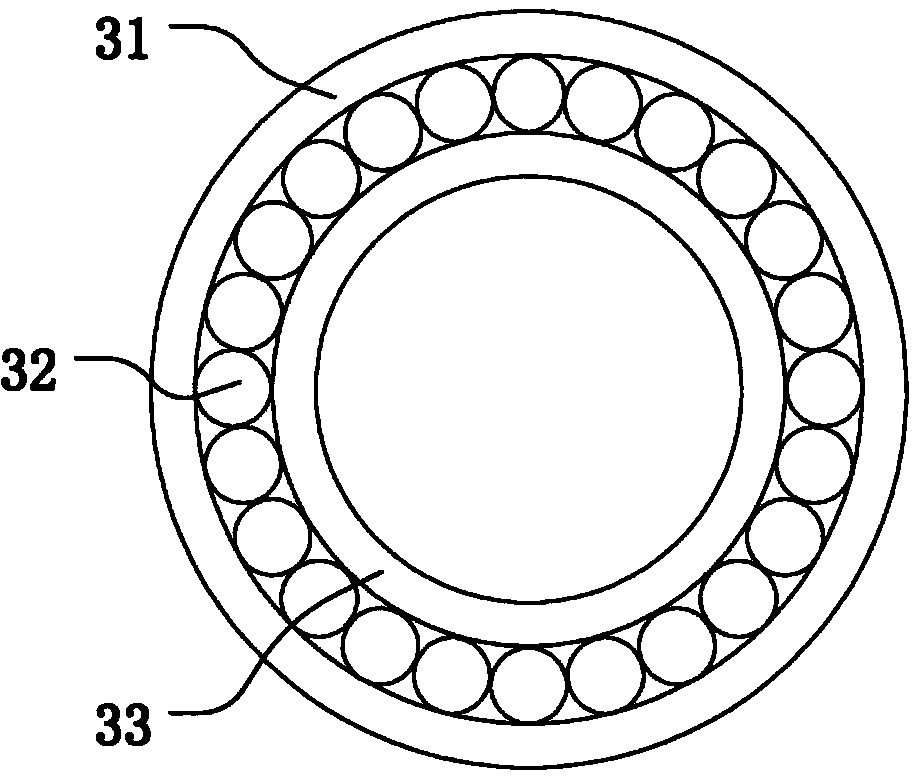

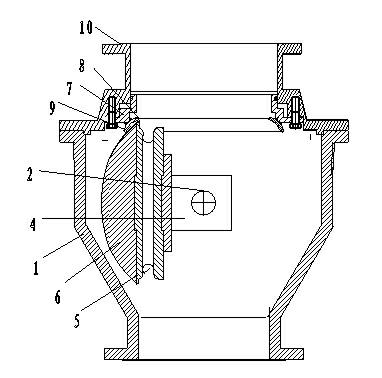

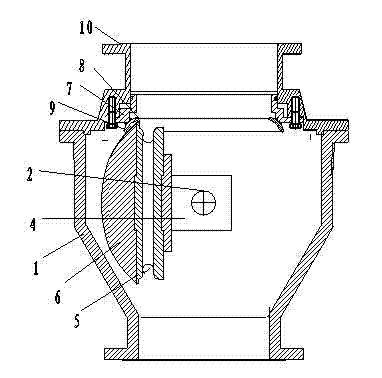

Magnetic pump

InactiveCN103470514AChange wear resistanceChange jobSpecific fluid pumpsPump componentsImpellerWear resistance

The invention provides a magnetic pump, which comprises a pump cavity, an inner magnetic assembly, an impeller, a pump shaft, two bearings and an outer magnetic assembly, wherein the pump cavity consists of a pump case and an isolation sleeve, the impeller is driven by the inner magnetic assembly, the two bearings are sheathed on the pump shaft, each bearing comprises a bearing inner ring, a rolling body, a bearing outer ring and a sealing cover, the sealing cover is arranged between the bearing inner ring and the bearing outer ring for protecting the rolling body, the outer magnetic assembly is used for driving the inner magnetic assembly to rotate under the effect of the external driving force, the pump shaft is a solid shaft, and the rolling bodies arranged in the bearings are densely distributed and arranged between the bearing inner ring and the bearing outer ring. The magnetic pump solves the problems that in the prior art, the bearings and the hollow pump shaft do not have the wear resistance, corrosion resistance or particle work medium resistance in the idle state, and the heavy load cannot be realized. The magnetic pump can realize the high-load heavy-load work under the condition of particular work media or corrosive environment, and in addition, the idle state can be realized.

Owner:浙江巨龙泵业有限公司

Composite material, manufacturing process therefor and uses thereof

ActiveCN104341714AEasy to cleanChange wear resistanceCarpet cleanersFloor cleanersAdhesiveMelamine formaldehyde resin

Owner:GO4HIT

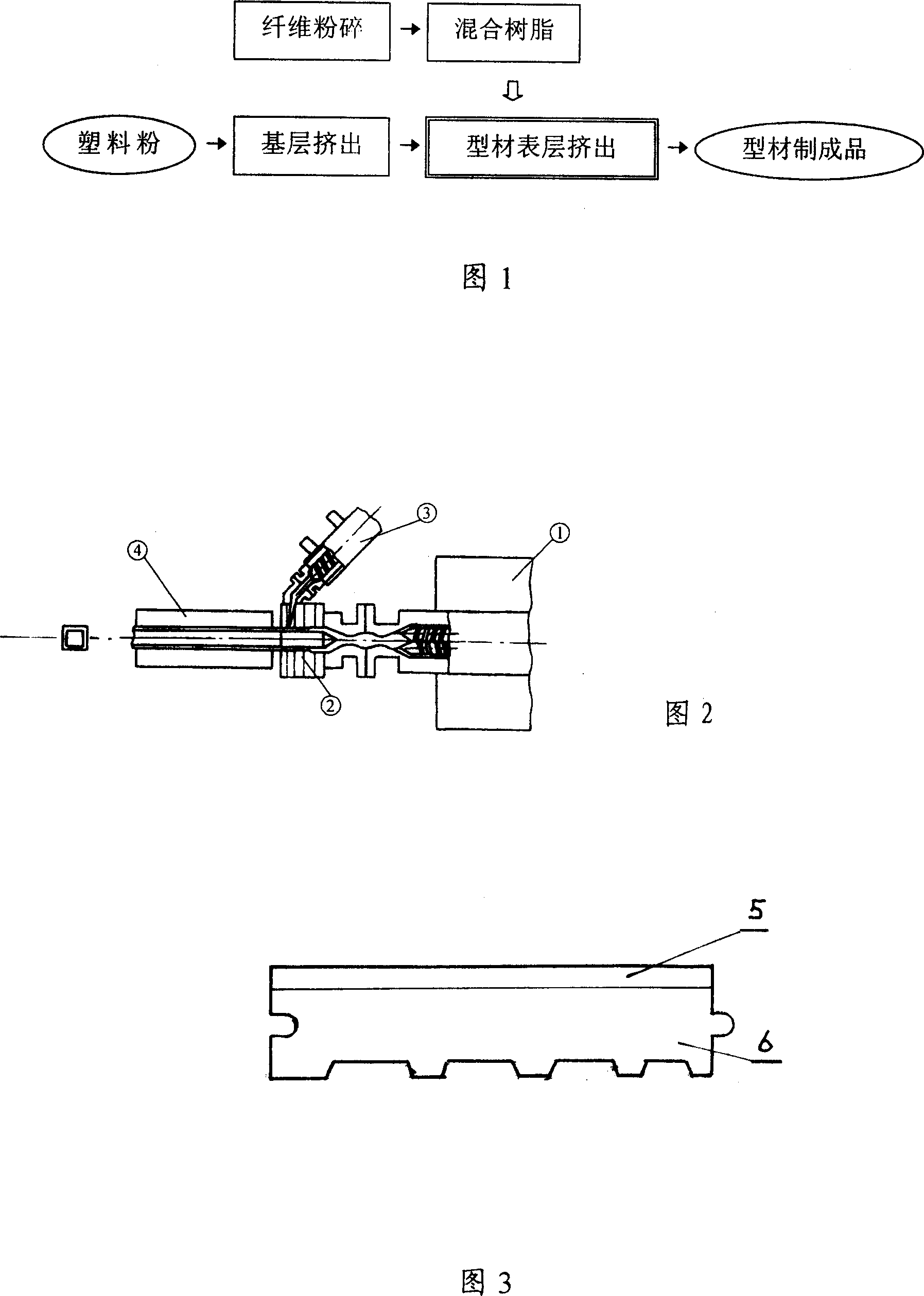

Method for manufacturing composite surface section bar and composite surface plastic section bar

InactiveCN101085545AImprove performanceSimple processSynthetic resin layered productsLacquerEngineering

The invention relates to the extrusion of compound section bar. It takes advantage of the abundant straw shell powders and other wood, and fiber as stuffs. It can make compound plastic section bar through one time extrusion. It is simple, cheap, stable, and anti-slippery. It has real wood sense, adjusted in the surface plastic component, being able to generate all kinds of visual effect, adjusting the surface thickness, and changing the abrasion resistant feature, anti slippery and lasting feature of it. It is easy and environment friendly.

Owner:金星洙

Waterproof paint special for fire protection clothing and preparation method of waterproof paint

InactiveCN109162108AImprove waterproof performanceGood heat insulationTextiles and paperFire extinguisherFiberCellulose

The invention discloses waterproof paint special for fire protection clothing. The waterproof paint comprises the following raw materials in parts by weight: 30-50 parts of acrylic emulsion, 10-20 parts of n-butyl acetate, 5-12 parts of modified nano-expanded vermiculite, 3-6 parts of vacuum ceramic powder, 2-5 parts of hexamethylenetetramine, 3-7 parts of dibutyl phthalate, 4-8 parts of modifieddiatomite, 3-9 parts of a cellulose solution, 2-6 parts of reinforced fibers, 3-5 parts of pentaerythritol, 2-4 parts of propylene glycol, 1-3 parts of magnesium hydroxide, 1-2 parts of aluminum hydroxide, 2-3 parts of nanometer titania, 2-3 parts of sodium stearate and 2-5 parts of an antifoaming agent. The waterproof paint special for fire protection clothing disclosed by the invention has excellent waterproof performance, thermal insulation property and fireproof performance, has high application safety, and is excellent in wear resistance, soft, portable and convenient to operate.

Owner:HEFEI YUANKE GARMENT DESIGN CO LTD

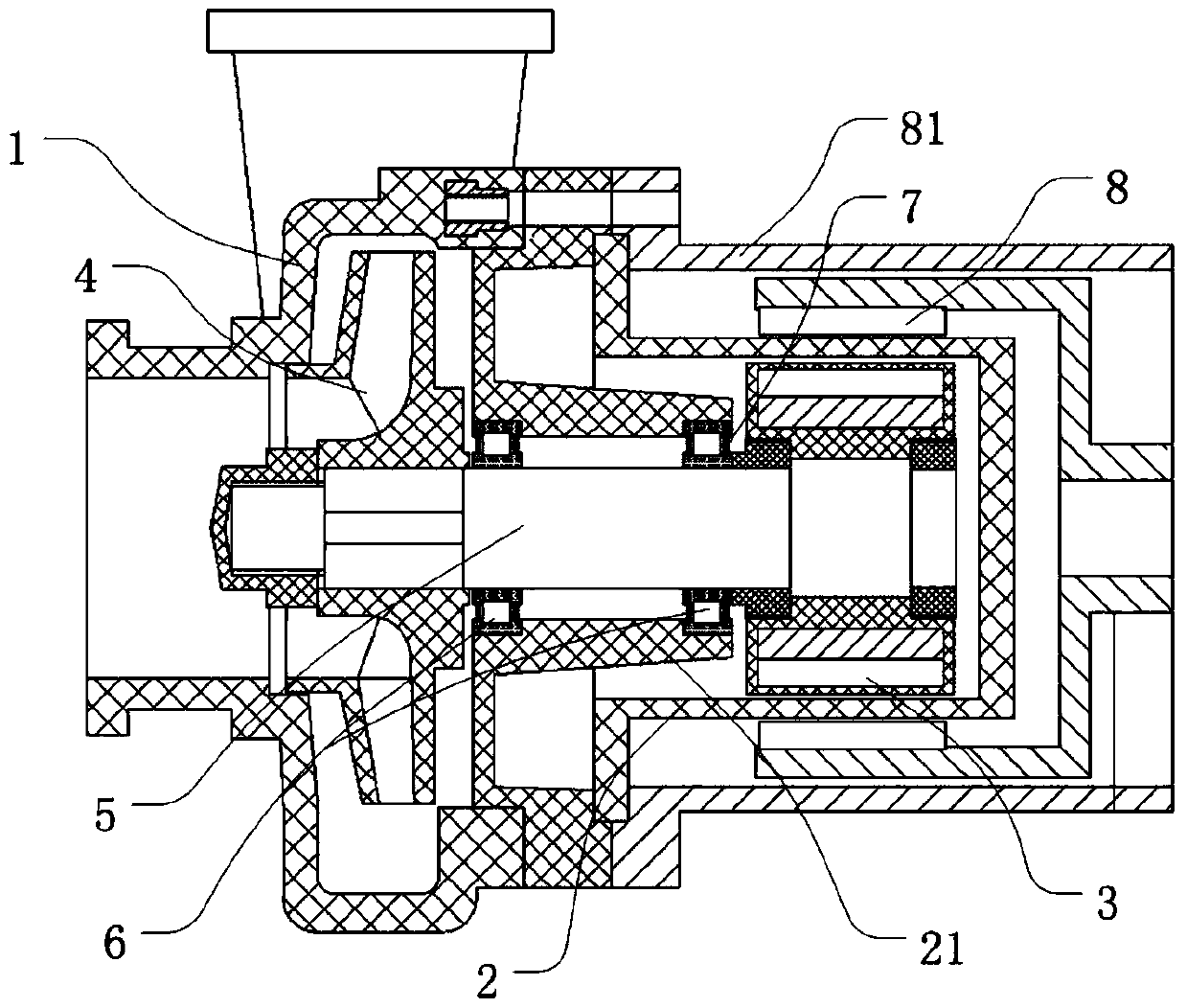

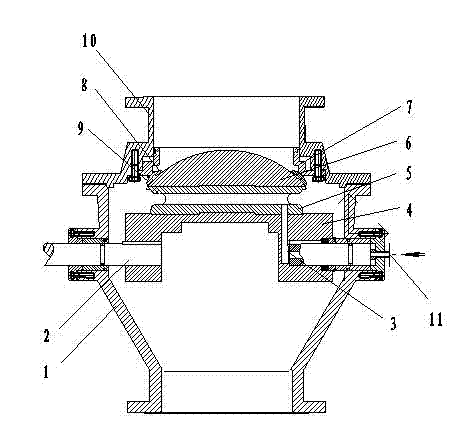

Magnetic pump

InactiveCN105422474AChange wear resistanceChange jobPump componentsEngine fuctionsImpellerEngineering

The invention discloses a magnetic pump which is mainly characterized in that a pump body is mounted on a base; an impeller is mounted on the left side surface of a left rotating shaft; a pump cover is mounted in a mounting hole in the right end of the pump body; a bracket is mounted on the right side surface of the pump cover; an internal magnet rotor component is mounted on the right end surface of the left rotating shaft; the left rotating shaft is mounted in a centrale hole of in the pump cover; a pressing plate is mounted on the right side surface of the pump cover; a thrust disc is mounted on the left rotating shaft; a shielding sleeve is fixedly mounted on the right end surface of the pump cover; an external magnet rotor component is mounted on a right rotating shaft; the left side surface of a bearing housing is mounted on the right side surface of the bracket; a left side bearing gland is mounted on the left side surface of the bearing housing; a left side bearing is mounted at the left end of the right rotating shaft; a right side bearing gland is mounted on the right side surface of the bearing housing; a right side bearing is mounted at the right end of the right rotating shaft; an oil lens is mounted on the bearing housing; the right end of the right rotating shaft is connected with the output shaft of a motor through a claw type coupler; the motor is fixedly mounted on the base; the bearing housing is mounted on the base through a support leg.

Owner:ZHENJIANG GREAT PUMP

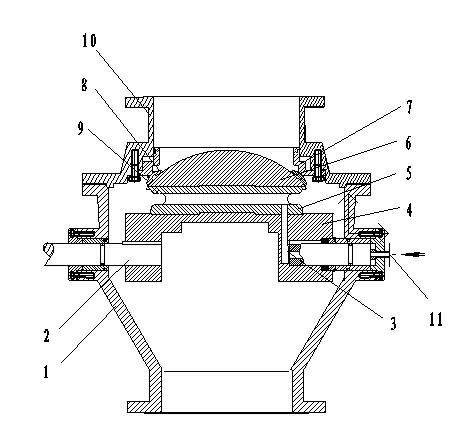

Micro-dynamic ash-discharging ball valve

The invention discloses a micro-dynamic ash-discharging ball valve belonging to the technical field of valves and aims to provide an ash-discharging ball valve with small opening torque, smooth ash-discharging process, good ash-cleaning effect on the surface of the ball valve and reliable seal. The technical scheme of the invention is as follows: the micro-dynamic ash-discharging ball valve comprises a valve body, a valve rod, a valve seat and a valve cover, and the ball body of the ball valve is a hemisphere; the micro-dynamic ash-discharging ball valve further comprises a hemisphere bracketand a metal bloated bag; the hemisphere bracket is fixedly connected with the valve rod; the bottom surface of the bloated bag is installed on the hemisphere bracket; the bottom surface of the hemisphere is connected with the top surface of the bloated bag to form a closed hollow cavity; the cavity of the bloated bag is communicated with a compressed air pipeline; and a double-sided stainless steel sealing ring is fixed on the valve seat and contacted with the surface of the hemisphere. According to the invention, the structure for fulfilling a seal depending on a constant pressure between the sealing ring and the ball body of the traditional ball valve is changed, and a drive torque in opening and closing processes is greatly reduced; a hard seal with an ash-scraping function has the advantages of excellent resistance to abrasion, temperature resistance and environmental protection adaptability; and multiple effects of labor-saving in transmission, smooth ash-discharging process, natural ash-cleaning effect, reliable seal, and the like are fulfilled.

Owner:HEBEI CHANGHONG VALVE CO LTD

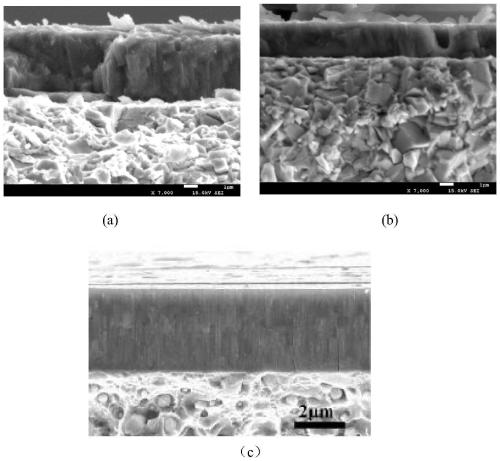

Preparation method of surface coating of high-speed steel screw tap

ActiveCN107034438AImprove bindingReduce coefficient of frictionVacuum evaporation coatingSputtering coatingFilm-coated tabletMaterials science

The invention discloses a preparation method of a surface coating of a high-speed steel screw tap and belongs to the technical field of nano-coatings. According to the method, during film coating, the manner that a cathode arc method and a magnetron sputtering method are combined is adopted; and in the N2 atmosphere, a Ti element is evaporated through the cathode arc method, meanwhile, a C element is sputtered through the magnetron sputtering method, and a TiN / C layer is prepared on the surface of the high-speed steel screw tap in a plated manner. Compared with an existing conventional method, by means of the method, the low production cost is kept, the environment is prevented from being polluted, and the comprehensive performance of the high-speed steel screw tap can be improved.

Owner:CHENGDU REALLY SHARP COATING TECH CO LTD +2

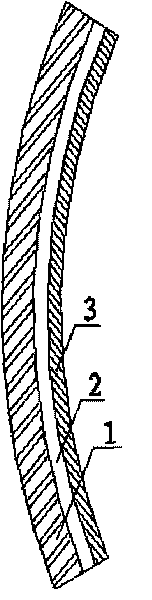

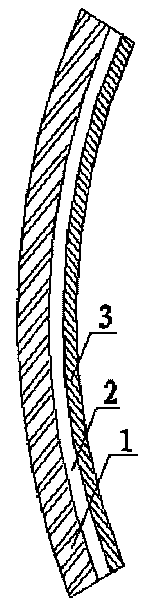

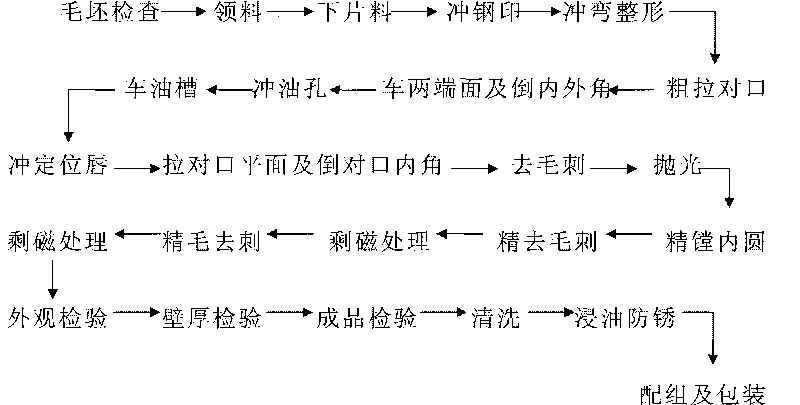

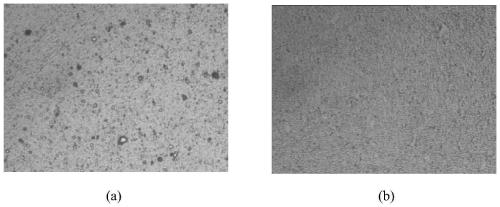

Sparingly soluble bearing of engine

InactiveCN101718303AChange wear resistanceImprove carrying capacityBearing componentsBiochemical engineeringLow emission

The invention relates to a bearing, in particular to a sparingly soluble bearing of an engine. The sparingly soluble bearing is characterized by comprising a steel back layer, a substrate layer and a sparingly soluble layer which are arranged from outside to inside, wherein the substrate layer is made of aluminum material; and the sparingly soluble layer is made of silicon-iron environment-friendly material. The invention saves energy in the manufacture process, has low cost and can satisfy the technical requirements of the engine, such as high voltage increase, great torque and low emission.

Owner:SHANDONG YUNCHENG HAORUN MACHINERY MFG

Preparation method of high-speed steel tap surface coating

ActiveCN107034438BImprove bindingReduce coefficient of frictionVacuum evaporation coatingSputtering coatingFilm-coated tabletAtmosphere

Owner:CHENGDU REALLY SHARP COATING TECH CO LTD +2

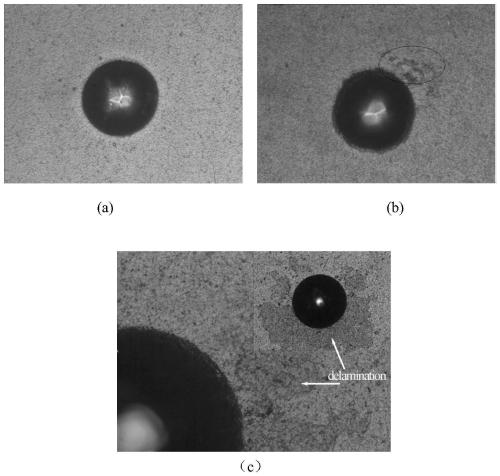

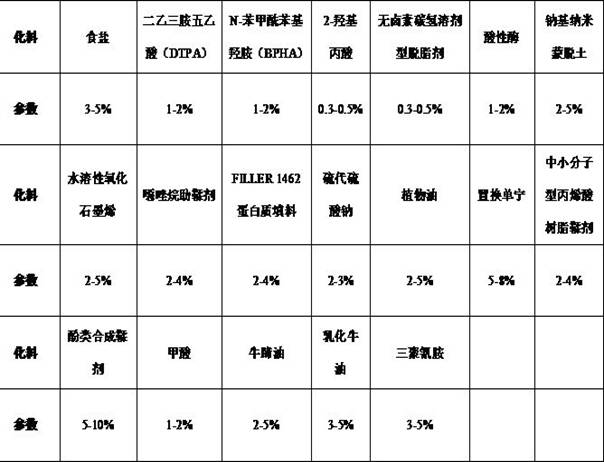

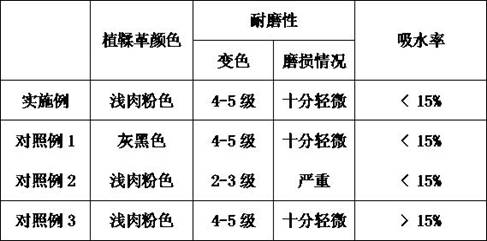

Waterproof wear-resistant environment-friendly vegetable tanning method for sole leather

ActiveCN112981015AImprove water resistanceImprove wear resistanceTanning treatmentPre-tanning chemical treatmentHydroxylamineWarm water

The invention belongs to the field of leather production, and particularly relates to a waterproof wear-resistant environment-friendly vegetable tanning method for sole leather, which sequentially comprises the following steps of softening, deironing, pre-tanning, neutralizing, tanning, oiling and post-processing. In the deironing process, diethylenetriaminepentaacetic acid (DTPA) and N-benzoylphenylhydroxylamine (BPHA) are added into a rotary drum, in the pre-tanning process, warm water at the temperature of 35-45 DEG C, sodium-based nano montmorillonite, water-soluble graphene oxide, an oxazolidine auxiliary tanning agent and FILLER 1462 protein filler are added into the rotary drum, and in the oiling process, warm water with the temperature of 35-45 DEG C, the cattle hoof oil, the emulsified beef tallow, the melamine and the cationic oil are added into a rotary drum according to the amount of the formula; The vegetable tanning sole leather process is environment-friendly, excellent in waterproofness and wear-resistant. The target product is excellent in waterproof performance and has the characteristics of environmental protection, wear resistance and the like.

Owner:阜新市飞翔皮革制品有限公司

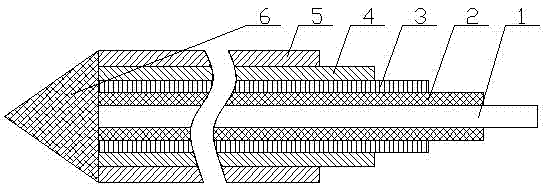

Oil well heating cable heated through flexible skin effect and short circuit

InactiveCN103208330AChange wear resistanceEasy downhole installationInsulated cablesInsulated conductorsElectrical conductorCopper wire

The invention discloses an oil well heating cable heated through a flexible skin effect and a short circuit. The cable comprises a cable body and a cone body, wherein the cable body comprises a conductor, a first insulating layer, a second insulating layer, a copper wire braiding layer and an armor layer sequentially from inside to outside, and the cone body is fixedly arranged at one end of the cable body and is connected with the conductor and the armor layer. The cone body is connected with the end portion of the cable body through a welding process and is located at the bottom of an oil well to enable the armor layer to be in short-circuit connection with the conductor, so that heating is achieved, and a pumping unit sucker rod is heated. By the aid of the oil well heating cable heated through the flexible skin effect and the short circuit, the flexibility and the abrasive resistance of an outer protective layer of the oil well heating cable can be improved, underground installation of products is facilitated, and service lives of products are prolonged.

Owner:ANHUI RUIKAN SCI CABLE

Improved nickel chromium molybdenum inlimited cold hard cast-iron for roller and its compound roller

ActiveCN1327022CChange wear resistanceChange in thermal crack resistanceCrack resistanceMetal machining

This invention relates to an improvement of NiCrMo infinite cooling hard cast iron used in roll materials of metal machining hot rolling and cold rolling plate, especially relates to a kind of NiCrMo infinite cold hard cast iron used in roll with excellent wear resistance and thermal crack resistance property, long longevity, the character is adding 0.03-0.1%(WT) B and 0.2-1.5% Nb in the component of NiCrMo infinite cold hard cast iron. As well as the composite roll made from this materials. Because of the addition of B and Nb, the wear resistance and thermal crack resistance property are remarkably improved, which overcomes the disadvantage of raw materials. The operating life of composite roll whose working layers are made from this materials is enormously improved compared with original life. The plate band rolling amount increases more than 20%; the improvement of thermal crack resistance property.

Owner:JIANGSU GONGCHANG ROLL

Micro-dynamic ash-discharging ball valve

Owner:HEBEI CHANGHONG VALVE CO LTD

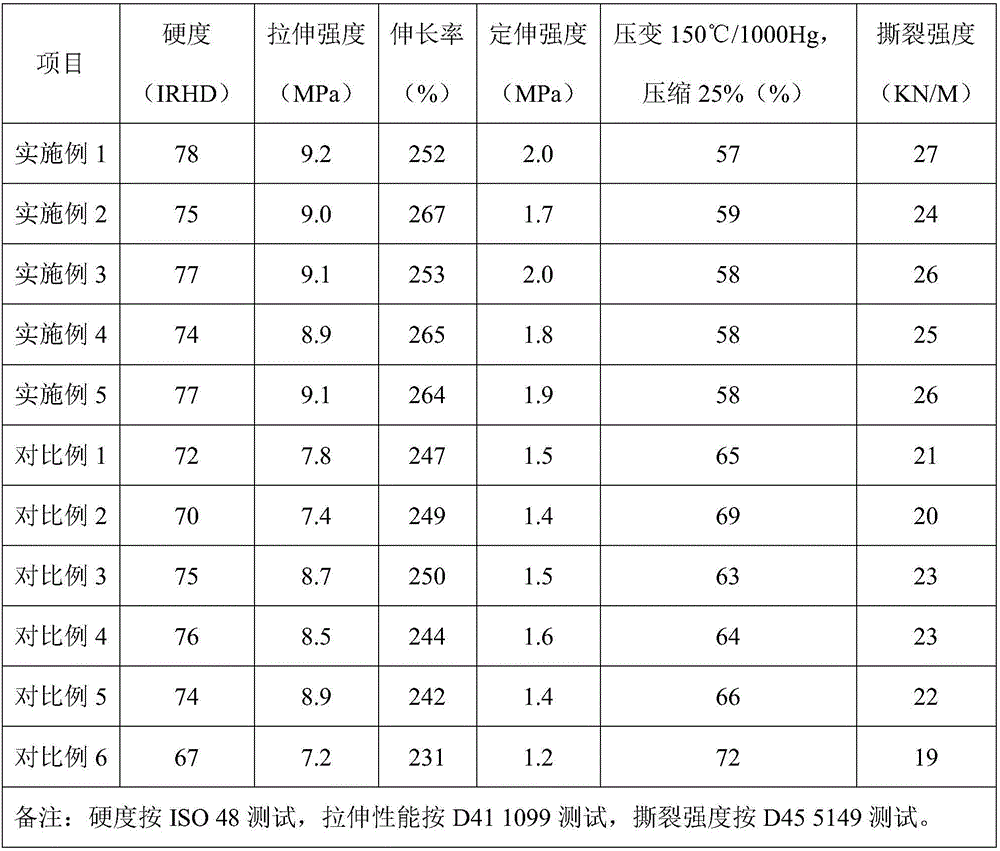

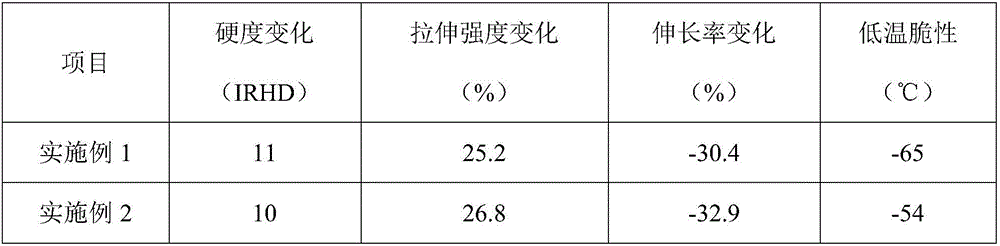

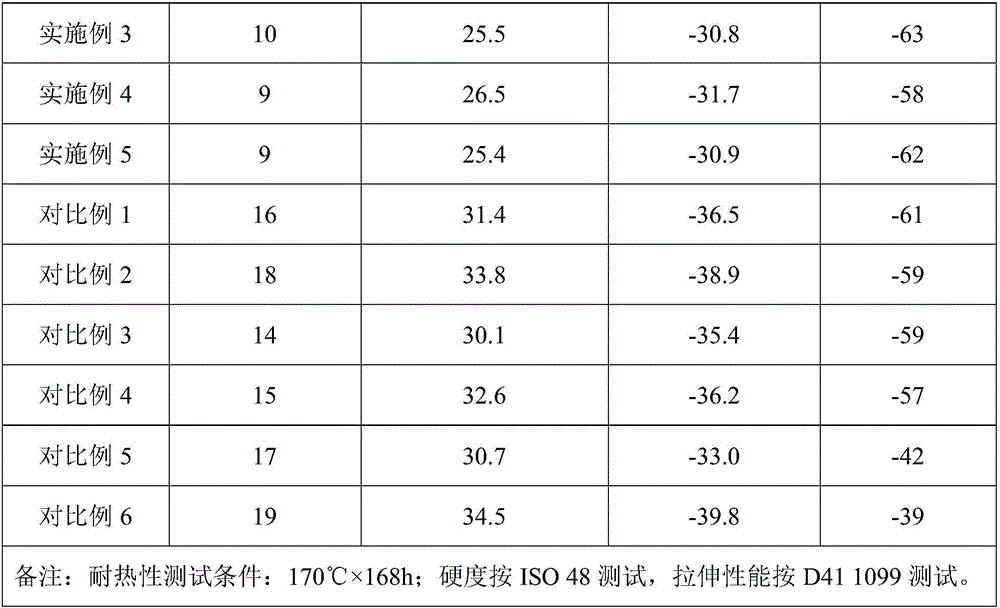

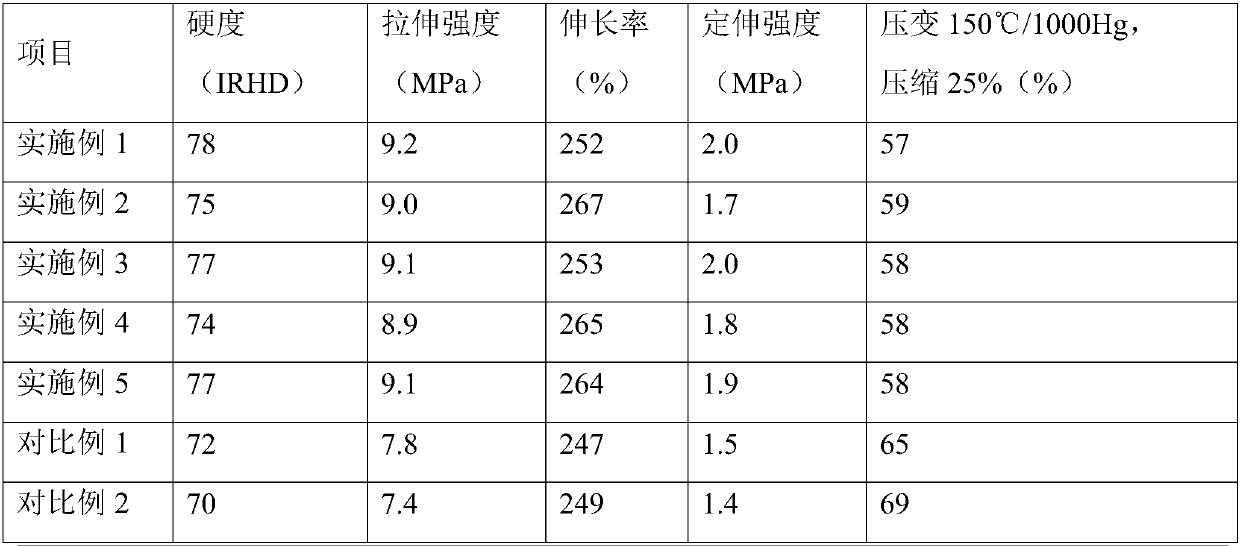

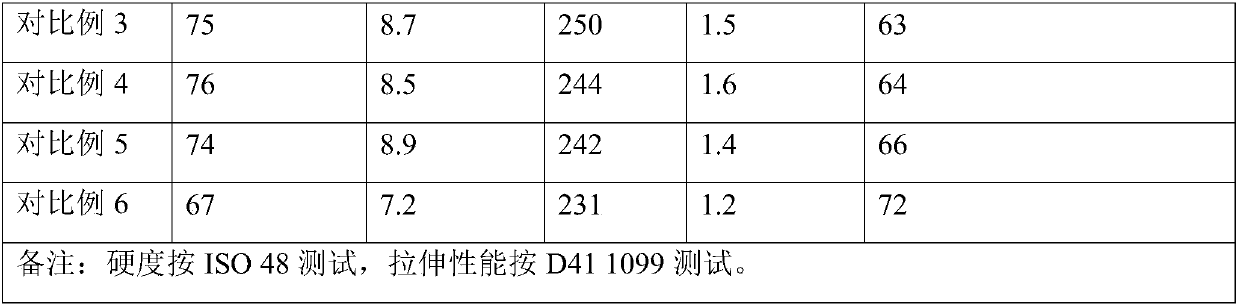

Automobile oil return pipe glue stock and preparation process thereof

The invention discloses an automobile oil return pipe glue stock and a preparation process thereof. The glue stock comprises, by weight, 70-85 parts of nitrile rubber, 15-30 parts of pyridine butadiene rubber, 20-25 parts of spraying carbon black, 1.2-1.5 of stearic acid, 2.0-2.8 parts of canola oil, 1.6-2.0 parts of dibutyl ester, 4-7 parts of sea-foam stone powder, 10-14 parts of quartz powder, 0.8-1.2 parts of anti-aging agents RD, 1.1-1.3 parts of anti-aging agents AW, 1.6-2.0 parts of anti-aging agents ODA, 6.5-7.8 parts of N,N'-meta phenylene bis maleimide, 0.20-0.27 parts of accelerator TMTD and 1.2-1.5 parts of accelerators DM. According to the automobile oil return pipe glue stock, the pyridine butadiene rubber and the nitrile rubber are compounded and used, and proper filling agents and the anti-aging agents are matched, so that the prepared glue stock meets requirements of oil resistance and heat resistance, cold-resistance and aging resistance of an automobile oil return pipe.

Owner:YANCHENG SAIFO AUTOMOBILE PARTS

Novel drill bit matrix

The invention discloses a novel drill bit matrix. The novel drill bit matrix is prepared from manufacturing materials in percentage by weight: 20-35% of tungsten carbide, 15-30% of ferroalloy powder,25-32% of bronze powder and 15-20% of auxiliary materials. The hardness and the abrasion resistance of the drill bit matrix are changed to a certain degree by changing the weight parts of the manufacturing materials of the novel drill bit matrix, the adopted manufacturing materials are simple and easy to obtain, and the use performance of the drill bit matrix is improved when the manufacturing cost is unchanged.

Owner:铜陵长江金刚石工具股份有限公司

Multifunctional plastic jetting-molding machine

A multifunctional injection moulding machine is composed of a rotary bench with multiple work positions for moulds consisting upper and lower die plates and driven by motor via drive mechanism, and injection moulding unit, a mould closing unit, which is a pressure-holding high-pressure mould locking structure consisting of guide sleeve, beating rod, guide rod and upper and lower die plates, and a hydraulic system consisting of high-pressure cylinder and the booster installed in the center of said rotary bench.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Processing technology of cotton felt

ActiveCN109594191AReduced service lifeThe rebound rate is maintainedNon-woven fabricsFiberCooking & baking

The invention discloses a processing technology of cotton felt. The processing technology of the cotton felt comprises the following steps: (1), cotton blending, wherein the ratio of PET to hollow fiber to LPET is 30%:40%:30%; (2), cotton mixing; (3), opening; (4), carding; (5), cotton laying; (6), hot baking, wherein the temperature is maintained at 220-250 DEG C, and the fan is controlled at 1200 + / - 200 rev / min; (7), rolling, wherein the thickness of the cotton felt is controlled at 10 + / - 2mm; (8), fan cooling: normal temperature; and (9), cutting and shipping. The cotton felt produced bythe processing technology of the cotton felt provided by the invention is small in volume and convenient to transport, and can be reused after being restored to the original state by heating.

Owner:翰诠特种纺织品(平湖)有限公司

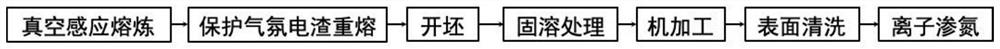

A kind of argon arc surfacing welding FECRC iron-based powder alloy and its preparation process

InactiveCN103231182BImprove economyChange intensityArc welding apparatusWelding/cutting media/materialsIron powderAlloy

Disclosed is a Fe-based alloy powder for argon arc overlay welding, the powder consisting of Fe-Cr, graphite, and iron powder. A process for preparing the Fe-based alloy powder for argon arc overlay welding comprises: uniformly mixing Fe-Cr, graphite, and iron powder according to a certain ratio, and preparing same into flakes with sodium silicate as a binder; the flakes are naturally dried for 10 h and then placed in a drying oven and dried at 200°C for 1.5 h, and oven cooled. With a tungsten electrode argon arc as a heat source, the obtained substance is overlay welded on the surface of a material to form a wear- and corrosion-resistant molten cladding layer. The molten cladding layer has a uniform texture, and can generate new phases such as chromium-carbon compounds; the deposit welded layer has a hardness greater than HRC55 and can effectively improve material performances such as wear-, corrosion-, and high temperature-resistance, so as to extend the service life of parts. In addition, the Fe-based alloy powder for argon arc overlay welding is simple to prepare, low in cost, and thus has a relatively high use value.

Owner:SHANDONG JIANZHU UNIV

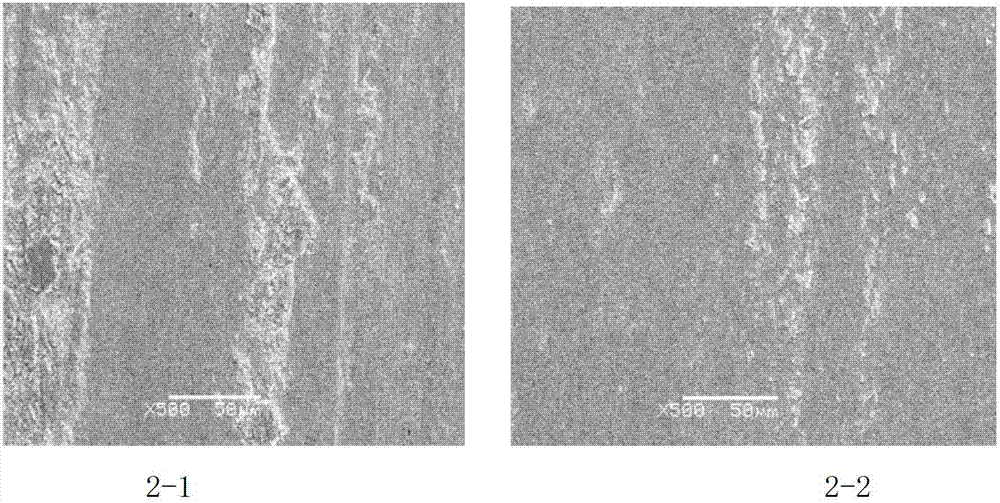

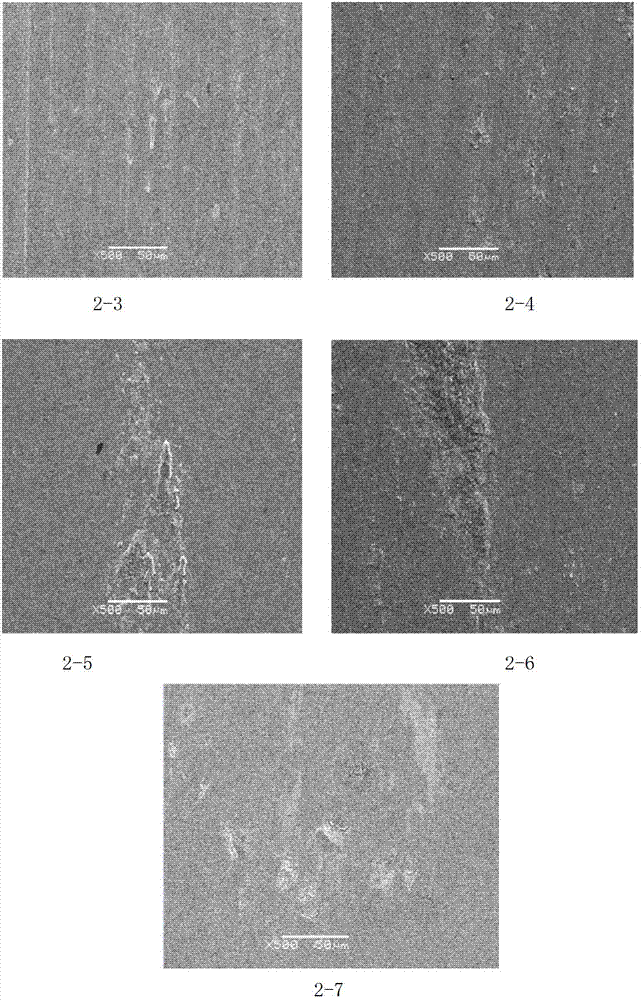

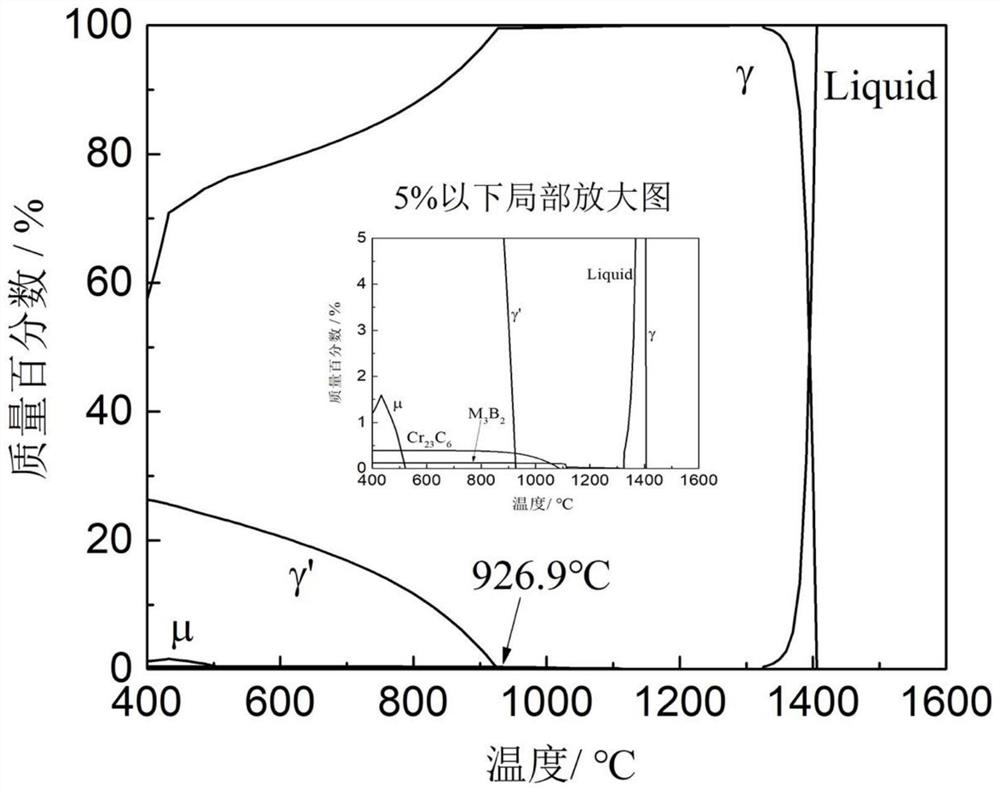

High-temperature alloy mold material as well as preparation method and application thereof

ActiveCN114752817AImprove heat strengthEffective pinningExtrusion diesSolid state diffusion coatingNonferrous metalHot working

The invention discloses a high-temperature alloy die material which comprises the following alloy chemical components in percentage by mass: 0.02 to 0.05 percent of C, 17.00 to 20.00 percent of Cr, 2.00 to 3.00 percent of Mo, 1.50 to 2.50 percent of Al, 1.50 to 2.50 percent of Ti, 8.00 to 10.00 percent of Fe, 0.01 to 0.05 percent of B, less than or equal to 0.01 percent of S and the balance of Ni, and the sum of the mass fractions of the Al element and the Ti element in the alloy is not less than 3.50 percent. The invention further discloses a preparation method of the high-temperature alloy die material and application of the high-temperature alloy die material in die steel. According to the method, the problem that the surface wear resistance is insufficient when an existing commercial high-temperature alloy serves as a non-ferrous metal hot working mold material is solved, the aging treatment process and the ion nitriding process are fused, the technological process is obviously shortened, and meanwhile the ion nitriding technology is environmentally friendly.

Owner:NANJING INST OF TECH

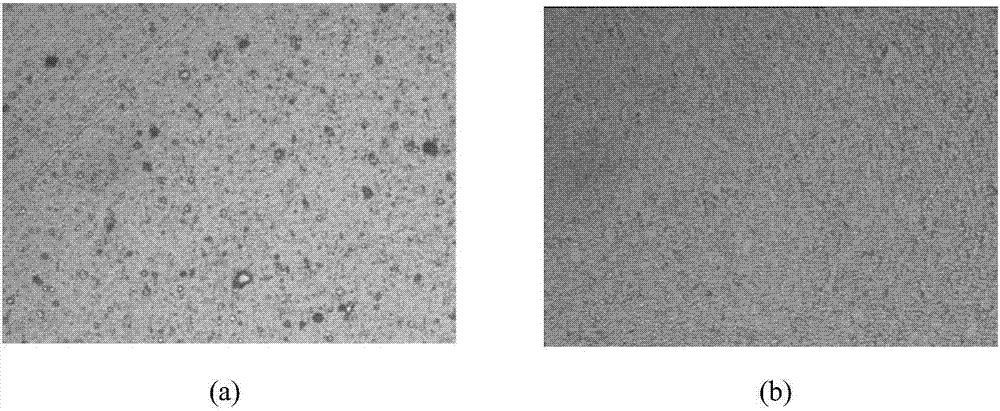

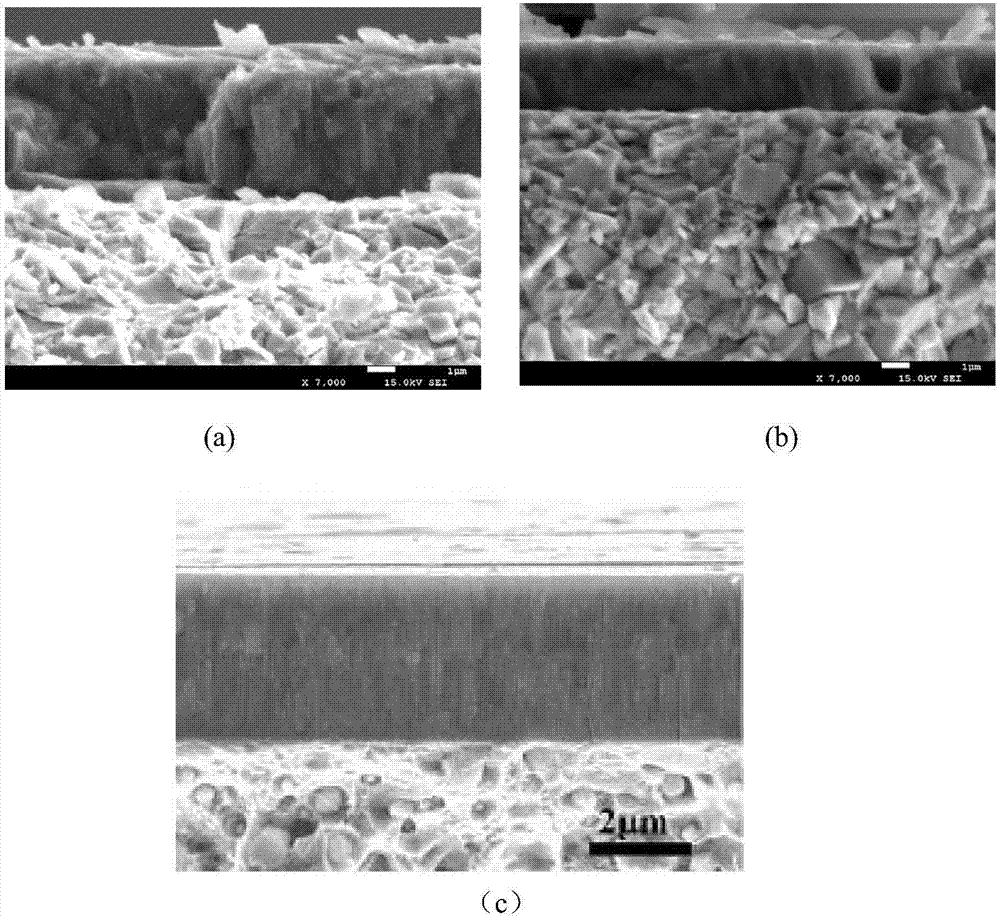

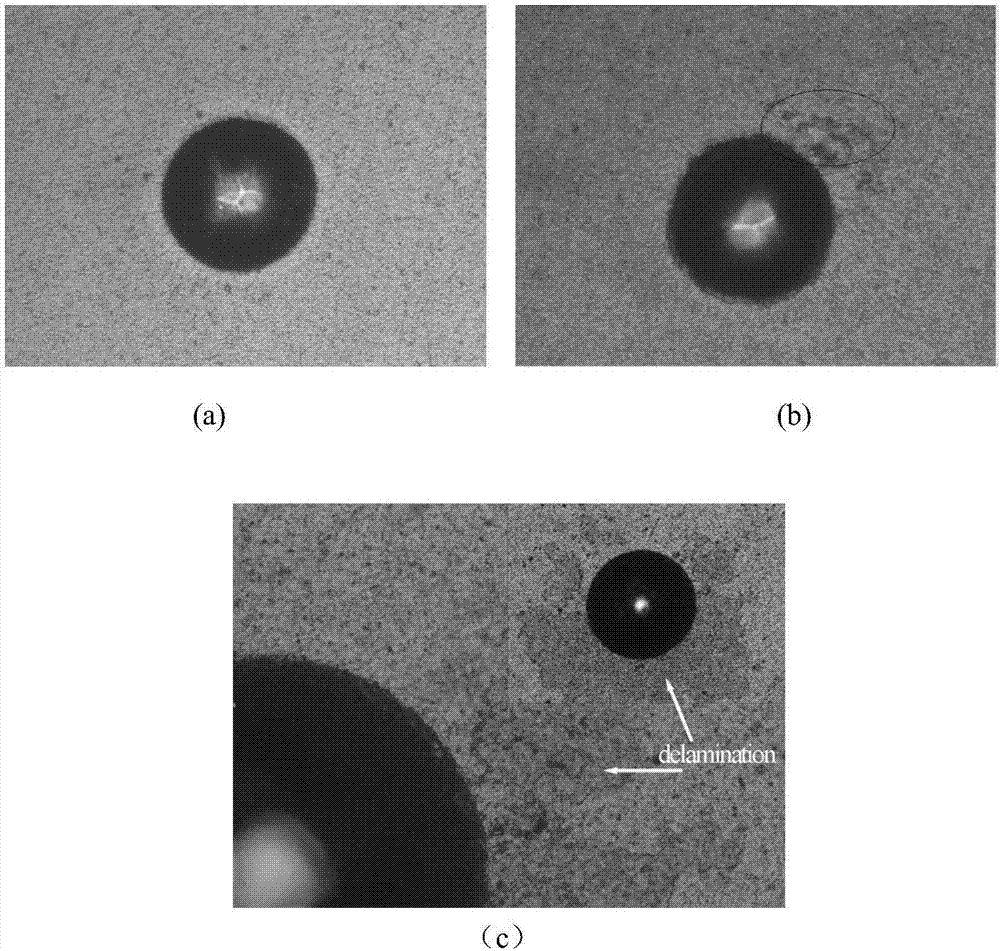

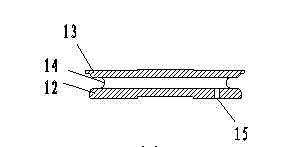

Stone with functional thin film layer and manufacturing method thereof

InactiveCN103029373AChange wear resistanceChange corrosivenessCeramic shaping apparatusCeramic layered productsWear resistanceMaterials science

The present invention provides a stone with a functional thin film layer and a manufacturing method thereof. The stone of the present invention is characterized in that the surface of the natural stone is adhered with the thin film layer having a certain characteristic. The stone of the present invention uses a physical sputtering method, wherein the substrate is a natural stone, and the target is a thin film material. The beneficial effects of the present invention are that: by using the industrial method, the surface of the natural stone is adhered with the thin film layer to change wear resistance or corrosion resistance on stone surface, so that the stove has better overall performances than natural stone and the designer has more selection space. The manufacturing method of the present invention enables the stone having the functional thin film layer to be mass-produced by an industrial method. The production scale can be very large in order to facilitate cost reduction.

Owner:孙宝春 +1

Preparation method for barium-containing flue gas denitration catalyst and denitration catalyst prepared by using same

PendingCN111135820AChange resilienceChange wear resistanceCatalyst carriersGas treatmentOXALIC ACID DIHYDRATEPtru catalyst

The invention discloses a preparation method for a barium-containing flue gas denitration catalyst, and relates to the technical field of denitration catalysts. The preparation method comprises the following steps: (1) adding ammonium metatungstate and ammonium metavanadate into an oxalic acid solution so as to prepare a mixed solution; (2) adding a barium compound and a titanium dioxide aqueous solution into the mixed solution obtained in the step (1), and carrying out ultrasonic treatment so as to obtain a raw material solution; (3) drying the raw material solution at 100 DEG C until the weight is constant, and carrying out calcining; and (4) adding water to wet barium-containing catalyst powder, adding an aluminum hydrosol, then adding an organic adhesive and a molding auxiliary agent,adjusting the moisture content of a mixture to 15-35%, and carrying out extrusion molding so as to obtain the barium-containing denitration catalyst. The preparation method disclosed by the inventionhas the following beneficial effects: the barium-containing compound and titanium dioxide macromolecules can generate a lattice doping phenomenon when being calcined at 450-650 DEG C, so the compression resistance and the wear resistance of a carrier are changed. Meanwhile, the denitration catalyst is guaranteed to reach denitration efficiency of 95% or above within a temperature range of 300-400DEG C.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH +1

Anticorrosion self-lubricating bolting cloth of oil field mud vibrating screen and manufacturing method thereof

The invention discloses anticorrosion self-lubricating bolting cloth of an oil field mud vibrating screen and a manufacturing method thereof. The anticorrosion self-lubricating bolting cloth is made by coating stainless steel screen cloth with anticorrosion self-lubricating coating, and the anticorrosion self-lubricating coating is formed by mixing alpha-crystal form composite aluminum oxide and nano-composite ceramic slurry according to a mass ratio. The nano-composite ceramic slurry is prepared from nano carbon black, nano ceramic powder and absolute ethyl alcohol according to a mass ratio; finished bolting cloth is naturally dried after being deoiled, degreased and descaled, and the dried screen cloth is subjected to spraying, brush coating and dip coating so that a coating can be completely attached to the screen cloth; the screen cloth coated with the coating is placed into a non-pollution drying room for continuous constant temperature drying, and then placed into the natural environment for natural ceramization; and the vibrating bolting cloth of the standard specification is directly manufactured. The bolting cloth is high in abrasion resistance, surface hardness and hydrophobicity, free of water and resistant to acid, alkali and corrosion, and the service life of the bolting cloth is prolonged by 50% or above.

Owner:新疆加福萨斯石油设备有限公司

Processing technology of cotton felt

ActiveCN109594191BReduced service lifeThe rebound rate is maintainedNon-woven fabricsHollow fibreFiber

Owner:翰诠特种纺织品(平湖)有限公司

A kind of rubber material for automobile oil return pipe and its preparation process

The invention discloses an automobile oil return pipe glue stock and a preparation process thereof. The glue stock comprises, by weight, 70-85 parts of nitrile rubber, 15-30 parts of pyridine butadiene rubber, 20-25 parts of spraying carbon black, 1.2-1.5 of stearic acid, 2.0-2.8 parts of canola oil, 1.6-2.0 parts of dibutyl ester, 4-7 parts of sea-foam stone powder, 10-14 parts of quartz powder, 0.8-1.2 parts of anti-aging agents RD, 1.1-1.3 parts of anti-aging agents AW, 1.6-2.0 parts of anti-aging agents ODA, 6.5-7.8 parts of N,N'-meta phenylene bis maleimide, 0.20-0.27 parts of accelerator TMTD and 1.2-1.5 parts of accelerators DM. According to the automobile oil return pipe glue stock, the pyridine butadiene rubber and the nitrile rubber are compounded and used, and proper filling agents and the anti-aging agents are matched, so that the prepared glue stock meets requirements of oil resistance and heat resistance, cold-resistance and aging resistance of an automobile oil return pipe.

Owner:YANCHENG SAIFO AUTOMOBILE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com