Waterproof paint special for fire protection clothing and preparation method of waterproof paint

A waterproof coating and clothing technology, applied in the field of firefighting clothing, can solve the problems of difficult operation, reduce the fabric layer of firefighting clothing, and the bulkiness of firefighting clothing, so as to improve impact resistance and tensile strength, improve wear resistance and waterproof effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

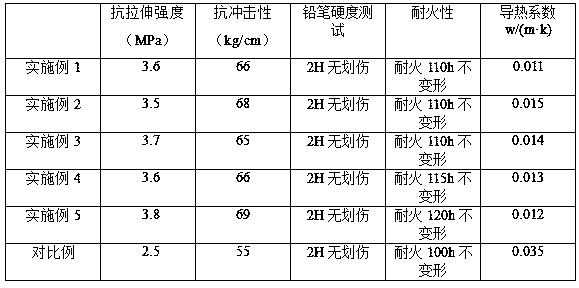

Examples

Embodiment 1

[0036] This embodiment relates to a special waterproof coating for fire-fighting clothing, including the following raw materials in parts by weight: 30 parts of acrylic emulsion, 10 parts of butyl acetate, 5 parts of modified nano-expanded vermiculite, 3 parts of vacuum ceramic powder, hexamethylene tetra 2 parts of amine, 3 parts of dibutyl phthalate, 4 parts of modified diatomaceous earth, 3 parts of cellulose solution, 2 parts of reinforcing fiber, 3 parts of pentaerythritol, 2 parts of propylene glycol, 1 part of magnesium hydroxide, 1 part of aluminum hydroxide 2 parts, 2 parts of nano titanium dioxide, 2 parts of sodium stearate, 2 parts of defoamer.

[0037] Wherein, the preparation method of described modified expanded vermiculite is as follows:

[0038] Soak the expanded vermiculite in the sodium alginate sol prepared in advance, and adopt the vacuum impregnation and adsorption process to make the nano-sodium alginate sol suck into the cavity of the expanded perlite t...

Embodiment 2

[0052] This embodiment relates to a special waterproof coating for fire-fighting clothing, including the following raw materials in parts by weight: 50 parts of acrylic emulsion, 20 parts of butyl acetate, 12 parts of modified nano-expanded vermiculite, 6 parts of vacuum ceramic powder, hexamethylene tetra 5 parts of amine, 7 parts of dibutyl phthalate, 8 parts of modified diatomaceous earth, 9 parts of cellulose solution, 6 parts of reinforcing fiber, 5 parts of pentaerythritol, 4 parts of propylene glycol, 3 parts of magnesium hydroxide, 2 parts of aluminum hydroxide 3 parts, 3 parts of nano-titanium dioxide, 3 parts of sodium stearate, 5 parts of defoamer.

[0053] Wherein, the preparation method of described modified expanded vermiculite is as follows:

[0054] Soak the expanded vermiculite in the sodium alginate sol prepared in advance, and adopt the vacuum impregnation and adsorption process to make the nano-sodium alginate sol suck into the cavity of the expanded perlit...

Embodiment 3

[0068] This embodiment relates to a special waterproof coating for fire-fighting clothing, including the following raw materials in parts by weight: 35 parts of acrylic emulsion, 12 parts of butyl acetate, 7 parts of modified nano-expanded vermiculite, 4 parts of vacuum ceramic powder, hexamethylene tetra 3 parts of amine, 4 parts of dibutyl phthalate, 5 parts of modified diatomaceous earth, 5 parts of cellulose solution, 3 parts of reinforcing fiber, 3.8 parts of pentaerythritol, 2.9 parts of propylene glycol, 1.3 parts of magnesium hydroxide, 1.1 parts of aluminum hydroxide 2.3 parts, 2.3 parts of nano titanium dioxide, 2.4 parts of sodium stearate, 3 parts of defoamer.

[0069] Wherein, the preparation method of described modified expanded vermiculite is as follows:

[0070] Soak the expanded vermiculite in the sodium alginate sol prepared in advance, and adopt the vacuum impregnation and adsorption process to make the nano-sodium alginate sol suck into the cavity of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com