Magnetic pump

A magnetic pump and pump cover technology, applied to pumps, pump devices, pump components, etc., can solve problems such as overheating of the pump shaft, demagnetization of internal magnetic components, and melting of plastic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

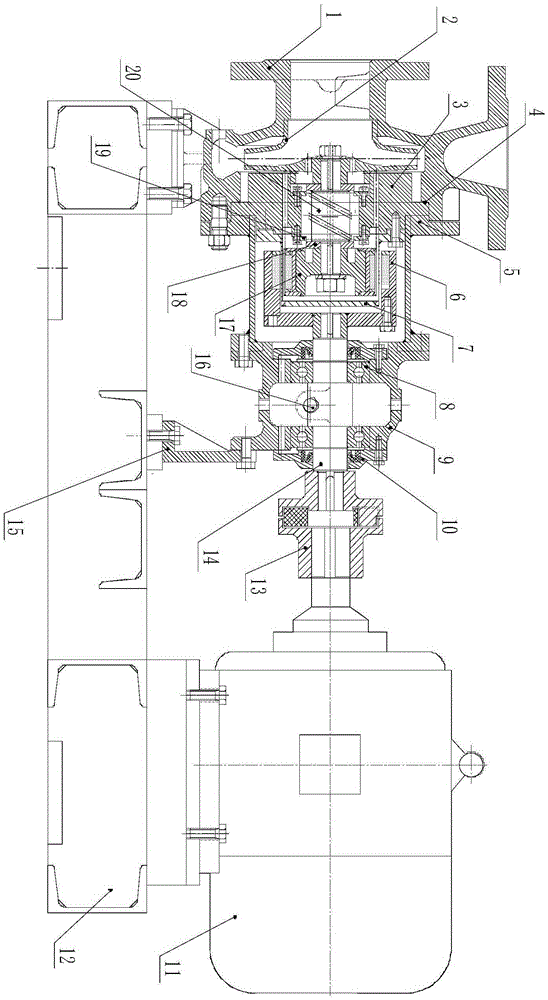

[0015] Examples such as figure 1 As shown, a magnetic pump includes a pump body 1, an impeller 2, a pump cover 3, a gasket 4, a bracket 5, an outer magnetic rotor component 6, a shielding sleeve 7, a bearing 8, a bearing housing 9, a bearing gland 10, Motor 11, base 12, claw type coupling 13, right shaft 14, foot 15, oil mirror 16, inner magnetic rotor part 17, thrust plate 18, pressure plate 19 and left shaft 20; the pump body 1 is fixedly installed on the base 12 and close to the left side of the base 12, the impeller 2 is fixed on the left side of the left shaft 20 by screws, the pump cover 3 is installed in the mounting hole at the right end of the pump body 1, the pump cover 3 and the pump body 1 A sealing gasket 4 is installed on the contact surface between the two, the bracket 5 is fixedly installed on the right side of the pump cover 3, and the inner magnetic rotor part 17 is fixedly installed on the left shaft 29 through screws and gaskets. On the right end face, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com