A kind of rubber material for automobile oil return pipe and its preparation process

A technology for oil return pipes and automobiles, applied in the field of automobile materials, which can solve the problems of poor insulation performance, poor ozone resistance, and low temperature resistance, and achieve the effect of improving oil resistance and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

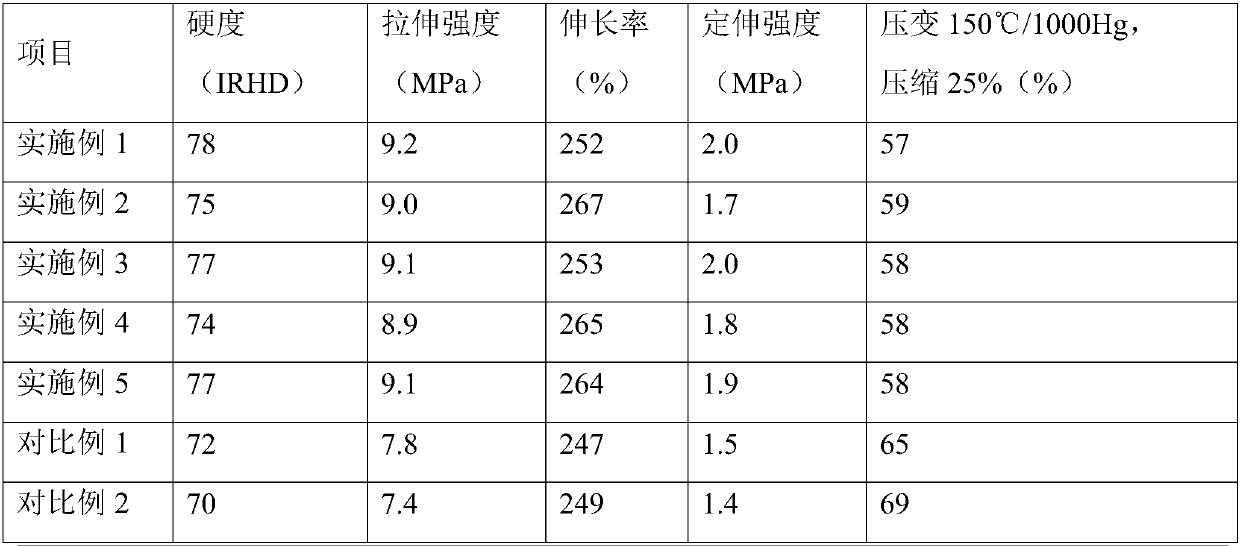

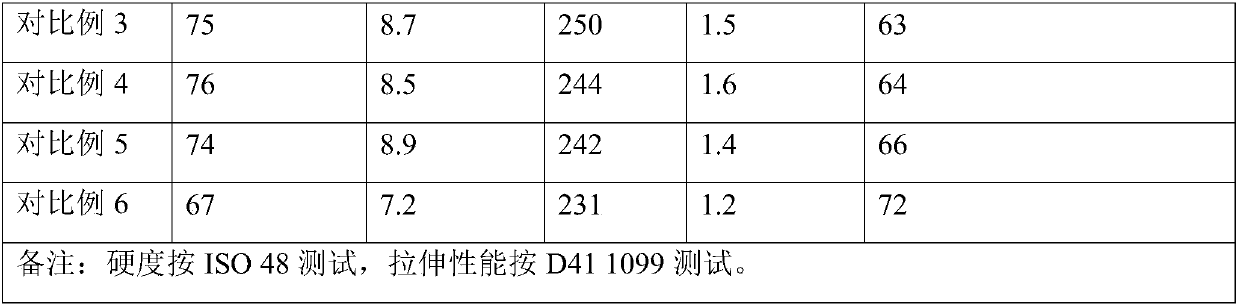

Examples

Embodiment 1

[0022] In the embodiment of the present invention, a rubber material for an automobile oil return pipe is composed of the following raw materials in parts by weight: 70 parts of nitrile rubber, 30 parts of butylpyridine rubber, 20 parts of spray carbon black, 1.5 parts of stearic acid, vegetable 2.0 parts of seed oil, 2.0 parts of dibutyl ester, 4 parts of sepiolite powder, 14 parts of quartz powder, 0.8 parts of anti-aging agent RD, 1.3 parts of anti-aging agent AW, 1.6 parts of anti-aging agent ODA, N,N'-m-phenylene bismas 7.8 parts of imide, 0.20 parts of accelerator TMTD, and 1.5 parts of accelerator DM.

[0023] The preparation process of the sizing material for the automobile oil return pipe comprises the following steps:

[0024] (1) Mix nitrile rubber, butyl rubber, stearic acid and rapeseed oil uniformly in proportion, and place ultrasonic power at 350W and ultrasonic frequency at 35kHz for ultrasonic dispersion for 16 minutes to obtain the first ultrasonic mixture; ...

Embodiment 2

[0031] In the embodiment of the present invention, a rubber material for an automobile oil return pipe is composed of the following raw materials in parts by weight: 85 parts of nitrile rubber, 15 parts of butylpyridine rubber, 25 parts of spray carbon black, 1.2 parts of stearic acid, vegetable 2.8 parts of seed oil, 1.6 parts of dibutyl ester, 7 parts of sepiolite powder, 10 parts of quartz powder, 1.2 parts of anti-aging agent RD, 1.1 parts of anti-aging agent AW, 2.0 parts of anti-aging agent ODA, N, N'-m-phenylene bismas 6.5 parts of imide, 0.27 parts of accelerator TMTD, and 1.2 parts of accelerator DM.

[0032] The preparation process of the sizing material for the automobile oil return pipe is the same as in Example 1.

Embodiment 3

[0034] In the embodiment of the present invention, a rubber material for an automobile oil return pipe is composed of the following raw materials in parts by weight: 76 parts of nitrile rubber, 24 parts of butylpyridine rubber, 22 parts of spray carbon black, 1.4 parts of stearic acid, vegetable 2.4 parts of seed oil, 1.8 parts of dibutyl ester, 5 parts of sepiolite powder, 14 parts of quartz powder, 0.9 parts of anti-aging agent RD, 1.3 parts of anti-aging agent AW, 1.6 parts of anti-aging agent ODA, N, N'-m-phenylene bismas 7.5 parts of imide, 0.24 parts of accelerator TMTD, and 1.4 parts of accelerator DM.

[0035] The preparation process of the sizing material for the automobile oil return pipe comprises the following steps:

[0036] (1) Mix nitrile rubber, butyl rubber, stearic acid and rapeseed oil uniformly in proportion, place ultrasonic power to 450W, ultrasonic frequency to carry out ultrasonic dispersion 12min under the condition of ultrasonic frequency 35kHz, obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com