Patents

Literature

59results about How to "Change resilience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing waterborne anticorrosion coating resin vinylidene chloride-acrylate

InactiveCN102250275AReduce adhesionGood emulsifying effectAnti-corrosive paintsEmulsionPolymer science

The invention discloses a method for preparing waterborne anticorrosion coating resin vinylidene chloride-acrylate. In the method, vinylidene chloride, acrylate and different compounded emulsifiers are pre-emulsified, and azodiisobutyronitrile is used for initiating polymerization reaction. The method comprises the following steps of: adding partial pre-emulsion into a reactor; heating to temperature higher than the initiation temperature of an initiator, adding the initiator, and performing polymerization reaction at constant temperature to obtain seeded emulsion; and dripping the rest pre-emulsion into the reactor and continuously performing the reaction at constant temperature. The emulsion has high stability, uniform particle size, high resin adhesion and high film and anticorrosion properties, is environment-friendly and nontoxic, and can provide good corrosion protection for carbon steel matrixes.

Owner:TIANJIN UNIV +1

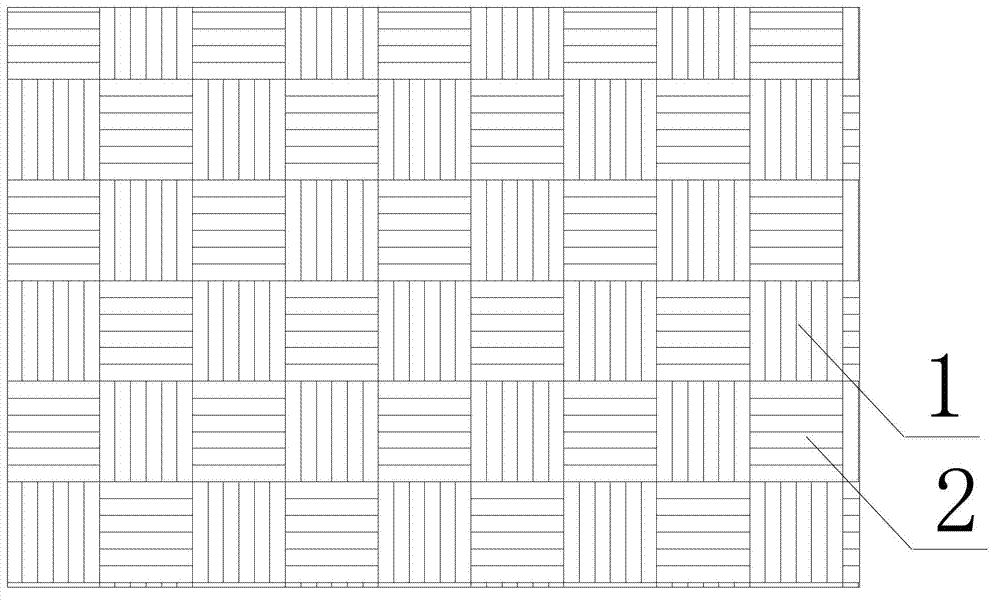

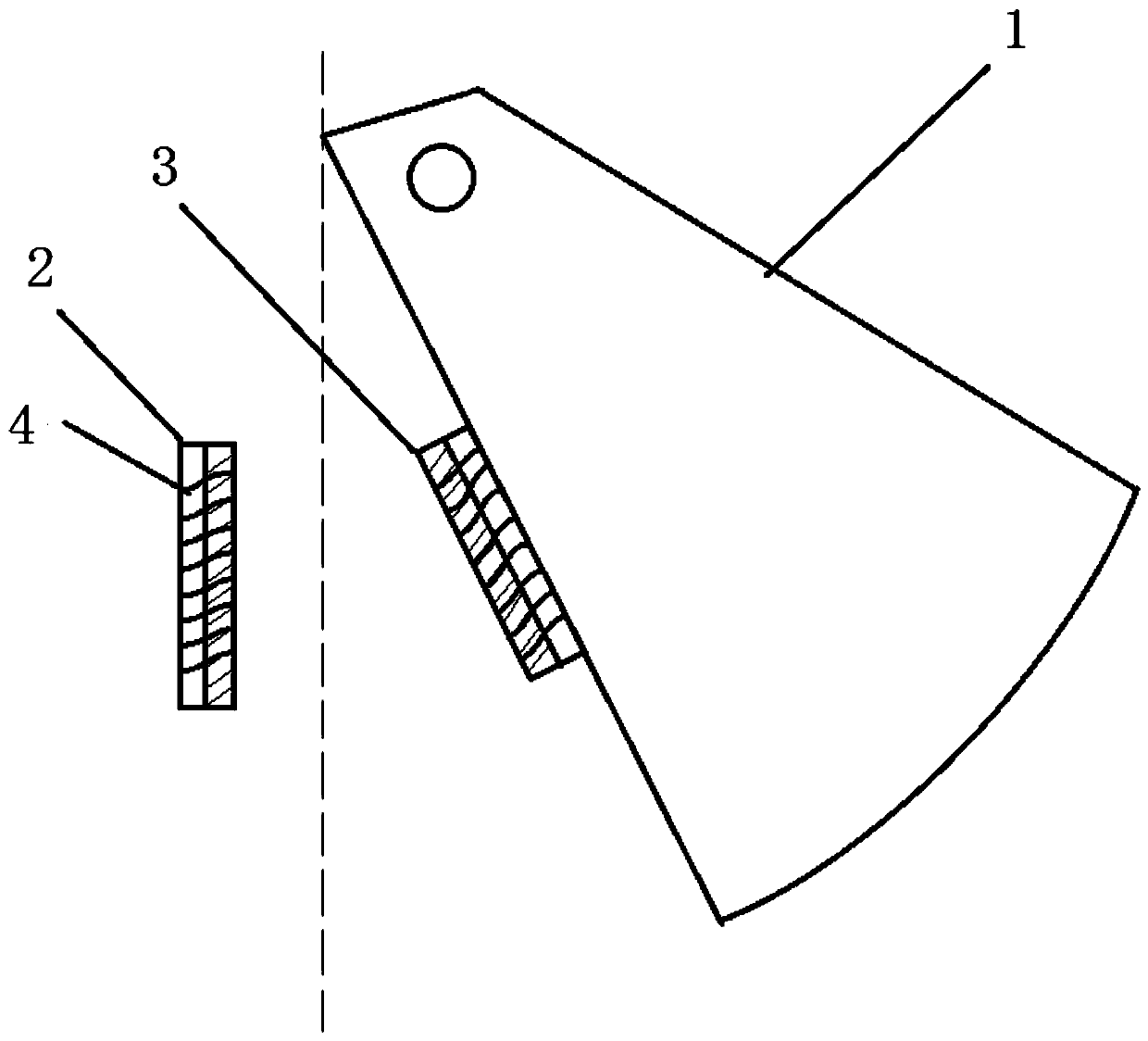

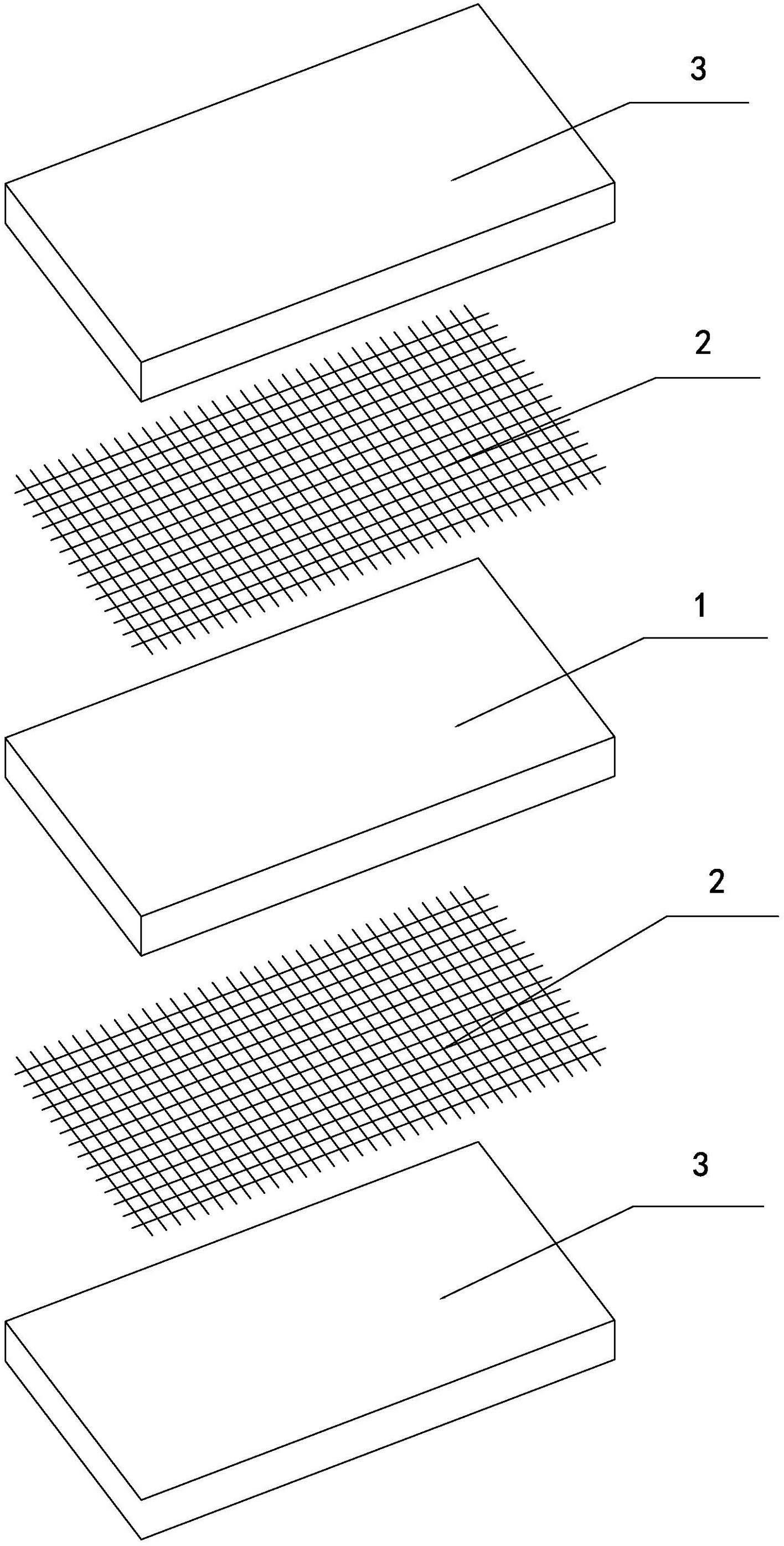

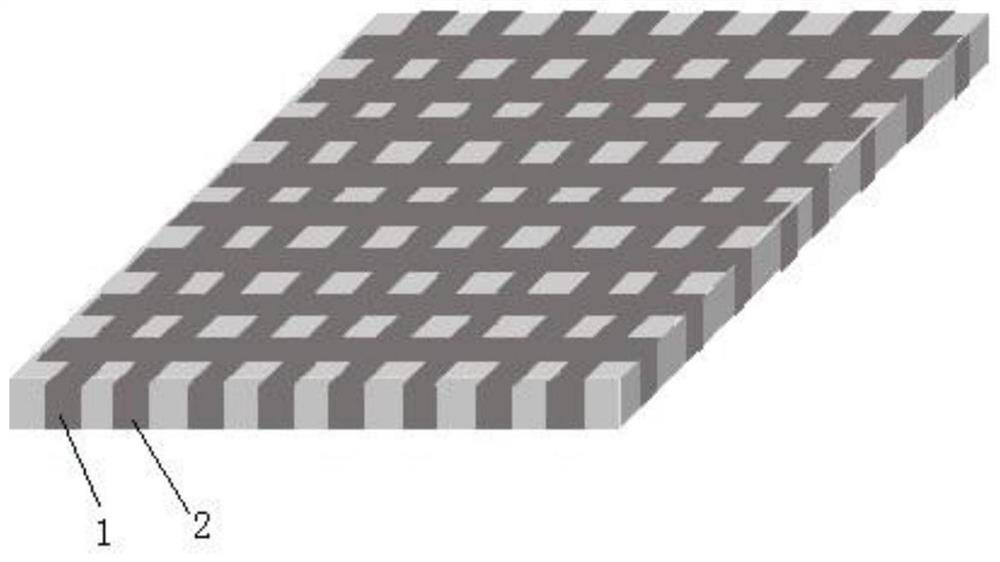

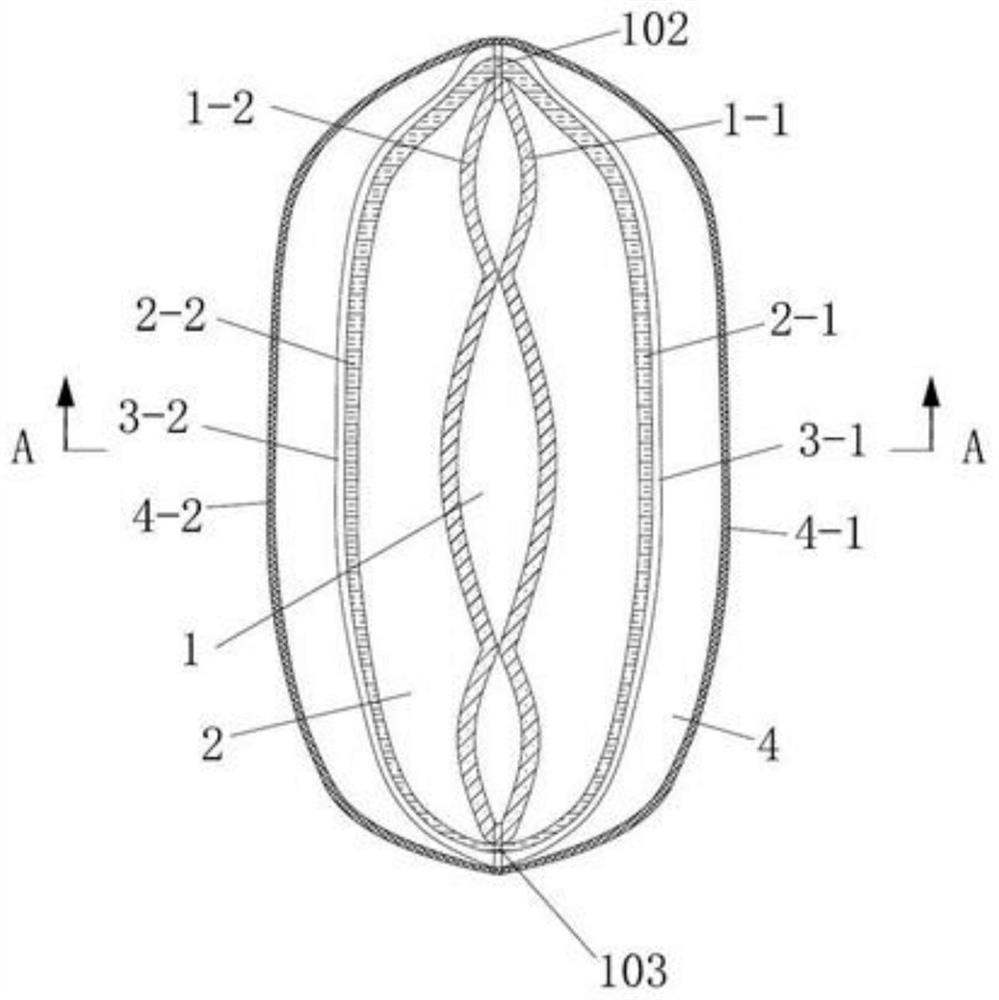

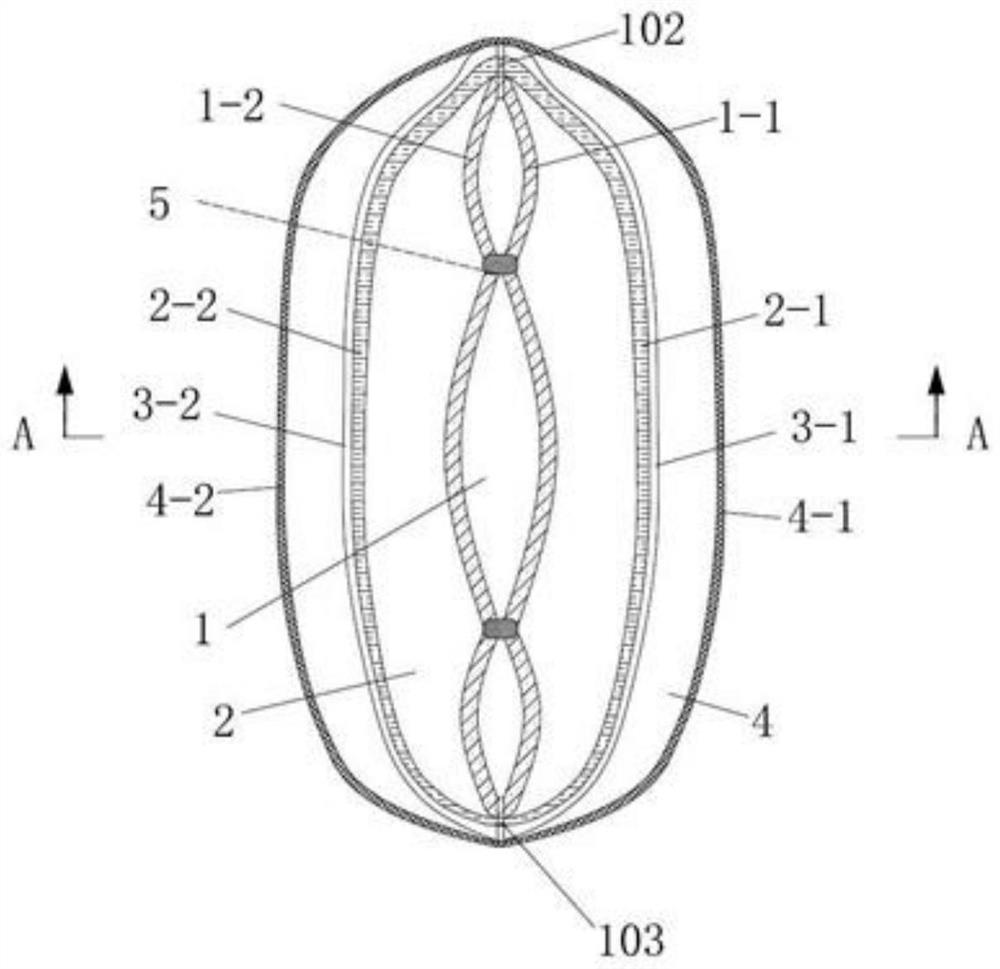

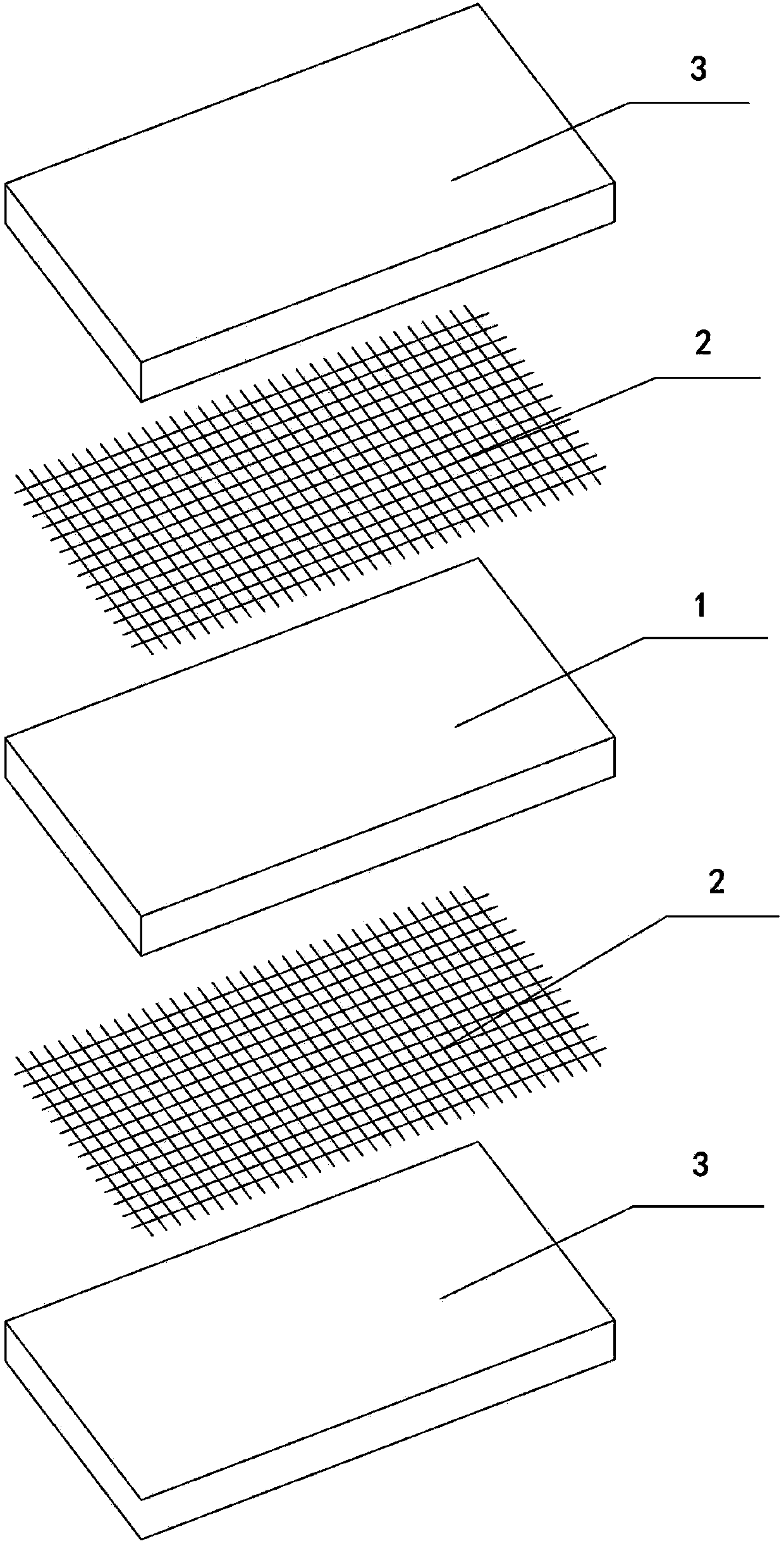

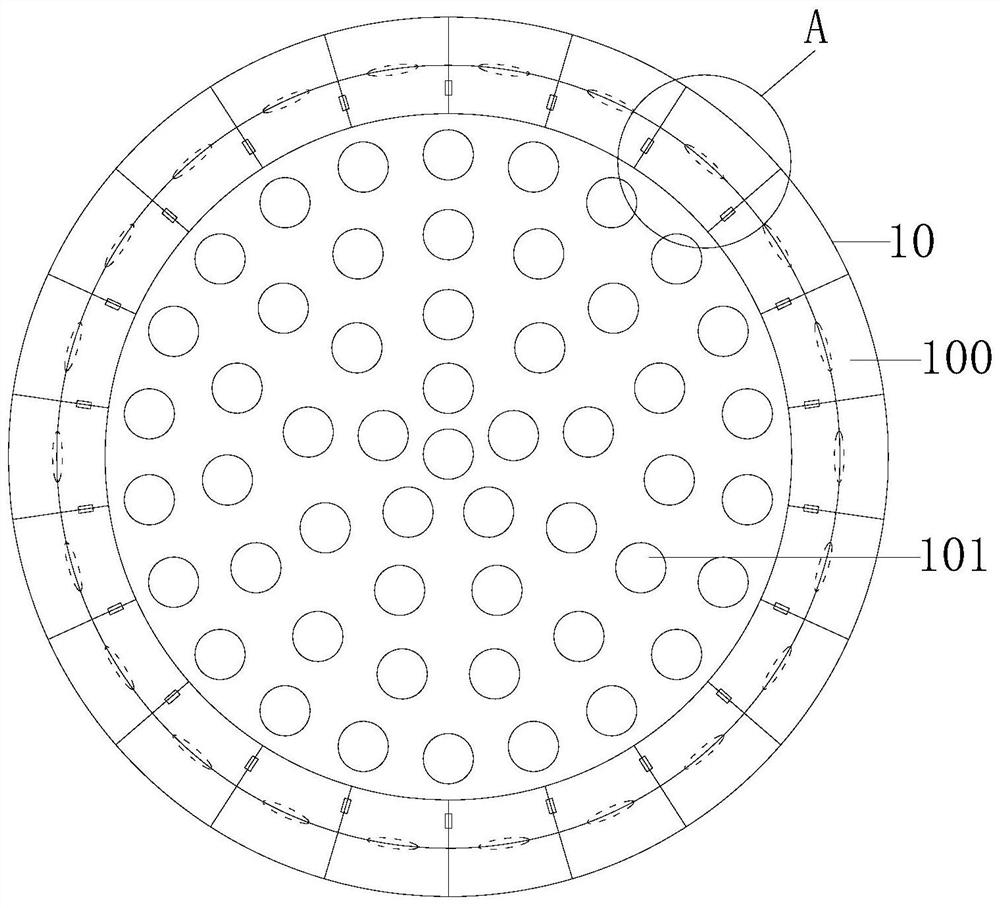

Hybrid textile cloth of aramid fiber and carbon fiber

InactiveCN102787422AChange resilienceChanging the color is too simpleWoven fabricsGlass fiberPolymer science

The invention discloses a hybrid textile cloth of an aramid fiber and a carbon fiber. The hybrid textile cloth comprises a warp-wise fiber strand (1) and a weft-wise fiber strand (2); the warp-wise fiber strand (1) is the aramid fiber (or the carbon fiber); the weft-wise fiber strand (2) is the carbon fiber (or the aramid fiber), and the aramid fiber and the carbon fiber are orderly laminated and staggered in a criss-crossed shape. According to the structure of the hybrid textile cloth, the problems that a single glass fiber reinforced plastic product just has rigidity without flexibility and does not resist impacts in the past are changed, so the strength of the product is greatly increased, the weight is greatly reduced, and fireproof, heat-insulating, and anti-puncture performances are also improved slightly.

Owner:YIXING HUAHENG HIGH PERFORMANCE FIBER WEAVING

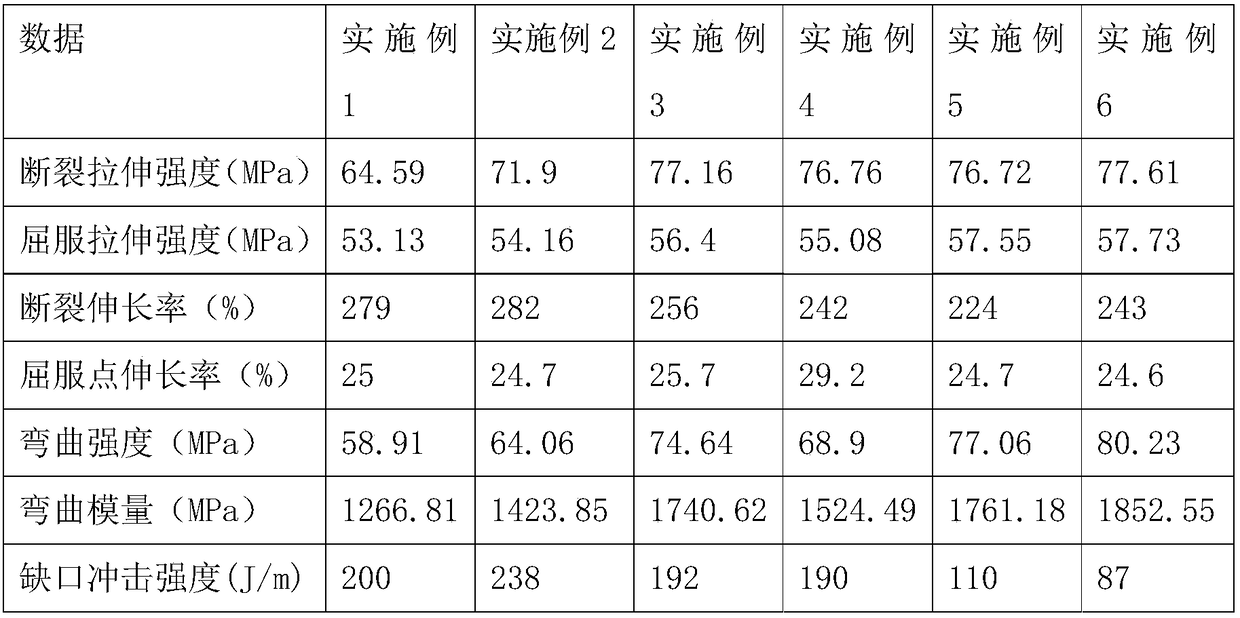

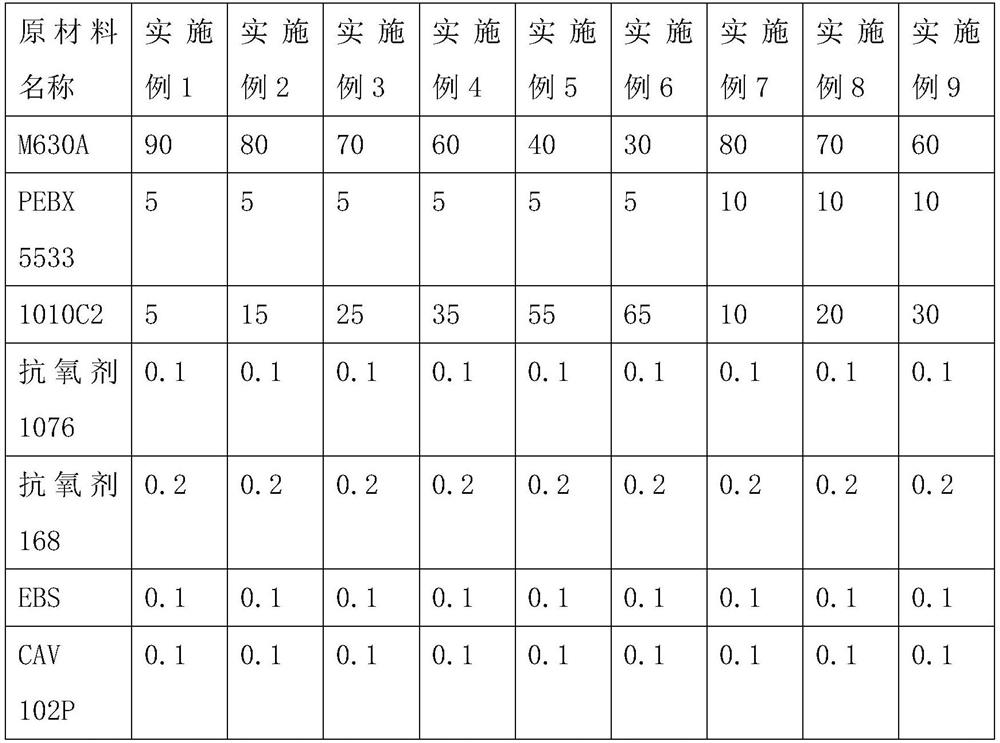

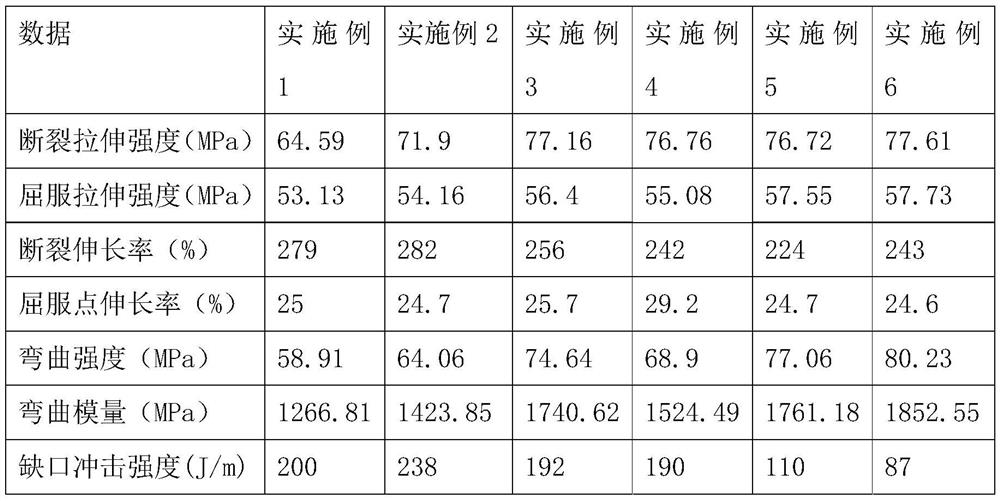

Preparation method of polypropylene composite material with high strength and high toughness

ActiveCN102532706AImprove tensile toughnessImprove impact toughnessFine chemicalPolypropylene composites

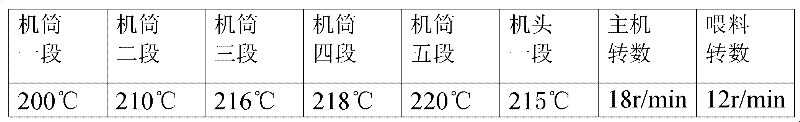

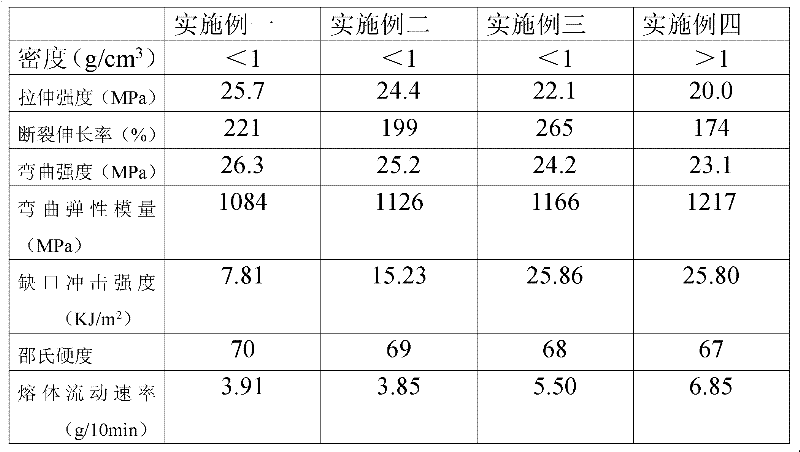

A preparation method of a polypropylene composite material with high strength and high toughness belongs to the fields of chemical engineering and fine chemical industry. The preparation method comprises the following steps: weighing components according to the following mass percents: 10-45% of homopolymerized polypropylene, 10-25% of copolymerized polypropylene, 15-40% of copolymerized polypropylene, 9-16% of POE, 5-35% of polypropylene reinforcing toughening modifiers, 0.15-0.4% of nucleating agents, 0.25-0.55% of anti-oxidants, and 0.2-0.5% of lubricants; adding the weighed materials into a high-speed mixer, fully mixing at a speed of 1000 r / min for two minutes, releasing the materials; adding the mixed materials into a hopper of a double screw extruder, extruding the materials according to technological parameters to obtain the composite material particles. According to the polypropylene composite material of the invention, the crystallization state of polypropylene is changed by components of the polypropylene reinforcing toughening modifier, the ethane-octylene copolymer, the nucleating agent and the like, and thus mechanical properties such as strength and toughness of the composite material are changed.

Owner:CHANGCHUN DALI NANO TECH DEV

Thermal sensitive ceramic material and preparation method thereof

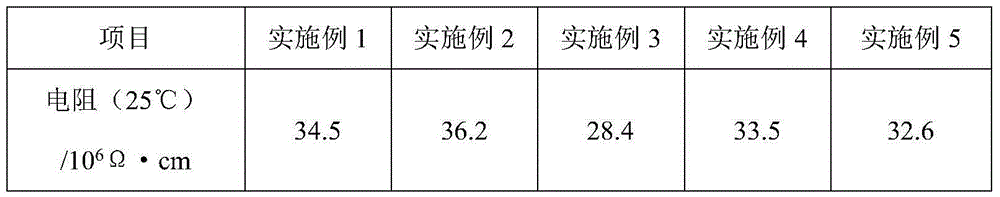

The invention discloses a thermal sensitive ceramic material and a preparation method thereof, relating to the technical field of materials. The main components of the thermal sensitive ceramic material are metal oxides which include Co3O4, Fe2O3, Ni2O3, SnO2, TiO2, Li2O and rear earth oxides, wherein a molar ratio of the substances of components in the material is that the Co:Fe:Ni:Sn:Ti:Li:rear earth is 1:(1-3):(0.3-0.7):(0.01-0.05):(0.02-0.05):(0.01-0.03):(0.1-0.3). The preparation method of the thermal sensitive ceramic material comprises the following steps: weighing, grinding, ball-milling, calcining, cutting into slices and coating an electrode material. The thermal sensitive ceramic material provided by the invention as well as thermal sensitive ceramic with a negative temperature coefficient provided by the preparation method have the characteristics of wide working temperature region and high sensitivity; and moreover, the thermal sensitive ceramic material has the advantages of simple preparation process, stable material performance and capacity of being recycled, and the like.

Owner:常熟市董浜科技创业投资发展有限公司

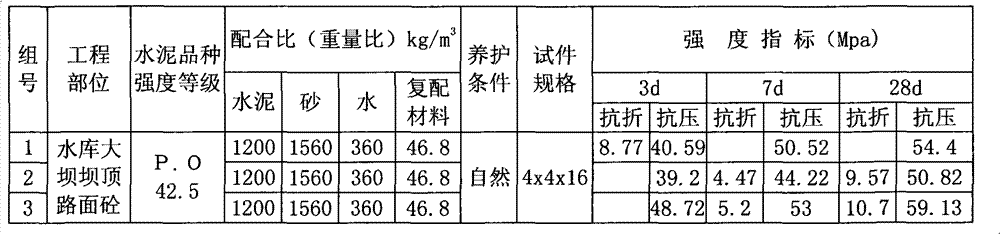

Hydraulic concrete surface layer slit sealing method

InactiveCN101994306AImprove adsorption capacityImprove adhesionMarine site engineeringGeneral purposeSurface layer

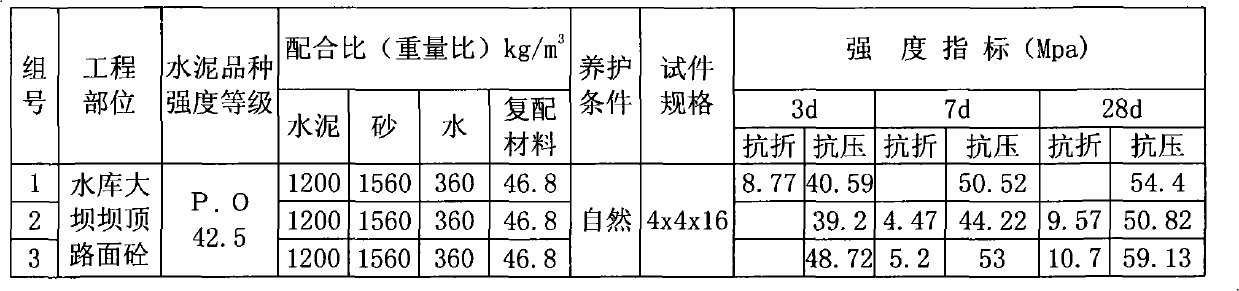

The invention relates to a hydraulic concrete surface layer slit sealing method belonging to a hydraulic concrete slit sealing method and comprising the following formula method: the formula contains 1000-1400 parts of general purpose portland cement PO42.5, 1100-2000 parts of medium coarse sand, 0-600 parts of chicken girt, 300-360 parts of water and a composite material; the method comprises the following steps of: (1) cutting a concrete surface layer crack; (2) cleaning the base surface of the concrete crack; and (3) preparing the composite material in the proportion of the formula, stirring the composite material with cement, the medium coarse sand and the water for 3 min at the stirring speed of 2000-2500R / min to form a cement gel material, and then pouring the cement gel material into slits. The invention is suitable for hydraulic concrete dam face slit treatment with better effect.

Owner:吉林省银河水利水电新技术设计有限公司

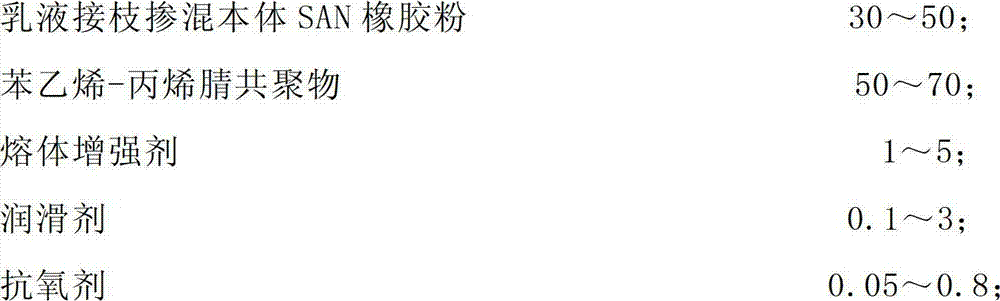

High-fatigue-resistance ABS (Acrylonitrile Butadiene Styrene) resin composition and preparation method thereof

The invention relates to a high-fatigue-resistance ABS (Acrylonitrile Butadiene Styrene) resin composition and a preparation method thereof. The composition comprises the following components in parts by mass: 30-50 parts of emulsion grafted mixed body SAN (Styrene Acryl Nitrile) rubber powder, 50-70 parts of styrene-acrylonitrile copolymer, 1-5 parts of melt reinforcing agent, 0.1-3 parts of lubricant and 0.05-0.8 part of antioxidant. The preparation method of the composition comprises the following steps of: putting the components into a high-speed mixer for premixing to obtain a premix compound; and melting and extruding the premix compound with a double screw extruder at the temperature of 190-240 DEG C and the screw rotating speed of 200-600 revolutions per minute, cooling and pelletizing to obtain the high-fatigue-resistance ABS resin composition. The fatigue resistance of the ABS resin composition is enhanced to a large extent. Moreover, the toughness, the specific weight and the superior appearance of the ABS resin composition do not change greatly.

Owner:GUANGDONG KUMHO SUNNY POLYMER MATERIAL

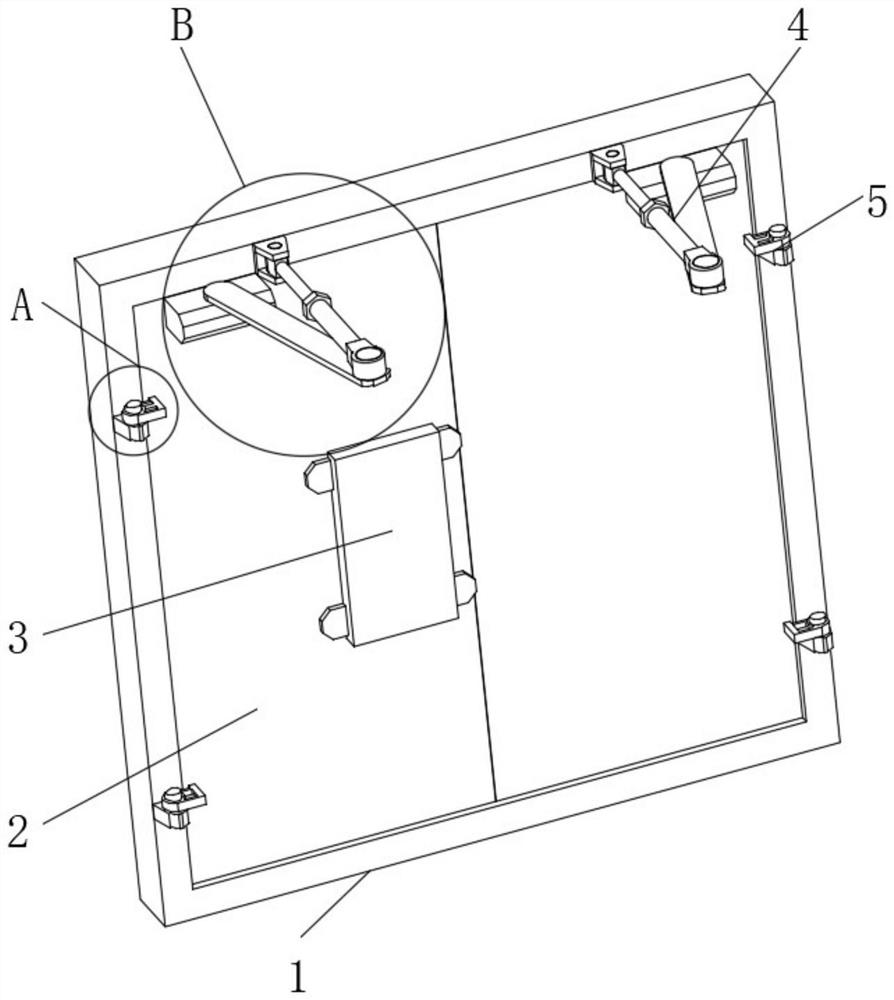

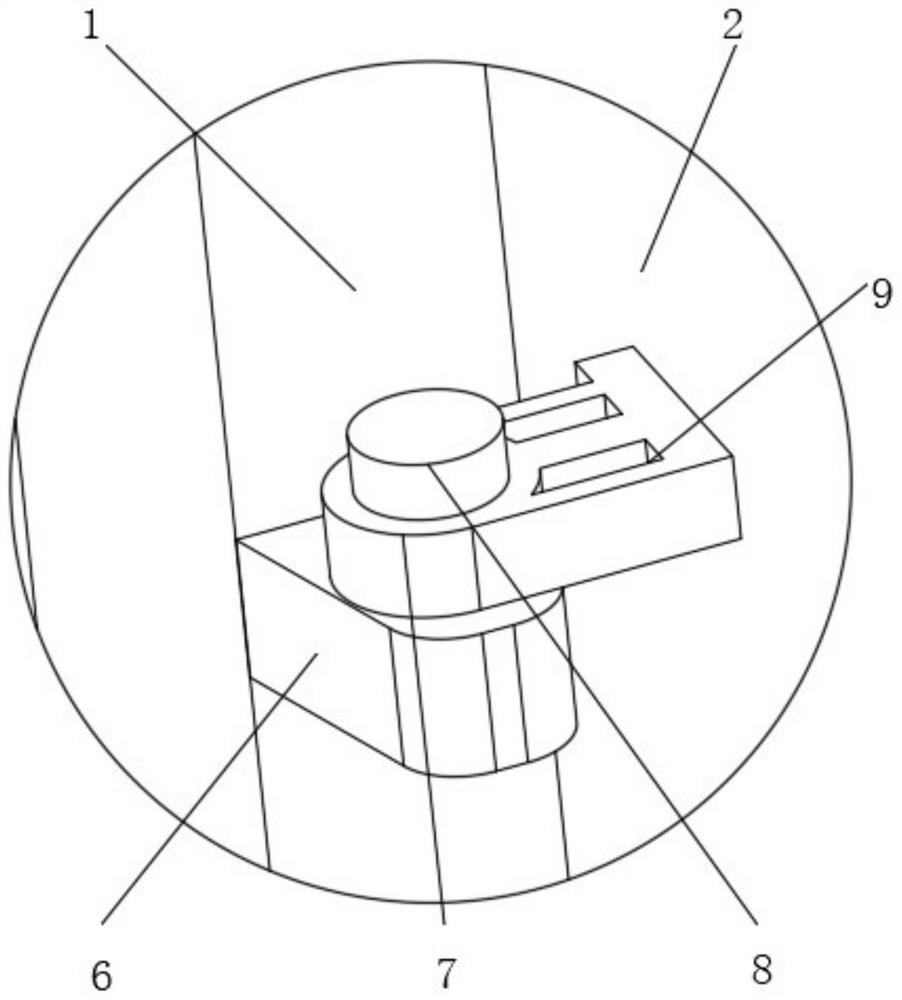

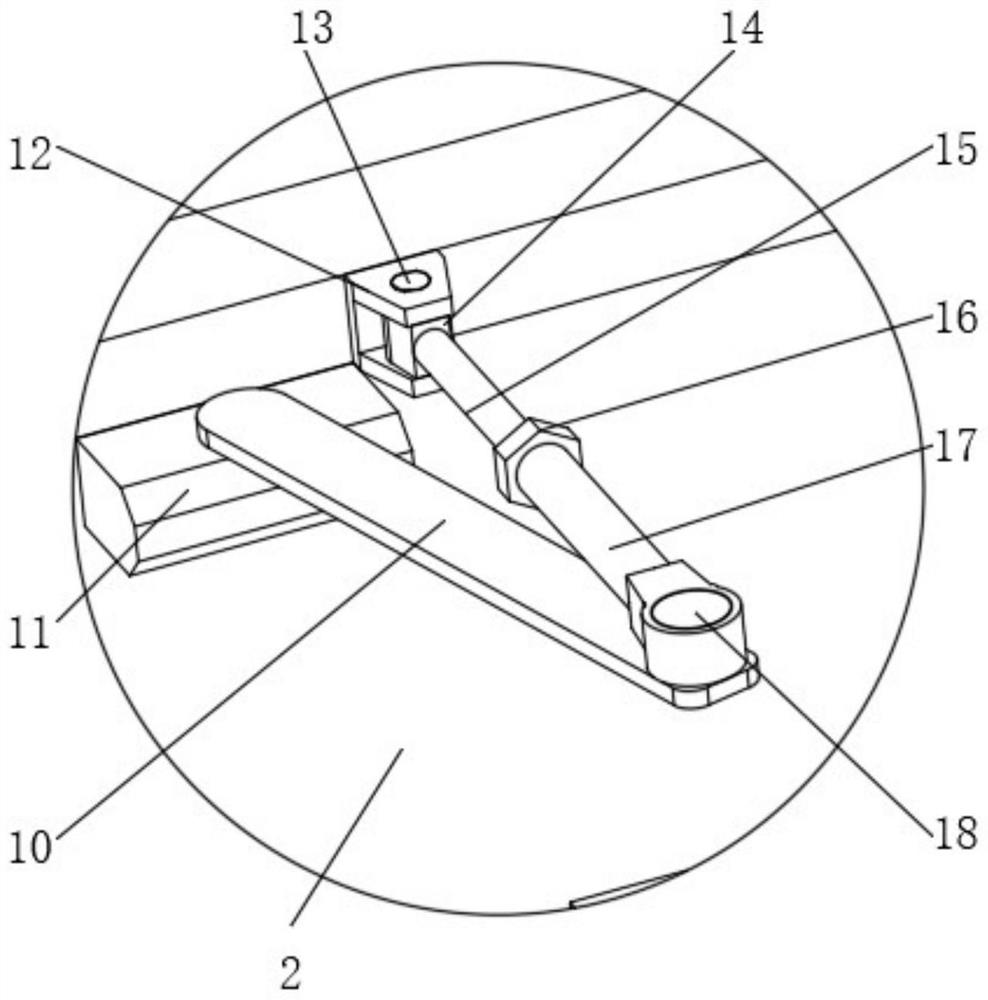

Trigger device and interactive terminal with same

The invention discloses a trigger device and an interactive terminal with the same. The trigger device comprises a trigger support and a trigger movably arranged on the trigger support. The trigger device also comprises: a trigger electromagnet, wherein the trigger electromagnet is fixed on the trigger; a support electromagnet which is relatively fixed with the trigger support, wherein the supportelectromagnet and the trigger electromagnet in the pressed state have the attraction or repulsion effect; and an electromagnetic control device which is connected with the electromagnetic coil of thetrigger electromagnet and the electromagnetic coil of the support electromagnet and used for adjusting voltage or current in the electromagnetic coil of the trigger electromagnet and the electromagnetic coil of the support electromagnet. According to the trigger device provided by the invention, the electromagnetic control device is used for adjusting the current in the electromagnetic coil of the trigger electromagnet and the electromagnetic coil of the support electromagnet, the magnetic force received by the trigger electromagnet is changed, the resilience force received by the trigger ischanged, different trigger feedback forces are provided for a user, and therefore different tactile feelings are provided for the user based on different game environments.

Owner:GEER TECH CO LTD

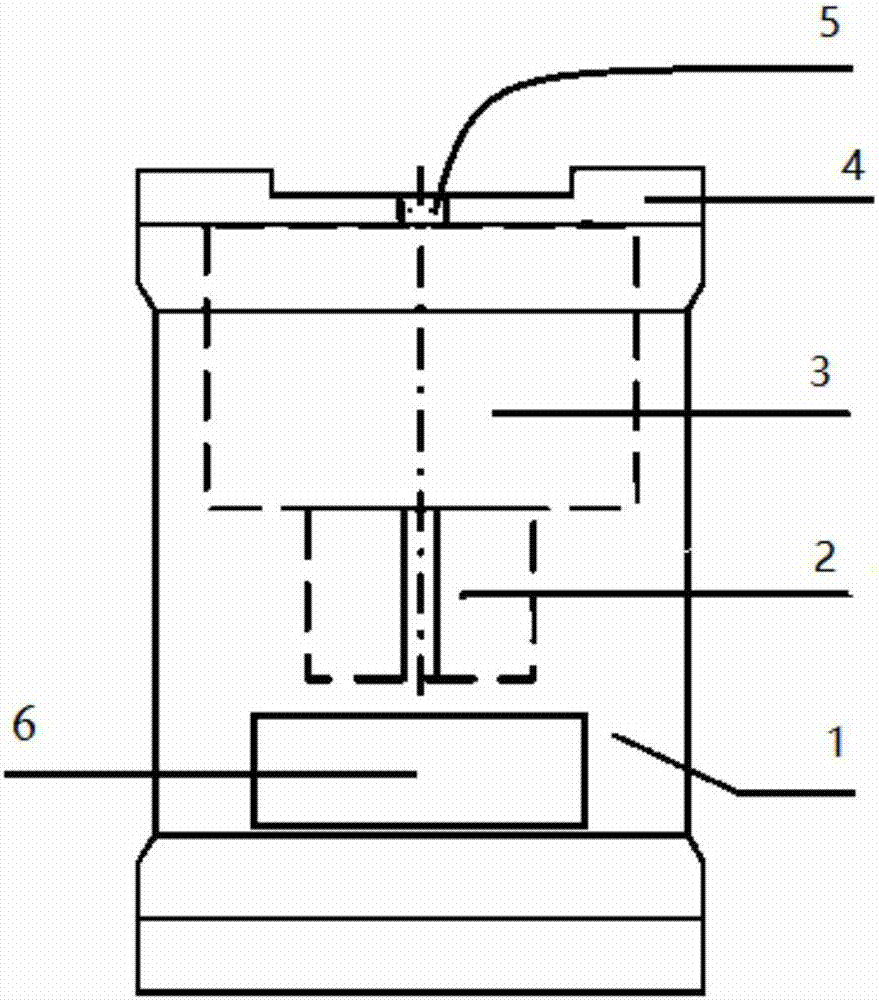

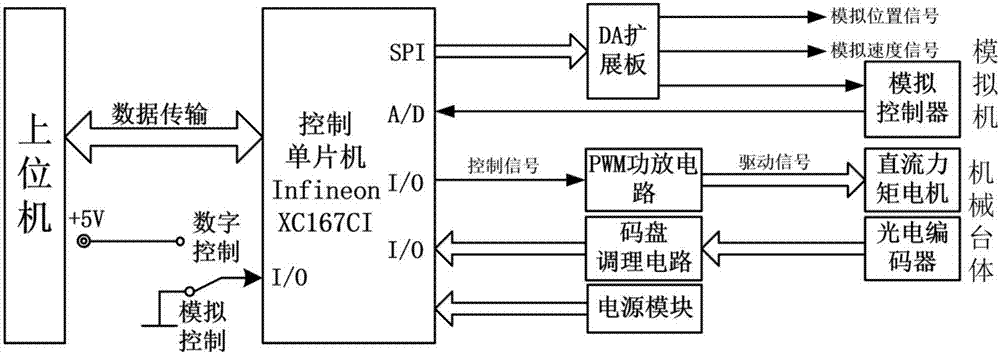

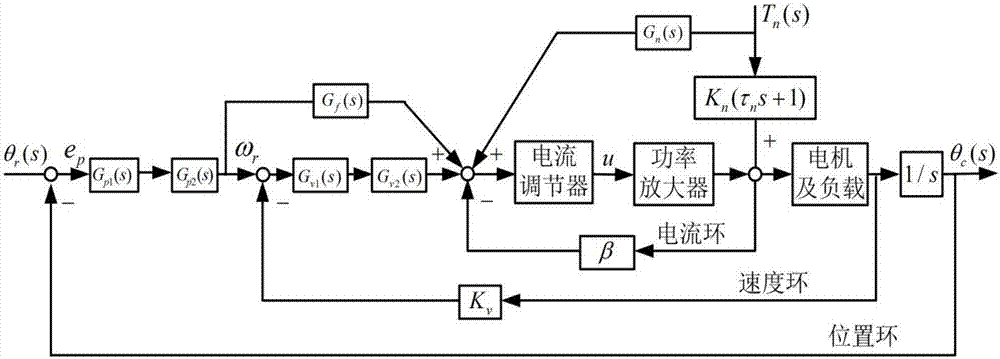

Automatic control principle experiment platform

InactiveCN106898229AConvenient simulation analysisConvenient verificationEducational modelsAutomatic controlEngineering

The invention relates to an automatic control principle experiment platform, and belongs to the technical field of experiment and testing technology experiment equipment. The automatic control principle experiment platform includes a rotary table body, a rotary encoder, a direct current moment motor, a load apparatus, a mechanical bearing and an embedded controller, wherein the rotary encoder, the direct current moment motor and the embedded controller are arranged in the vertical type rotary table body; the direct current moment motor is connected with the load apparatus at the top of the rotary table body through the mechanical bearing; the rotary table body is arranged below the direct current moment motor, and is connected with the direct current moment motor coaxially; and the embedded controller is arranged below the rotary encoder. The automatic control principle experiment platform integrates a servo rotary table system with an automatic control principle experiment so as to improve the engineering practicalness of experiment and enrich the experiment content.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

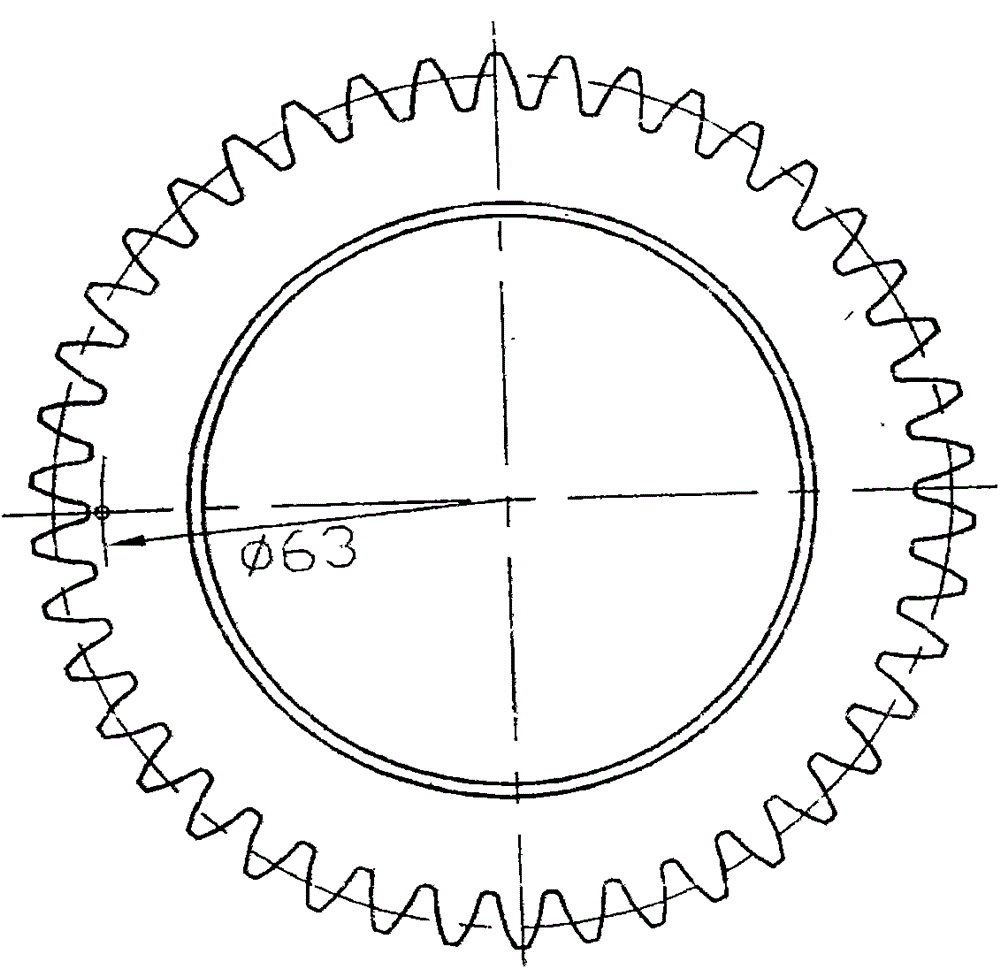

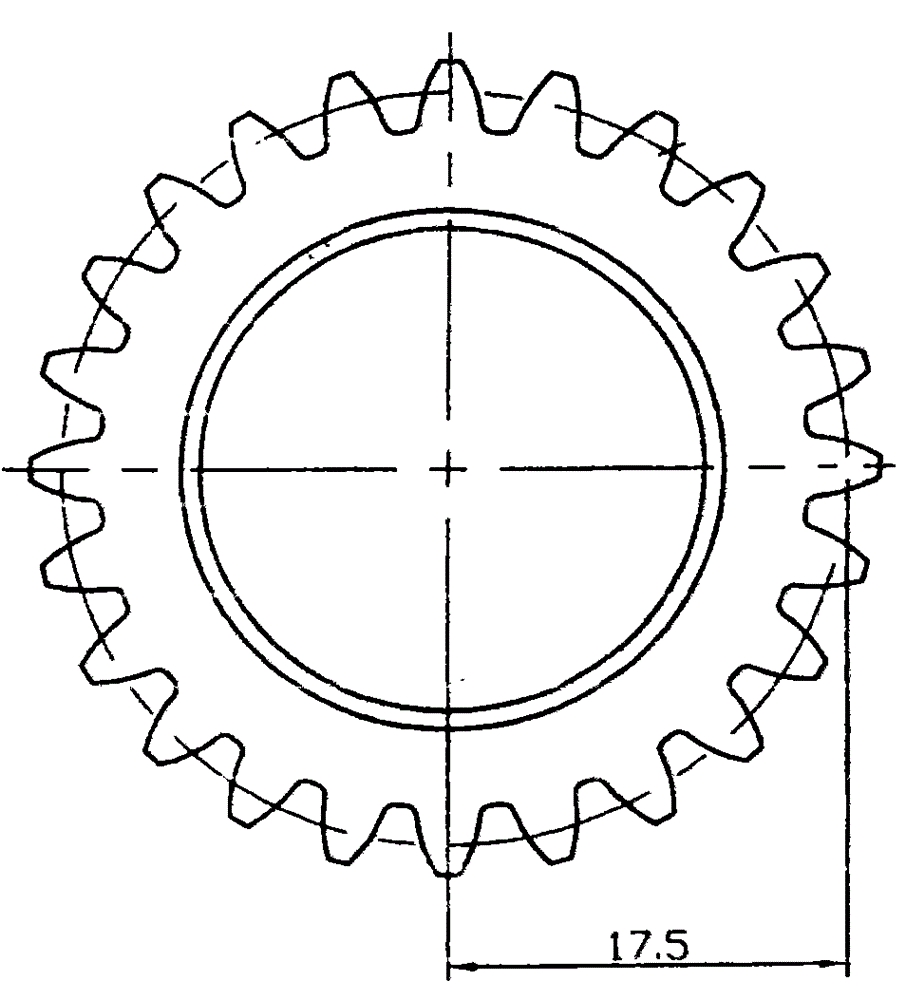

Powder metallurgy helical gear and manufacturing process thereof

InactiveCN105312553AChange hardnessChange resiliencePortable liftingGearing elementsManufacturing technologyIron powder

The invention discloses a powder metallurgy helical gear and a manufacturing process thereof. The gear is made of, by weight, powder raw materials including 0.7-1.0 parts of graphite, 0.5-3.0 parts of copper powder, 1.0-5.0 parts of nickel powder, 0.5-0.8 part of lubricating agents, iron powder and certain inevitable impurities; besides, the manufacturing process of the powder metallurgy helical gear includes the steps of raw material mixing, compressing, sintering, oil immersing and the like. The powder metallurgy helical gear and the manufacturing process thereof have the advantages that with respect to process, compared with a manufacturing process of an existing product, waste of raw materials is reduced, and the whole production energy consumption is saved by 1 / 4; besides, with respect to gear performance, the gear has the good performance that the torsion is over 120 N / M, and the hardness HRB is larger than 70, and the gear can well meet the requirement of a power device.

Owner:重庆道宇机电制造有限公司

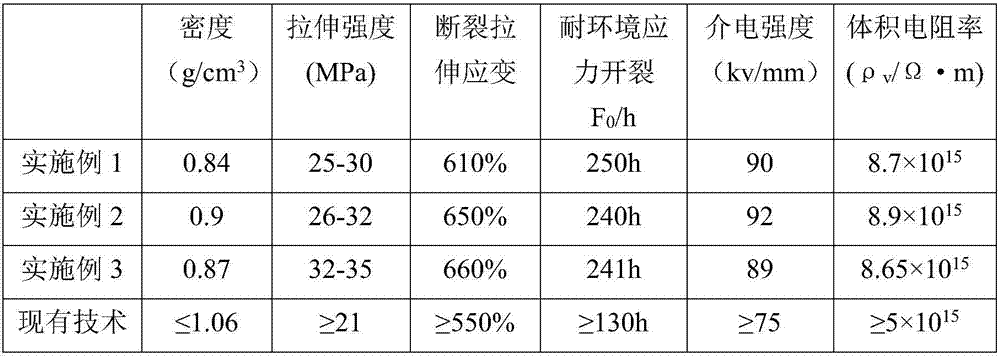

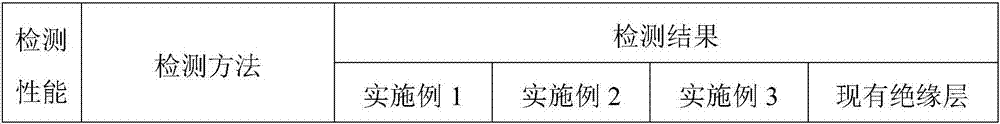

Insulating layer for power transmission and transformation lines

InactiveCN107216631AImprove insulation performanceIncrease flame retardancyPlastic/resin/waxes insulatorsBuilding insulationsChemistryRosin

The invention discloses an insulating layer for power transmission and transformation lines, which consists of the following materials in parts by weight: 5 to 15 parts of silicone rubber; 6 to 15 parts of isoprene rubber; 15 to 20 parts of mineral colloid; 2 to 5 parts of chlorinated polyether; 15 to 40 parts of polycarbonate; 1 to 3 parts of ethylene-vinyl acetate copolymer; 15 to 20 parts of ABS plastic; 4 to 10 parts of dioctyl sodium sulfosuccinate; 2 to 4 parts of lead monoxide; 1 to 3 parts of graphite powder; 1 to 3 parts of rosin; 2 to 5 parts of epoxy fatty acid octyl ester; 2 to 4 parts of poly diallyldimethylammonium chloride; 10 to 15 parts of hexamethylenetetramine; 5 to 15 parts of fire retardant; 1 to 4 parts of cross-linking agent; and 5 to 10 part of filler. The insulating layer for power transmission and transformation lines provided by the invention has excellent properties, such as mechanical property, breakdown resistance and heat resistance.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Method for producing low-gluten wheat flour with medium-gluten wheat by steam explosion technique

ActiveCN106234947AEfficient killingExtended shelf lifeSeed preservation by heatingFood dryingSteam pressureWheat gluten

The invention discloses a method for producing low-gluten wheat flour with medium-gluten wheat by a steam explosion technique. According to the invention, a steam explosion is carried out on medium-gluten wheat grains, the steam pressure is 1.4-2.0MPa, the steam explosion lasts for 10-60s, then the explosion is produced instantly, and the exploded wheat grains are immediately collected, and cooled by low temperature air, and dried by hot air until the water contents of the wheat grains are 12-14%. By adoption of the technical method of the invention, the wheat gluten content in wheat can be lowered, the wet gluten content is lowered from original 30-40% to 12-20%, the medium-gluten wheat can be processed into the low-gluten wheat flour and the wheat flour is high in quality, so that the problems of the current domestic low-gluten wheat flour such as insufficient production raw materials and incapability of meeting market demands are solved. Furthermore, the method for producing the low-gluten wheat flour with the medium-gluten wheat by the steam explosion technique has the characteristics of simple technology, low energy consumption, good product quality, long shelf life and the like.

Owner:JIANGNAN UNIV

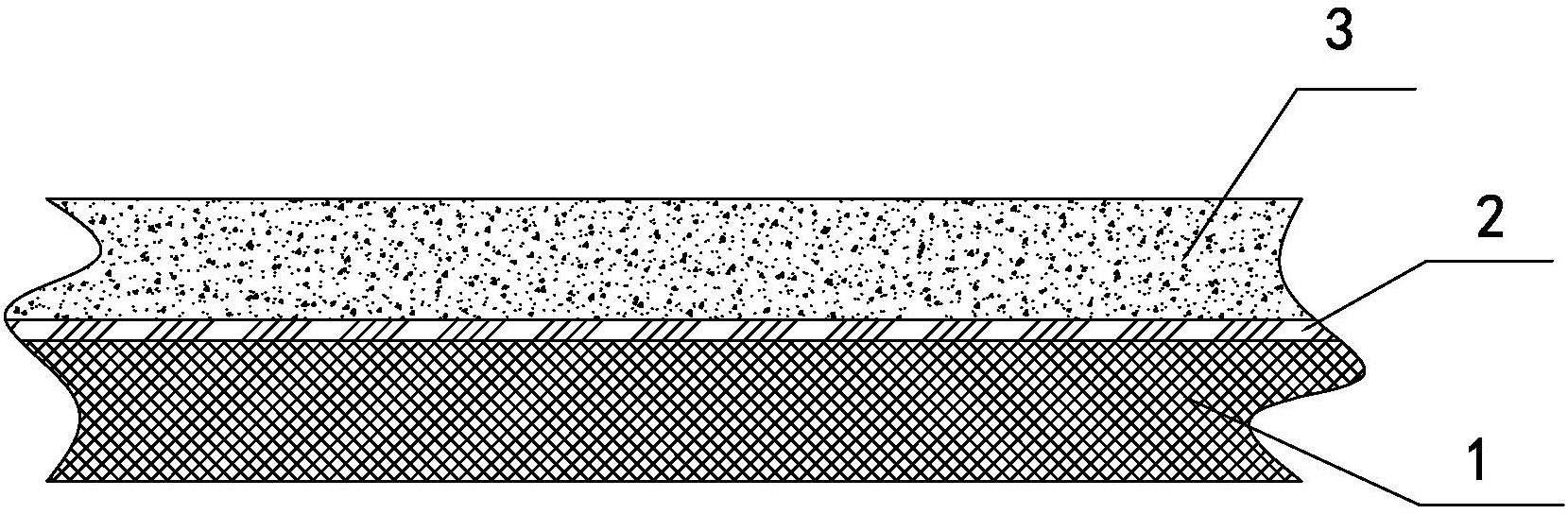

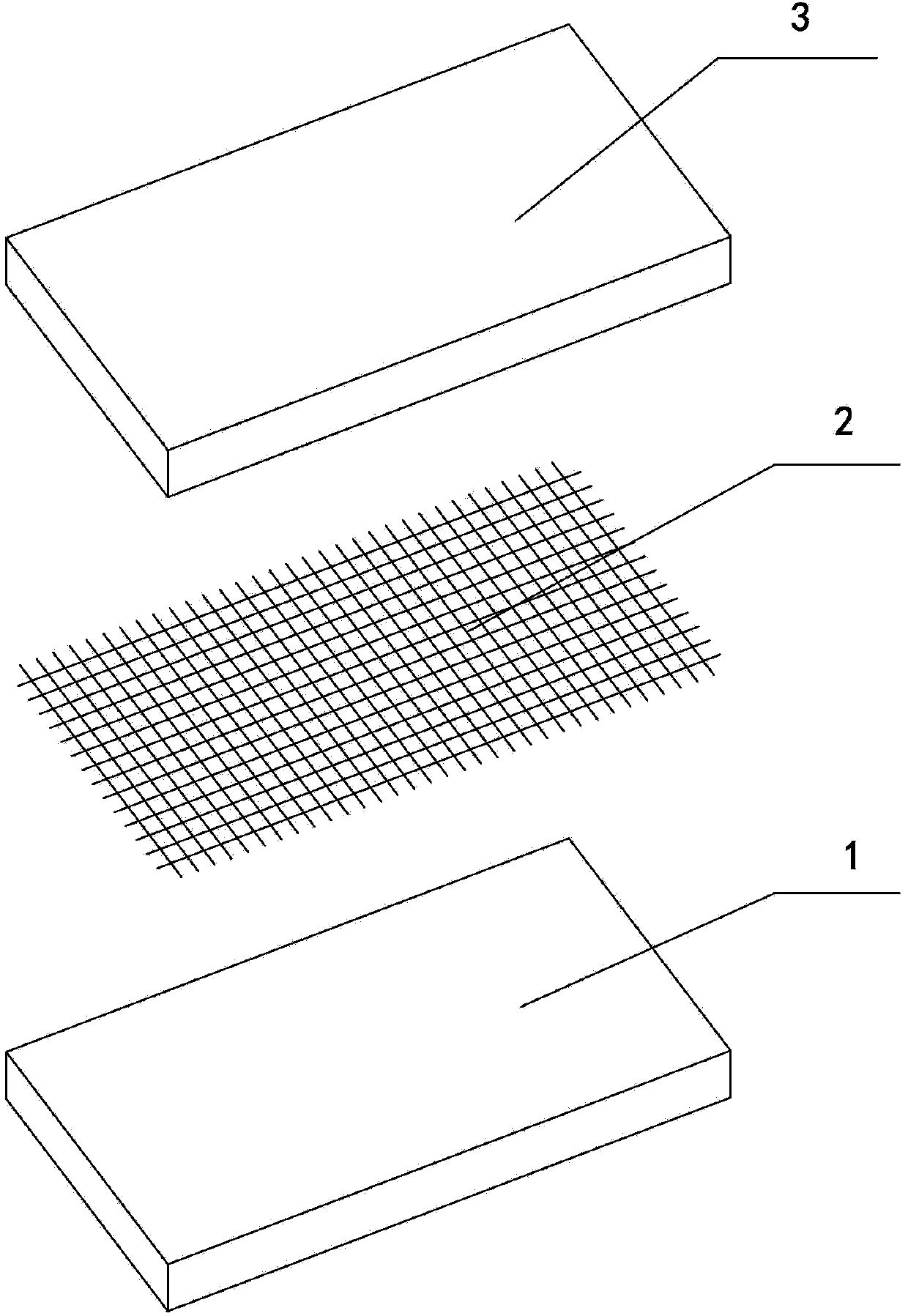

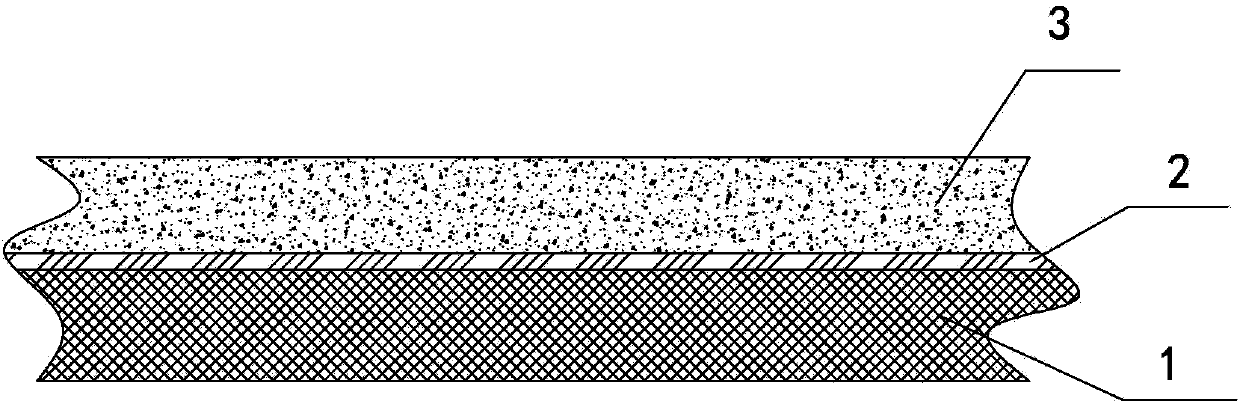

A kind of stone plank and its production process

The invention discloses a stone-wood plate and a manufacturing process thereof. The stone-wood plate comprises a wood core plate and an artificial quartz stone arranged on one surface or two surfaces of the wood core plate, wherein a glass fiber or an iron wire net is fixed on the surface with the artificial quartz stone of the wood core plate, and the artificial quartz stone is integrated with the glass fiber or iron wire net. The stone-wood plate provided by the invention has all the characteristics of the artificial quartz stone. The structure of the artificial quartz stone is changed, so that the thickness of the artificial quartz stone can be less than 12mm, the artificial quartz stone is prevented from being broken and cracked, the toughness and the strength of the artificial quartz stone are changed, the whole weight of the artificial quartz stone is lightened, and the application scope is widened.

Owner:程治国

Hydraulic concrete surface layer slit sealing method

The invention relates to a hydraulic concrete surface layer slit sealing method belonging to a hydraulic concrete slit sealing method and comprising the following formula method: the formula contains 1000-1400 parts of general purpose portland cement PO42.5, 1100-2000 parts of medium coarse sand, 0-600 parts of chicken girt, 300-360 parts of water and a composite material; the method comprises the following steps of: (1) cutting a concrete surface layer crack; (2) cleaning the base surface of the concrete crack; and (3) preparing the composite material in the proportion of the formula, stirring the composite material with cement, the medium coarse sand and the water for 3 min at the stirring speed of 2000-2500R / min to form a cement gel material, and then pouring the cement gel material into slits. The invention is suitable for hydraulic concrete dam face slit treatment with better effect.

Owner:吉林省银河水利水电新技术设计有限公司

Production process of wear-resistant anti-slip safety belt

InactiveCN113334889AImprove tensile propertiesChange resilienceSynthetic resin layered productsLaminationPolyesterEngineering

The invention discloses a production process of a wear-resistant anti-slip safety belt. The method includes: drawing Nylon fibers and polyester fibers, wherein the strand number ratio of the two kinds of yarn strips in the drawing process is 1:2; preparing two kinds of card slivers with the counts of 20S and 41S, further processing the card slivers into drawn slivers, and processing the drawn slivers into rough yarns with the same count and different twists; and spinning the roving into spun yarns with a certain special number, and spooling the blended spun yarns. By adopting a three-layer composite fabric form, the tensile property and the safety performance of the safety belt are improved, the anti-skid fabric layer is provided with linear stripes and the friction force is increased by adjusting the section diameters of the warp yarns and the weft yarns, and the phenomenon of slipping when the safety belt is manually adjusted is effectively improved; by padding the wear-resistant liquid, the molecular structure can be effectively prevented from being damaged, so that the wear-resistant effect is achieved, the safe use performance is improved, the use cost is reduced, and the energy is saved.

Owner:安徽乙纤新材料科技有限公司

Steel fireproof door for inflammable storage warehouse

InactiveCN111980555AGuaranteed mutual lockingGuaranteed normal opening and closingFireproof doorsBuilding braking devicesMechanical engineeringIndustrial engineering

The invention discloses a steel fireproof door for an inflammable storage warehouse, and relates to the technical field of fireproof doors. The steel fireproof door aims at solving the locking problem. The steel fireproof door specifically comprises a door frame, door leaves, a connecting mechanism used for connecting the door frame with the door leaves, closing mechanisms used for ensuring that the door leaves are normally closed and an automatic locking mechanism used for locking the door leaves when a fire occurs, wherein the automatic locking mechanism comprises clamping blocks arranged inone of the door leaves and clamping grooves formed in the other door leaf and matched with the clamping blocks; and containing grooves are formed in the inner walls of the door leaves, and containingcylinders are fixedly arranged on the inner walls of the containing grooves. According to the steel fireproof door for the inflammable storage warehouse, by arranging the automatic locking mechanism,if the fire occurs, liquid inside the containing cylinders is heated and evaporated, therefore the internal pressure intensity of the containing cylinders is sharply increased, locking pistons push piston connecting rods to stretch out, and then the clamping blocks stretch out and are inserted into the clamping grooves, so that it is guaranteed that the two door leaves are mutually locked, and the blocking effect is safely and reliably achieved.

Owner:杭州嘉威机械配件有限公司

Method for preparing waterborne anticorrosion coating resin vinylidene chloride-acrylate

InactiveCN102250275BReduce adhesionGood emulsifying effectAnti-corrosive paintsEmulsionPolymer science

The invention discloses a method for preparing waterborne anticorrosion coating resin vinylidene chloride-acrylate. In the method, vinylidene chloride, acrylate and different compounded emulsifiers are pre-emulsified, and azodiisobutyronitrile is used for initiating polymerization reaction. The method comprises the following steps of: adding partial pre-emulsion into a reactor; heating to temperature higher than the initiation temperature of an initiator, adding the initiator, and performing polymerization reaction at constant temperature to obtain seeded emulsion; and dripping the rest pre-emulsion into the reactor and continuously performing the reaction at constant temperature. The emulsion has high stability, uniform particle size, high resin adhesion and high film and anticorrosion properties, is environment-friendly and nontoxic, and can provide good corrosion protection for carbon steel matrixes.

Owner:TIANJIN UNIV +1

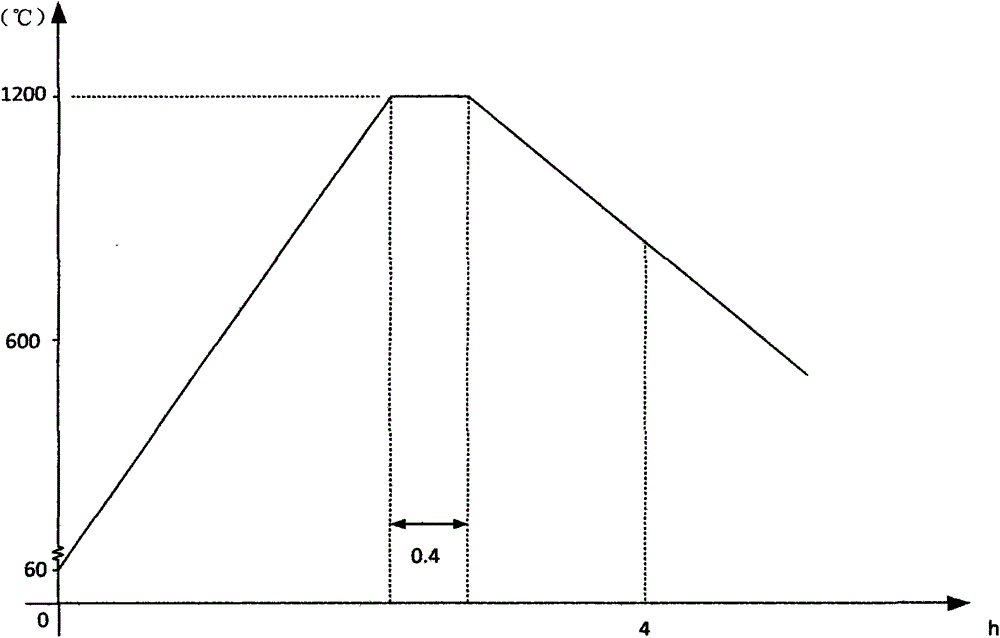

Steel wire heat treatment quenching process

PendingCN113416834AImprove performanceSuitable for drawingFurnace typesHeat treatment furnacesPhysicsPearlite

The invention discloses a steel wire heat treatment quenching process. The steel wire heat treatment quenching process comprises the following steps of leading out a steel wire through a roller of a pay-off machine, horizontally outputting the steel wire after passing through a positioning device, and heating the steel wire to 900-950 DEG C to convert the structure into austenite; quenching and preserving heat the austenite in molten lead or salt (a mixture of sodium nitrate and potassium nitrate or calcium chloride, sodium chloride and potassium chloride) with the temperature of 480-550 DEG C for a period of time to enable the austenite to be subjected to isothermal transformation into fine pearlite, heating the wire to the temperature above a critical point, preserving heat for a certain time, and quickly cooling to a standard value temperature; the heat preservation time is long enough to form a required spheroidized structure; heating to the temperature above the upper critical point, quickly cooling to the temperature which is about 30 DEG C higher than the standard value, and cooling to the temperature below the lower critical point (about 650 DEG C) at the speed of 5 DEG C / h; heating to a lower critical point or a slightly lower temperature, preserving heat for enough time to form a required spheroidized structure (generally 8-12 hours), and heating the steel wire to 30-50 DEG C above the lower critical point.

Owner:陈冬英

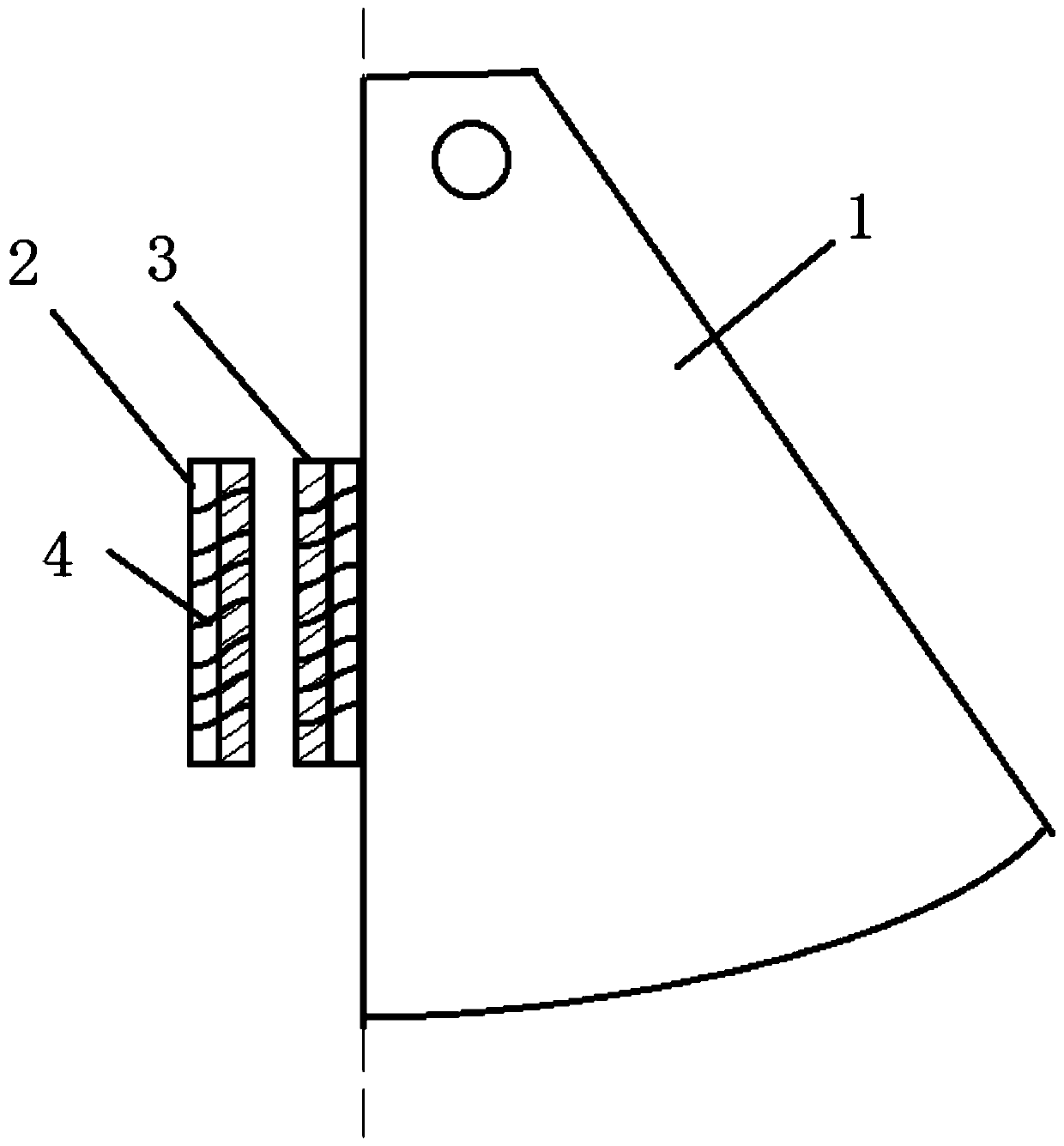

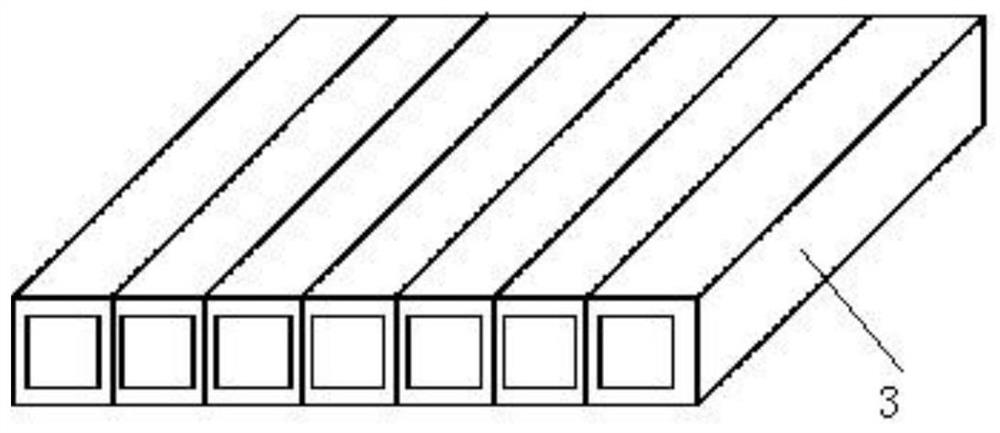

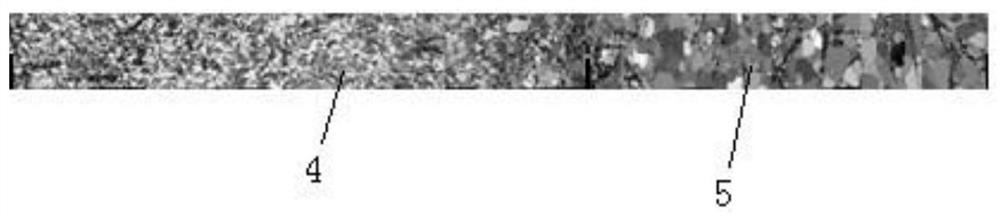

Preparation method of high-strength and high-toughness metal material with shell-like brick mud structure

The invention discloses a preparation method of a high-strength and high-toughness metal material with a shell-like brick mud structure. The preparation method comprises the following steps that S1, an alloy plate is completely annealed to eliminate anisotropy; S2, the surface of the annealed alloy plate is pretreated; S3, the pretreated alloy plate is placed on a workbench, an alternate cooling and heating system (3) is placed between the workbench and the alloy plate, and pre-tightening force is applied for locking; and S4, a stirring head is installed on friction stir machining equipment, the rotating speed, the welding speed, the machining distance, the pressing amount and the stirring needle front inclination angle of a stirring head are selected, the locked alloy plate is subjected to friction stir welding, and a first long and straight welding seam (1) is formed. According to the preparation method of the high-strength and high-toughness metal material with the shell-like brickmud structure, the shell-like brick mud structure is achieved through alternating of weld joints and base metal, the alloy strength is improved, meanwhile, the toughness of the material is reserved, and the method is an economical and effective technical method used for preparing the high-performance alloy plate and capable of achieving industrial production.

Owner:NANJING INST OF TECH

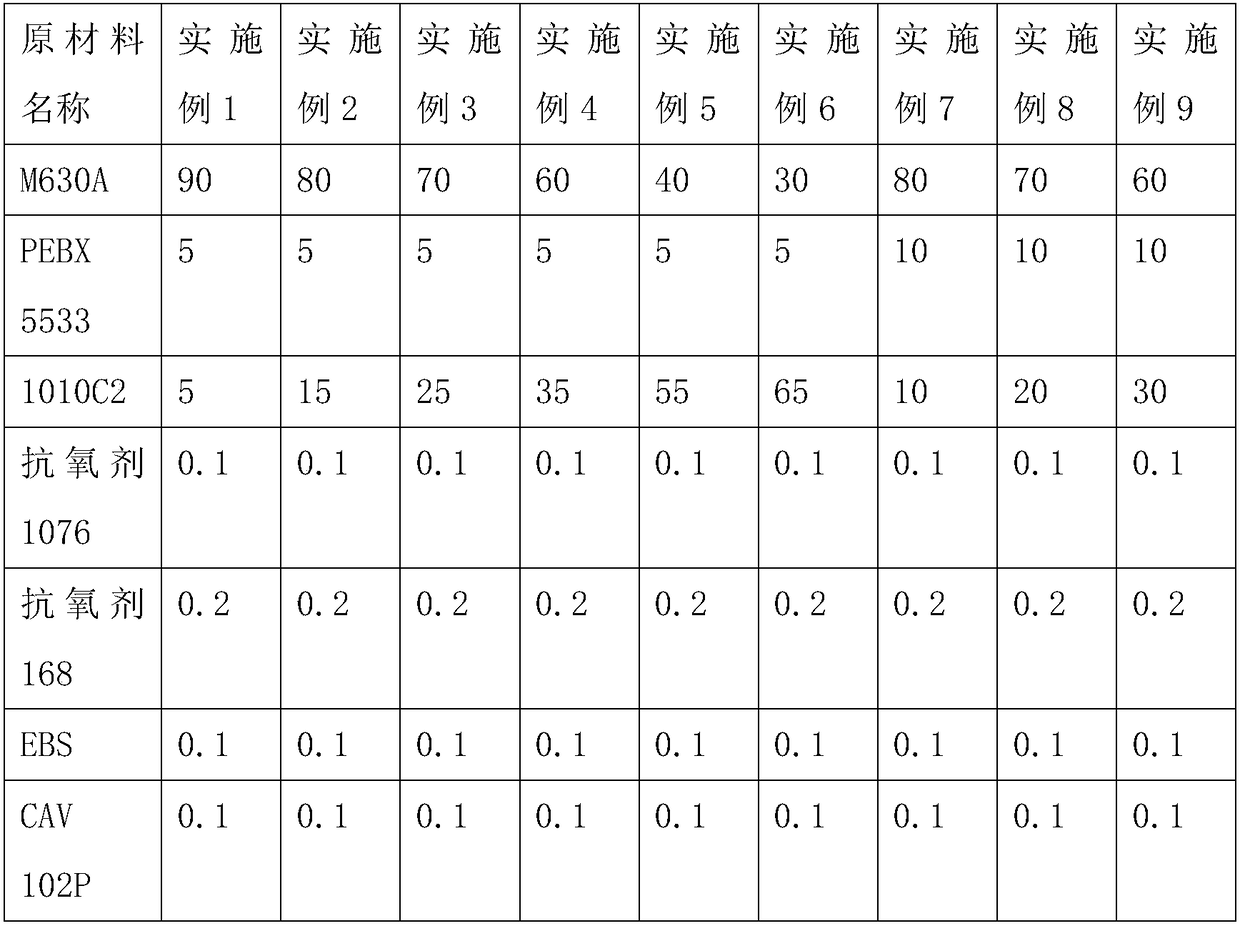

Stiffness and toughness balanced ternary blend alloy material and preparation method thereof

The invention discloses a stiffness and toughness balanced ternary blend alloy material which is prepared from the following components in parts by weight: 30-90 parts of POK polyketone, 5-30 parts ofnylon elastomers, 5-70 parts of PA6, 0.05-0.3 part of a nucleating agent, 0.05-1 part of a lubricating agent, 0.05-0.3 part of a primary antioxidant and 0.05-0.3 part of an auxiliary antioxidant. Theinvention further provides a preparation method of the ternary blend alloy material. The preparation method comprises the following steps: mixing the components in parts by weight, and performing melt extrusion granulating by a twin-screw extruder unit, thereby obtaining the ternary blend alloy material disclosed by the invention. Compared with ordinary POK or nylon, the ternary blend alloy material disclosed by the invention maintains low water-absorbing quality and high wear resistance of the POK material, the characteristics of the nylon material such as high modulus and excellent chemicalresistance are additionally increased, and another function that is not owned by the two is increased, namely, the excellent characteristic of high toughness.

Owner:SHANGHAI GAOXINKE PLASTIC PROD

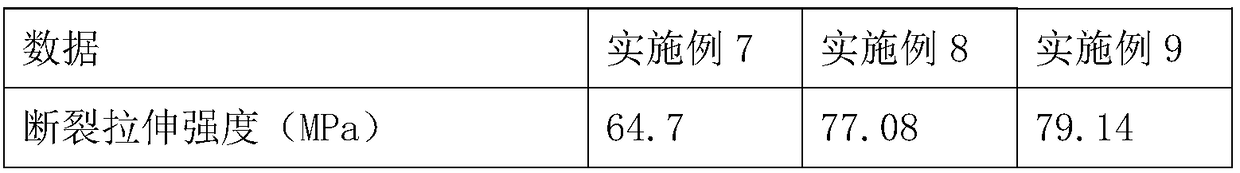

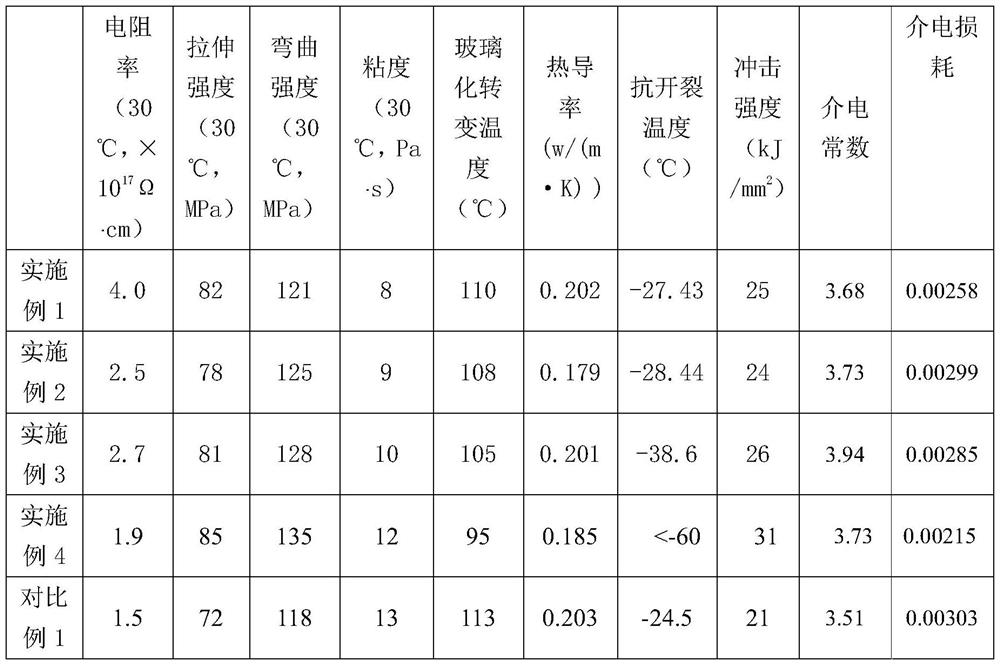

Epoxy resin composite material and preparation method thereof

The invention provides an epoxy resin composite material and a preparation method thereof. The epoxy resin composite material is prepared from, by mass, 2.5-10 parts of monohydroxy polyether alcohol grafted epoxy resin, 100 parts of epoxy resin, 60-100 parts of curing agent and 1 part of accelerant. According to the invention, the tensile strength of the epoxy resin composite material prepared through the method reaches up to 85 MPa, the bending strength reaches 135 MPa, and cracking is still avoided when the temperature is reduced to -60 DEG C, so that the packaging requirement of electricalequipment such as a high-frequency transformer and the like is greatly met, and the preparation method provided by the invention is simple, reliable and suitable for large-scale production.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

Method for improving silk production rate of silkworm cocoons

InactiveCN107815738AChange complianceChange resilienceAnimal materialSilk filament obtainingSodium bicarbonateProduction rate

The invention discloses a method for improving a silk production rate of silkworm cocoons and belongs to the technical field of silk production of silkworm cocoons. The method disclosed by the invention comprises the following steps: soaking silkworm cocoons in brine for 1-5 hours before silk reeling of the silkworm cocoons; taking out the silkworm cocoons, and rinsing the residual brine on the surfaces of the silkworm cocoons; adding the silkworm cocoons treated in the step A into a soaking solution prepared from sodium bicarbonate, polyethylene wax, sodium stearate, perfiuoro-sodium sulfonate, sodium borate, sodium pyrophosphate, sodium tripolyphosphate, polyether and water, and soaking for 2-6 hours; and taking the silkworm cocoons out, and rinsing the residual soaking solution on the surfaces of the silkworm cocoons. According to the method disclosed by the invention, the silkworm cocoons are added into the brine at the specific temperature and concentration before silk reeling, sothat the surface tension is changed; and the silkworm cocoons are added into the soaking solution prepared from the sodium bicarbonate, polyethylene wax, sodium stearate, perfiuoro-sodium sulfonate,sodium borate, sodium pyrophosphate, sodium tripolyphosphate, polyether and water, so that the smoothness and toughness of silk in the silkworm cocoons are changed, and the silk production rate of thesilkworm cocoons in the silk reeling process is effectively improved.

Owner:LUZHAI GUISHENG COCOON SILK IND & TRADE

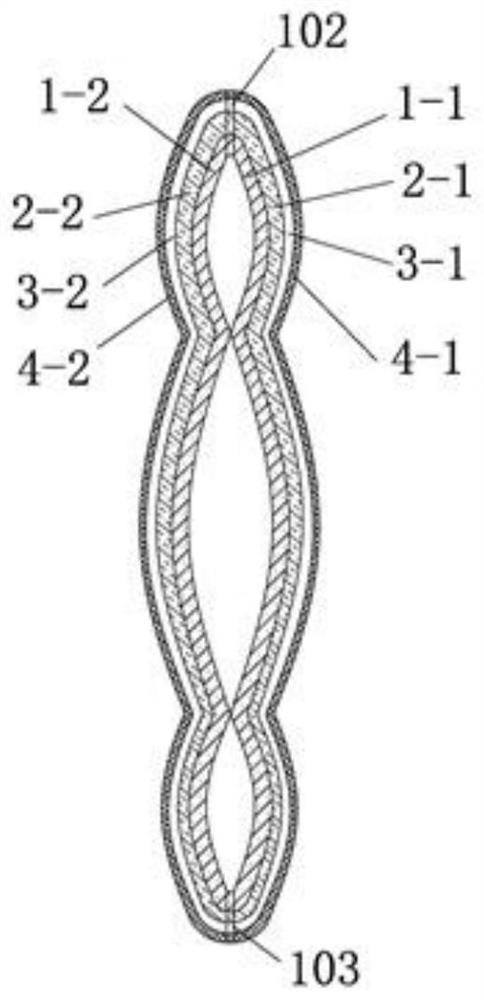

Multi-layer protective inflatable packaging bag with self-adhesive film

PendingCN112061593AImprove adhesion strengthFast bondingSynthetic resin layered productsSacksAdhesiveEngineering

The invention provides a multi-layer protective inflatable packaging bag with a self-adhesive film. The multi-layer protective inflatable packaging bag with the self-adhesive film which is characterized in that an upper-layer bag body is formed by a first-layer film, a third-layer film, a fifth-layer film and a seventh-layer film; a lower-layer bag body is formed by a second-layer film, a fourth-layer film, a sixth-layer film and an eighth-layer film; the first-layer film to the eighth-layer film are fixedly connected through a first heat sealing line and a second heat sealing line which are located on two sides of the bag body in a heat sealing mode; and a tight cavity used for placing a transported object is formed by the first-layer film and the second-layer film, a first inflation cavity is formed by the first-layer film to the fourth-layer film, and a second inflation cavity is formed by the fifth-layer film to the eighth-layer film. Through double-layer protection of the two inflation cavities, the occurrence of the phenomenon that in the object conveying process, one inflation cavity is damaged, air leaks, and the conveyed object loses protection can be prevented. The third-layer film to the fifth-layer film are pressure stimulation response self-adhesive films, have good adhesive strength, durability and low peel strength, ensure rapid and low-void-ratio bonding, and donot need to use external bonding technologies such as back glues or heat sealing.

Owner:杭州空气盒子包装有限公司

High-fatigue-resistance ABS (Acrylonitrile Butadiene Styrene) resin composition and preparation method thereof

The invention relates to a high-fatigue-resistance ABS (Acrylonitrile Butadiene Styrene) resin composition and a preparation method thereof. The composition comprises the following components in parts by mass: 30-50 parts of emulsion grafted mixed body SAN (Styrene Acryl Nitrile) rubber powder, 50-70 parts of styrene-acrylonitrile copolymer, 1-5 parts of melt reinforcing agent, 0.1-3 parts of lubricant and 0.05-0.8 part of antioxidant. The preparation method of the composition comprises the following steps of: putting the components into a high-speed mixer for premixing to obtain a premix compound; and melting and extruding the premix compound with a double screw extruder at the temperature of 190-240 DEG C and the screw rotating speed of 200-600 revolutions per minute, cooling and pelletizing to obtain the high-fatigue-resistance ABS resin composition. The fatigue resistance of the ABS resin composition is enhanced to a large extent. Moreover, the toughness, the specific weight and the superior appearance of the ABS resin composition do not change greatly.

Owner:GUANGDONG KUMHO SUNNY POLYMER MATERIAL

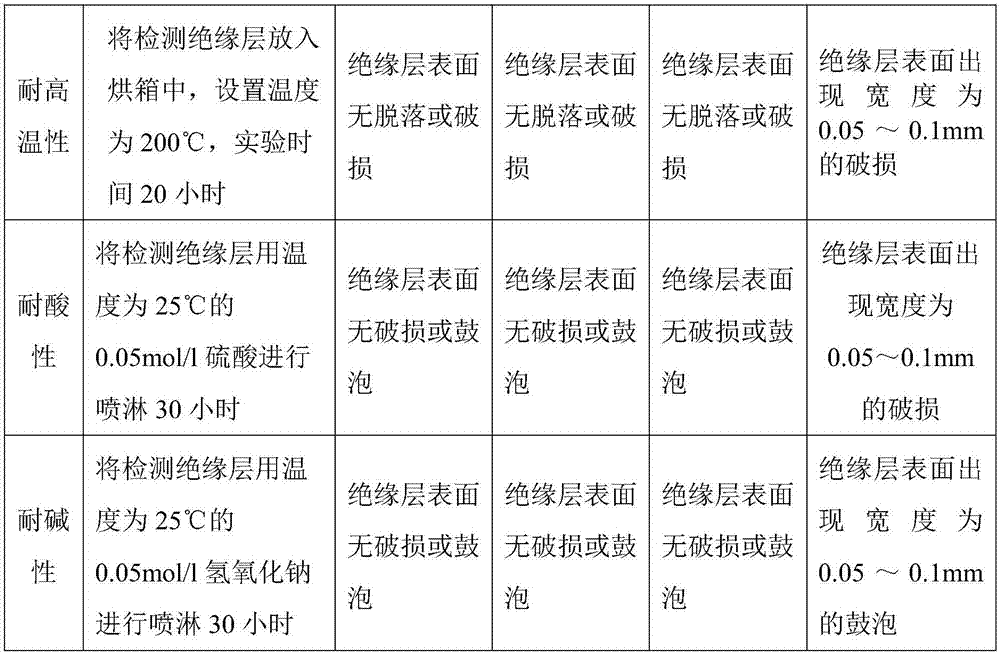

Stone-wood plate and manufacturing process thereof

The invention discloses a stone-wood plate and a manufacturing process thereof. The stone-wood plate comprises a wood core plate and an artificial quartz stone arranged on one surface or two surfaces of the wood core plate, wherein a glass fiber or an iron wire net is fixed on the surface with the artificial quartz stone of the wood core plate, and the artificial quartz stone is integrated with the glass fiber or iron wire net. The stone-wood plate provided by the invention has all the characteristics of the artificial quartz stone. The structure of the artificial quartz stone is changed, so that the thickness of the artificial quartz stone can be less than 12mm, the artificial quartz stone is prevented from being broken and cracked, the toughness and the strength of the artificial quartz stone are changed, the whole weight of the artificial quartz stone is lightened, and the application scope is widened.

Owner:程治国

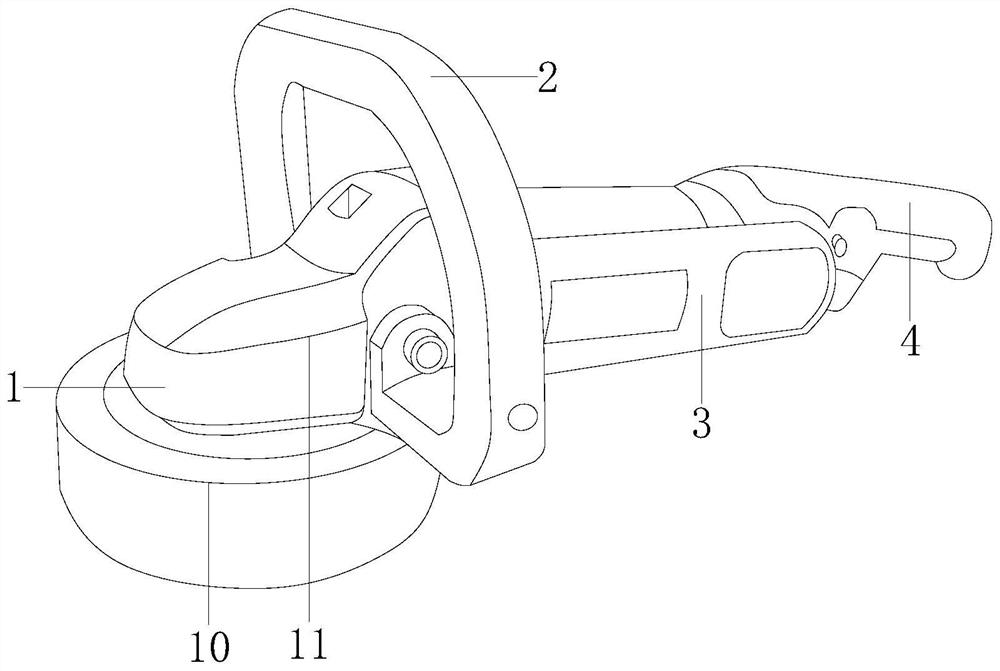

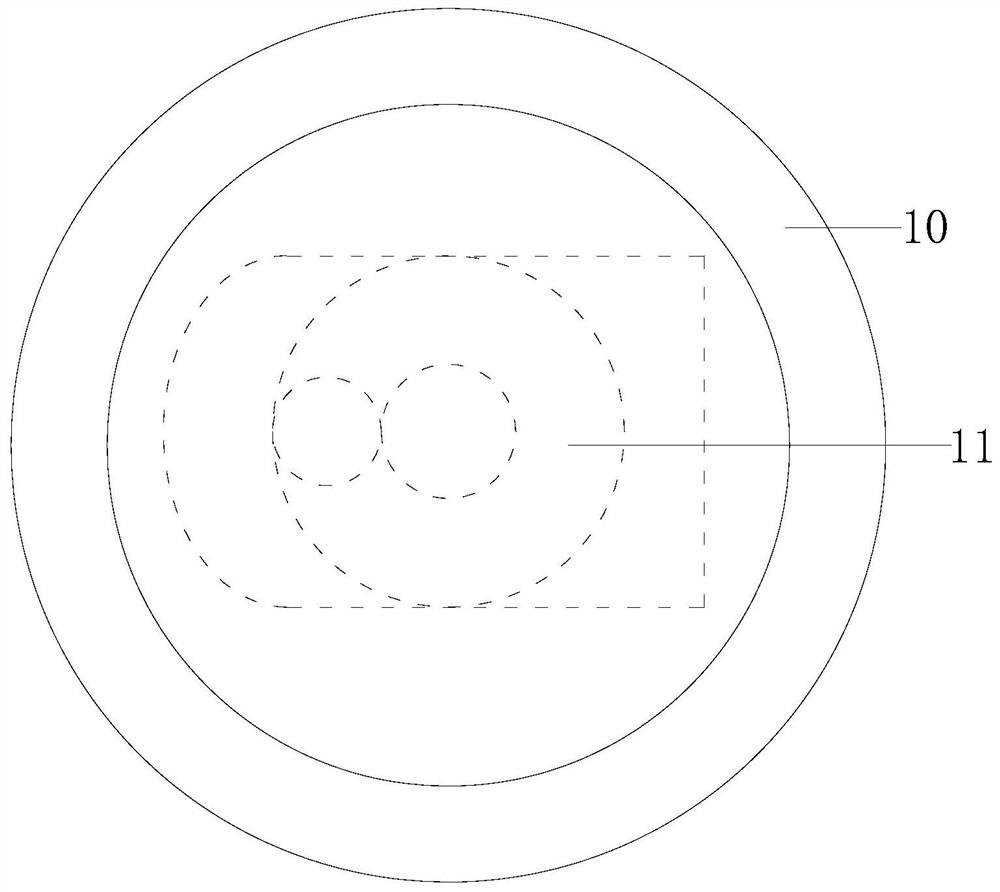

Finish machining grinding machine and using method

InactiveCN112809517ARealize centered movementUpright stackingPortable grinding machinesBonded abrasive wheelsWear particleMachine

The invention discloses a finish machining grinding machine and a using method. The finish machining grinding machine structurally comprises a machine head structure, a machine handle, a machine body and a machine tail, wherein the machine head structure is connected with the machine body in an installing mode, the machine body and the machine tail are embedded, the machine head structure is composed of a grinding material and a machine head, the grinding material is connected with the machine head in an installing mode, the grinding material comprises a grinding outer ring and a grinding inner circle, and the grinding outer ring and the grinding inner circle are embedded. According to the finish machining grinding machine, the machining mode that the outer ring is combined with the inner circle is adopted for grinding materials, the grinding outer ring is finely ground, the grinding inner circle is ground, grinding is realized, broken abrasive particles are collected, the machine head is pushed through the stacking of the abrasive particles, the rotating speed of the abrasive materials is changed, the hardness and toughness during grinding are enhanced, the sharpness is improved through the hardness, the attaching distance between the grinding material and a grinding piece is increased, so that the toughness is improved, and the machining quality is improved.

Owner:赖太忠

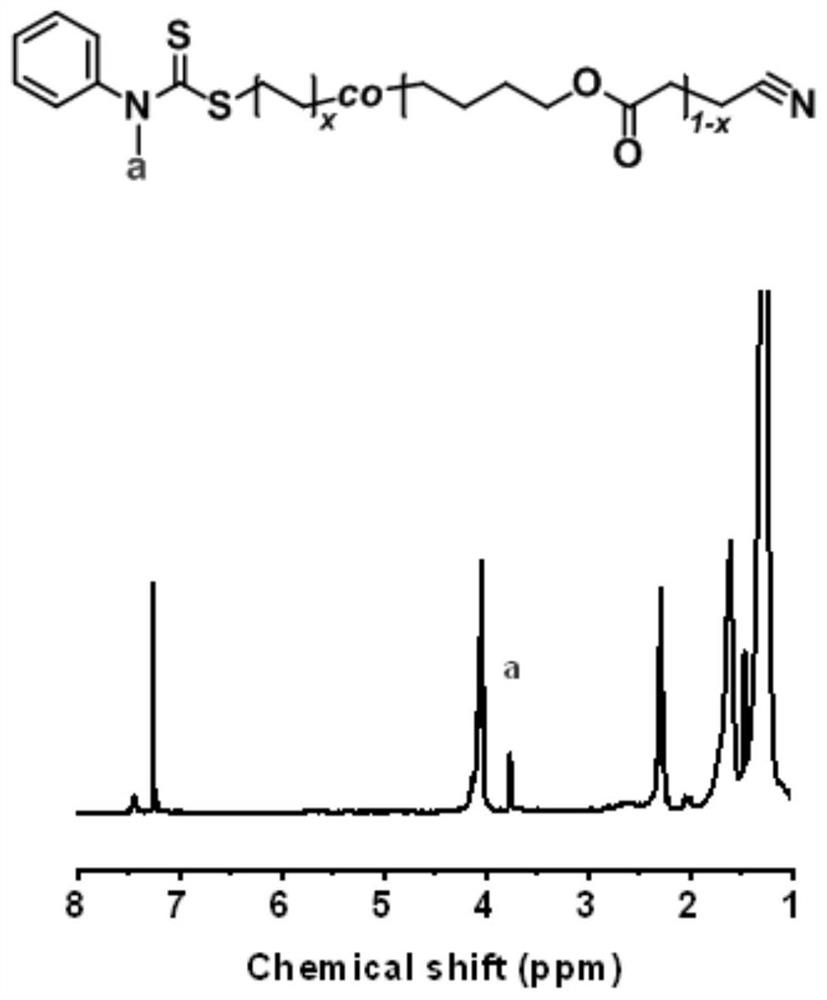

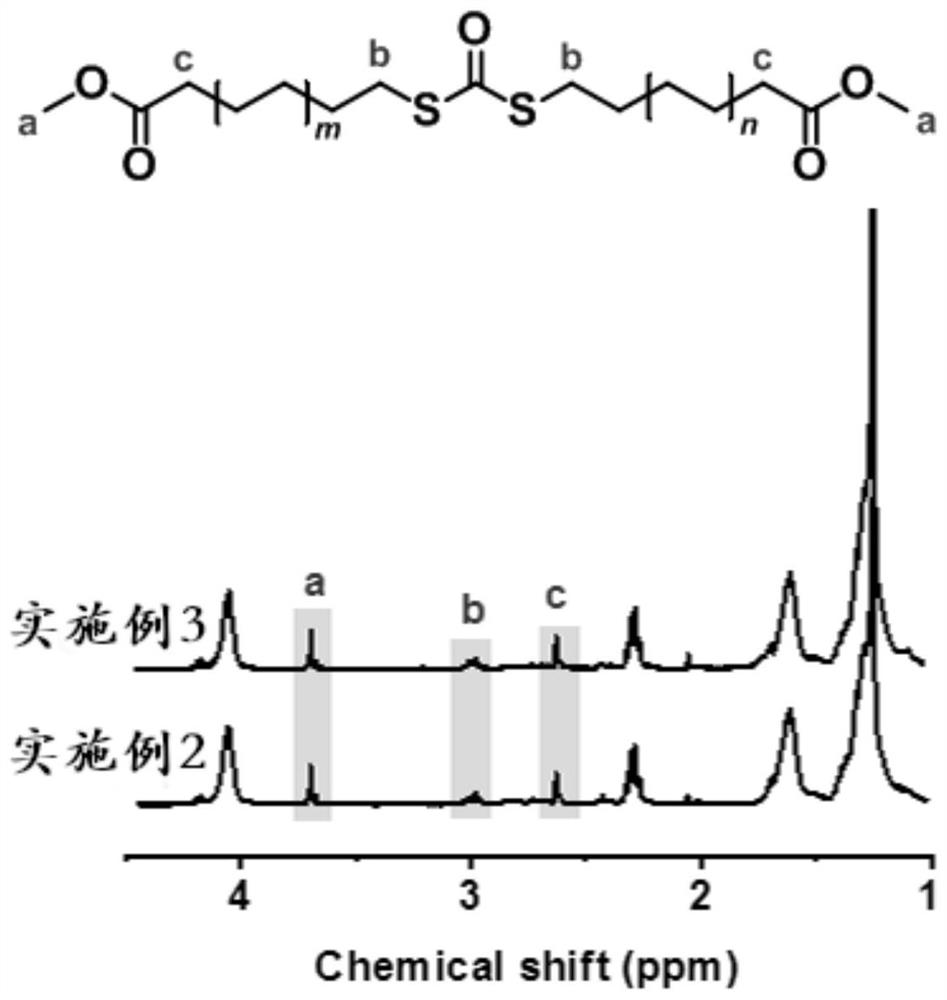

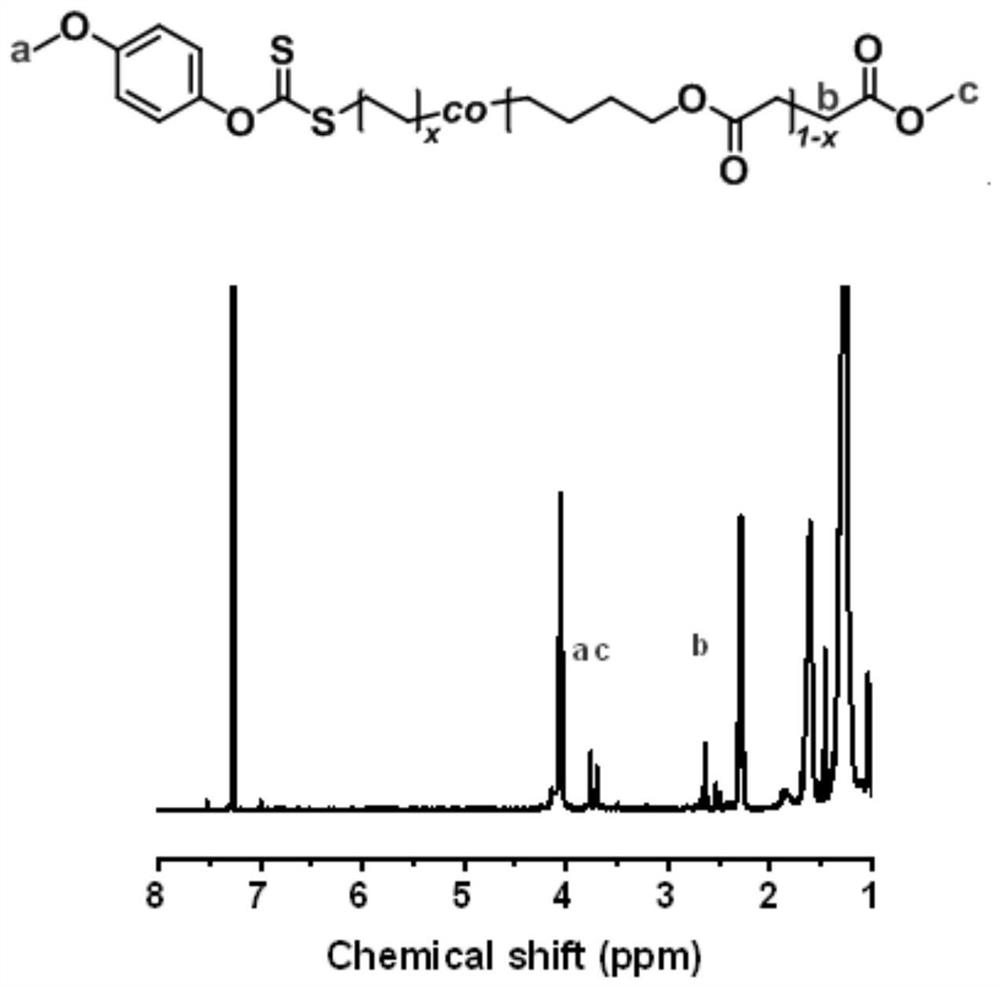

A polyolefin material with controllable degradation unit and high monomer utilization rate and its preparation method

Owner:UNIV OF SCI & TECH OF CHINA

A ternary blend alloy material with balanced rigidity and toughness and preparation method thereof

The invention discloses a stiffness and toughness balanced ternary blend alloy material which is prepared from the following components in parts by weight: 30-90 parts of POK polyketone, 5-30 parts ofnylon elastomers, 5-70 parts of PA6, 0.05-0.3 part of a nucleating agent, 0.05-1 part of a lubricating agent, 0.05-0.3 part of a primary antioxidant and 0.05-0.3 part of an auxiliary antioxidant. Theinvention further provides a preparation method of the ternary blend alloy material. The preparation method comprises the following steps: mixing the components in parts by weight, and performing melt extrusion granulating by a twin-screw extruder unit, thereby obtaining the ternary blend alloy material disclosed by the invention. Compared with ordinary POK or nylon, the ternary blend alloy material disclosed by the invention maintains low water-absorbing quality and high wear resistance of the POK material, the characteristics of the nylon material such as high modulus and excellent chemicalresistance are additionally increased, and another function that is not owned by the two is increased, namely, the excellent characteristic of high toughness.

Owner:SHANGHAI GAOXINKE PLASTIC PROD

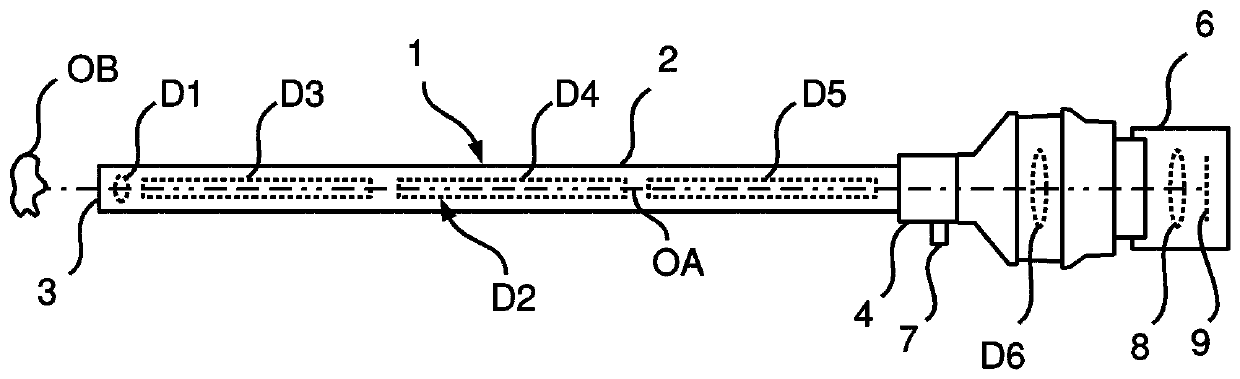

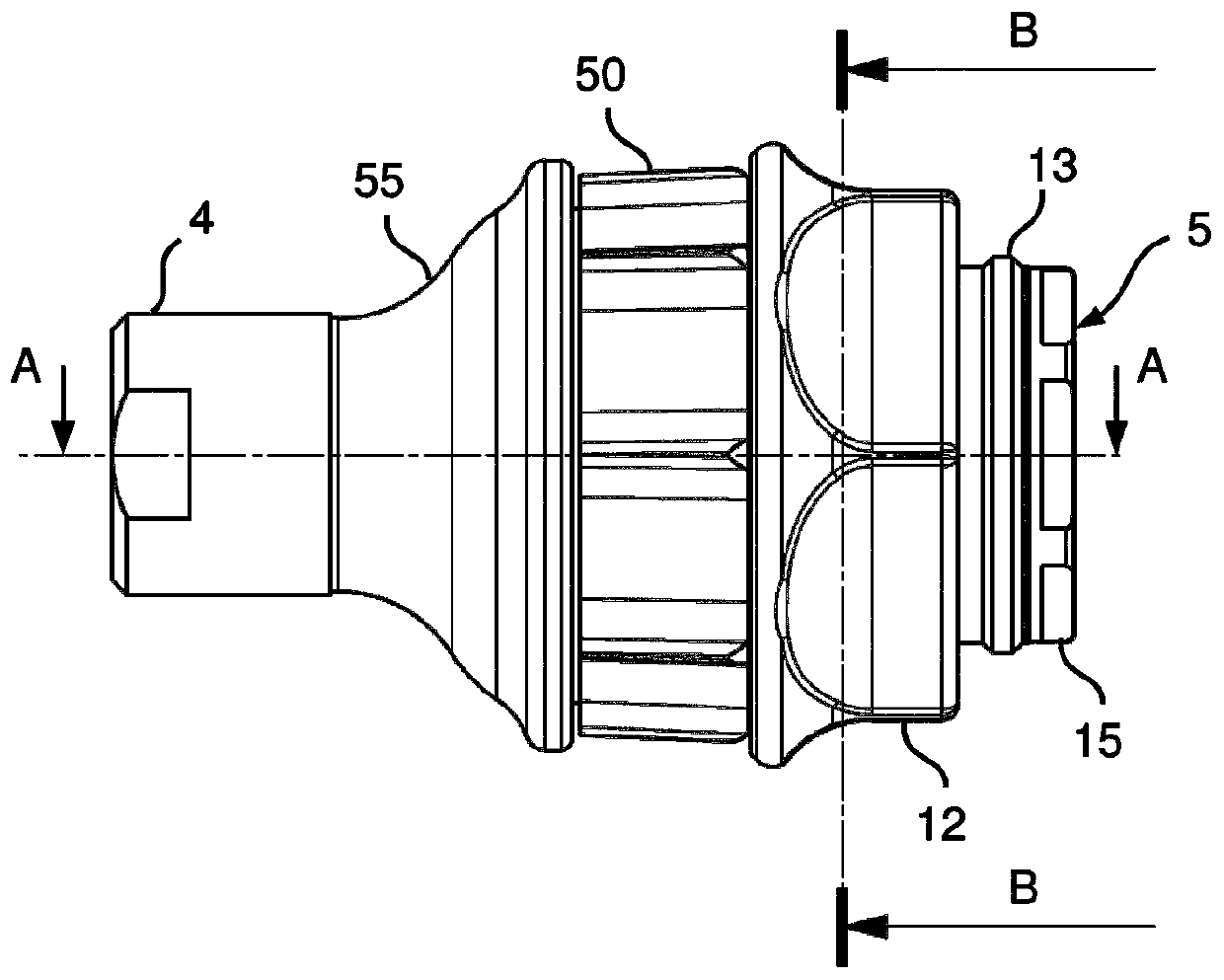

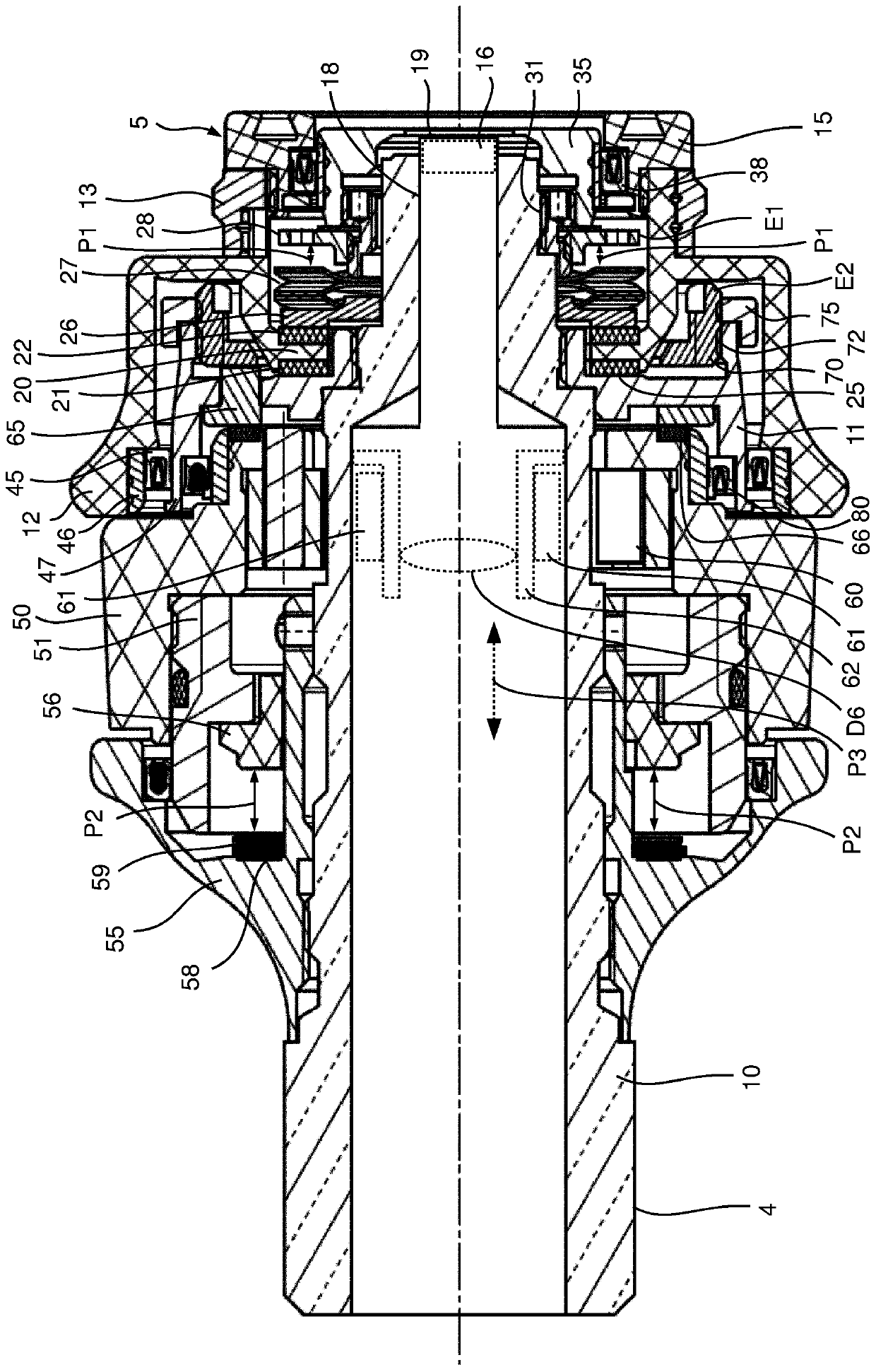

Endoscope

An endoscope has an endoscope shaft 2 and a main body 4, the main body is connected to the endoscope shaft 2, and a first dial 12, 50 that has a first contact surface is mounted on the main body in arotatable manner. The main body 4 has a second contact surface against which the first contact surface bears. The contact surfaces move against one another when the first dial 12, 50 is rotated. A first setting unit E1, E2 is provided, using which a pressure force with which the first contact surface is pressed against the second contact surface is settable in order to set a minimum torque that isnecessary in order to rotate the first dial 12, 50.

Owner:HENKE SASS WOLF

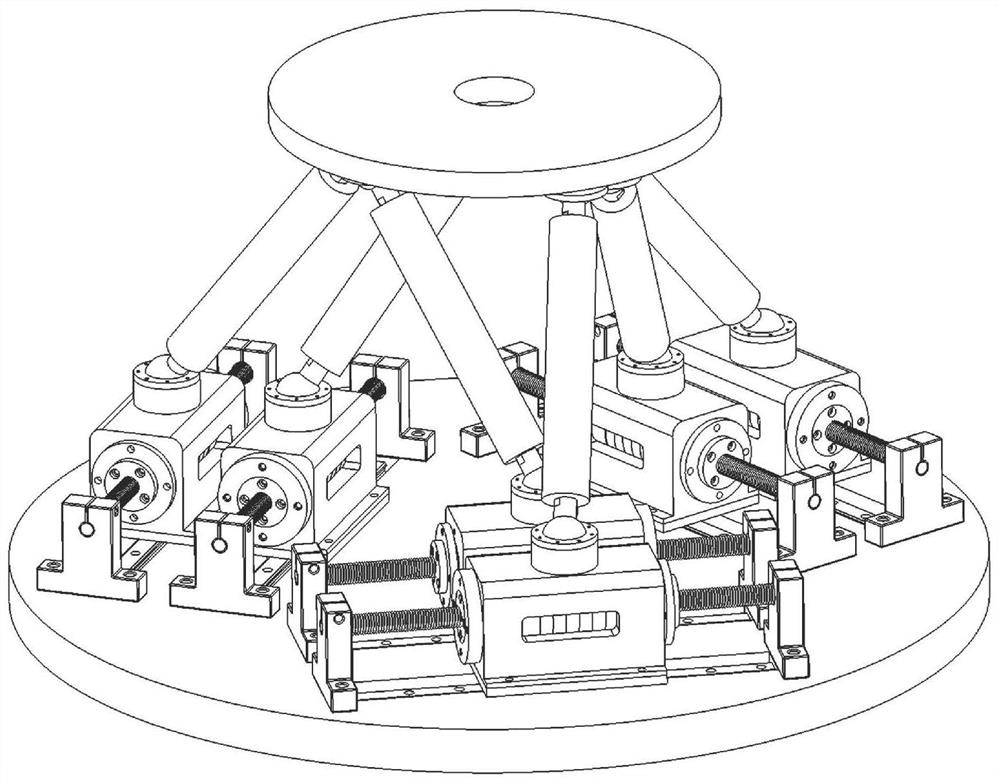

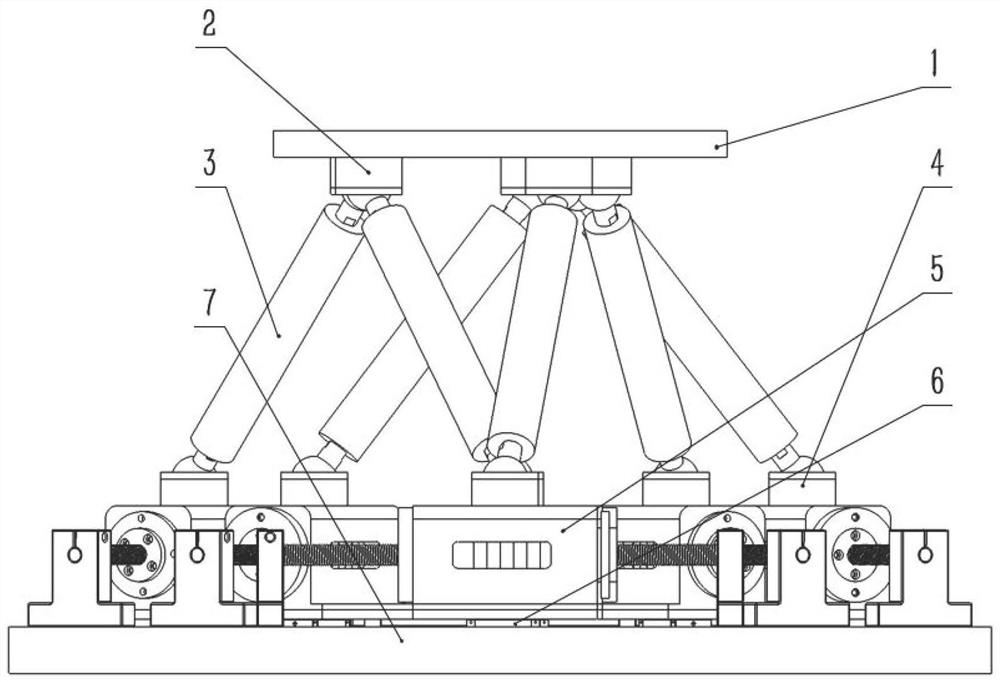

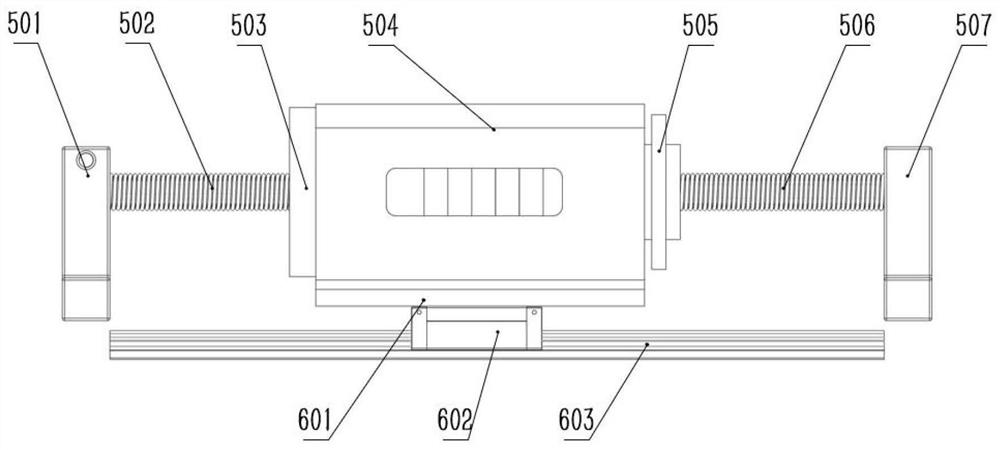

Horizontally-arranged six-degree-of-freedom constant-rigidity mechanism

ActiveCN112943848AChange resilienceStiffness adjustmentSpringsVibration dampersAdjustable stiffnessStructural engineering

The invention discloses a horizontally-arranged six-degree-of-freedom constant-rigidity mechanism which comprises an upper platform, a bottom plate, composite spherical hinges, a spherical hinge, supporting rods, a guide rail sliding block assembly and six electromagnetic rigidity-adjustable units of the same structure. The two ends of a shaft, fixedly provided with a permanent magnet, in each electromagnetic rigidity-adjustable unit are fixed to the bottom plate through shaft supports, shells moving in the axial direction in the electromagnetic rigidity-adjustable units are fixed to a sliding block of the guide rail sliding block assembly through sliding block base plates, and the guide rail sliding block assembly is fixed to the bottom plate. The spherical hinge is installed at the top of the shell, the three composite spherical hinges are evenly installed at the bottom of the upper platform, one end of each supporting rod is in threaded connection with the spherical hinge, and the other ends of the supporting rods are in threaded connection with the composite spherical hinges. According to the horizontally-arranged six-degree-of-freedom constant-rigidity mechanism, when the pose of a system or an external load changes, the rigidity of the system can be kept constant through current control.

Owner:CHONGQING UNIV

A kind of argon arc surfacing welding FECRC iron-based powder alloy and its preparation process

InactiveCN103231182BImprove economyChange intensityArc welding apparatusWelding/cutting media/materialsIron powderAlloy

Disclosed is a Fe-based alloy powder for argon arc overlay welding, the powder consisting of Fe-Cr, graphite, and iron powder. A process for preparing the Fe-based alloy powder for argon arc overlay welding comprises: uniformly mixing Fe-Cr, graphite, and iron powder according to a certain ratio, and preparing same into flakes with sodium silicate as a binder; the flakes are naturally dried for 10 h and then placed in a drying oven and dried at 200°C for 1.5 h, and oven cooled. With a tungsten electrode argon arc as a heat source, the obtained substance is overlay welded on the surface of a material to form a wear- and corrosion-resistant molten cladding layer. The molten cladding layer has a uniform texture, and can generate new phases such as chromium-carbon compounds; the deposit welded layer has a hardness greater than HRC55 and can effectively improve material performances such as wear-, corrosion-, and high temperature-resistance, so as to extend the service life of parts. In addition, the Fe-based alloy powder for argon arc overlay welding is simple to prepare, low in cost, and thus has a relatively high use value.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com