Hydraulic concrete surface layer slit sealing method

A technology for hydraulic concrete and closed treatment, applied in water conservancy projects, marine engineering, construction and other directions, can solve the problems of poor adhesion of concrete on both sides, threat to project operation, and difficult construction, and achieve good plasticity retention and convenient construction. , good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prescription: the weight and number ratio of each component is:

[0033] Universal Portland cement PO42.5 1000g,

[0034] Medium coarse sand 1100g,

[0035] 300g of water,

[0036] The composite material comprises the following raw materials in parts by weight:

[0037] Polycarboxylate superplasticizer 8g,

[0038] Cement waterproofing agent 20g,

[0039] Mortar Companion: Mortar rheological additive BANAQUA4000 2g,

[0040] Redispersible latex powder 1.5g;

[0041] method:

[0042] (1) Concrete surface crack cutting, the cutting width is 5cm, and the cutting depth is 5cm;

[0043] (2) Clean the base surface of concrete cracks, remove all gravel, dust and impurities in the groove, soak and rinse with clean water, and blow dry with a fan to achieve water retention inside the old concrete base material, dry outside surface, and no excess water on the joint surface. Then carry out the perfusion of the slit treatment material;

[0044] (3) Configure the compound ma...

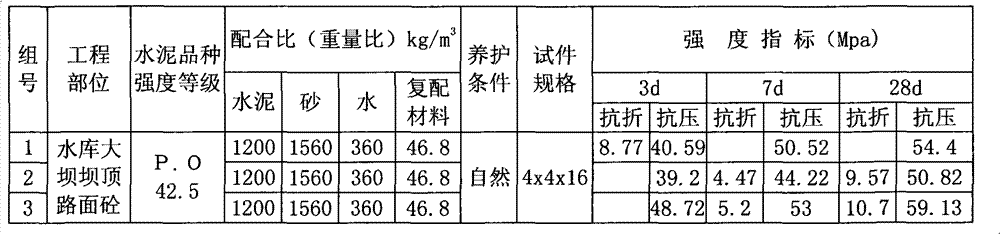

Embodiment 2

[0046] Prescription: the weight and number ratio of each component is:

[0047] Universal Portland cement PO42.5 1200g,

[0048] Medium coarse sand 1560g,

[0049] Guazi stone, particle size 0.5cm 300g,

[0050] 330g of water,

[0051] The composite material comprises the following raw materials in parts by weight:

[0052] Polycarboxylate superplasticizer 12g,

[0053] Cement waterproofing agent 25g,

[0054] Low viscosity thickening plasticizer, viscosity 75cps 2g,

[0055] Mortar Companion: Mortar rheological additive BANAQUA4000 8g,

[0056] Redispersible latex powder SWF-05 8g;

[0057] method:

[0058] (1) Concrete surface crack cutting, the cutting width is 8cm, and the cutting depth is 8cm;

[0059] (2) Clean the base surface of concrete cracks, remove all gravel, dust and impurities in the groove, soak and rinse with clean water, and blow dry with a fan to achieve water retention inside the old concrete base material, dry outside surface, and no excess water ...

Embodiment 3

[0062] Prescription: the weight and number ratio of each component is:

[0063] Universal Portland cement PO42.5 1400g,

[0064] Medium coarse sand 2000g,

[0065] Guazi stone, particle size 1cm 600g,

[0066] 300g of water,

[0067] The composite material comprises the following raw materials in parts by weight:

[0068] Polycarboxylate superplasticizer 15g,

[0069] Cement waterproofing agent 30g,

[0070] Low viscosity thickening plasticizer, viscosity 100cps 5g,

[0071]Mortar Companion, Mortar Rheology Additive BANAQUA4000 15g,

[0072] Redispersible latex powder SWF-05 15g;

[0073] method:

[0074] (1) Concrete surface crack cutting, the cutting width is 10cm, and the cutting depth is 10cm;

[0075] (2) Clean the base surface of concrete cracks, remove all gravel, dust and impurities in the groove, soak and rinse with clean water, and blow dry with a fan to achieve water retention inside the old concrete base material, dry outside surface, and no excess water o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com