Patents

Literature

144results about How to "Production safety and stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Real-time control method for coal gas dynamic balancing in steel plants based on cabinet position prediction

InactiveCN101109952AReduce urban environmental pollutionImprove overall utilization efficiencyTotal factory controlProgramme total factory controlPlant basedImbalance problems

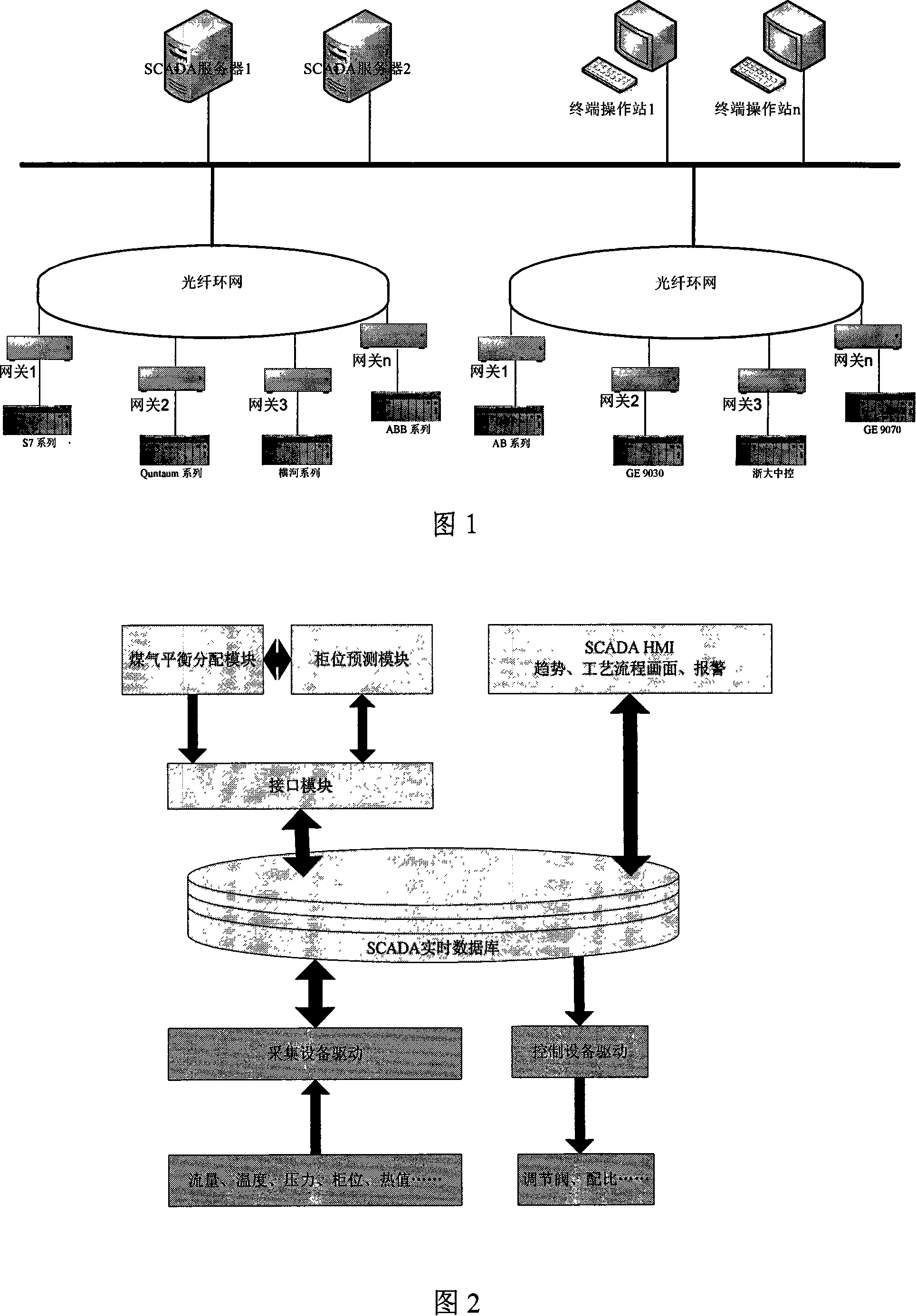

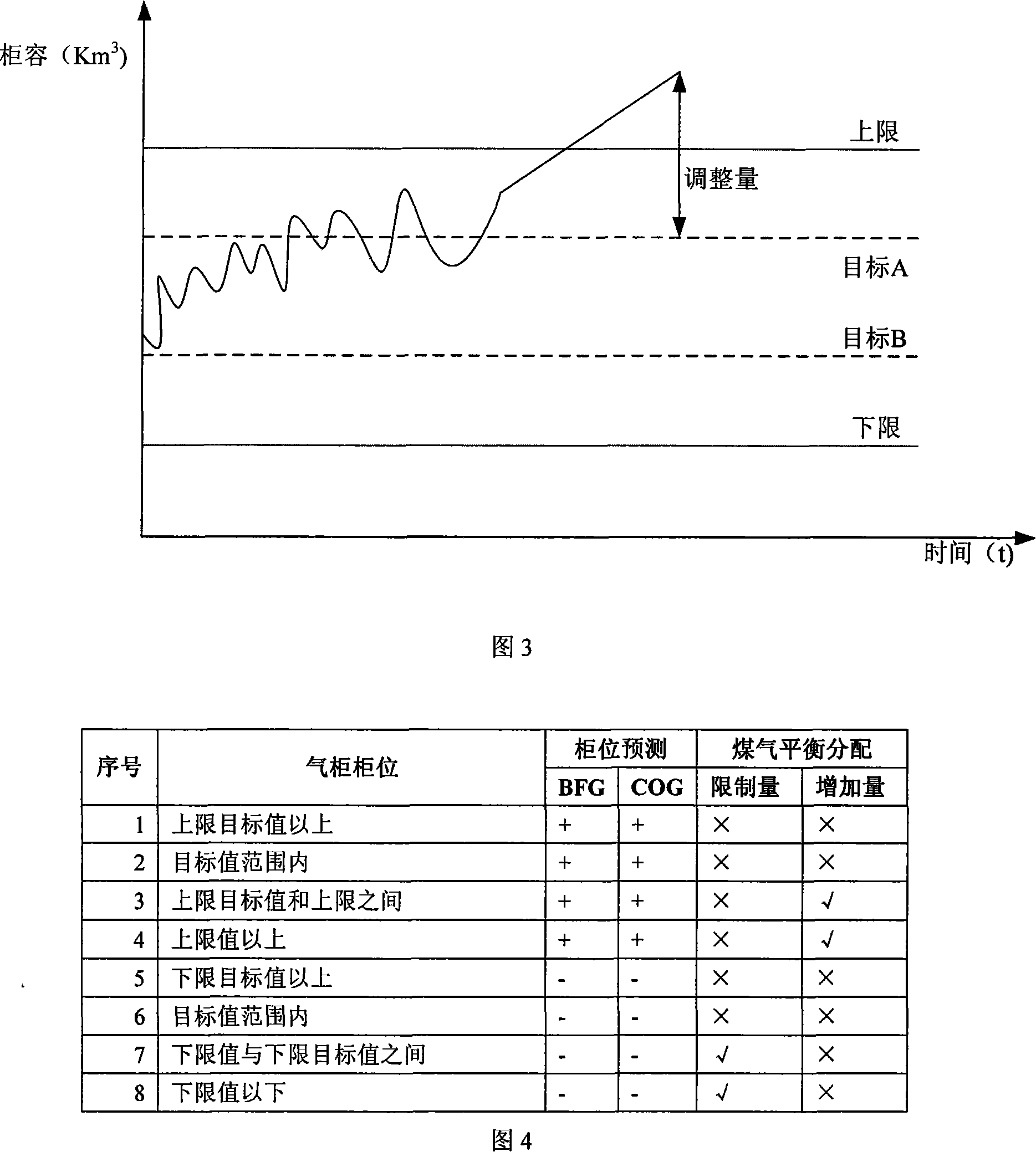

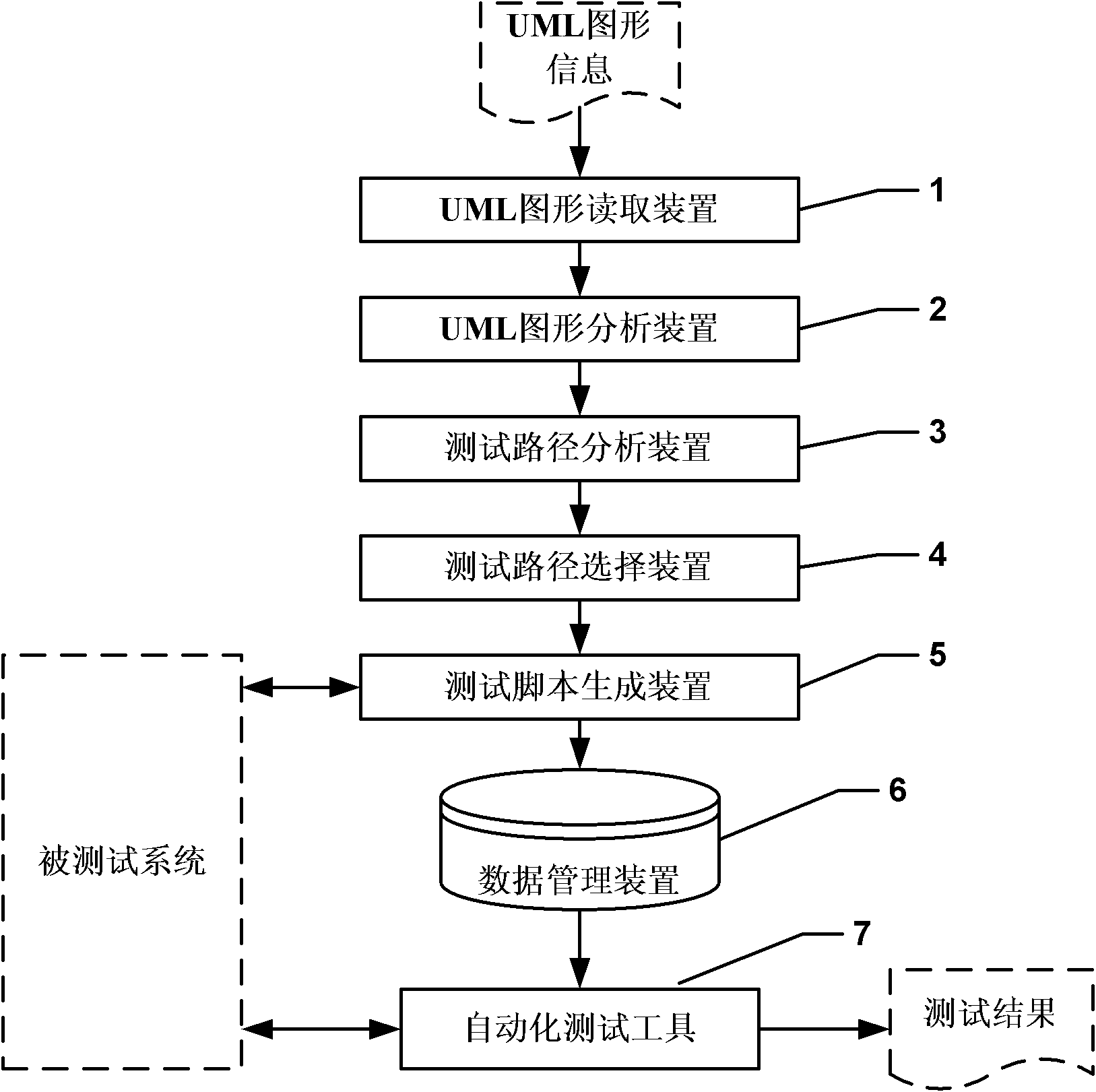

A cabinet-based prediction method for the real-time control of the gaskinetic equilibrium in the steel enterprise, relating to the real-time control technique for the kinetic equilibrium of the by-product gas in the steel enterprise; the utility model is used to solve the off-balance between the supply and demand of the gas system for a short period of time. As the detection technique and the control medium of the automatic gas system are perfected, the operator can fully control the operating condition of the gas system, including the main pipeline pressure, the flow, the user flow, the conveyer equipment and the storage facility. Meanwhile, the regression model is adopted to forecast the future developing trend of the gas system as per the real operation data and the estimation on the main performance currently. Furthermore, based on the balance-related experiences of the site operator, the system will dynamically give out the operating recommendation concerning the adjustable gas use volume or the calorific value in the blending station, so as to balance the gas use level rapidly and decrease the gas emission. Thus, the gas can be effectively used.

Owner:JIGANG GRP

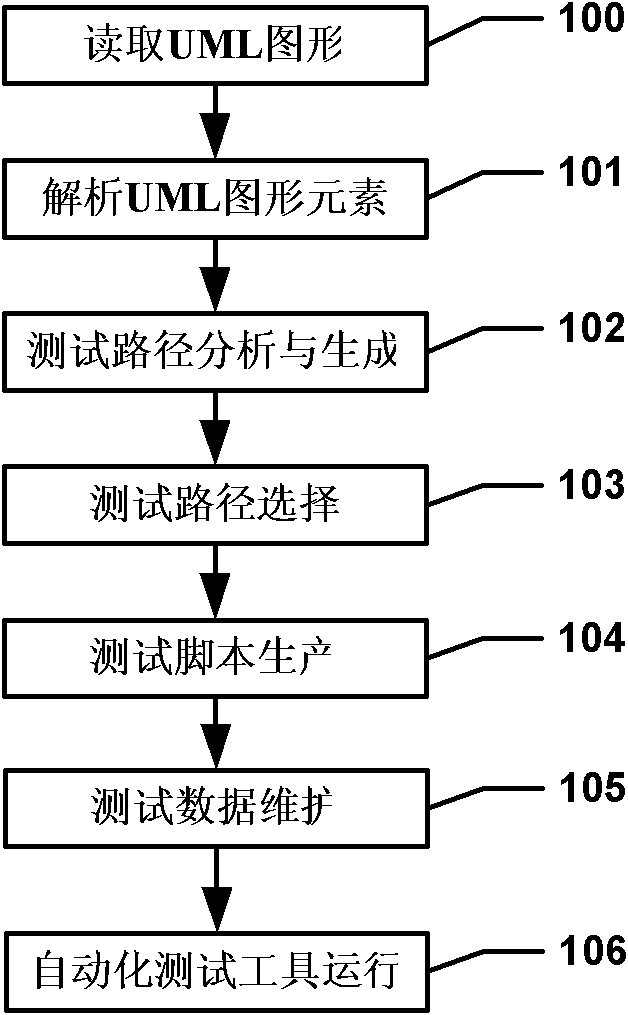

Device and method for automatically testing software based on UML (unified modeling language) graphs

InactiveCN102053912AImprove test efficiencyImprove test qualitySoftware testing/debuggingTest efficiencyGraphics

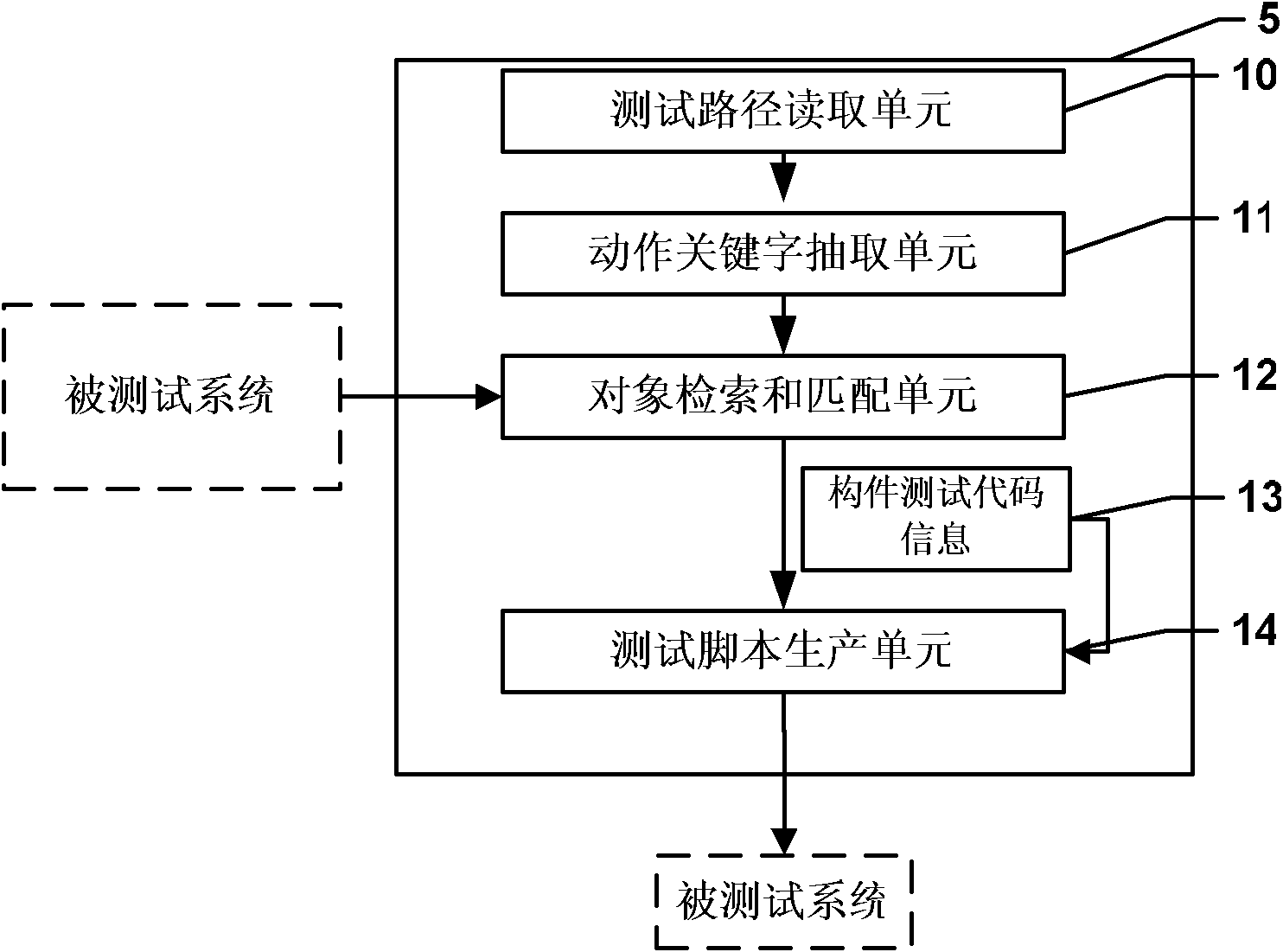

The invention discloses a device and method for automatically testing software based on UML (unified modeling language) graphs. The device comprises a UML graph reading device, a UML graph analyzing device, a testing route analyzing device, a testing route choosing device, a testing script generating device, a data management device and an automatic testing tool which are connected in sequence. The device realizes automatic testing of the software by analyzing UML graphs and generating a test script according to the content of the UML graphs. Through the device and method provided by the invention, the problems that the frequently repeated transcribing process and testing script modifying process required by the traditional process of automatic testing result in low testing efficiency, low accuracy and low coverage rate are solved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

Transparent, flame retardant, thermoformable oriented film made from cristallizble thermoplastics materials, production method and the utilization thereof

InactiveUS6794432B2Promote reproductionImprove tensile propertiesSignboardsSynthetic resin layered productsPolymer scienceOptical property

The invention concerns transparent, flame-retardant, single layered or multilayered thermoformable films, containing a crystallizable thermoplastic material, preferably polyethyleneterephthalate, and at least one flame retarding agent as main components. Said films are characterized by good stretchability, thermoformability and good mechanical and optical properties, which makes them and the shaped bodies made from said films suitable for both inner and outer applications.

Owner:MITSUBISHI POLYESTER FILM

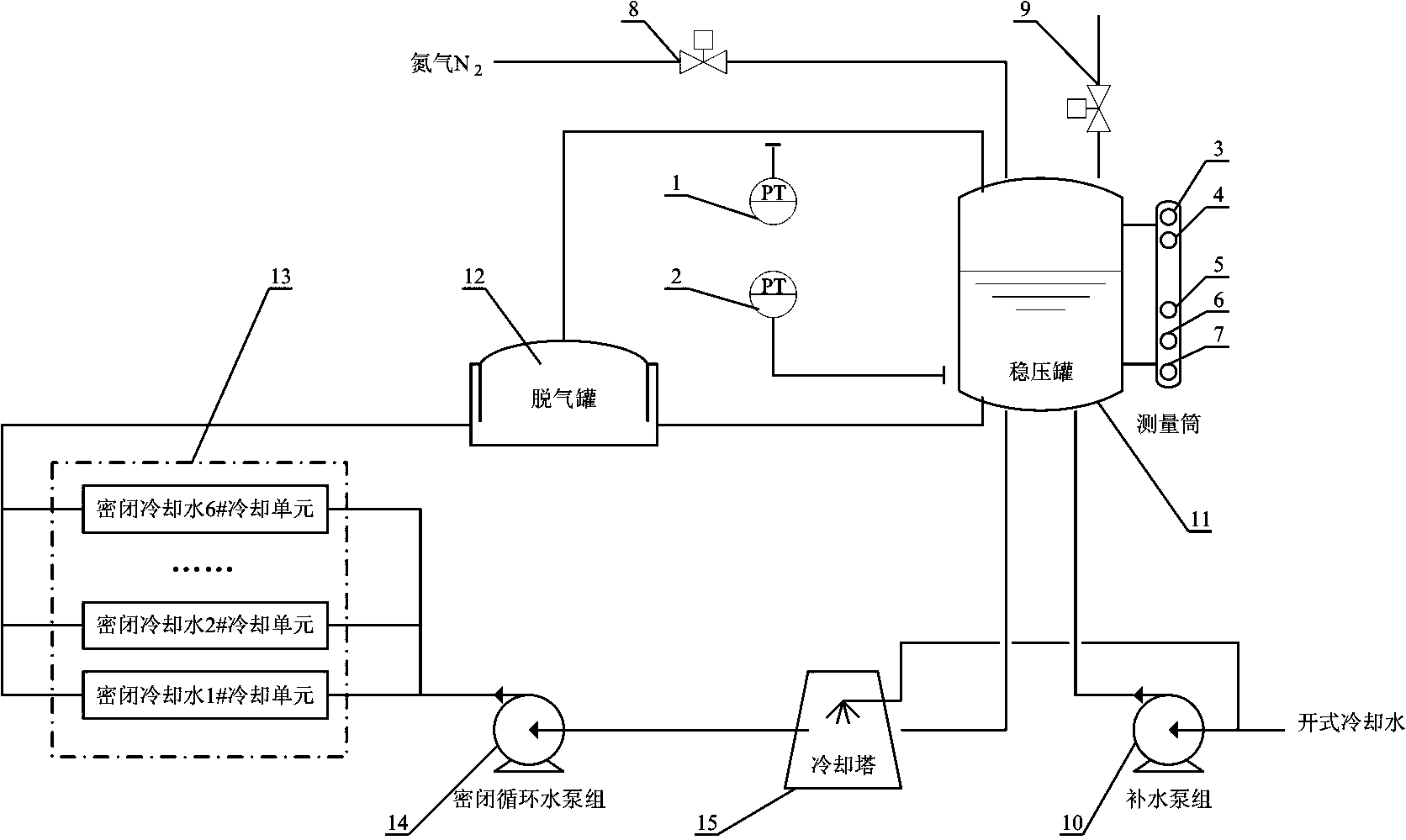

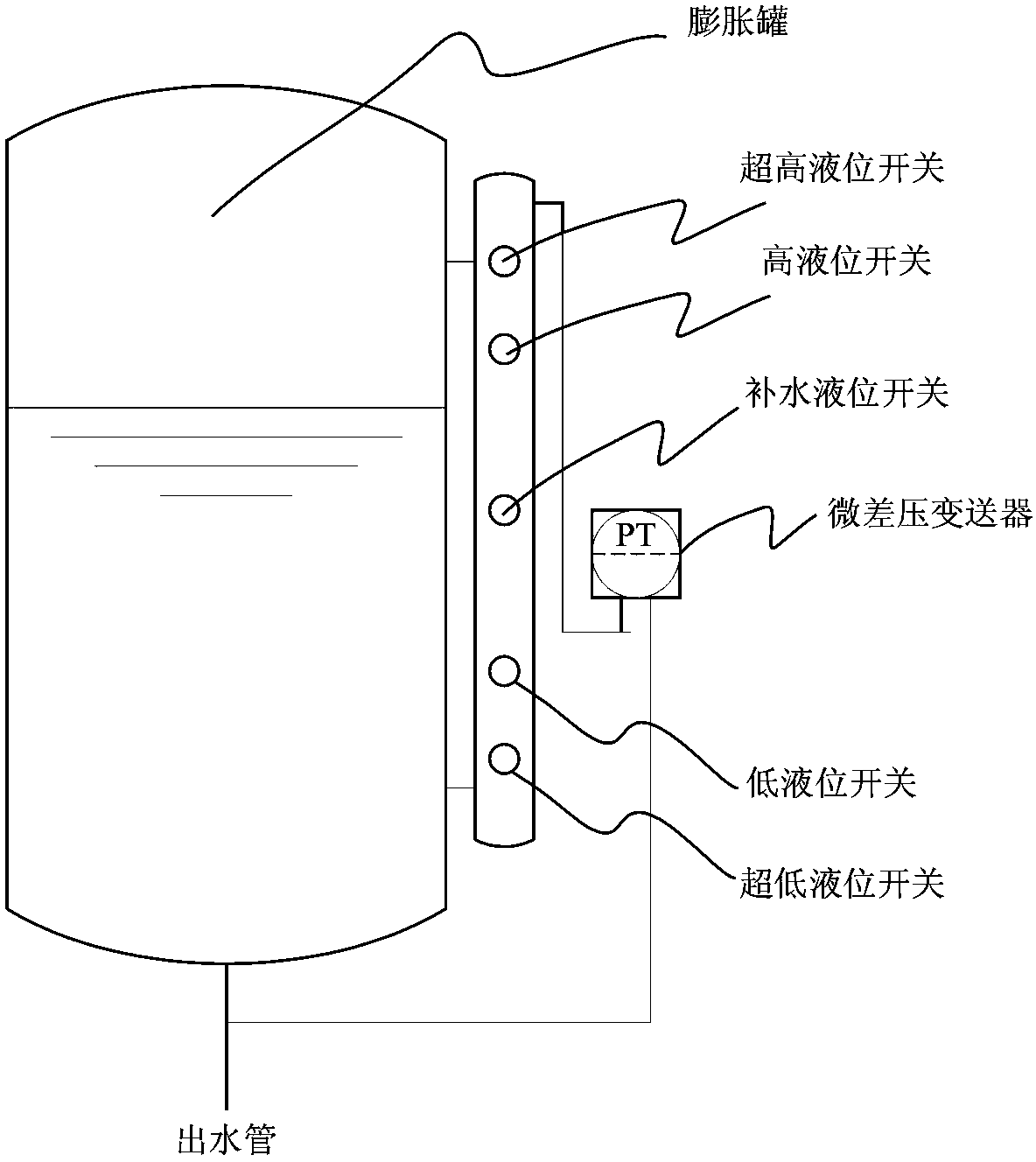

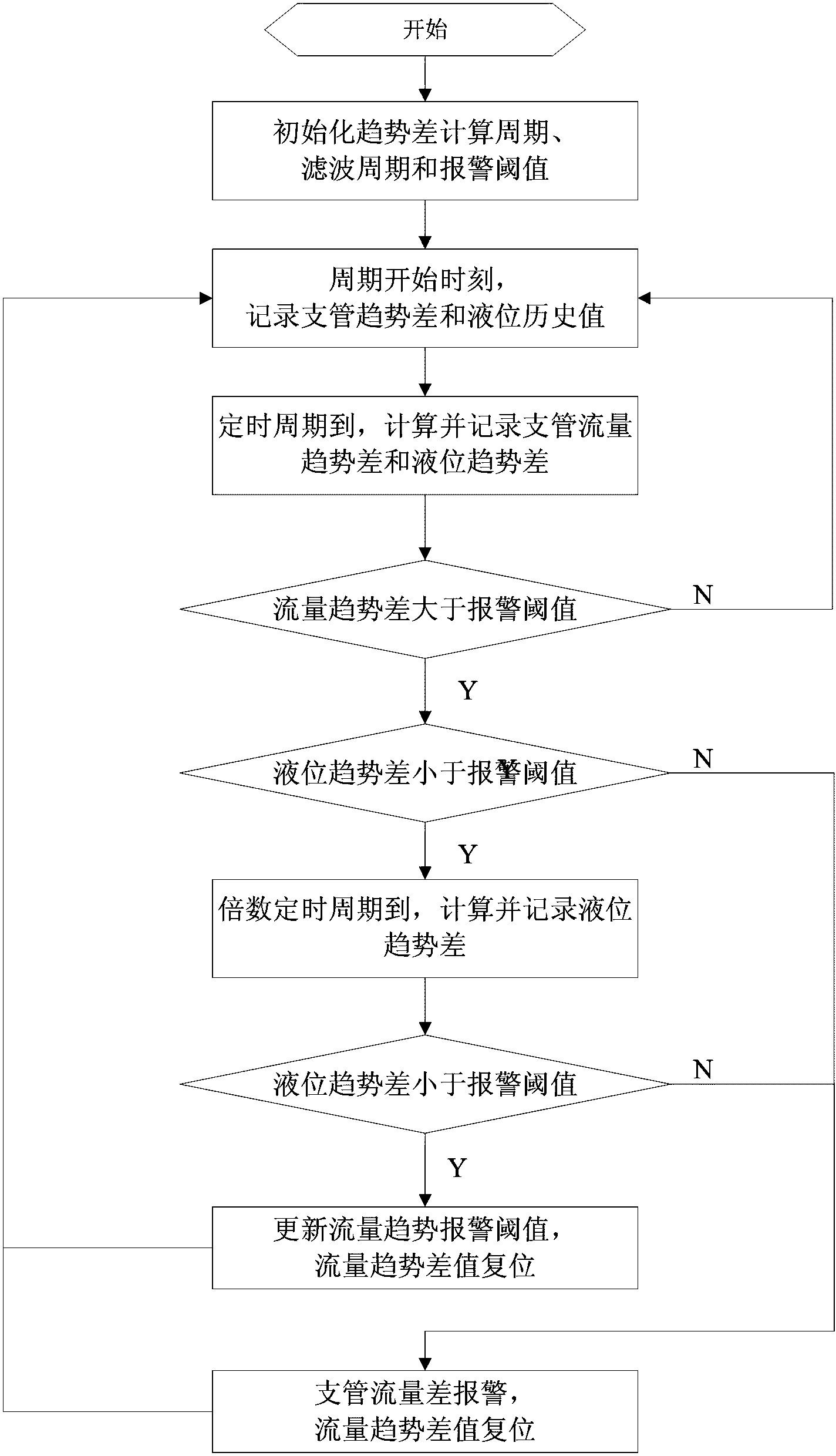

Leakage detection method for closed circulating water system of calcium carbide furnace

ActiveCN103913282ARapid positioningReduce the number of installationsMeasurement of fluid loss/gain rateSurge tankDifferential pressure

The invention discloses a leakage detection method for a closed circulating water system of a calcium carbide furnace. The method comprises the following steps that flow meters and thermometers are installed on cooling water return branch pipes of all equipment parts of the calcium carbide furnace to collect data in real time, and the change trend of flow and the change trend of temperature of all the branch pipes are recorded; a micro-differential pressure transmitter is arranged on the water supplement position of a high-level surge tank of the system to record the change trend of the liquid level; a dynamic alarm model between the change trend of the flow of the branch pipes and the change trend of the liquid level is established; alarm values of the trend difference of the flow of the branch pipes are synthesized to obtain alarm thresholds of the trend difference of the liquid level of the surge tank of different cycles, and leakage detection and positioning performed on the closed circulating water system of the calcium carbide furnace are completed according to the change trend of the flow and the change trend of the temperature of all the branch pipes. According to the leakage detection method for the closed circulating water system of the calcium carbide furnace, the number of the installed high-accuracy flow meters is greatly reduced, the leakage detection accuracy of the system is improved, the response speed is increased, and meanwhile system cost is effectively lowered. In this way, the leakage detection method provides a reliable guarantee for stable and safe production of calcium carbide furnaces.

Owner:WISDRI ENG & RES INC LTD

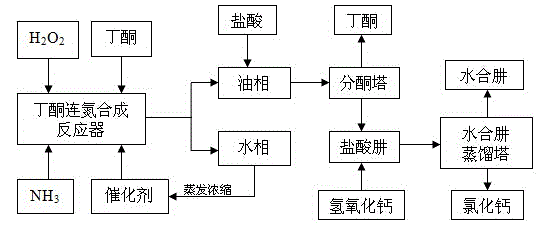

Preparation method of hydrazine hydrate

The invention belongs to the technical field of chemical synthesis, particularly relates to a preparation method of hydrazine hydrate and aims at improving production process of a hydrogen peroxide method and provides a hydrazine hydrate preparation method which is low in energy consumption, high in yield and free of pollution. The hydrazine hydrate preparation method provided by the invention comprises the following steps: carrying out reaction on ammonia, hydrogen peroxide and butanone in the presence of a catalyst to generate methyl ethyl azine; separating the methyl ethyl azine -containing upper oil phase from the catalyst-containing water phase; concentrating the catalyst-containing water phase to reuse; acid decomposing the methyl ethyl azine into hydrazonium salt and butanone, recycling the butanone, neutralizing the hydrazonium salt into hydrazine hydrate by alkali and distilling and recovering to obtain a hydrazine hydrate solution. The method can be used for preparing hydrazine hydrate and is high in yield and free of pollution.

Owner:重庆锦杉科技有限公司

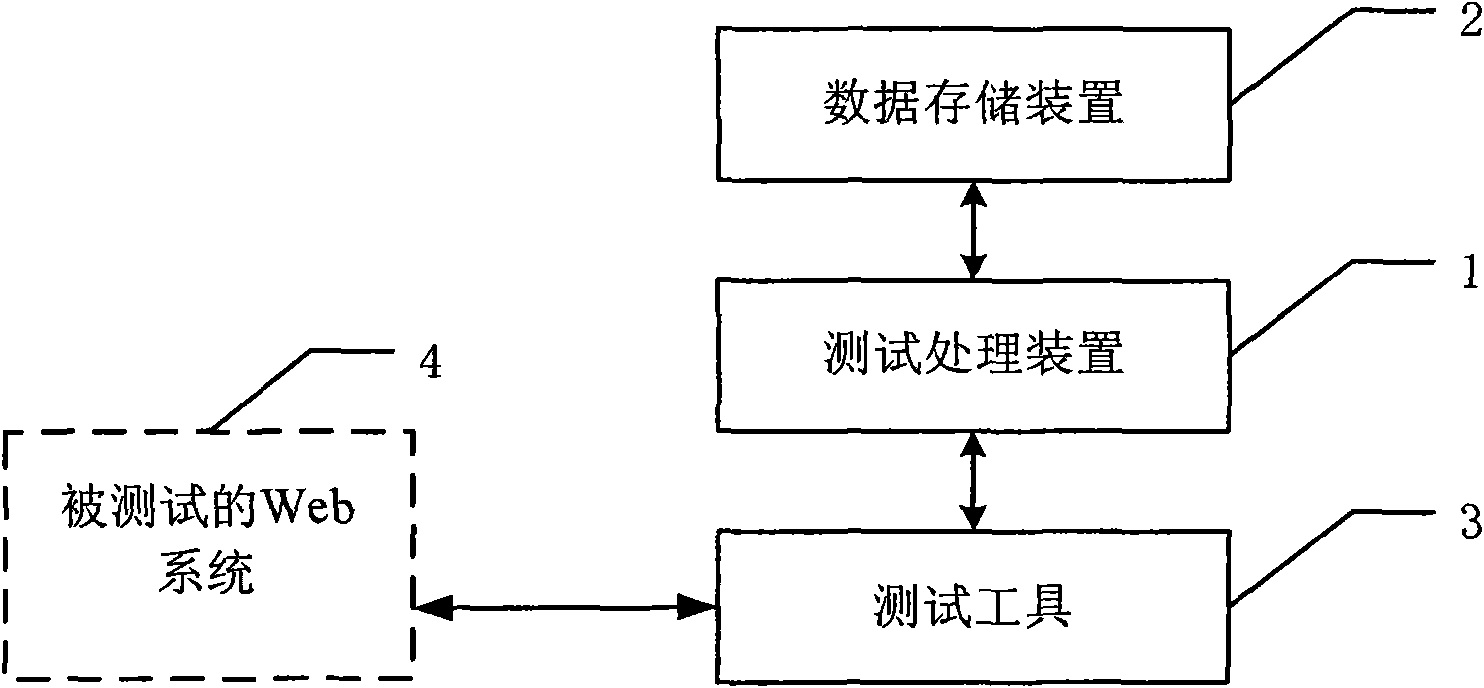

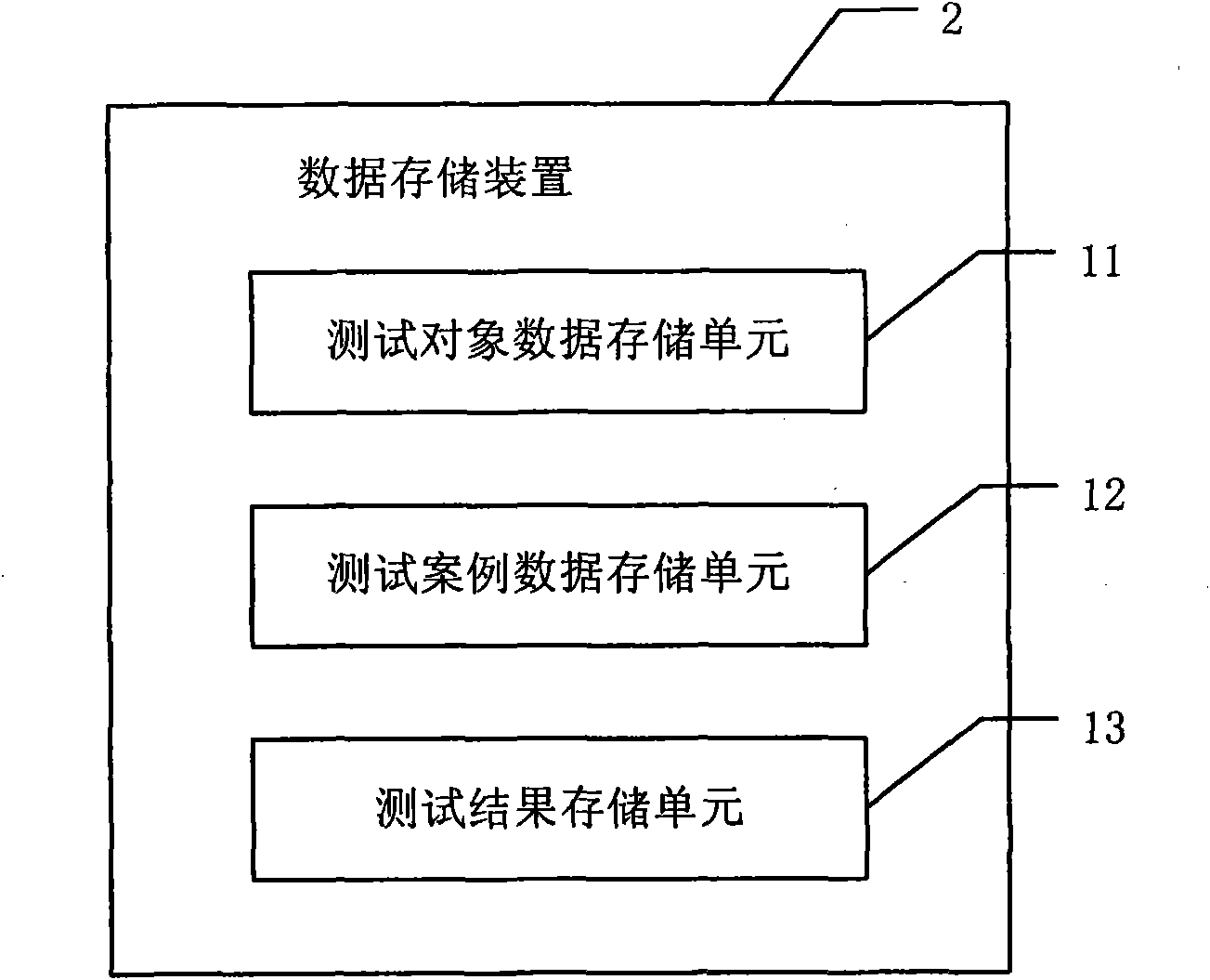

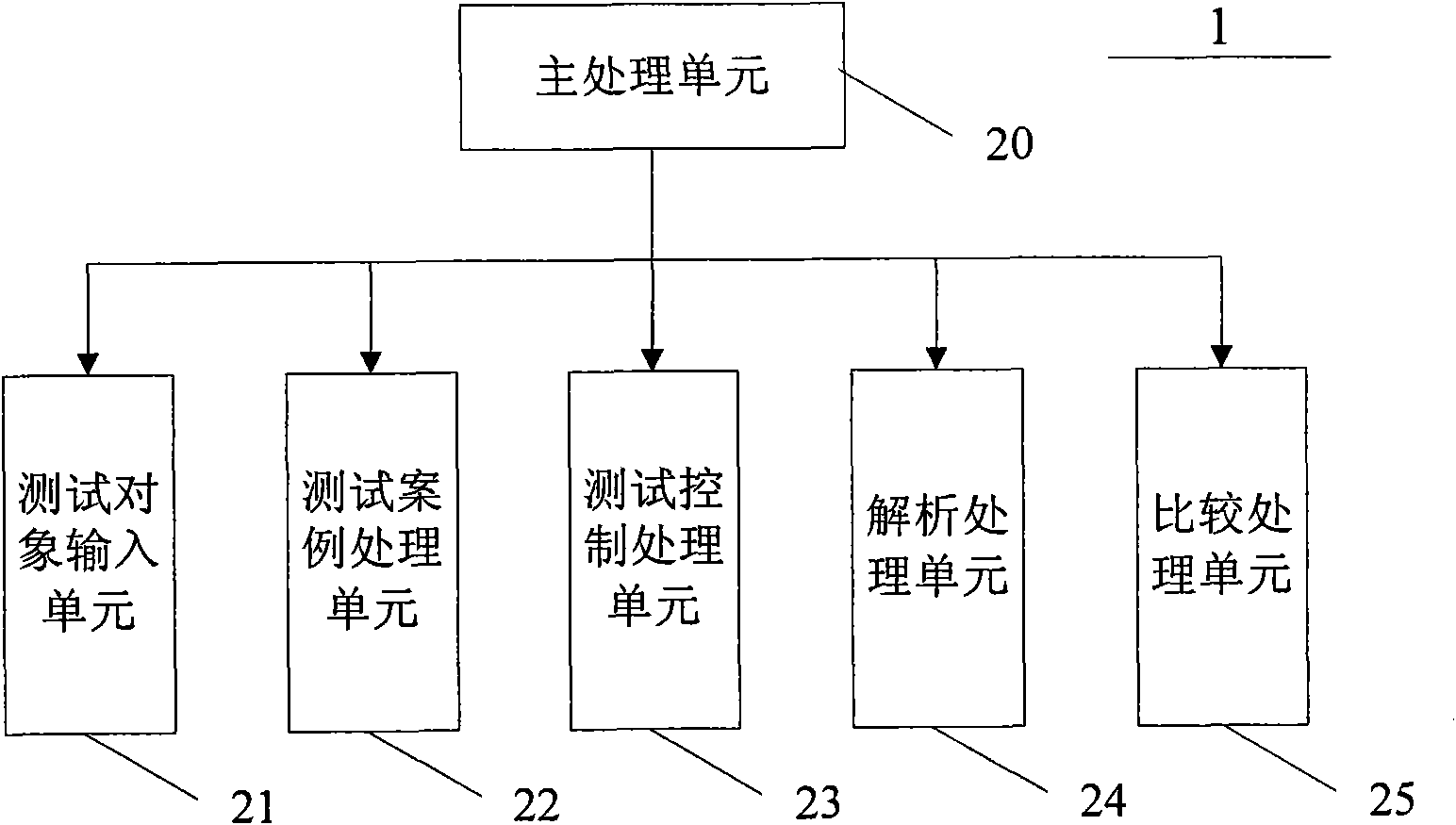

Device and method for automatically testing web page

ActiveCN102012857AImprove automated testing efficiencyQuality improvementSoftware testing/debuggingSpecial data processing applicationsTest efficiencyWeb page

The present invention discloses a device for automatically testing a web page, including the following components: a testing and processing apparatus to test and process a web page; a data storage apparatus used to store information of tested web pages, tested cases and data of test results; a testing tool to browse web pages, parse contents, control execution processes and to obtain error information; wherein the data storage apparatus and the testing tool are both connected with the testing and processing apparatus, and the testing tool is connected with the detected web system. The invention also discloses a method for automatically testing a web page. With the invention, the testing efficiency of web pages is greatly enhanced through parsing input domain objects of web pages and employing a testing method based on objects of web pages, and the invention will effectively improve software quality, guarantee stability and security of enterprise production.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

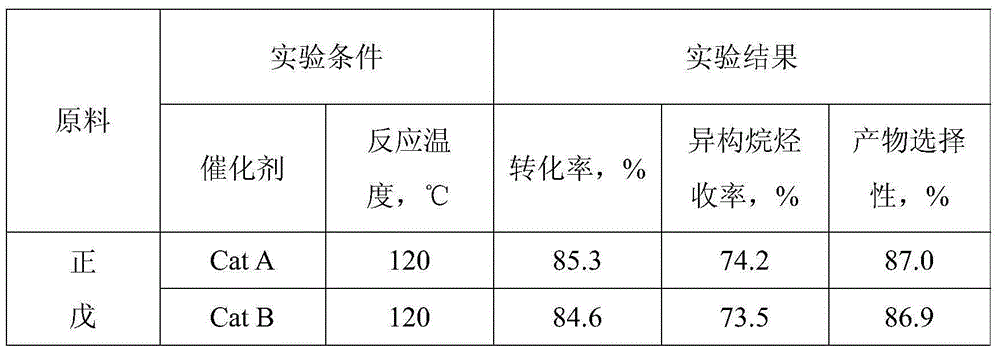

N-alkane low-temperature isomerization catalyst as well as preparation method and application thereof

ActiveCN105080578AHigh activityImprove stabilityHydrocarbon by isomerisationPhysical/chemical process catalystsAlkaneIsomerization

The invention discloses an n-alkane low-temperature isomerization catalyst as well as a preparation method and an application of the n-alkane low-temperature isomerization catalyst. The catalyst disclosed by the invention comprises the following components in percentage by weight: 0.1%-1.0% of loaded metal Pt, 5.0%-10.0% of an element Cl, and the balance of a carrier gamma-Al2O3. The preparation method of the catalyst disclosed by the invention comprises the following steps: dipping chloroplatinic acid on the carrier gamma-Al2O3, and then drying and roasting to obtain Pt / gamma-Al2O3 catalyst containing 0.1%-1% of the Pt; and firstly reducing a platinum-containing catalyst, then uniformly dipping a chlorinating agent on the surface of the Pt / gamma-Al2O3 catalyst by adopting a chlorinating way of liquid-phase dipping, and then carrying out programmed warming for curing the chlorinating agent to obtain the Pt / gamma-Al2O3-Cl n-alkane isomerization catalyst with high chloride loading quantity (5%) and uniform distribution of the chlorine element. The catalyst provided by the invention has relatively high chlorine content, also has good chlorine distribution, and achieves high acidity loading quantity, high isomerization activity and high stability of the catalyst.

Owner:BEIJING SINO SPHERE PETROCHEM TECH CO LTD

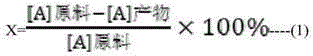

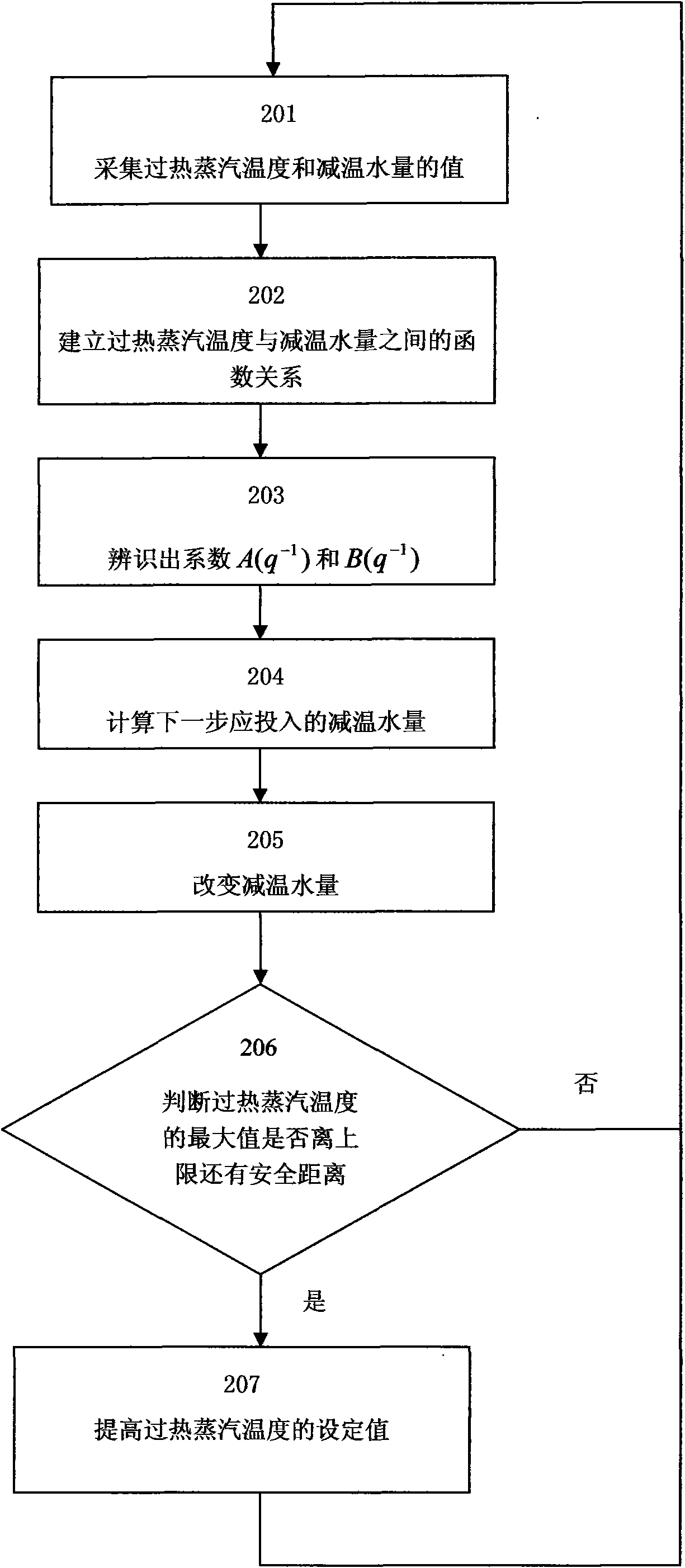

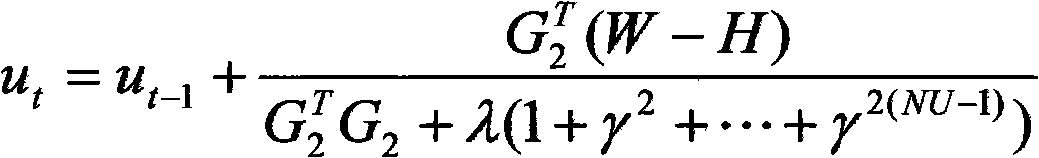

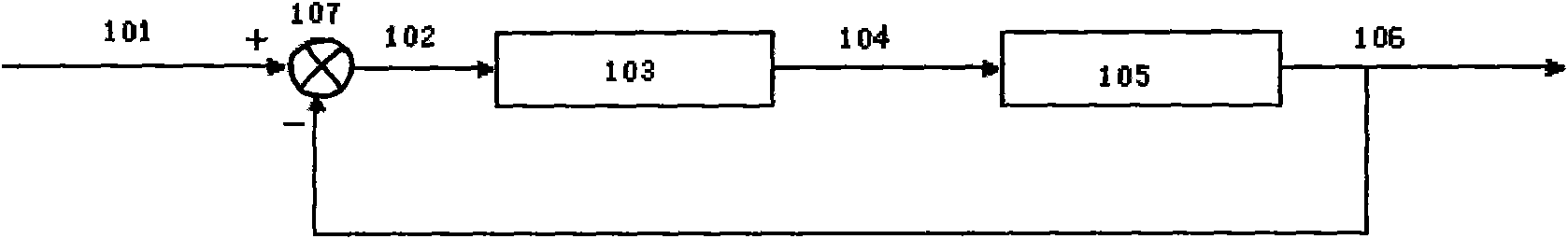

Method for improving efficiency of steam turbine of thermal power unit by steam temperature predictive control

InactiveCN101899996AImprove efficiencyReduce energy consumptionSteam useEngine componentsEngineeringSuperheated steam

The invention discloses a method for improving the efficiency of a steam turbine of a thermal power unit by steam temperature predictive control. The method comprises the following steps of: a, acquiring the values of a superheated steam temperature and a temperature reduction water quantity; b, establishing a functional relation between the superheated steam temperature and the temperature reduction water quantity, namely, A(q<-1>)yt=B(q<-1>)ut-d+xi / delta; c, identifying coefficients, namely, A(q<-1>) and B(q<-1>); d, calculating the quantity of temperature reduction water to be input in a next step; and e, judging whether the maximum value of the superheated steam temperature is a safe distance away from an upper limit or not, and if so, increasing the set value of the superheated steam temperature and circularly performing the steps from a to e.

Owner:SHANGHAI JIEKONG SOFTWARE TECH

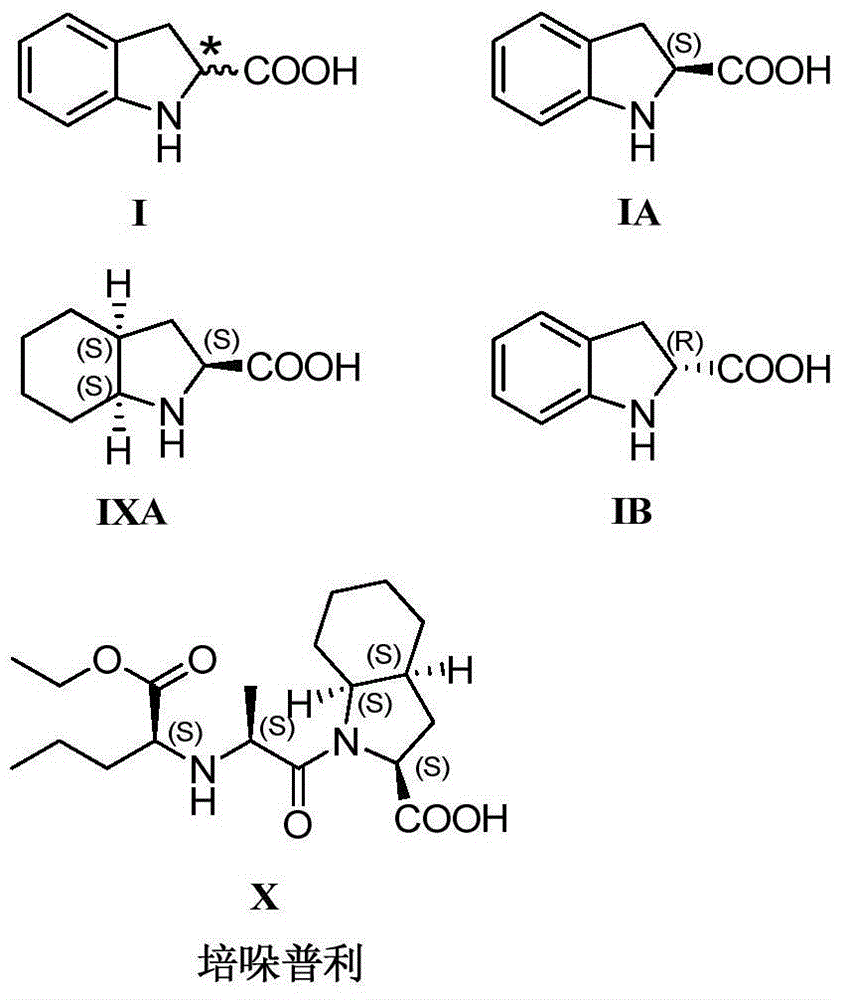

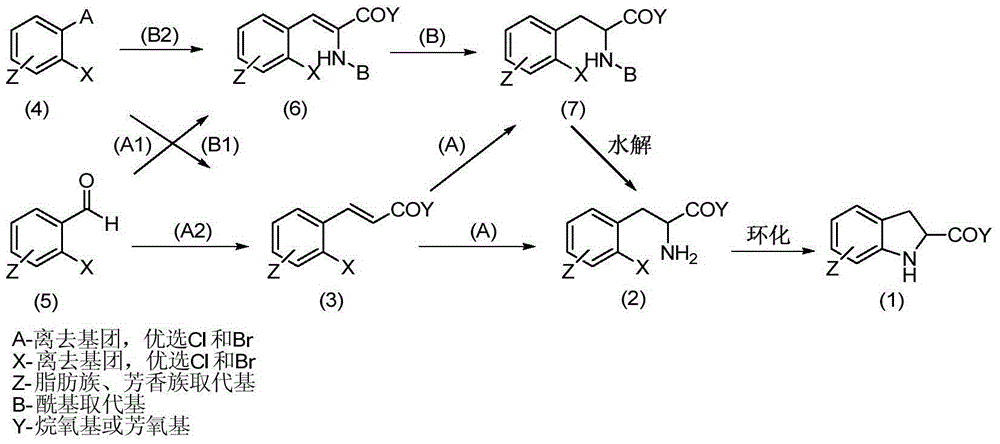

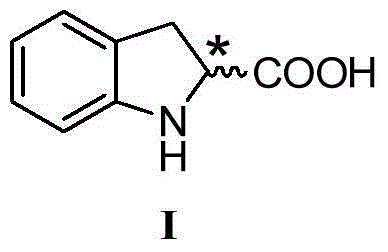

Synthesis method of enantiomer-enriched indoline-2-formic acid

ActiveCN104672124ASimple reaction conditionsImprove conversion rateOrganic chemistryEnantiomerSynthesis methods

The invention discloses a synthesis method of enantiomer-enriched indoline-2-formic acid shown in a formula (I). The synthesis method of the enantiomer-enriched indoline-2-formic acid comprises the following steps: by adopting low-cost and available ortho-position halogen substituted benzaldehyde and N-benzoyl substituted glycine as starting materials, carrying out Erlenmeyer-Plochl cyclization, alkaline hydrolysis and asymmetric catalytic hydrogen for constructing a chiral center, and then carrying out acid catalysis, deprotection and cyclization sequentially or cyclization, acid catalysis and deprotection sequentially, so that the enantiomer-enriched indoline-2-formic acid is obtained. The synthesis method of the enantiomer-enriched indoline-2-formic acid has the advantages that raw materials used in the whole process route are low-cost and easily available, harmful substances or multiple danger special processes are not used, reaction conditions are mild, technological operation is simple, production is safe and stable, the product yield is high, the purity is high, less three wastes are produced, and the energy consumption is low, so that the synthesis method of the enantiomer-enriched indoline-2-formic acid is a process route especially applicable to industrial production. The formula (1) is described in the specification.

Owner:ZHEJIANG CHANGMING PHARMA

Oxidized organic compound manufacturing method

ActiveUS20110306788A1Decline in yieldStable and safe productionOrganic compound preparationOxygen compounds preparation by hydrocarbon oxidationIndustrial scaleReaction tube

The object of the present invention is to provide, in the production of a useful oxidized organic compound by a catalytic gas-phase oxidation reaction on an industrial scale, a manufacturing method which, even when operation has been temporarily interrupted for periodic inspection or emergency shutdown, fully avoids the danger of an explosion due to reaction feedstock gases and the like remaining inside the reaction apparatus, and which, when operation is restarted, is able to shorten, relative to the prior art, the period required for the reaction to return to a stable steady state, and moreover which, after operation has restarted, does not undergo a decrease in yield, and allows a high yield to be stably maintained over a long period, whereby the production efficiency can be greatly increased.The disclosed invention is a method for manufacturing an oxidized organic compound which includes a step of forming an oxidized organic compound, in use of a fixed-bed reactor having a reaction tube packed with an oxide catalyst, by supplying at least one type of organic compound as a reaction feedstock gas and using a molecular oxygen-containing gas to carry out a catalytic gas-phase oxidation reaction; and a step of stopping the catalytic gas-phase oxidation reaction. In the manufacturing method, when stopping the catalytic gas-phase oxidation reaction, the supply of the reaction feedstock gas is stopped, after which an inert gas is supplied to the reactor, then a molecular oxygen-containing gas is supplied, subsequent to which the supply of the molecular oxygen-containing gas to the reactor is stopped.

Owner:NIPPON SHOKUBAI CO LTD

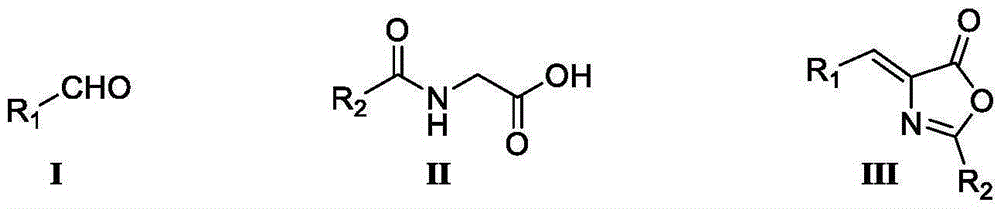

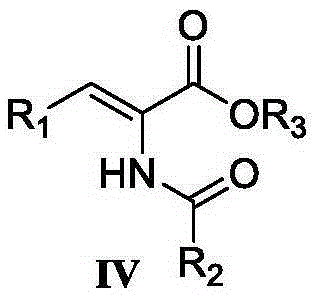

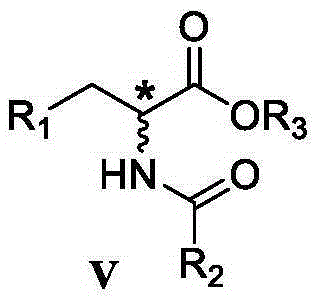

Preparation method of chiral alpha-amino acid

InactiveCN105330557ASimple processSafe, stable and reliable productionOrganic compound preparationAmino-carboxyl compound preparationGlycineAcid hydrolysis

The invention discloses a preparation method of chiral alpha-amino acid. Initial raw materials comprising aldehyde and N-acryl substituted glycine undergo Erlenmeyer-Plochl cyclization, hydrolysis or alcoholysis, asymmetric catalytic hydrogenation and acid hydrolysis to obtain the chiral alpha-amino acid compound. The method adopting the above synthesis route has the advantages of mild reaction conditions, simple technological operation, safe and stable production, realization of high yield, good chemical purity and good optical purity of the above obtained product, wide application range, and suitableness for industrial production.

Owner:天台宜生生化科技有限公司

Process for preparing recombinant human thrombin with culture cell

InactiveUS20090137001A1Low costProduction safety and stabilityAnimal cellsPeptide/protein ingredientsZymogenCulture cell

The present invention provides for a process for preparing a recombinant human thrombin. A process for preparing a recombinant human thrombin which comprises: (1) obtaining a transfectant cell producing a human prothrombin by introducing an expression vector, wherein a gene fragment coding for a human prothrombin gene is incorporated, into an animal cell; (2) purifying a human prothrombin from the culture of the transfectant cell above by an anion exchanger; (3) converting the purified human prothrombin into a human thrombin by subjecting said human prothrombin to the action of ecarin; and (4) purifying the human thrombin from the solution after treatment with ecarin by an affinity method using benzamidine and a cation exchanger, and human thrombin obtained by said process, and a CHO cell that produces human prothrombin.

Owner:JURIDICAL FOUND THE CHEMO SERO THERAPEUTIC RES INST

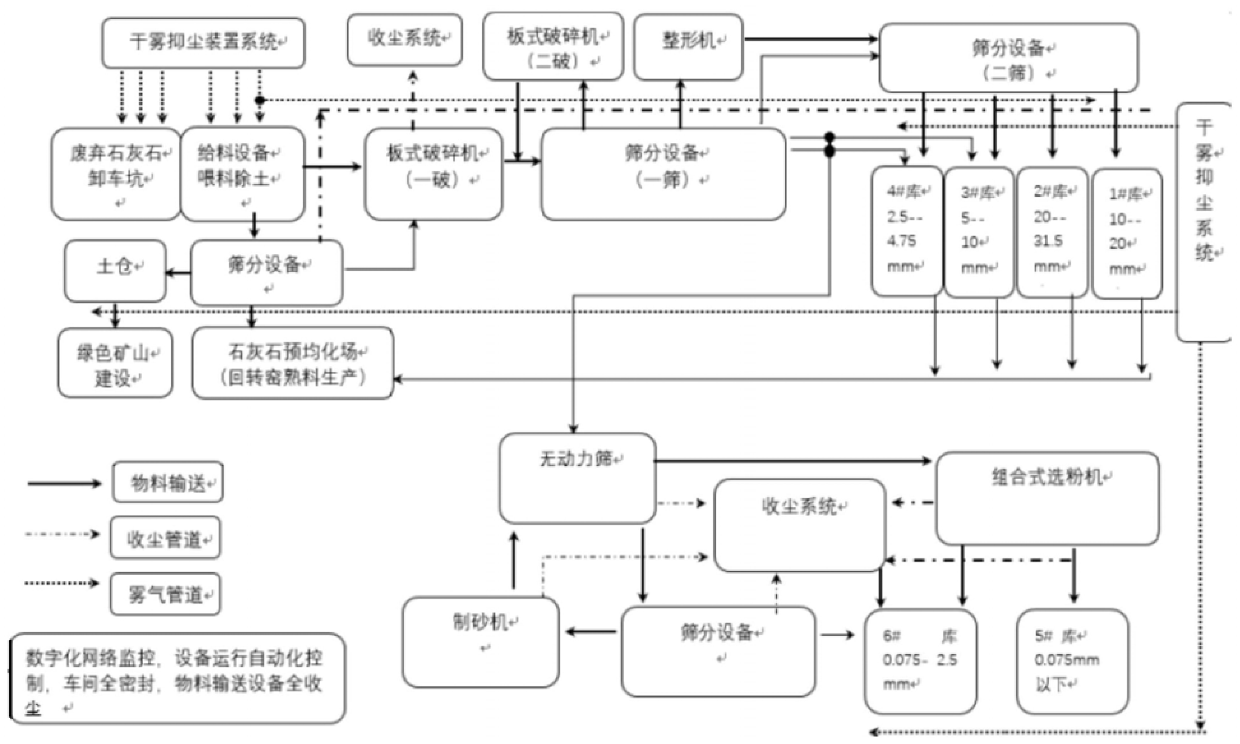

Waste limestone environmentally-friendly reuse dry sand making method

InactiveCN111530597AAdvanced production technologyThe production process is safe and stableSolid waste managementCement productionScrapEngineering

The invention discloses a waste limestone environmentally-friendly reuse dry sand making method. The method comprises the steps of riddle, coarse crushing, first screening, fine crushing, second screening, shaping, sand making, humidification and the like. Used equipment comprises a two-stage impact crusher, a shaping machine, a screening machine and the like, and a dry mist dust removal system isused in the entire production process. Used raw materials comprises low-grade waste limestone such as mine high-magnesium and high-silicon, stone scraps, sorted construction waste and the like, and through the cooperation of the production process, the recycling efficiency of waste limestone is improved, the production technology is advanced, and the production process is safe, stable, environmentally-friendly and sanitary, ranking the leading level in the country. Workshop buildings for fine aggregate machine sand making production line are closed, and dust collectors and dry mist dust suppression devices can be adopted to relevant dust raising points, so that the recycling of waste limestone is efficiently achieved, the dust raising is reduced, the method is more environmentally-friendly, the development prospect is better, and the practicability is stronger.

Owner:平邑中联水泥有限公司

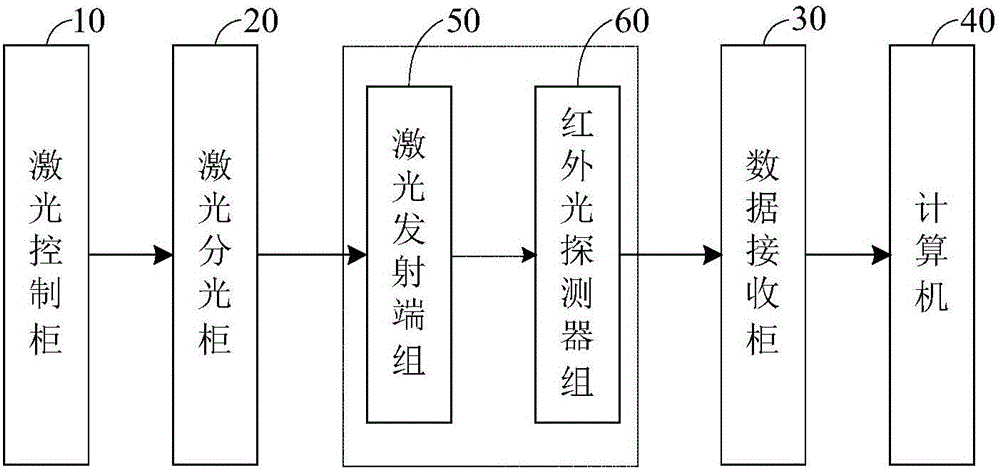

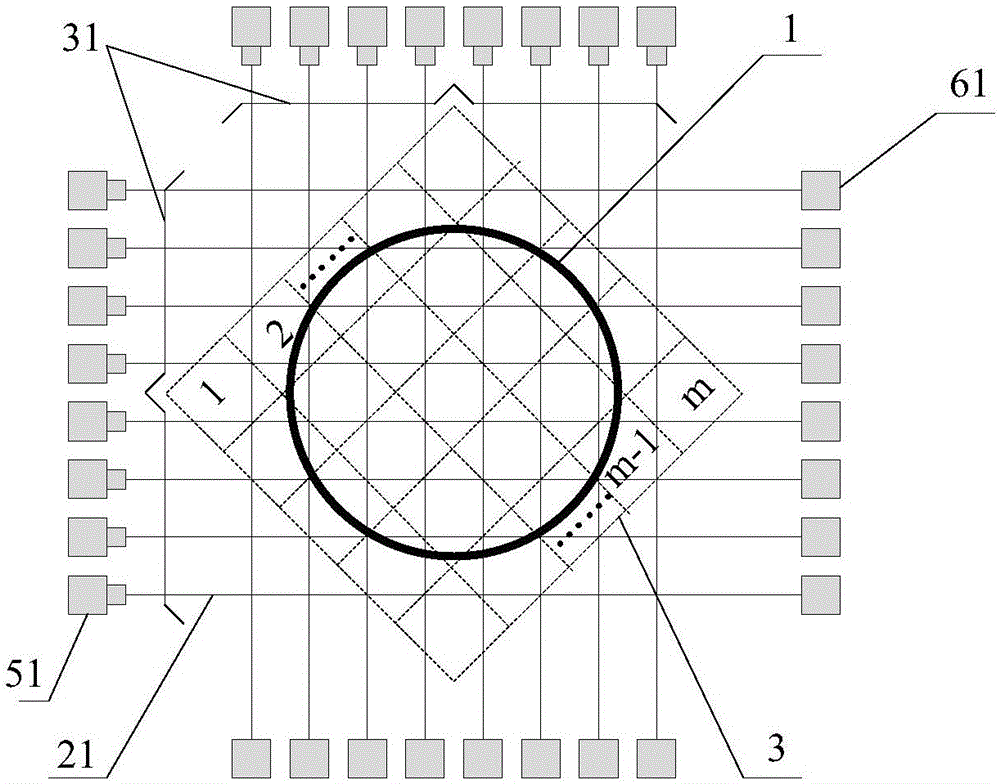

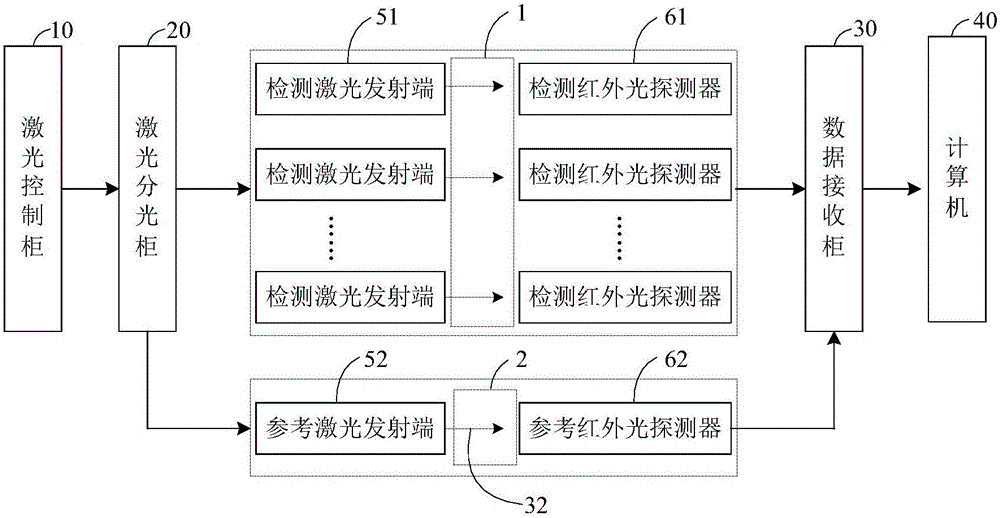

Gas concentration two-dimensional distribution on-line detection system and method

ActiveCN106769974AAccurately reflectObjective reflectionMaterial analysis by optical meansLuminositySpectroscopy

The invention discloses a gas concentration two-dimensional distribution on-line detection system and method, and belongs to the technical field of laser spectroscopy gas on-line detection. Compared with the prior art, the system has the advantages that a laser beam splitting cabinet splits a laser path emitted from a laser control cabinet into a plurality of paths of detection light paths and a one-path reference light path in reticular distribution; the multi-path detection light paths and the one-path reference light path respectively pass through a target gas region to be detected and a reference target gas region and are then received by a data receiving cabinet; a computer calculates the gas concentration two-dimensional distribution data according to the multi-path detection light paths and the one-path reference light path processed by the data receiving cabinet. The method has the advantages that the absorption coefficient of target gas in each pixel is calculated according to the integral light absorption degree of each path of detection light path and the light path in each pixel; the two-dimensional concentration value of target gas in a target gas region to be detected is calculated by referring to each known parameter of the target gas region. The gas environment in the industrial production process can be precisely reflected through calculating the two-dimensional concentration value of the target gas.

Owner:HEFEI GOLD STAR MECHATRONICS TECH DEV CO LTD

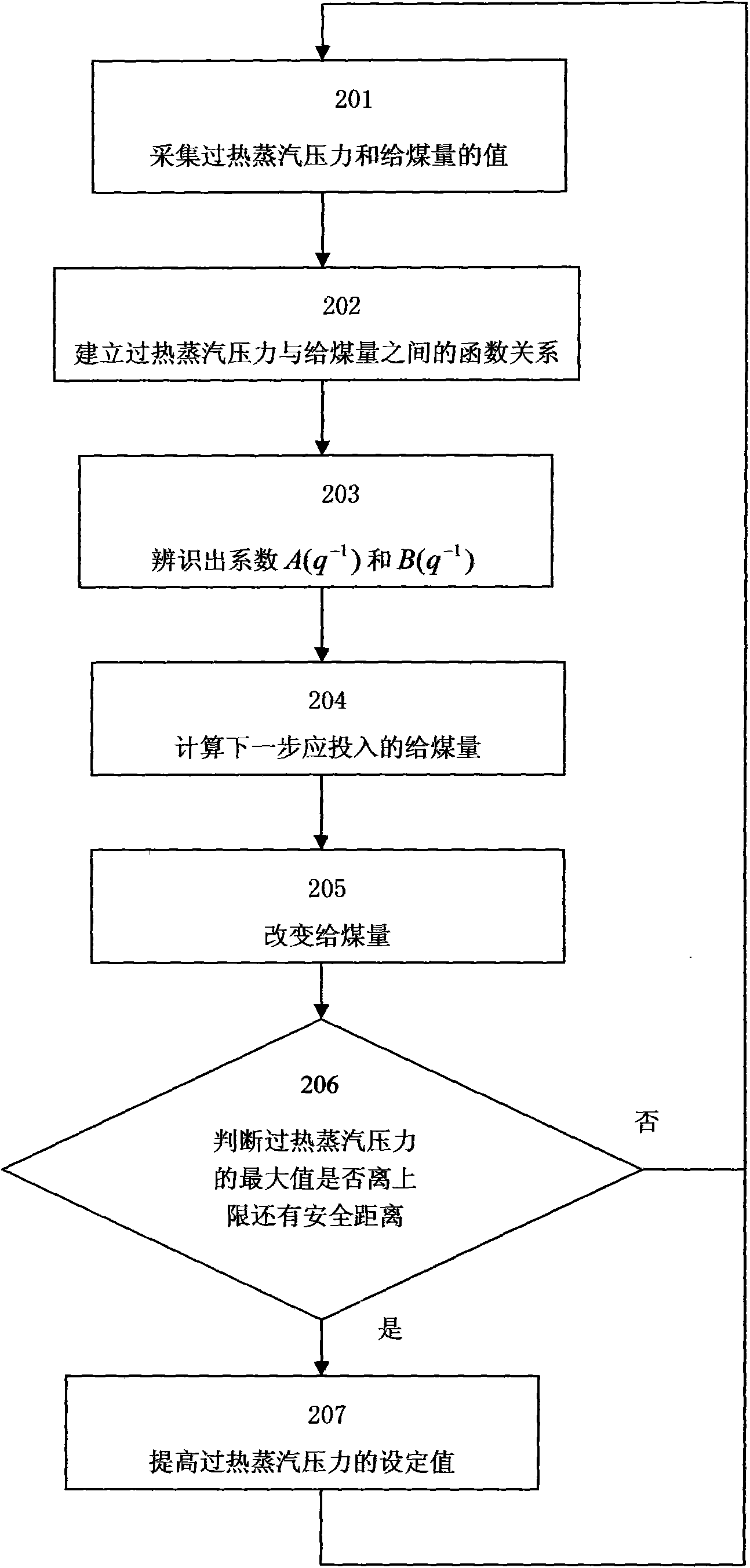

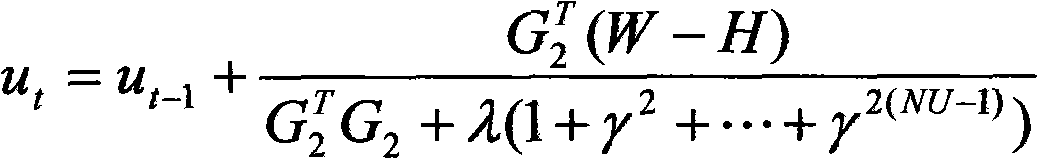

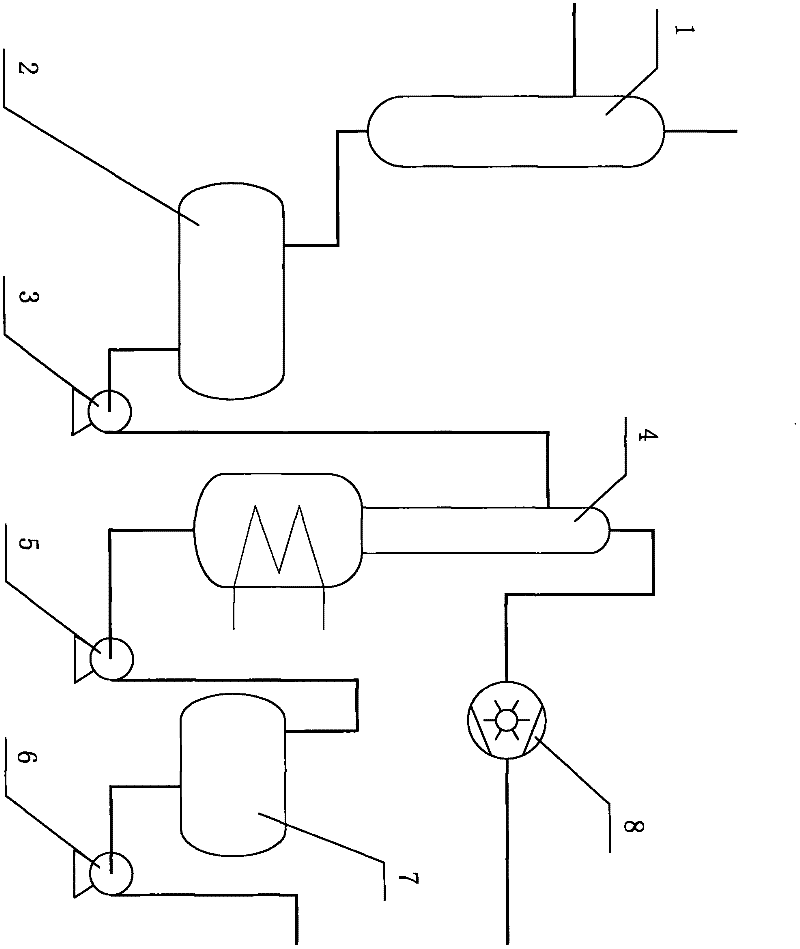

Method for predicting, controlling and improving efficiency of thermal power unit steam turbine by using steam pressure

InactiveCN101900348AImprove efficiencyReduce energy consumptionFuel supply regulationSteam pressureEngineering

The invention discloses a method for predicting, controlling and improving the efficiency of a thermal power unit steam turbine by using steam pressure, which comprises the following steps of: a, acquiring values of overheating steam pressure and coal supply; b, establishing a functional relation A(q-1)yt=B(q-1)ut-d+xi t / delta between the overheating steam pressure and the coal supply; c, identifying the coefficients A(q-1) and B(q-1); d, calculating the coal supply to be added in the next step; and e, judging whether a safety distance is present from the maximum of the overheating steam pressure to an upper limit, if so, increasing the set value of the overheating steam pressure, and circularly executing the steps a to e.

Owner:SHANGHAI JIEKONG SOFTWARE TECH

Production method of environment-friendly formaldehyde-free plywood glue

ActiveCN102827338AGuaranteed to be environmentally friendlyPromote environmental protectionAldehyde/ketone condensation polymer adhesivesAdhesive glueProcess engineering

The invention relates to a production method of environment-friendly formaldehyde-free plywood glue, which comprises the following steps: respectively weighing formaldehyde and urea in a mol ratio of 1:1.1-1:1.02, and adding urea for the first time; after finishing keeping the temperature, adding urea for the second time; when the solution viscosity reaches 5000mPa.s, adding urea for the third time, and carrying out vacuum dehydration for more than 120 minutes; after finishing dehydration, adding urea for the fourth time; and after carrying out dissolution reaction for 30 minutes, cooling to 38-42 DEG C, regulating the pH value to 7.8-8.5, and discharging the glue, thereby obtaining the environment-friendly formaldehyde-free plywood glue product. The proportional and fractional addition of urea and the low mol ratio ensure the environment friendliness of the glue; the invention has the advantages of simple and reasonable technique, low manufacturing cost, no gelation or tank spraying in the production process, and high production safety and stability; the storage period of the glue is more than 90 days; the glue can be stored, used and transported in both hot summer and cold winter; and the formaldehyde release of the artificial board produced from the environment-friendly E0-Grade glue product is E0<=3mg / 100g.

Owner:广东始兴县华洲木业有限公司

Method for purifying ethylene dichloride in vinyl chloride rectification raffinate

ActiveCN102267865AReduce usageLow costChemical industryHalogenated hydrocarbon preparationEthane DichlorideVacuum pump

The invention relates to a method for purifying dichloroethane from vinyl chloride rectification residual liquid. In the method, a rectification tower, a residual liquid tank, a residual liquid pump, a vacuum distillation tower, a dichloroethane pump and a dichloroethane tank which are connected sequentially are provided, and a vacuum pump for controlling the vacuum degree of the vacuum distillation tower is also provided. The method provided by the invention is characterized in that: according to the volatility difference at different temperatures and different pressures of each component in the vinyl chloride rectification residual liquid, the rectification residual liquid from the bottom of the rectification tower is introduced to the vacuum distillation tower to remove the impurity gases in the residual liquid, so that the mass percentage of dichloroethane in the rectification residual liquid is not less than 98%, and then refined dichloroethane is conveyed to a refined dichloroethane tank for storage from the tower bottom of the vacuum distillation tower through the dichloroethane pump, thereby the purpose of dichloroethane purification is finally realized. The method provided by the invention has the advantages of less equipment, simple and reasonable process, easy implementation, simple operation, easy control and very stable production, and can achieve the purposes of safe production, energy saving, consumption reduction and quality improvement.

Owner:XINJIANG TIANYE GRP

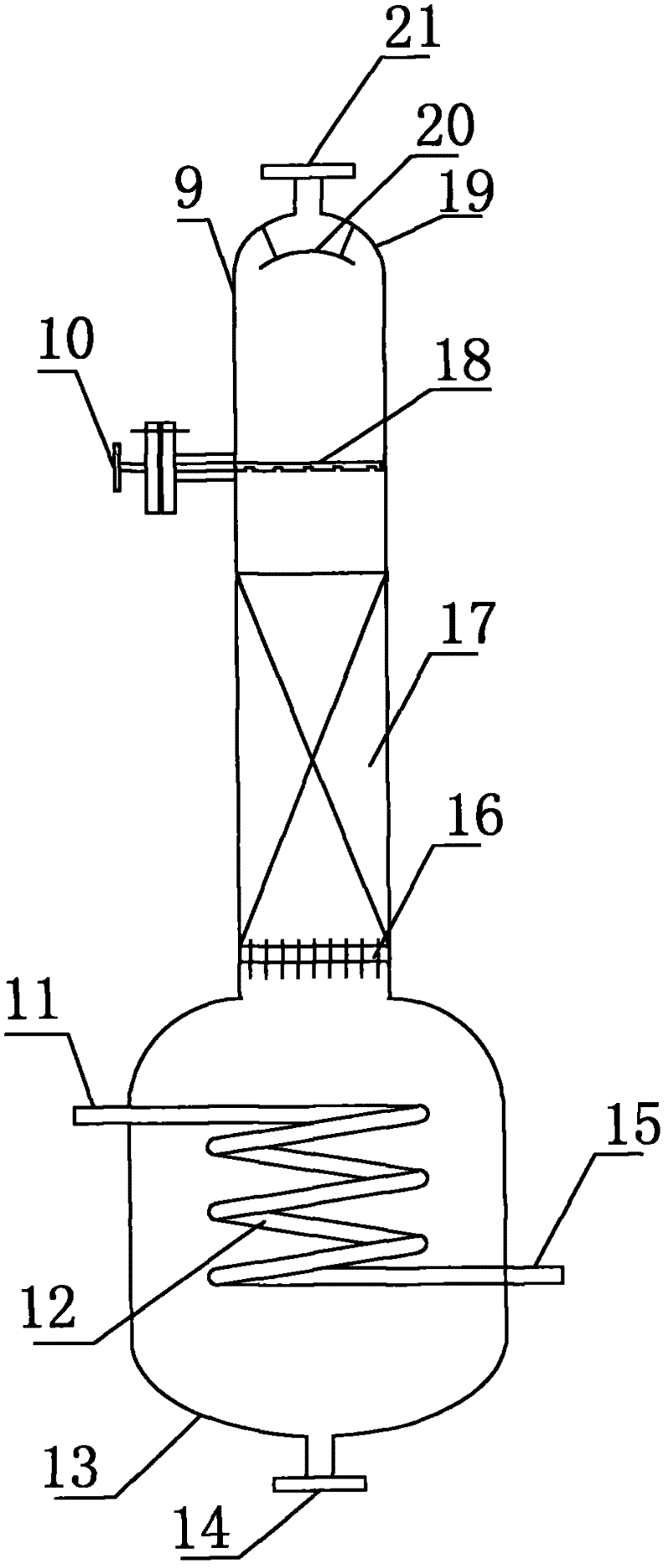

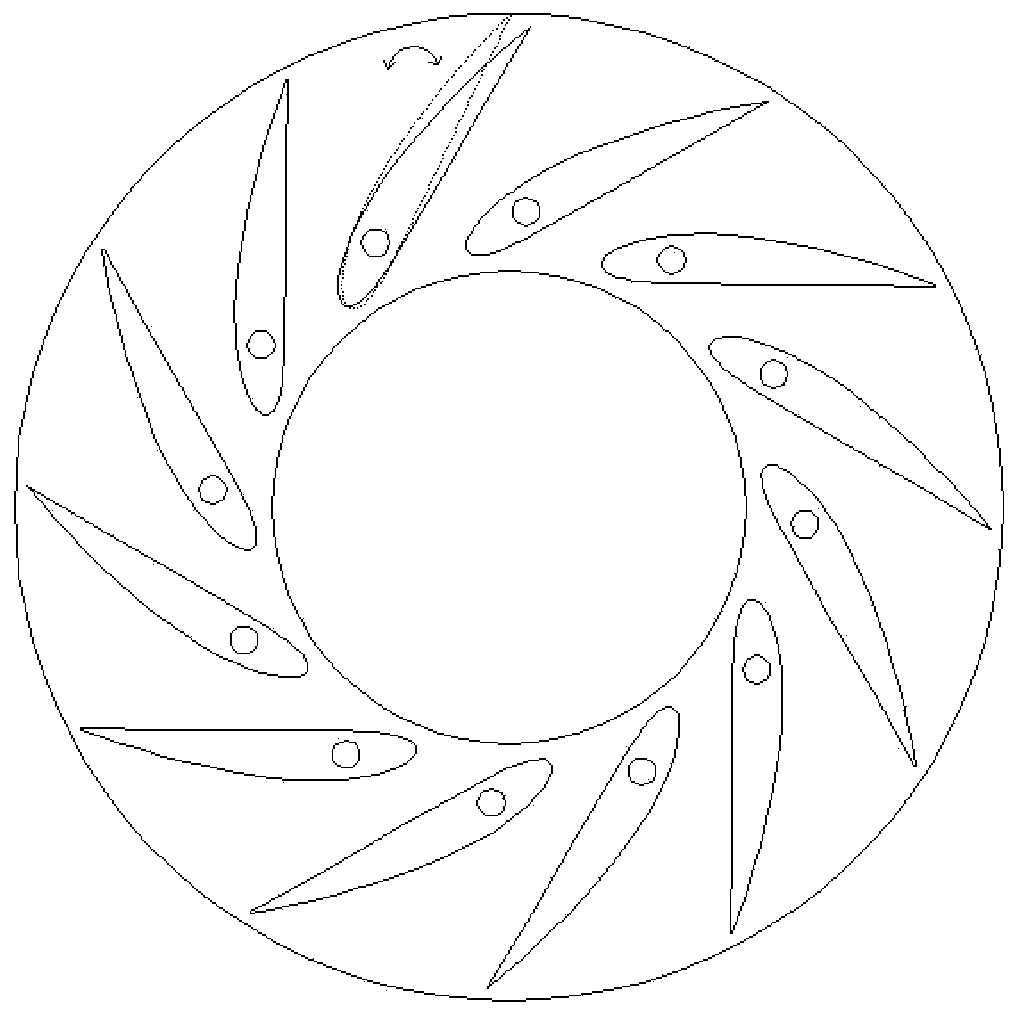

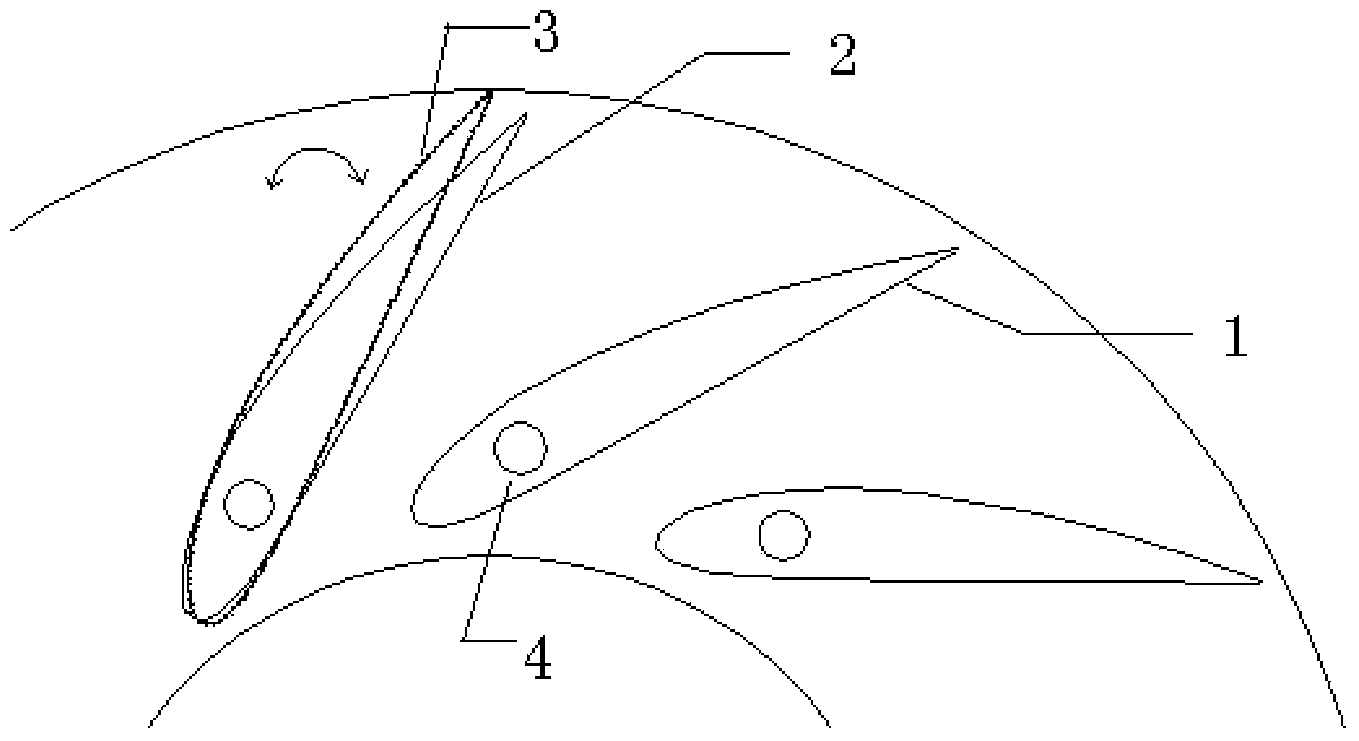

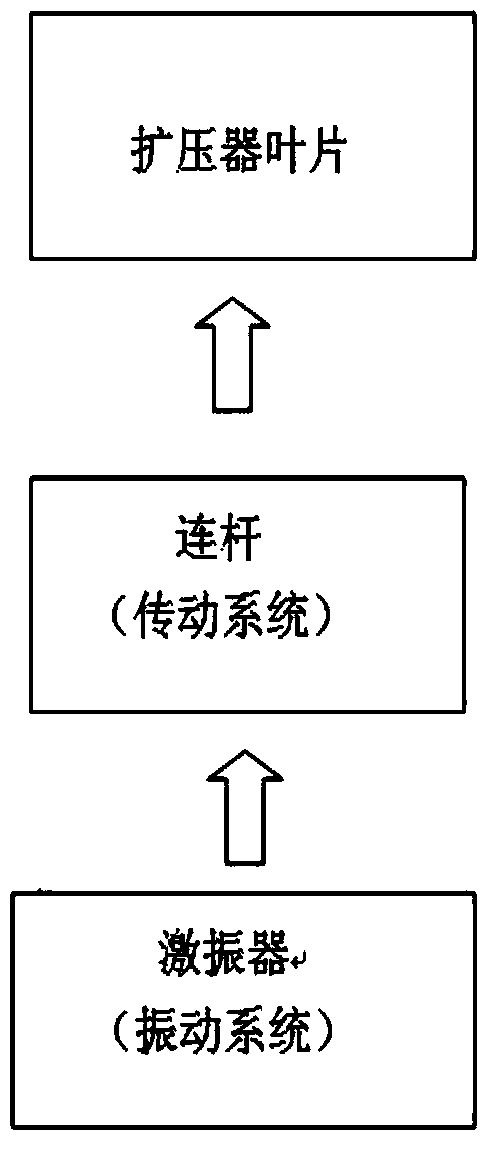

Centrifugal compressor with vibratory diffuser blade

The invention discloses a centrifugal compressor with a vibratory diffuser blade. The centrifugal compressor comprises an air incoming chamber, an impeller, a diffuser, a curve, a return flow device and a volute, the diffuser blade for diversion is arranged in the diffuser and connected with a partition through a diffuser blade rotating shaft, and a vibration exciter is connected with the diffuser blade through a transmission mechanism. When the vibration exciter works, vibration is generated and transmitted to the diffuser blade, and the diffuser blade vibrates around the diffuser blade rotating shaft and actively controls a flow field in the diffuser; or the diffuser blade is connected with an elastic element through the transmission mechanism, and when gas flows through the diffuser, the diffuser blade generates self-excited vibration to realize self-adaptive control on the flow field in the diffuser. In the constantly-changing flow field, the blade slightly vibrates around a rotating shaft, a runner is enabled to be capable of effectively adapt to flowing change, separation in flowing is reduced, energy loss is lowered, and overall performance of the diffuser is improved.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

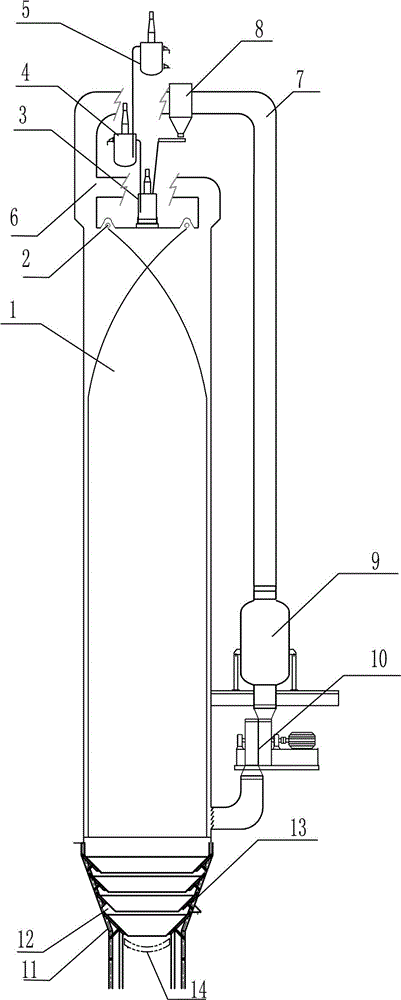

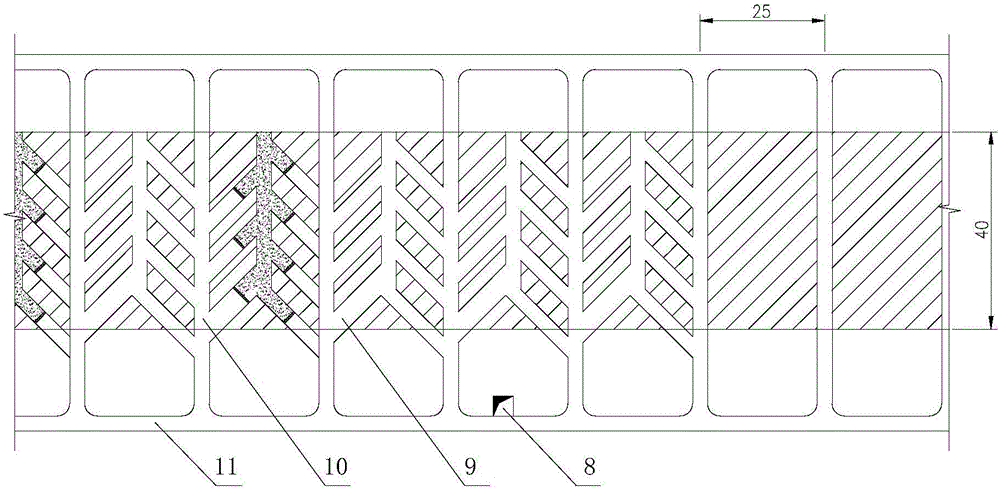

Granulating system and method thereof

ActiveCN105233756AEfficient use ofSufficient heat exchangeGranulation by liquid drop formationFertilizer mixturesPulp and paper industryTower

The invention discloses a granulating system and a method thereof, and belongs to the field of chemical fertilizer production. The granulating system comprises a tower body, a feeding device and a material receiving device, wherein the cross section of the tower body is polygonal; at least two spray heads are arranged at the periphery of the top of the tower body; the feed opening of each nozzle is communicated with a discharge opening of the feeding device; first exhaust pipes arranged at the top of the tower body wind extend out of the tower body across the top of the tower body, and are communicated with a temperature and humidity lowering device outside the tower body; the air outlet of the temperature and humidity lowering device is communicated with the air inlet of an induced draft fan; the induced draft fan is positioned at the position close to the bottom of the tower body outside the tower body; the induced draft fan is communicated with the inner cavity of the tower body; a dust remover is additionally arranged on a second exhaust pipe; a powder outlet of the dust remover is communicated with the feeding device. According to the granulating system disclosed by the invention, the height of the tower body is lowered by 20-50%; the maximum radius of the tower body is smaller than 8m; granulation is not influenced by seasons or weather; various problems which are confronted with when chemical fertilizers are produced through tower granulation can be solved, and safe and stable production of composite fertilizers is realized.

Owner:TIANJI COAL CHEM IND GROUP

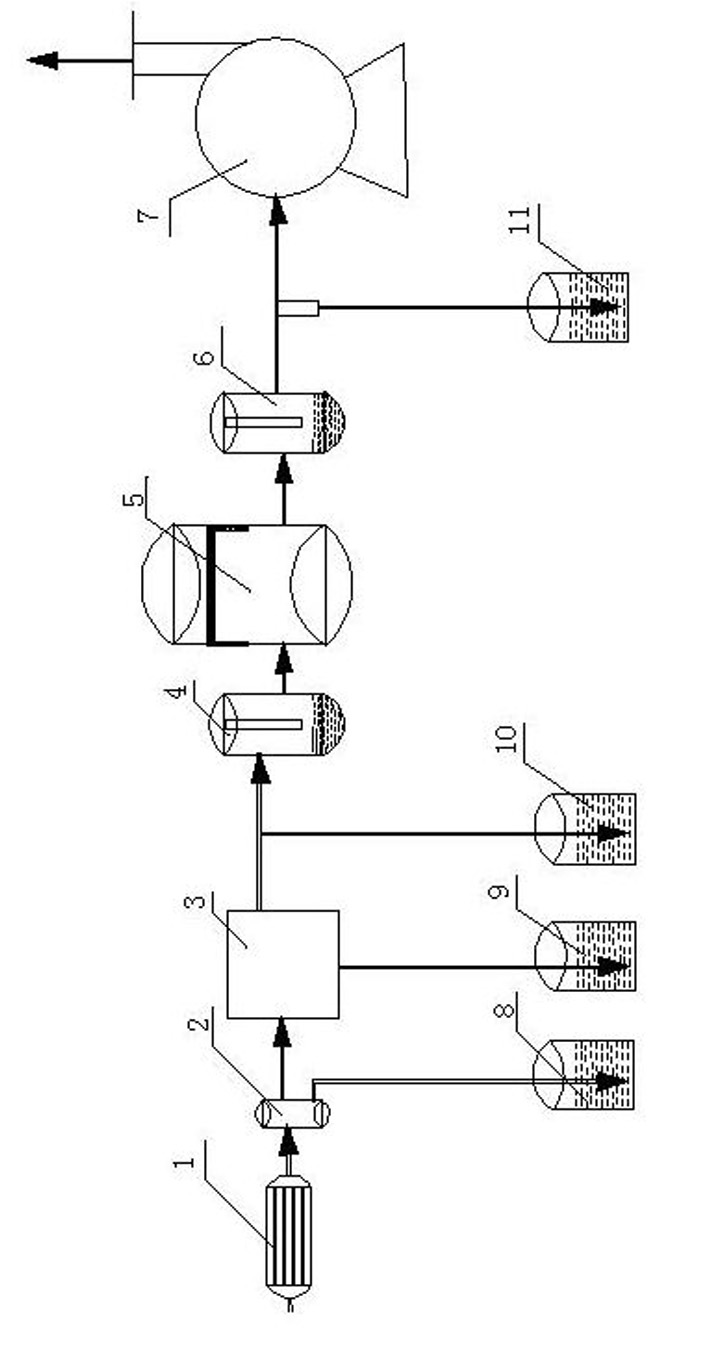

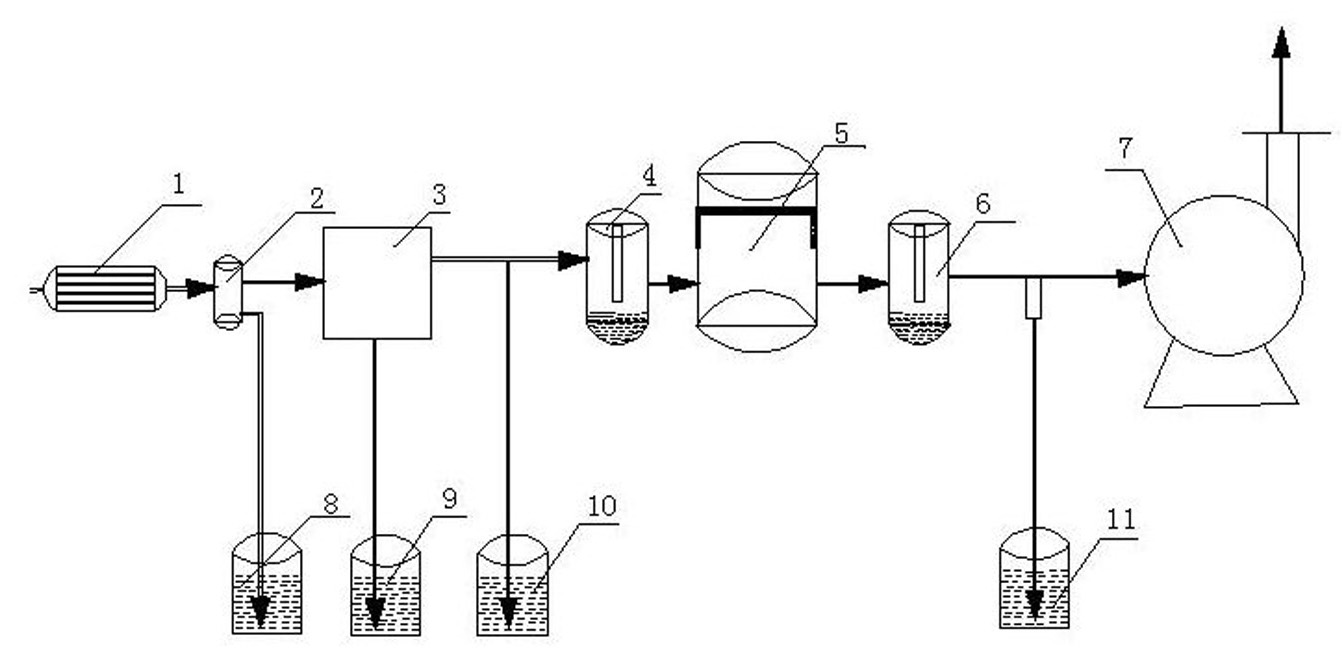

Hydrogen purification and transportation method

InactiveCN101982403AHigh purityLow maintenanceHydrogen separation using solid contactDispersed particle separationVapor–liquid separatorSodium chlorate

The invention relates to a hydrogen purification and transportation method which comprises the following steps: 1. a gas mixture containing water vapor and hydrogen from the upstream industrial production of sodium chlorate firstly enters a cooler, the gas mixture is cooled, the cooled synthetic gas enters a gas-liquid separator, the condensed water vapor is separated from the gas mixture, and the condensation water is discharged into a water seal; 2. the dewatered gas mixture obtained in step 1 enters an active carbon adsorption plant; and 3. the gas processed in step 2 is sent into a dry gas-holder to be stored, and the gas in the dry gas-holder is compressed by a compressor and then sent to the outside.

Owner:湖南双阳高科化工有限公司

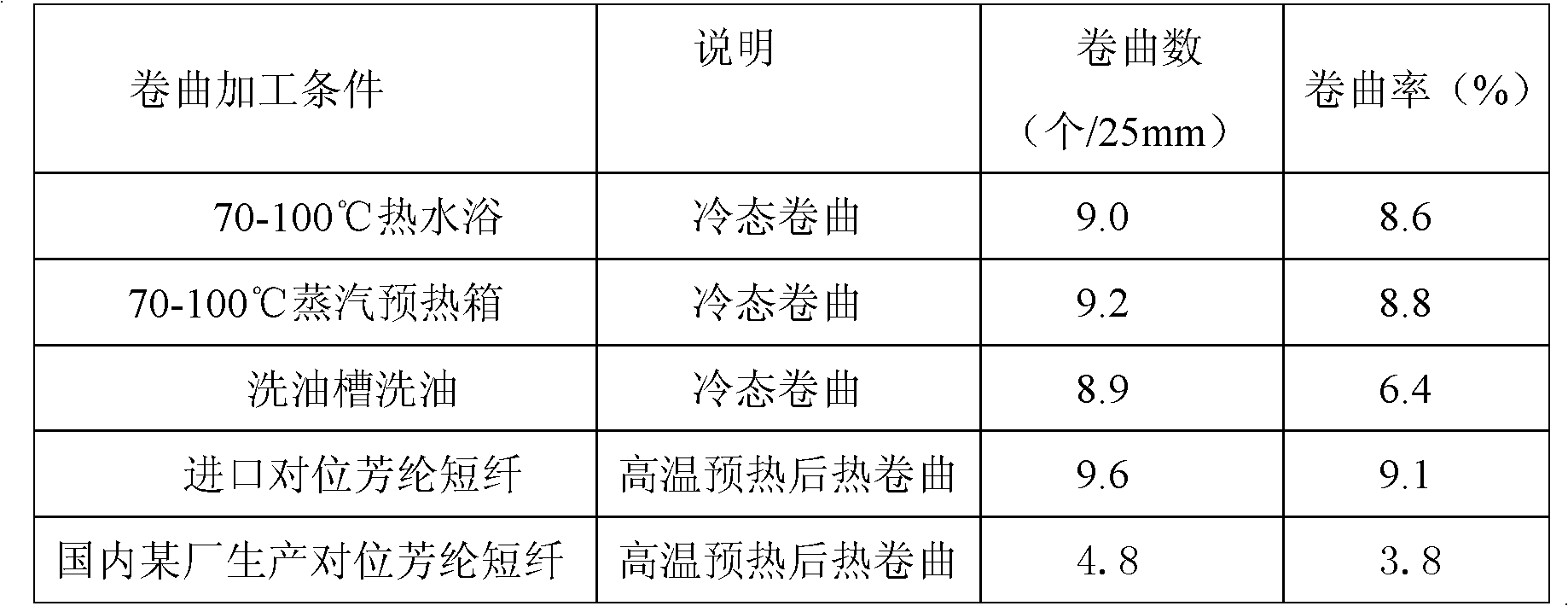

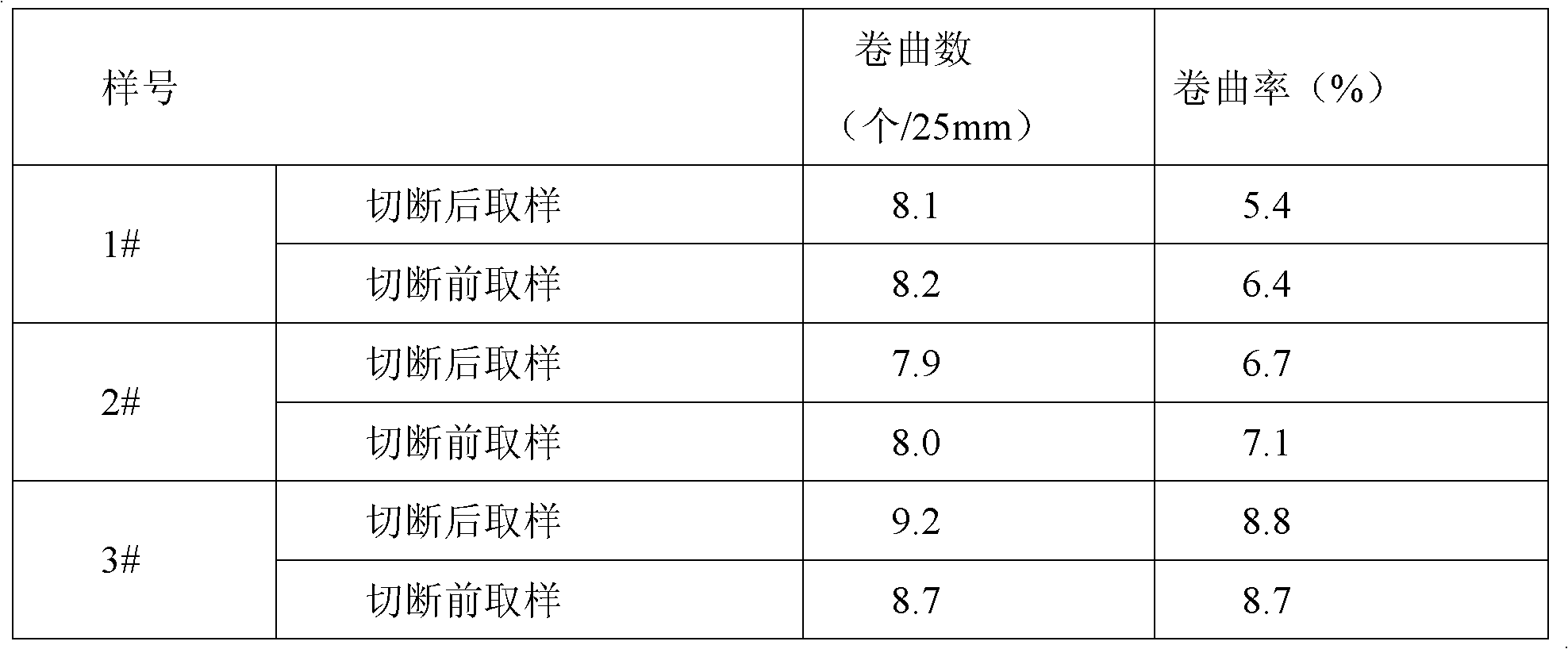

Method for curling para-position aramid short fibers

The invention discloses a cold-state curling method for producing para-position aramid short fibers. The method comprises the following steps of: bunching aramid filaments, washing by the oil washing of an oil washing tank or hot water bath or a low-pressure steam heat box, and curling the softened aramid filaments in a mechanical stuffing curling box; after curling the aramid filaments, drying the curled fibers in a drying oven at the temperature of between 80 and 140 DEG C; and performing tensioning, and cutting the fibers off in a cut-off machine to obtain the para-position aramid short fibers with high curling performance. According to the method, before entering the curling box, the fibers are not needed to be subjected to high-temperature preheating treatment at the temperature which is higher than the glass transition temperature of 340 DEG C of the fibers so as to soften molecular chain segments, the fibers are not needed to be heated at high temperature in the curling box, and the curled fibers are not needed to be subjected to high-temperature setting of about 340 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

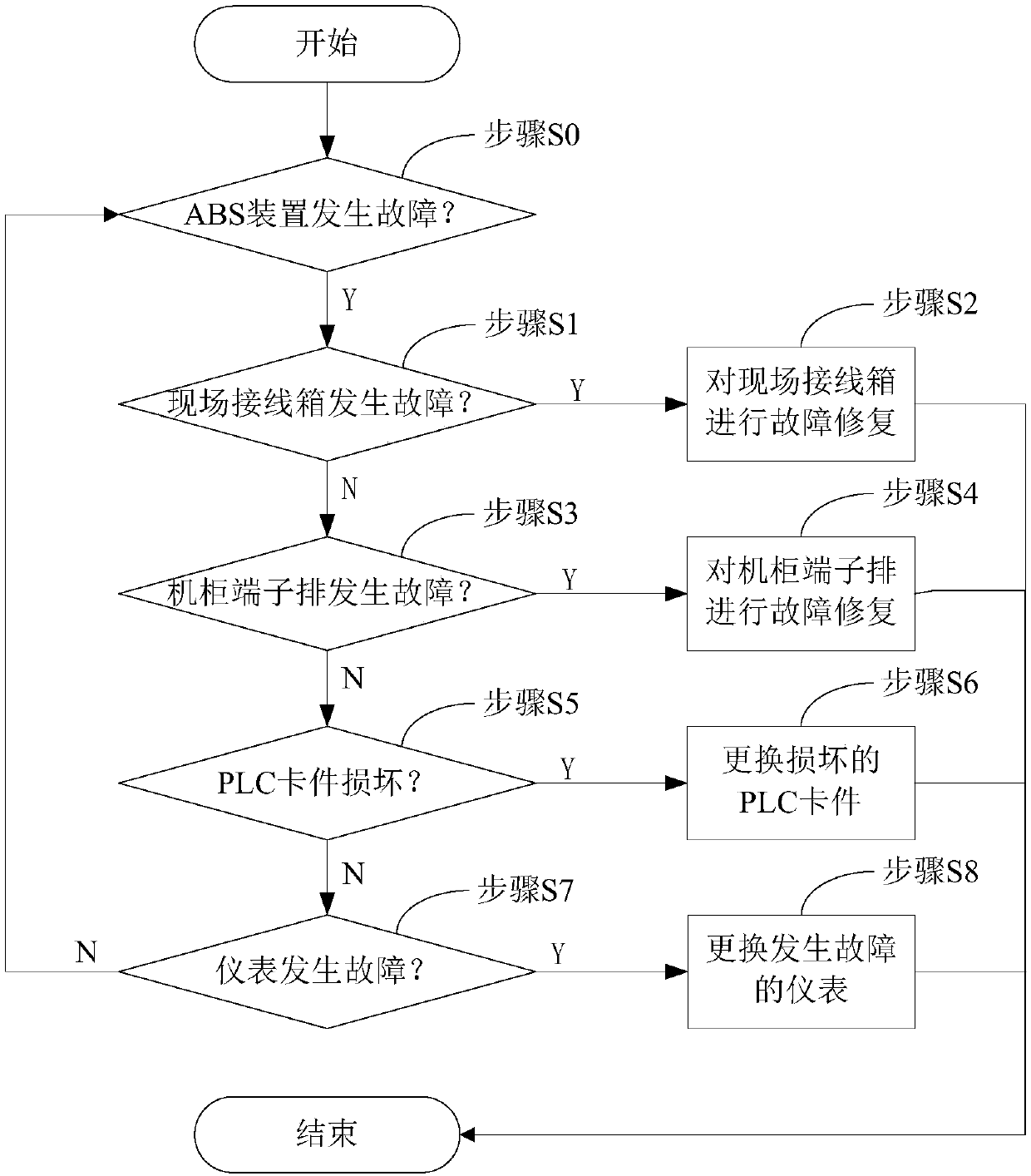

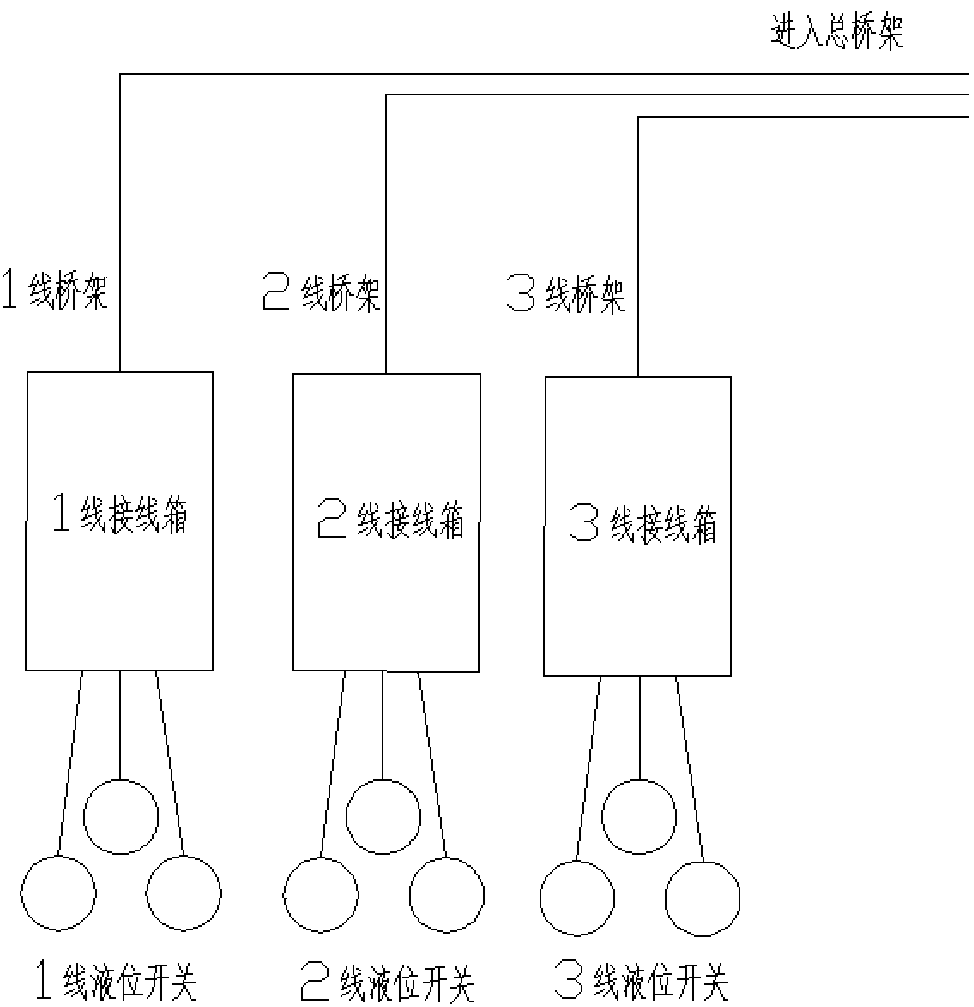

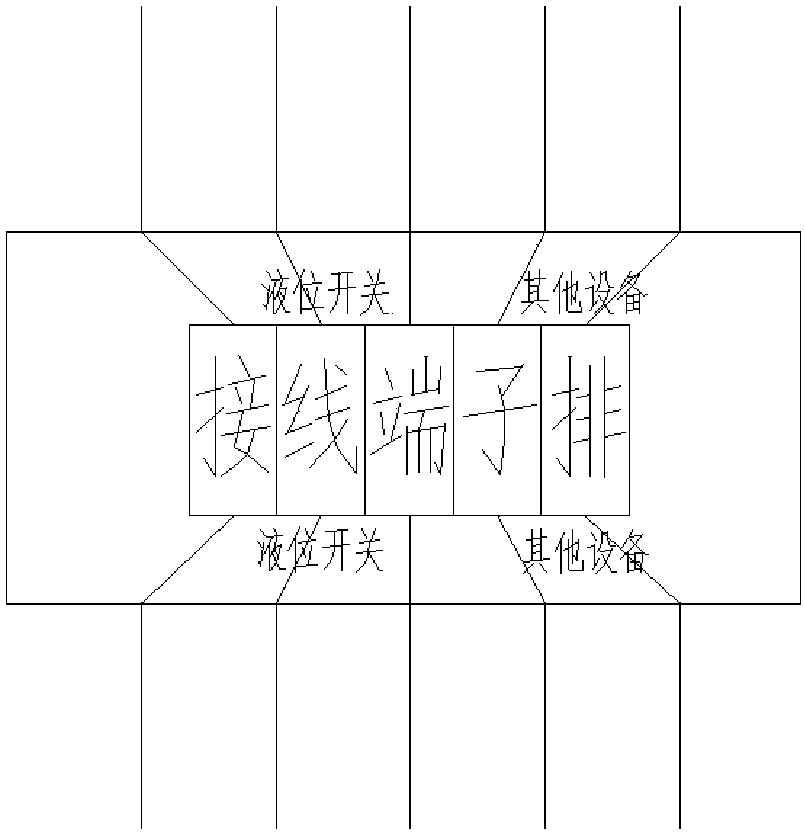

Instrument fault elimination method used for ABS composite material production device

InactiveCN107831754AEliminate Meter FailuresProduction safety and stabilityElectric testing/monitoringElimination methodReliability engineering

An instrument fault elimination method used for an ABS composite material production device comprises the steps of checking whether an on-site junction box in which an instrument accesses goes wrong,if yes, repairing the fault of the on-site junction box, if not, checking whether a cabinet terminal line in which the instrument accesses goes wrong, if yes, repairing the fault of the cabinet terminal line, if not, checking whether a PLC fastening member in which the instrument accesses goes wrong, if yes, replacing the damaged PLC fastening member, if not, orderly checking whether all instruments go wrong, and replacing the faulted instruments. The instrument fault elimination method of the present invention can effectively eliminate the instrument faults of the ABS composite material production device, guarantees that a vacuum system is located in a redundant state, and guarantees the safe and stable production of the ABS composite material production device.

Owner:SHANGHAI GAOQIAO SGPEC PETROCHEM ENG & CONSTR

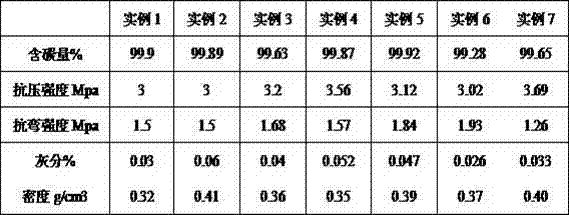

Production method of insulation materials used for crystal pulling furnace

InactiveCN103193495AThe production process is safe and stableReduce manufacturing costCarbon fiber compositeAdhesive

The invention provides a production method of insulation materials used for a crystal pulling furnace. The method comprises: selecting carbonized or graphitized carbon fiber composite, immersing the carbon fiber composite or coating the surface of the carbon fiber composite for 1-3 times with organic composite resin, drying for later use; curing, coating a hole sealing agent on the surface of the carbon fiber composite, drying for later use; selecting carbonized or graphitized carbon fibrofelt, immersing the carbon fibrofelt or coating surfaces of the carbon fibrofelt with the organic composite resin, drying for later use; respectively coating an adhesive on surfaces of the treated carbon fiber composite and the carbon fibrofelt, winding and fitting the two materials, fixing by using a mold, curing; sending the product into a high temperature furnace for carbonization and graphitization, performing surface treatment, sending into a purifying furnace, purifying in inert gas and chlorine, and taking out to obtain the finish product. The method solves problems of difficultly controlled production technology and poor quality of finished products in prior art.

Owner:LIAOYANG JINGU CARBON FIBER SCI TECH CO LTD

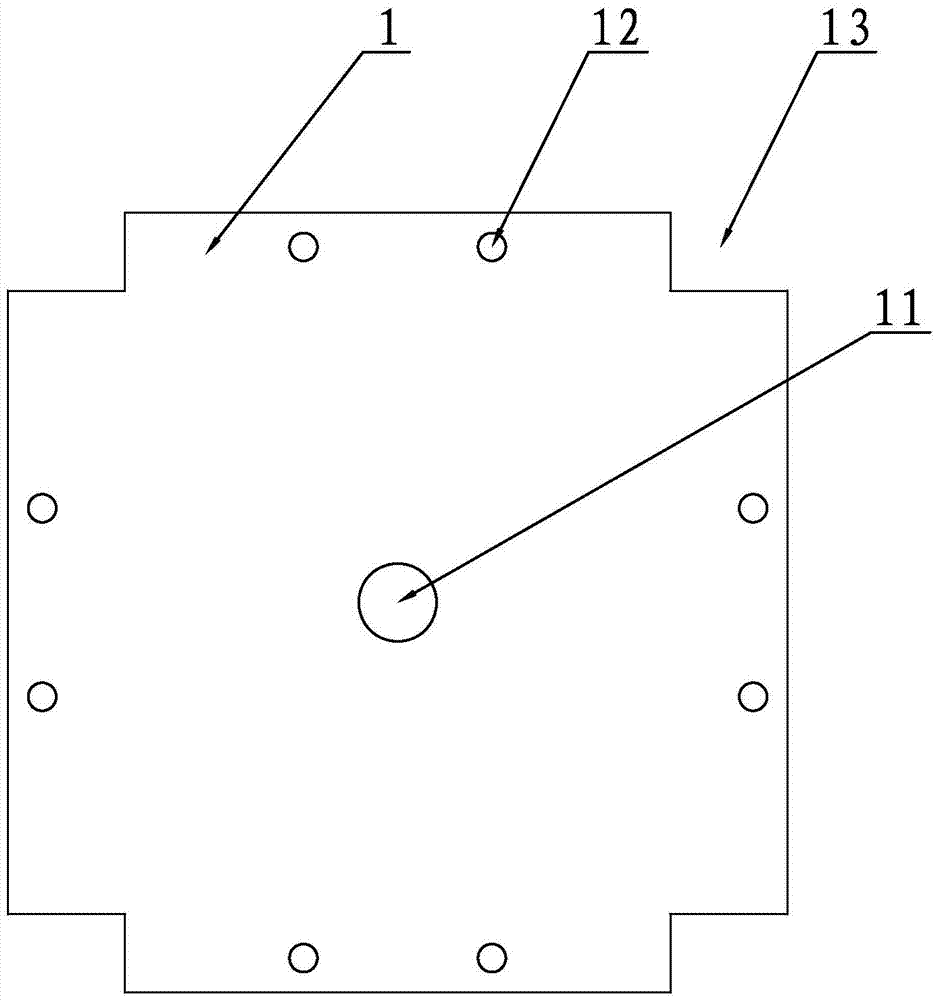

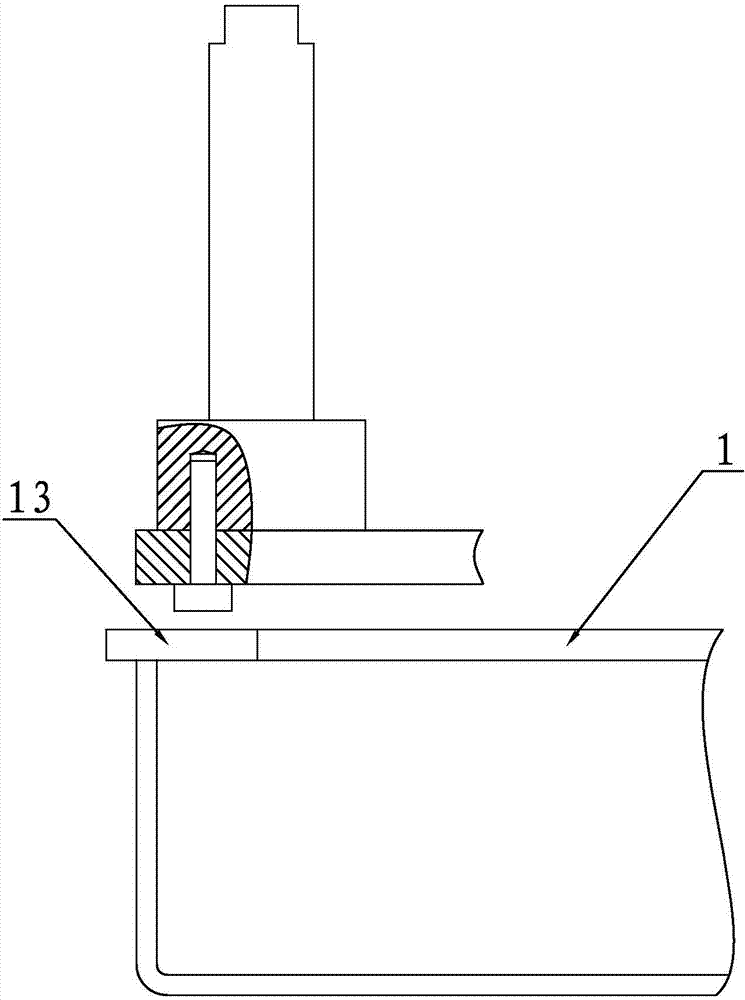

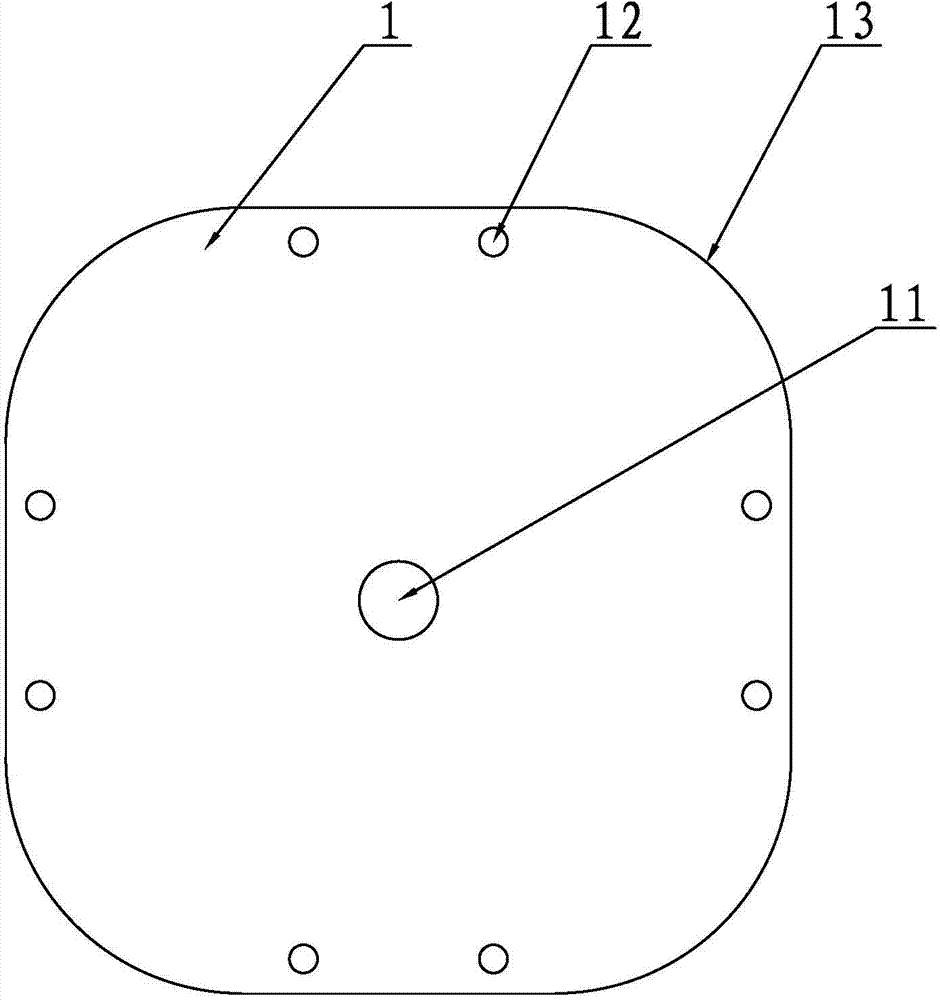

Polycrystalline ingot casting anti-arcing furnace crucible cover plate and use method thereof

InactiveCN104711672AExtended use timeGuarantee normal productionPolycrystalline material growthSingle crystal growth detailsCrucibleIngot casting

A polycrystalline ingot casting anti-arcing furnace crucible cover plate comprises a square cover plate body, the square cover plate body is provided with a center hole and a vent hole, the center hole is arranged in the center of the square cover plate body, and four corners of the square cover plate body are provided with avoiding gaps. The avoiding gaps can be square, right angled isosceles triangular or right angle sectored in shape. The part of the four corners upward warping due to deformation, in contact with a top graphite heating plate, is cut off to form the gaps, so the contact of the crucible cover plate with a bolt on the top graphite heating plat due to bending deformation is avoided, an arching sparking phenomenon is avoided, and damages of arcing to an ingot casting furnace heating element are avoided. The cover plate disclosed in the invention has 3-6 month longer life, discarding of a graphite heater and the graphite bolt due to sparkling is avoided, and the safe stable production of an ingot casting furnace is guaranteed.

Owner:JIANGSU ZHAOJING PHOTOELECTRIC TECH DEV

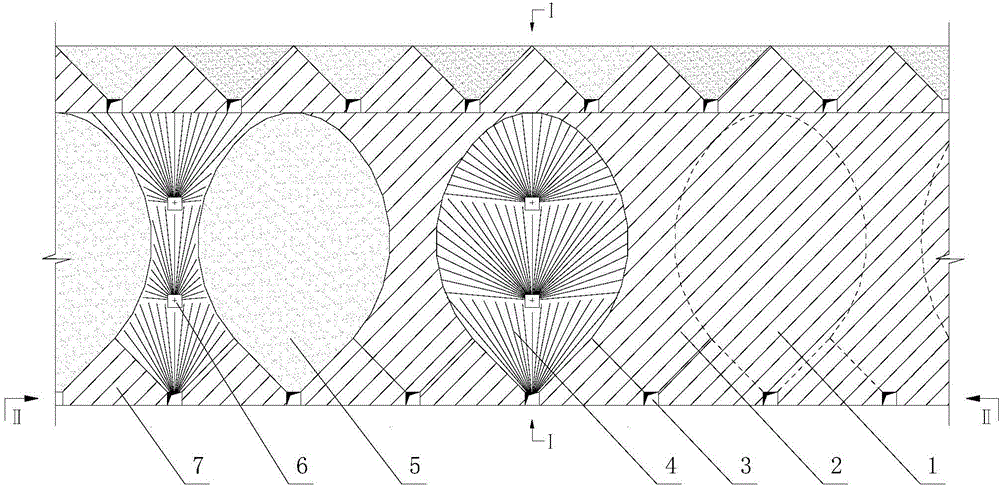

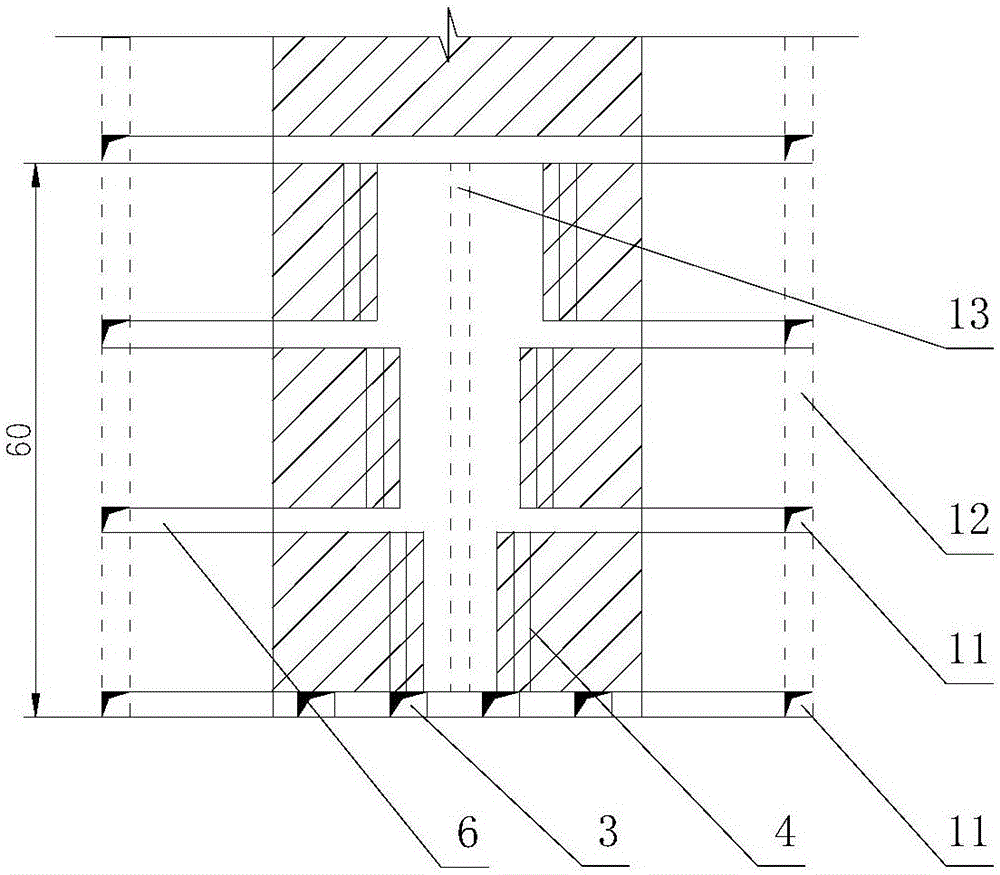

Deep part high-stress environment self-stabilizing arched stope arrangement mining method

ActiveCN106640080ASolve problems such as poor mining safetyImprove stope stabilityUnderground miningSurface miningHigh stressComputer science

The invention discloses a deep part high-stress environment self-stabilizing arched stope arrangement mining method, which comprises the following steps of (1) ore block arrangement; (2) mining-cutting engineering; (3) stopping; (4) ventilation; (5) ore removal work; (6) filling work; (7) self-stabilizing arched ore pillar stopping. The method provided by the invention belongs to the deep part high-stress environment self-stabilizing arched stope arrangement mining method capable of effectively improving the stope stability and providing the effective safety guarantee for the deep part high-stress ore deposit safe exploitation.

Owner:CENT SOUTH UNIV

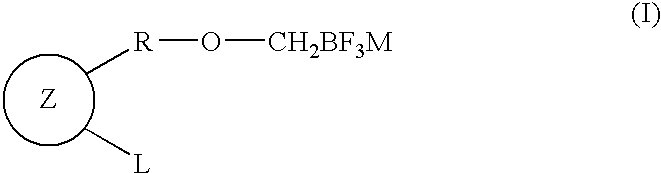

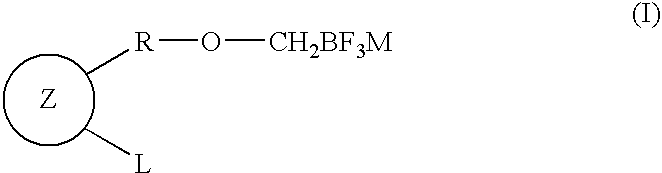

Fluoroboron compound having aromatic ring or salt thereof, and method for producing compound having cyclic ether-fused aromatic ring using the same

InactiveUS20100056788A1Easy to handleImprove securityGroup 3/13 element organic compoundsPhosphorus organic compoundsHalogenCyclic ether

Provided is a fluoroboron compound which is highly safe and stable and is capable of forming a cyclic ether-fused ring by the intramolecular alkoxymethylation reaction, or a salt thereof. The compound can be synthesized by the intramolecular alkoxymethylation reaction of a fluoroboron compound represented by the formula (I) or a salt thereof in the presence of a metal catalyst.(wherein the moiety represented by the formularepresents an aromatic ring; L represents a substituent such as a halogen atom; R represents a substituted or unsubstituted alkylene group having 1 or 2 carbon atoms; and M represents an alkali metal cation or the like, with the proviso that L and —R—OCH2BF3M are respectively located on contiguous carbon atoms on the aromatic ring, or in the case of a fused aromatic ring, on two carbon atoms adjacent to one carbon at the fused position).

Owner:EISIA R&D MANAGEMENT CO LTD

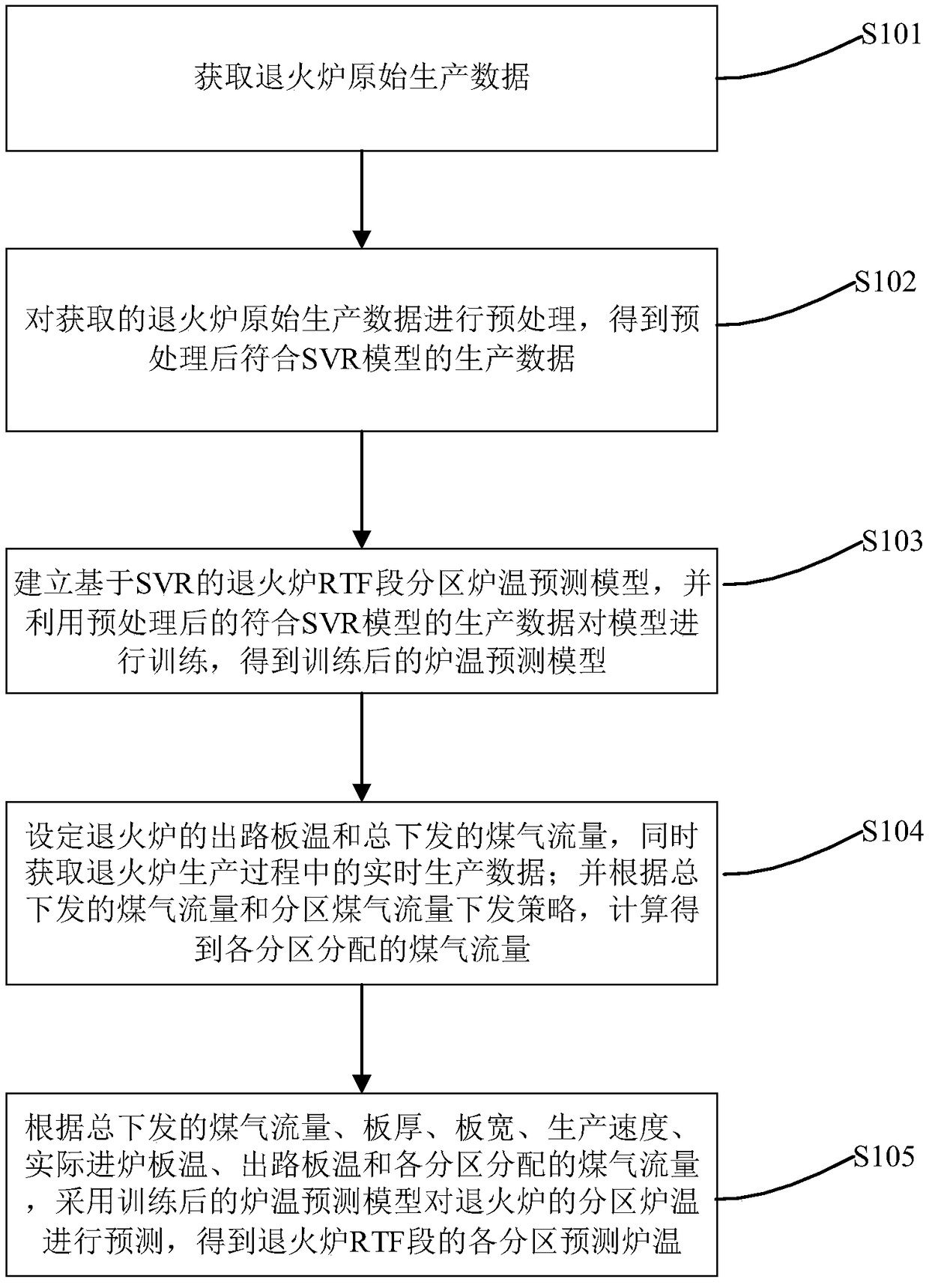

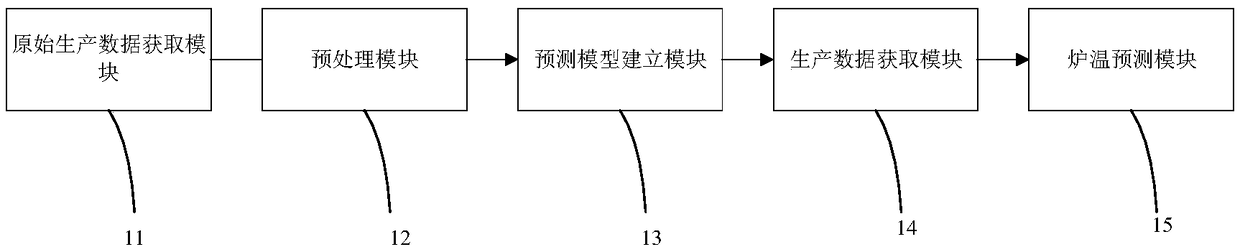

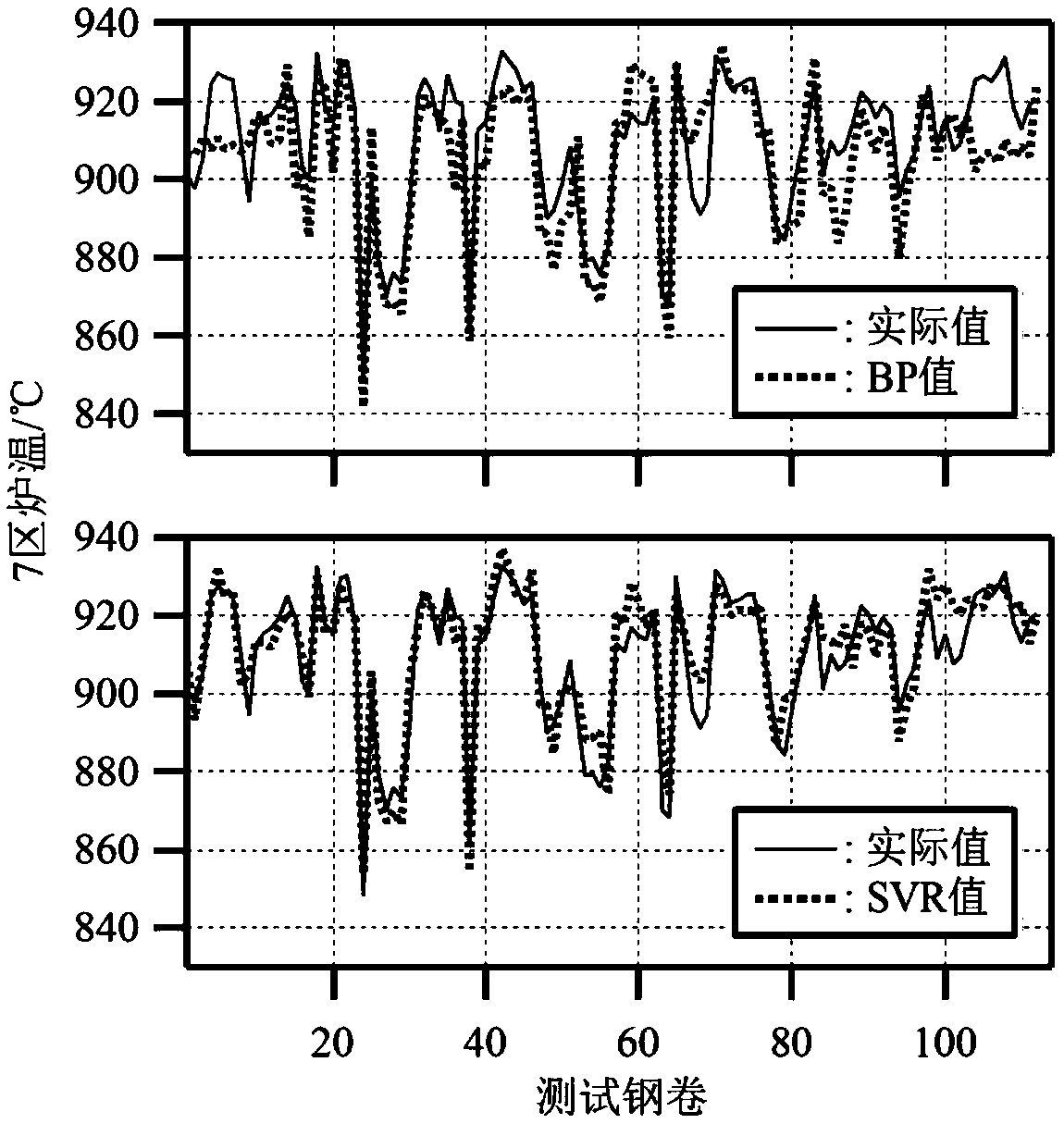

Annealing furnace temperature prediction method and system

ActiveCN109492335AGood predictive guidanceEffective control basisFurnace typesDesign optimisation/simulationFurnace temperatureTemperature control

The invention provides an annealing furnace temperature prediction method and system. The method comprises the steps that the method is adopted; Firstly, an SVR-based annealing furnace temperature prediction model is established; and then training the established model by adopting a ten-fold cross validation method of a neural network and the collected original production data, and finally settingactual production parameters and predicting the furnace temperature of the annealing furnace by utilizing the trained furnace temperature prediction model in combination with the field production data collected in real time. The method has the beneficial effects that a good prediction and guidance effect can be achieved on the actual production of the annealing furnace, an effective control basisis provided for annealing furnace plate temperature control, the steel coil over-temperature alarm proportion in the annealing furnace production process is reduced, the production environment is improved, and the production process is safe and stable.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

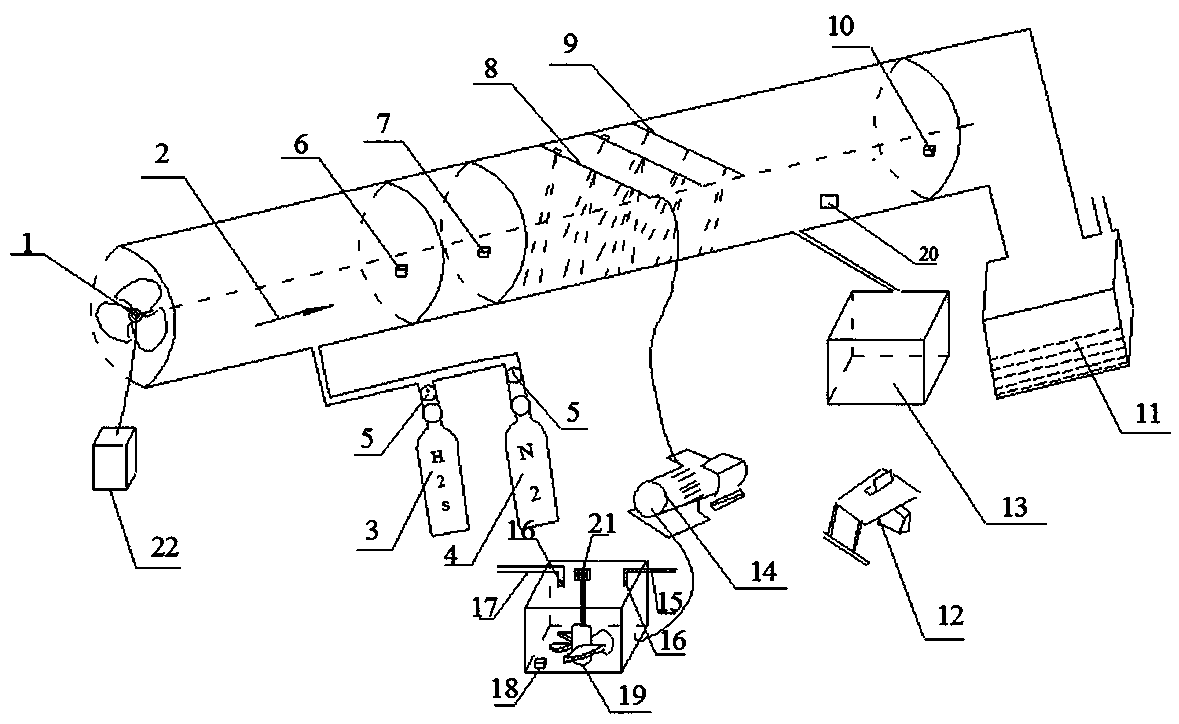

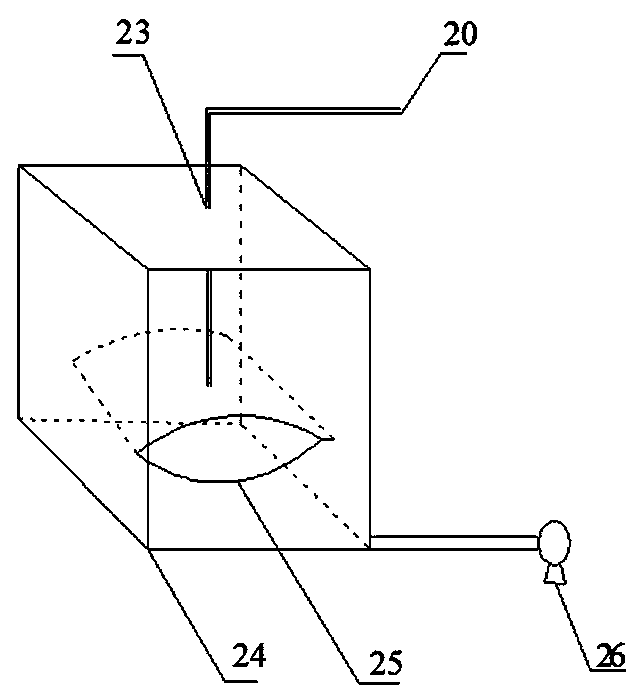

Simulation device for removing hydrogen sulfide from roadway airflow

InactiveCN108970377AAnalog stabilizationHigh simulationDispersed particle separationGas cylinderSpray nozzle

The invention belongs to the technical field of mine production equipment, and particularly relates to a simulation device for removing hydrogen sulfide from roadway airflow. The simulation device comprises a simulated roadway, an air generating device, a hydrogen sulfide generating device, a spraying device and a sampling hole, wherein the air generating device is arranged at a starting port of the simulated roadway, the hydrogen sulfide generating device is connected to the air generating device, the spraying device is arranged in the middle of the simulated roadway, and the middle or the tail end of the simulated roadway is provided with the sampling hole; the simulated roadway is long-cylinder-shaped; the air generating device is a fan at the air inlet position of the starting port ofthe simulated roadway; the hydrogen sulfide generating device comprises a hydrogen sulfide gas bottle and a nitrogen gas bottle which are each provided with a valve and are connected in parallel; thespraying device comprises a plurality of rows of spraying pipes which are arranged above the middle part of the simulated roadway; a plurality of nozzles are arranged on the spraying pipes; the sampling device is a sealed box body; a sampling bag which can be taken out is arranged in the box body; and the box body is connected with a vacuum pump. According to the simulation device, the problem ofthe hydrogen sulfide contained in the roadway airflow in the mine construction can be better simulated and can be better guided, and therefore a foundation is laid for safe and stable production.

Owner:HENAN POLYTECHNIC UNIV

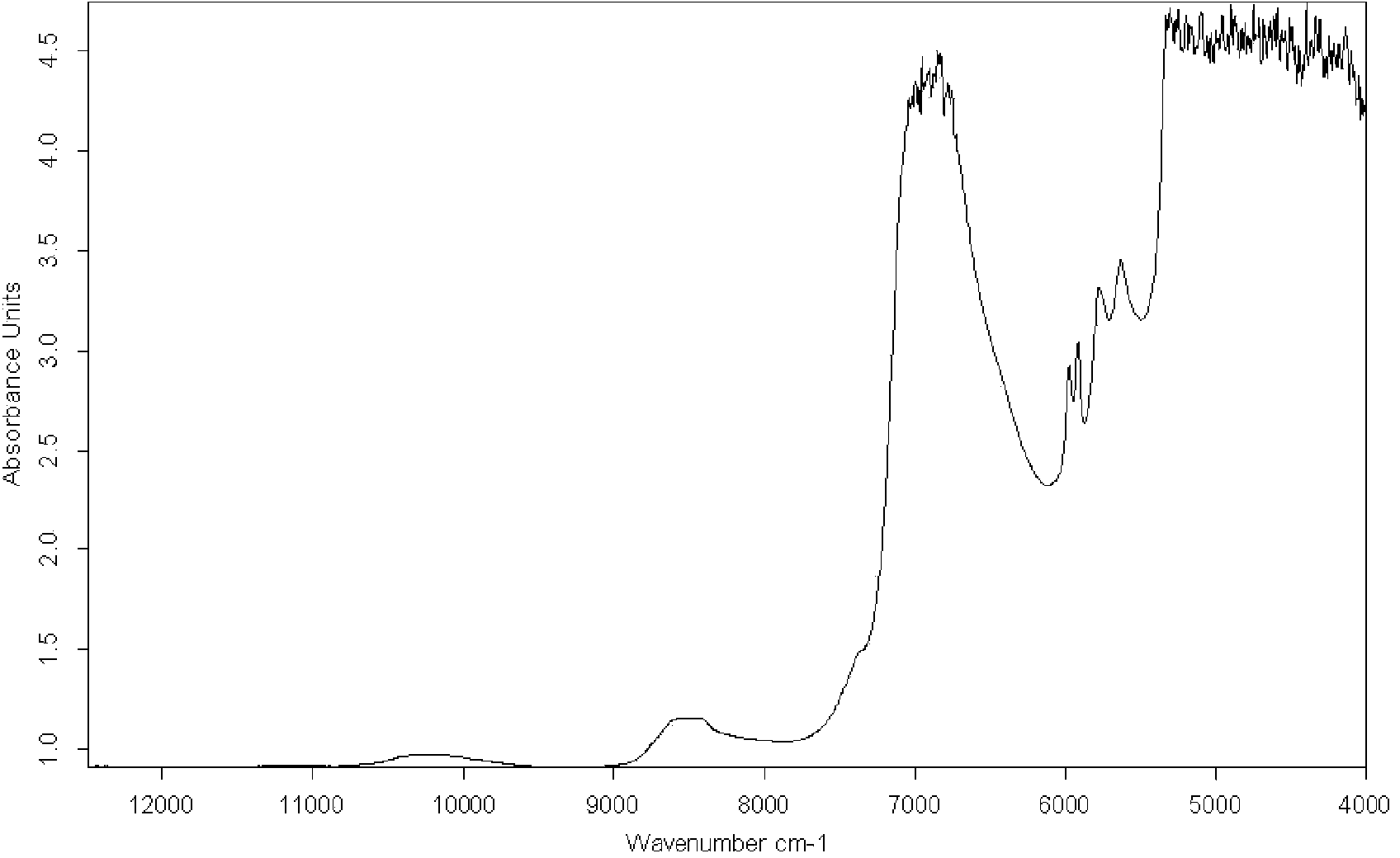

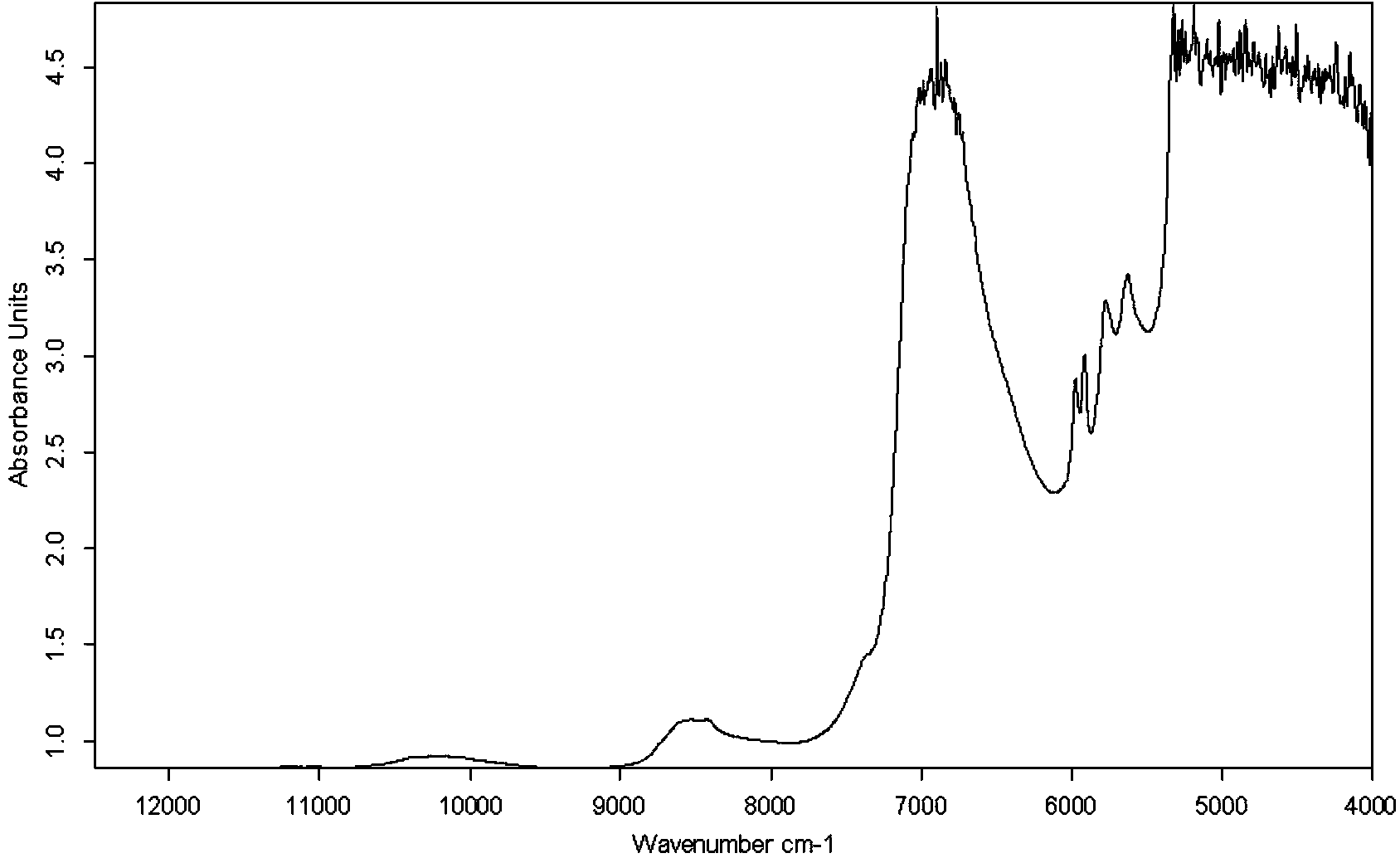

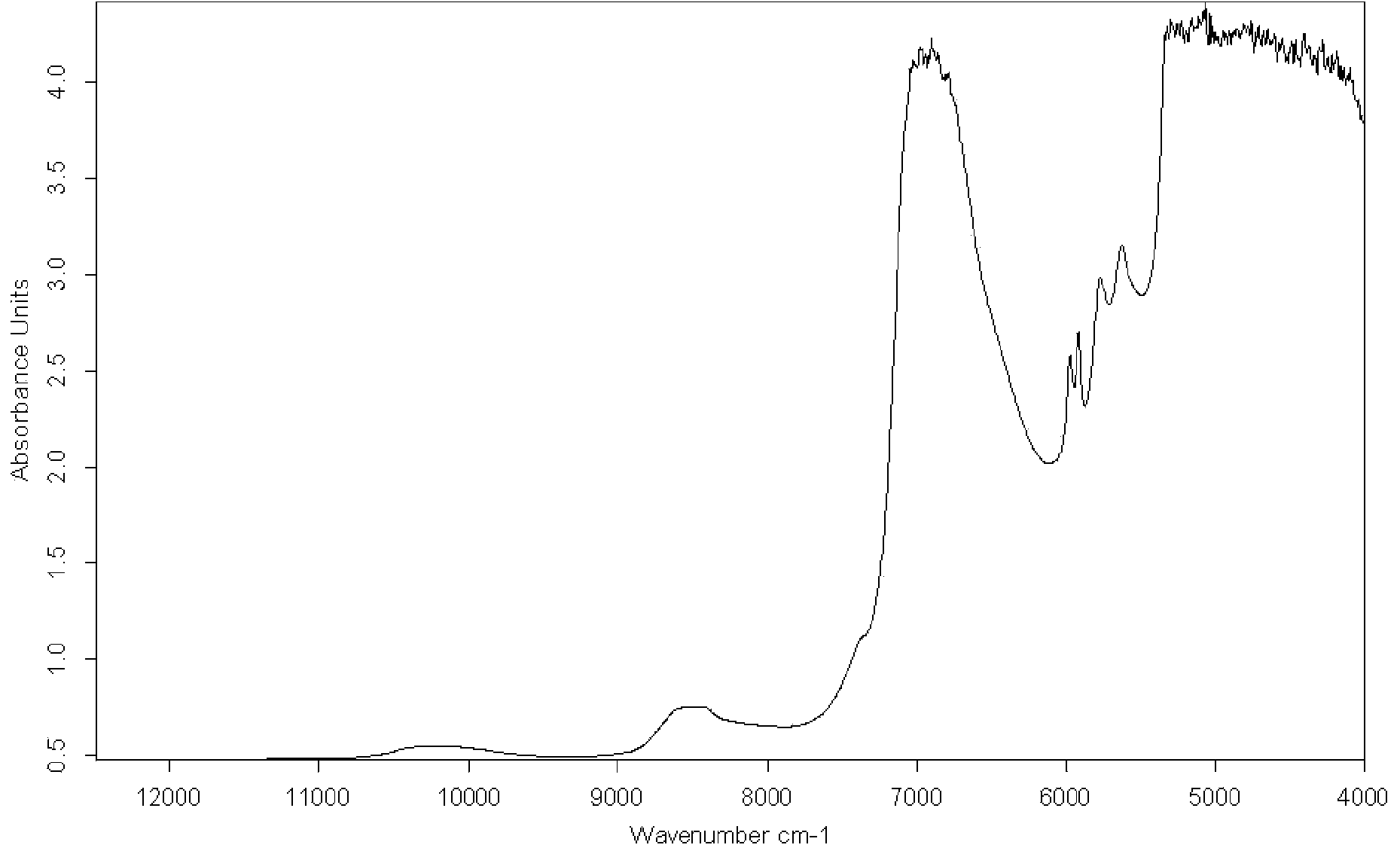

Online detection method of crystal-transformation reaction endpoint in production process of cyclotetramethylene tetranitramine

InactiveCN103411917AGuaranteed qualityOvercoming time lagColor/spectral properties measurementsCrystal transformationTime delays

The invention belongs to the field of explosives and provides an online detection method of a crystal-transformation reaction endpoint in a production process of cyclotetramethylene tetranitramine. The online detection method comprises the following steps of: acquisition of a near infrared spectrum of a sample, selection of an optimal modeling interval, pretreatment of an original spectrum, and establishment of a model by adopting main-component analysis and online detection of the crystal-transformation reaction endpoint. The online detection method provided by the invention has the advantages that a near infrared technology is used for determining the crystal-transformation reaction endpoint in the production process of the cyclotetramethylene tetranitramine, online determination of the endpoint of an energetic material in the synthesis process is realized, field detection and monitoring of the energetic material in the synthesis process are realized, the quality of a product is ensured, the defect of time delay in the existing detection method of the crystal-transformation reaction endpoint in the production process of the cyclotetramethylene tetranitramine is overcome, the online control for the crystal-transformation reaction process is realized, the safety and the stability of the production process are achieved, and the online detection method is very important for the quality control in the synthesis process of the energetic material.

Owner:XIAN MODERN CHEM RES INST

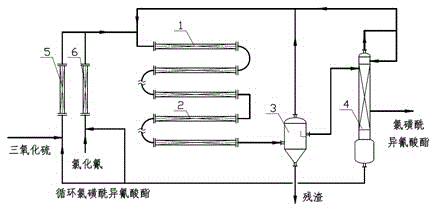

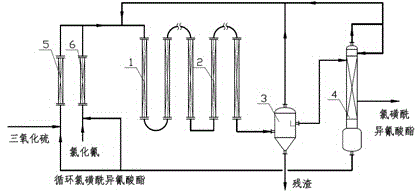

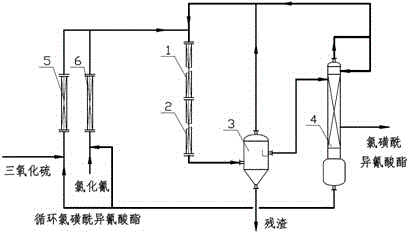

Method for producing chlorosulfonyl isocyanate by taking cyanogen chloride and sulfur trioxide as raw materials

InactiveCN104447438AUniform and controllable residence timeEnhanced mass transferOrganic compound preparationSulfonic acid amide preparationCyanogen halideImpurity

The invention relates to a method for producing chlorosulfonyl isocyanate by taking cyanogen chloride and sulfur trioxide as raw materials, belonging to the methods for producing chlorosulfonyl isocyanate. The method comprises the following steps: feeding the raw materials into a tubular reactor at a theoretical molar ratio, enabling the raw materials to react continuously in the tubular reactor, feeding the by-products of reaction into a tubular thermal decomposition reactor of by-products, continuously converting the by-products of reaction to the desired product, separating the crude product, and purifying to obtain the high-purity chlorosulfonyl isocyanate. The method provided by the invention can realize the production of the chlorosulfonyl isocyanate through continuous reaction in the tubular reactor, and the method has the advantages of low investment in devices, high production efficiency and strong production capacity. The advanced production process is adopted to produce the chlorosulfonyl isocyanate, a few by-products are generated during reaction in the tubular reactor, and the by-products can be completely converted into the target product through thermal decomposition reaction. No by-product is sent out of the bound in addition to the impurities involved into the raw materials in the production process, the utilization rate of the raw materials is high, the product has high quality, the production process is stable, and the method is easy to operate and has large operating flexibility.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com