Method for producing chlorosulfonyl isocyanate by taking cyanogen chloride and sulfur trioxide as raw materials

A chlorosulfonyl isocyanate, sulfur trioxide technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of sulfonic acid amides, etc. Filler blockage and other problems, to achieve the effect of safe and stable production process, uniform and controllable residence time, and thorough reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

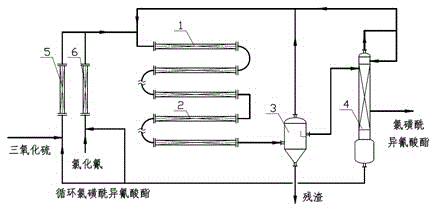

[0034] The production method of chlorosulfonyl isocyanate is prepared by tubular reaction, and the raw materials used in the production process are cyanogen chloride and sulfur trioxide. The production equipment used includes cyanogen chloride dispersive dilution tubes and sulfur trioxide dispersive dilution tubes, tubular reactors and tubular by-product thermal decomposition reactors, crude product separation devices, purification and separation towers, connecting pipelines, metering and control instruments and appendix. Among them, the cyanogen chloride dispersion dilution pipe and the sulfur trioxide dilution pipe are equipped with chemical fillers, the tubular reactor and the tubular thermal decomposition reactor are multiple commercially available static mixers with jackets connected in series through connecting pipes, and the crude product separation device is simultaneously It has the functions of flash evaporation and sedimentation, and the purification and separat...

Embodiment 2

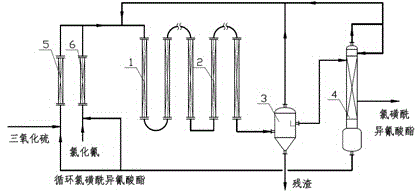

[0036] Embodiment 2 is the same as Embodiment 1, except that the cyanogen chloride dispersing dilution tube, the sulfur trioxide dispersing mixing tube, the tubular reactor, and the tubular by-product thermal decomposition reactor are filled with fillers in the tube, and the material In the tubular reactor, the tubular by-product pyrolysis reactor flows downwards and upwards.

Embodiment 3

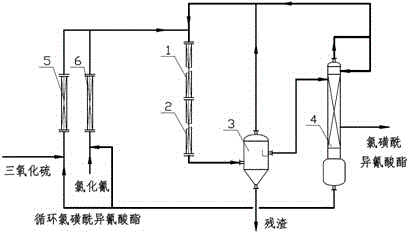

[0038] Embodiment 3 is basically the same as Embodiment 1, the difference is that the tubular reactor and the tubular by-product thermal decomposition reactor are vertically arranged, and the material is unidirectionally downward in the tubular reactor and the tubular by-product thermal decomposition reactor flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com