A method of falling film melt polycondensation reaction between rows of tubes for preparing high-viscosity melt and its reactor

A technology of melt polycondensation and reactor, which is applied in the field of falling film melt polycondensation reaction between rows of tubes for preparing high-viscosity melt and its reactor, which can solve the problem of increased film-forming area and surface renewal frequency and difficulties in the application of high-viscosity materials , complex built-in structure and other problems, to achieve the effect of simple and feasible reaction method, uniform and controllable residence time, and large flow film forming area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

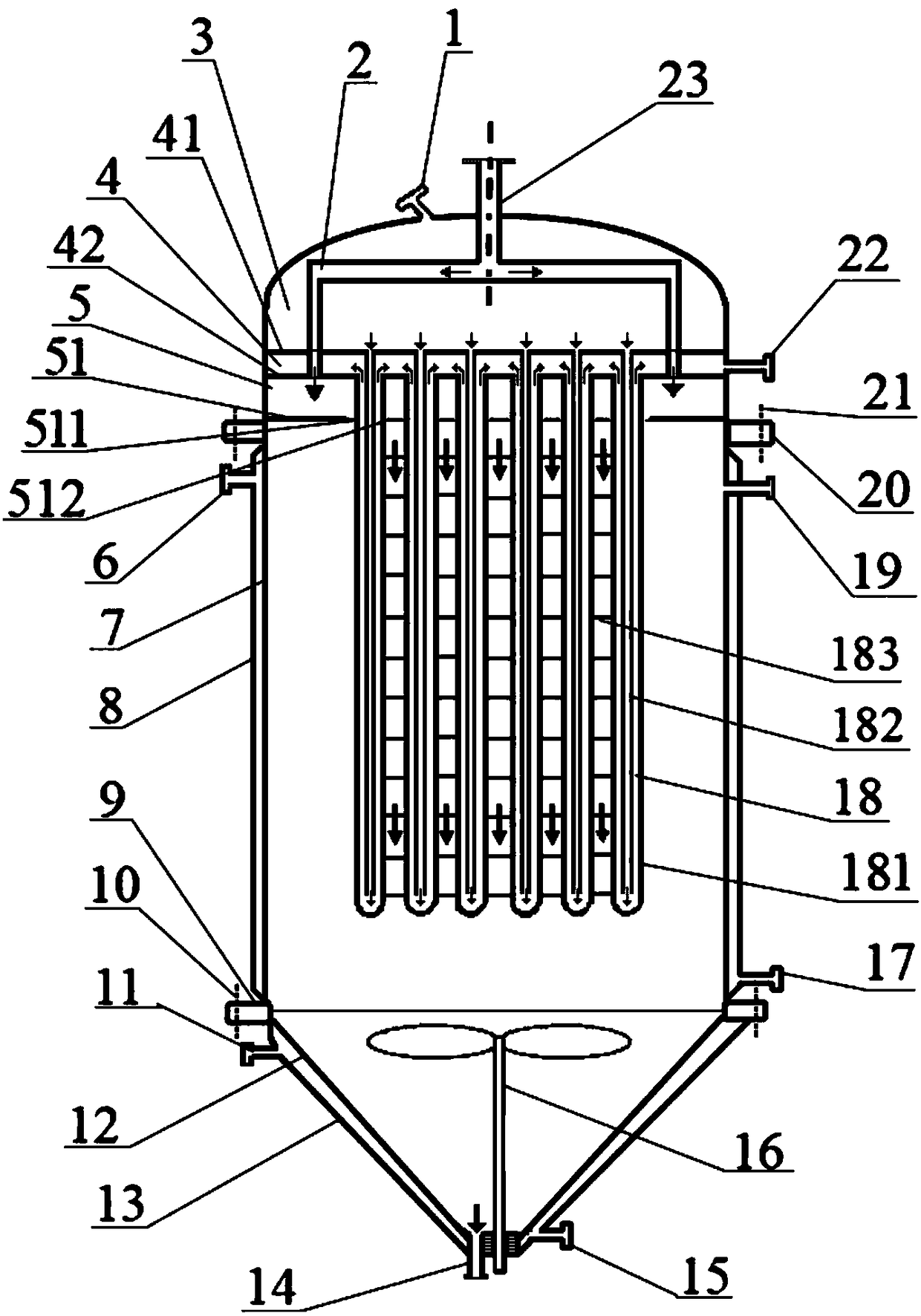

[0029] Embodiment 1, with reference to attached figure 1 , 4 , 5a, 5b, 5c.

[0030] In this embodiment, the outer tube 181 of the falling film support tube 18 is a straight tube with a constant diameter.

[0031] A falling film melt polycondensation reactor between rows of tubes for preparing a high-viscosity melt provided by this embodiment, such as figure 1 As shown, it includes a vertical housing 7, a material feed box connected to the upper end of the vertical housing 7 and a bottom shell 12 at the lower end, a heat medium outflow box 4 is arranged above the material feed box 5, and the heat medium flows out A heat medium inflow box 3 is provided on the box 4, a reactor heat medium inlet 1 is arranged on the heat medium inflow box 3, and a reactor heat medium outlet 22 is arranged on the heat medium outflow box 4, arranged in rows The falling film support pipe 18 is connected to the heat medium outflow box 4 and the heat medium inflow box 3 to form a heat medium circulati...

Embodiment 2

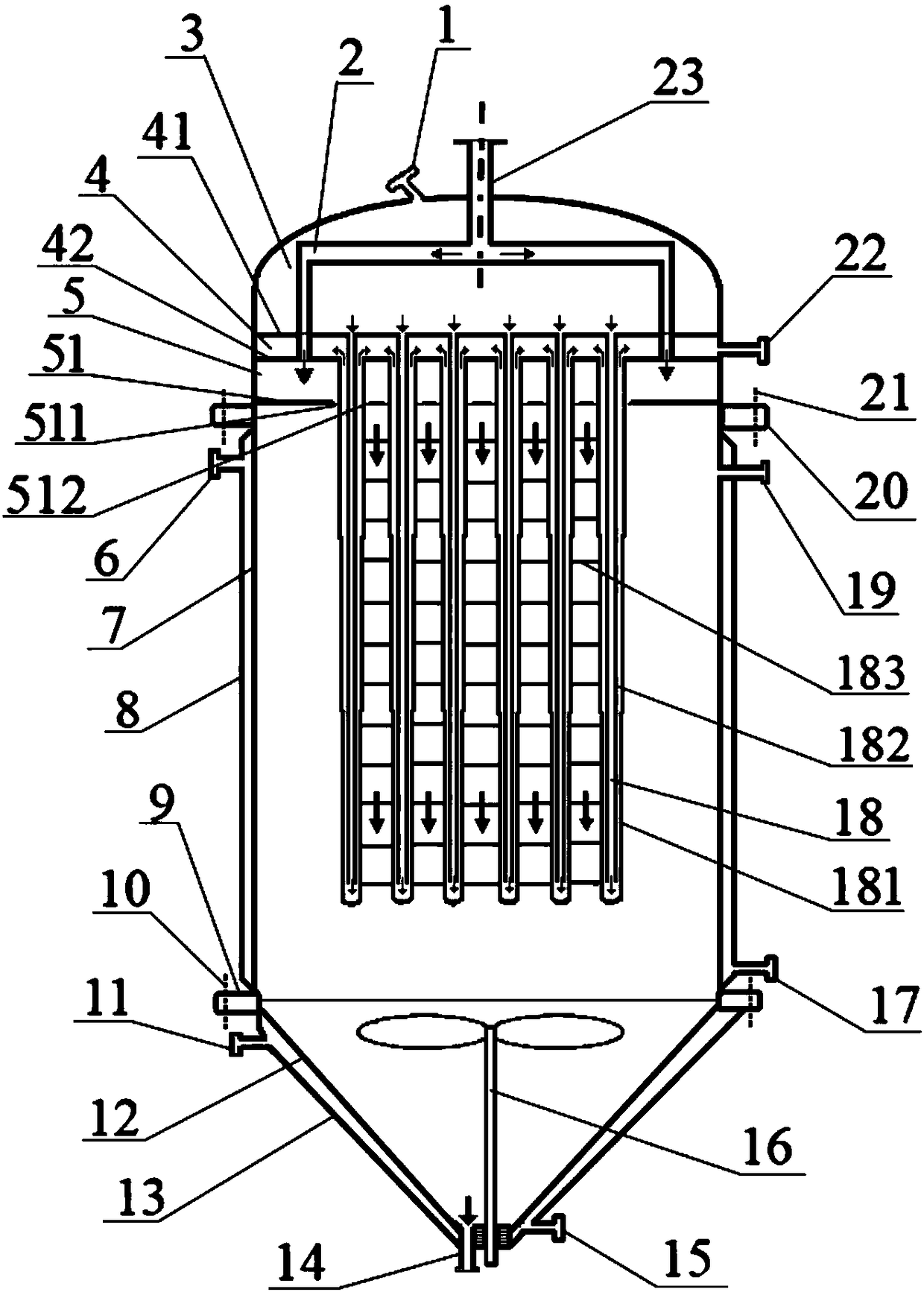

[0051] Embodiment 2, with reference to attached figure 2 , 4 , 5a, 5b, 5c.

[0052] In this embodiment, the outer tube 181 of the inter-tube falling film support tube 18 adopts a coaxial straight tube with reduced diameter.

[0053] The outer tube 181 of the falling film supporting tube 18 between the tubes changes in diameter within the same distance below the film distribution plate 51, and becomes a straight tube with multiple sections of different diameters but continuous communication. The upper and lower sections are coaxial, from the bottom of the film distribution plate 51 to the tube At the bottom of the falling film support pipe 18, the outer diameter of the straight pipe decreases step by step.

[0054] Preferably, the number of variable diameter sections of the outer tube 181 can be 2 to 100, the outer diameter of the first straight tube near the bottom of the membrane plate 51 is 20 to 30 mm, and the diameter of the last straight tube near the end of the tube b...

Embodiment 3

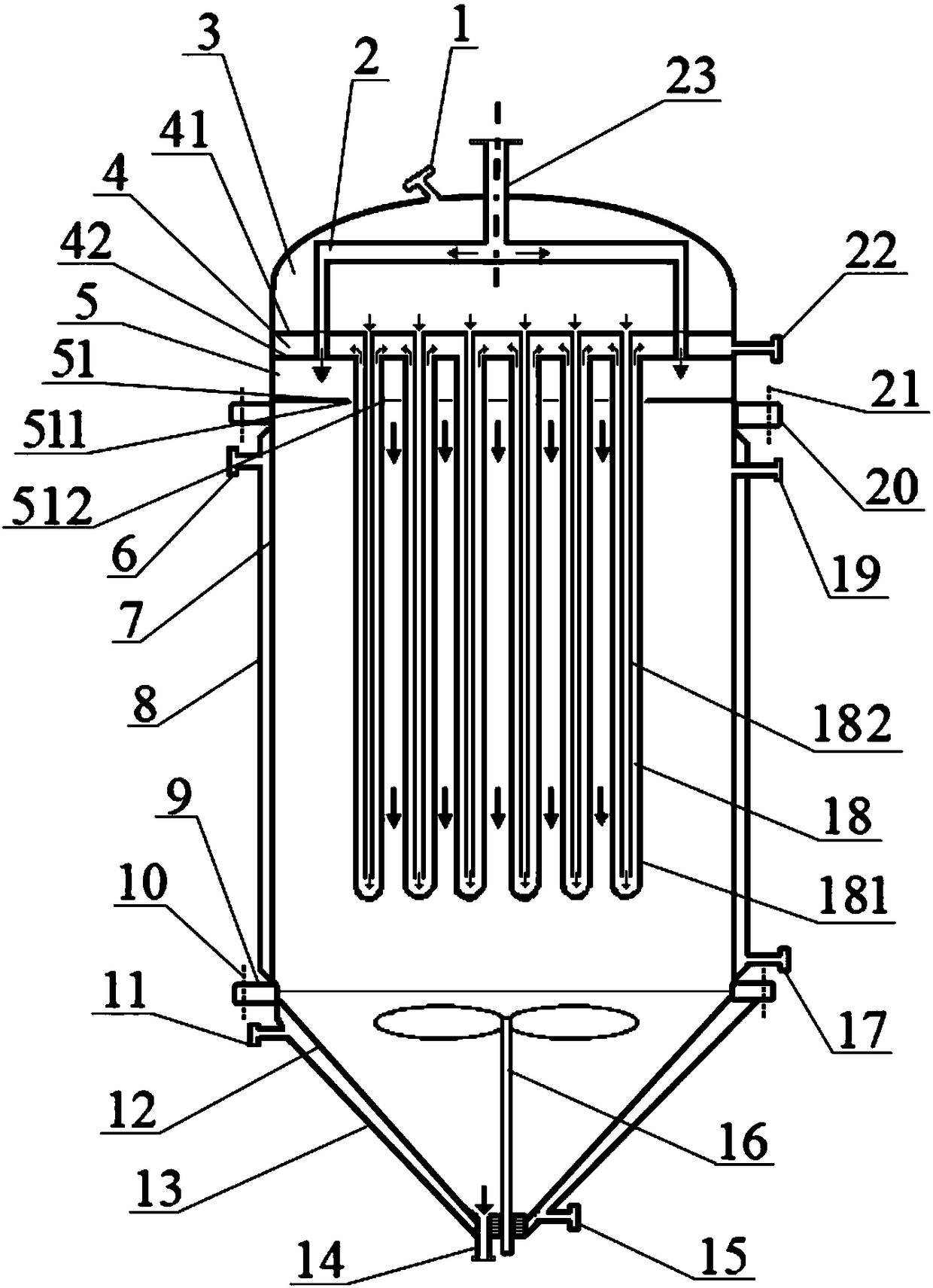

[0057] Embodiment 3, with reference to attached image 3 , 4 , 5a, 5b, 5c.

[0058] In this embodiment, the outer tube 181 of the inter-tube falling film support tube 18 is a straight tube with a constant diameter, and there is no horizontal inter-tube connecting wire between two adjacent inter-tube falling film support tubes.

[0059] Preferably, the ratio of the distance between the tubes of the falling film support tubes between adjacent tubes to the tube diameter is 0.1-10.

[0060] Other parts and implementation method of this embodiment are the same as embodiment 1, in image 3 , the reference numerals and figure 1 The same means the same meaning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com