Patents

Literature

153results about How to "Consistent flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

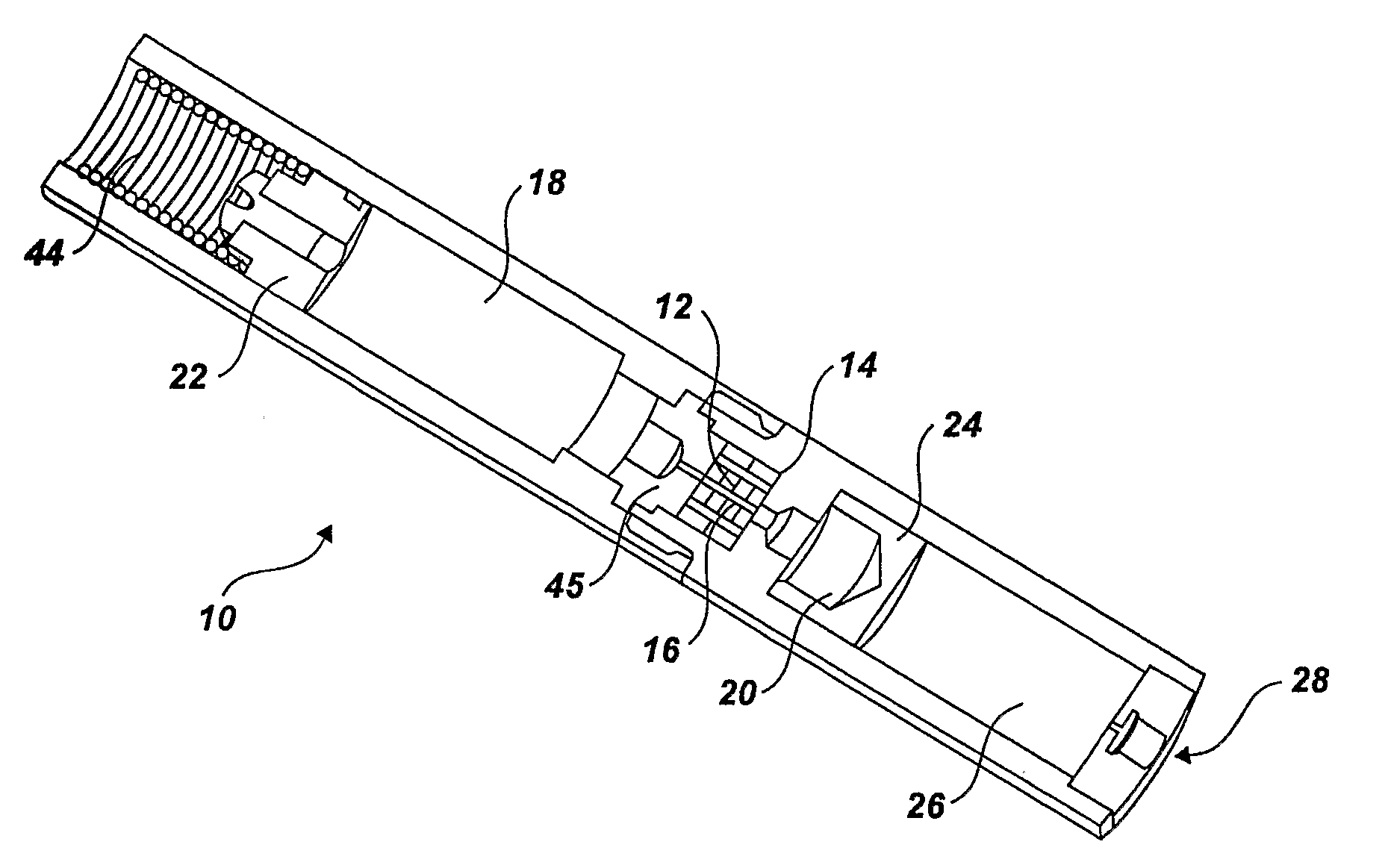

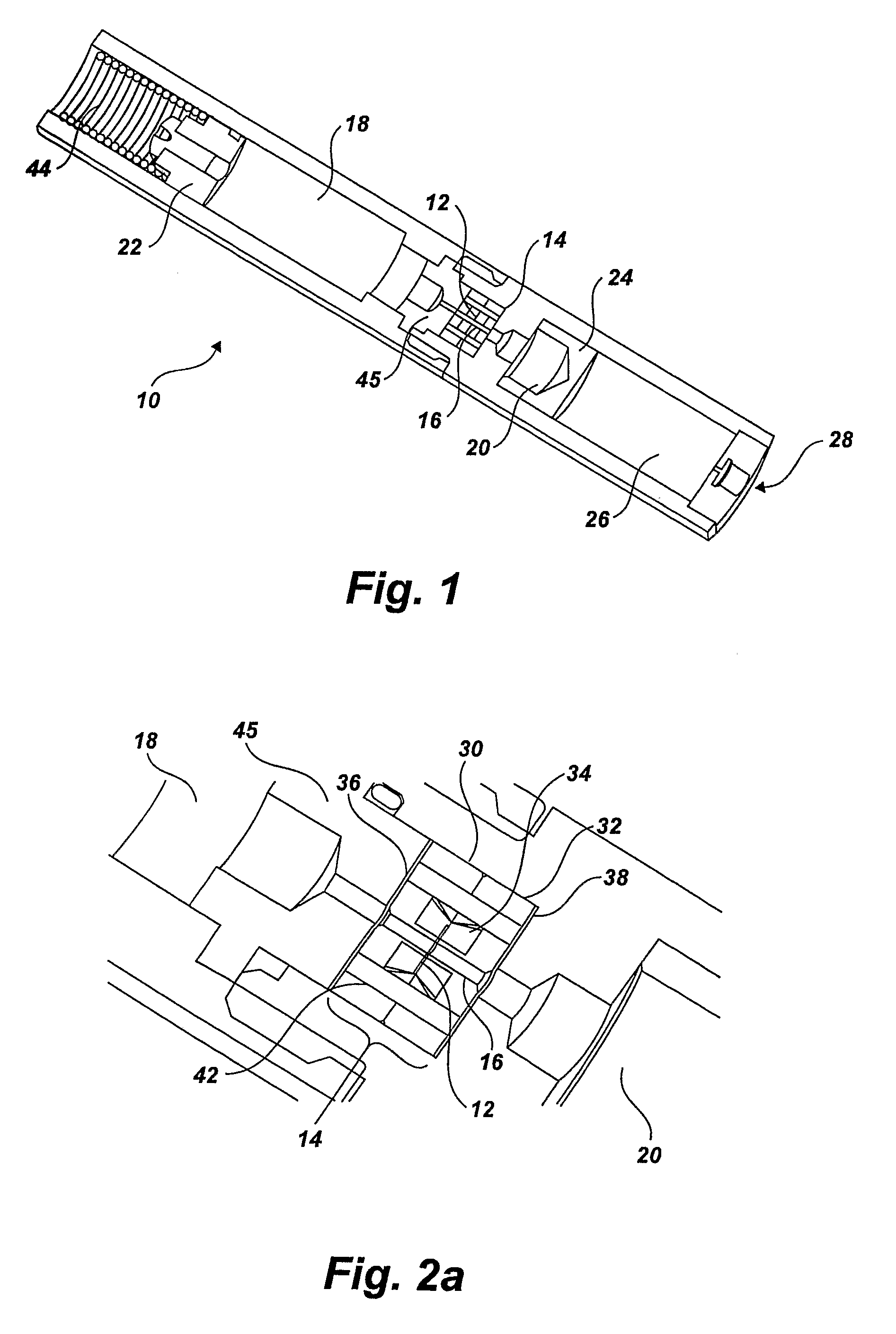

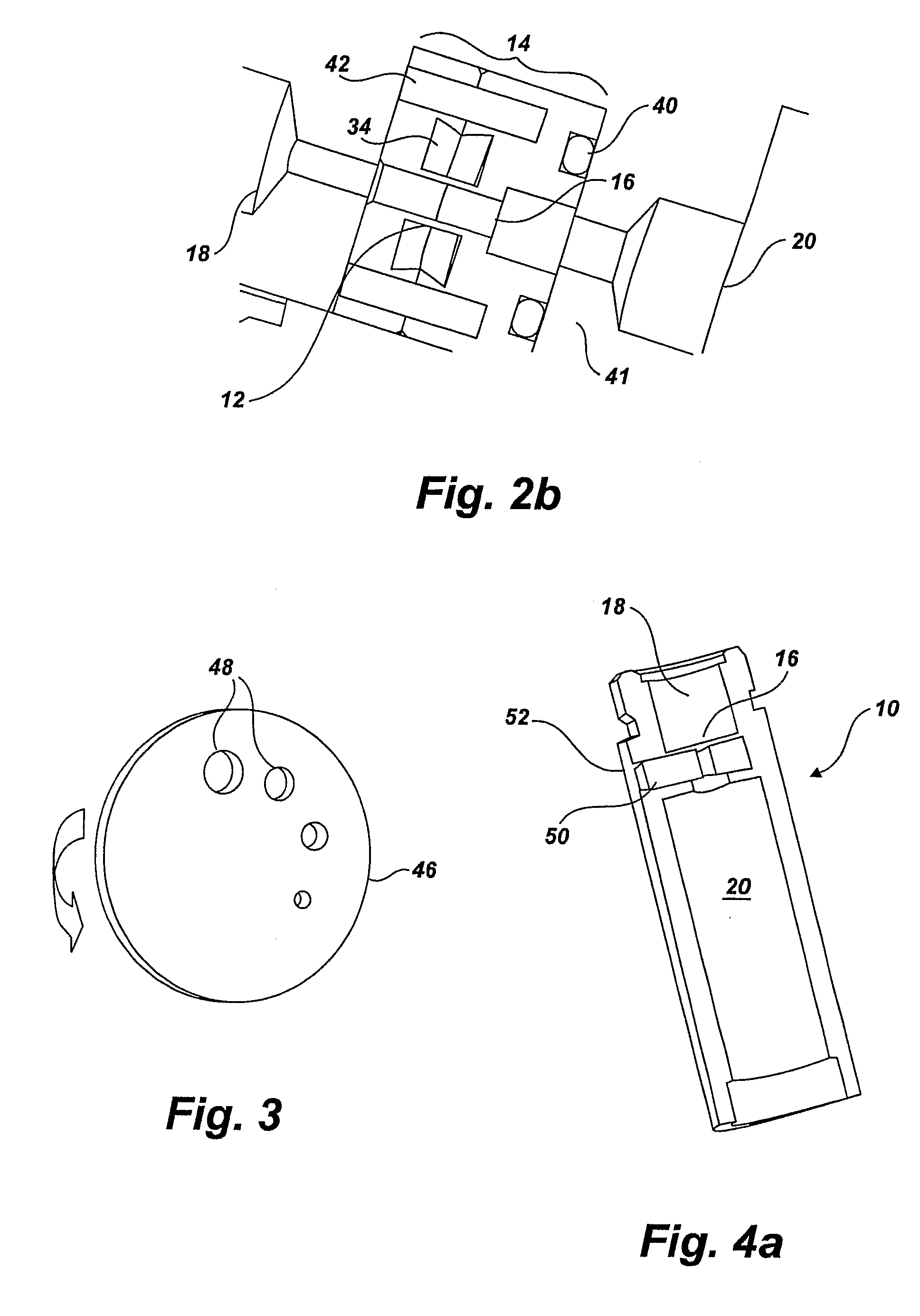

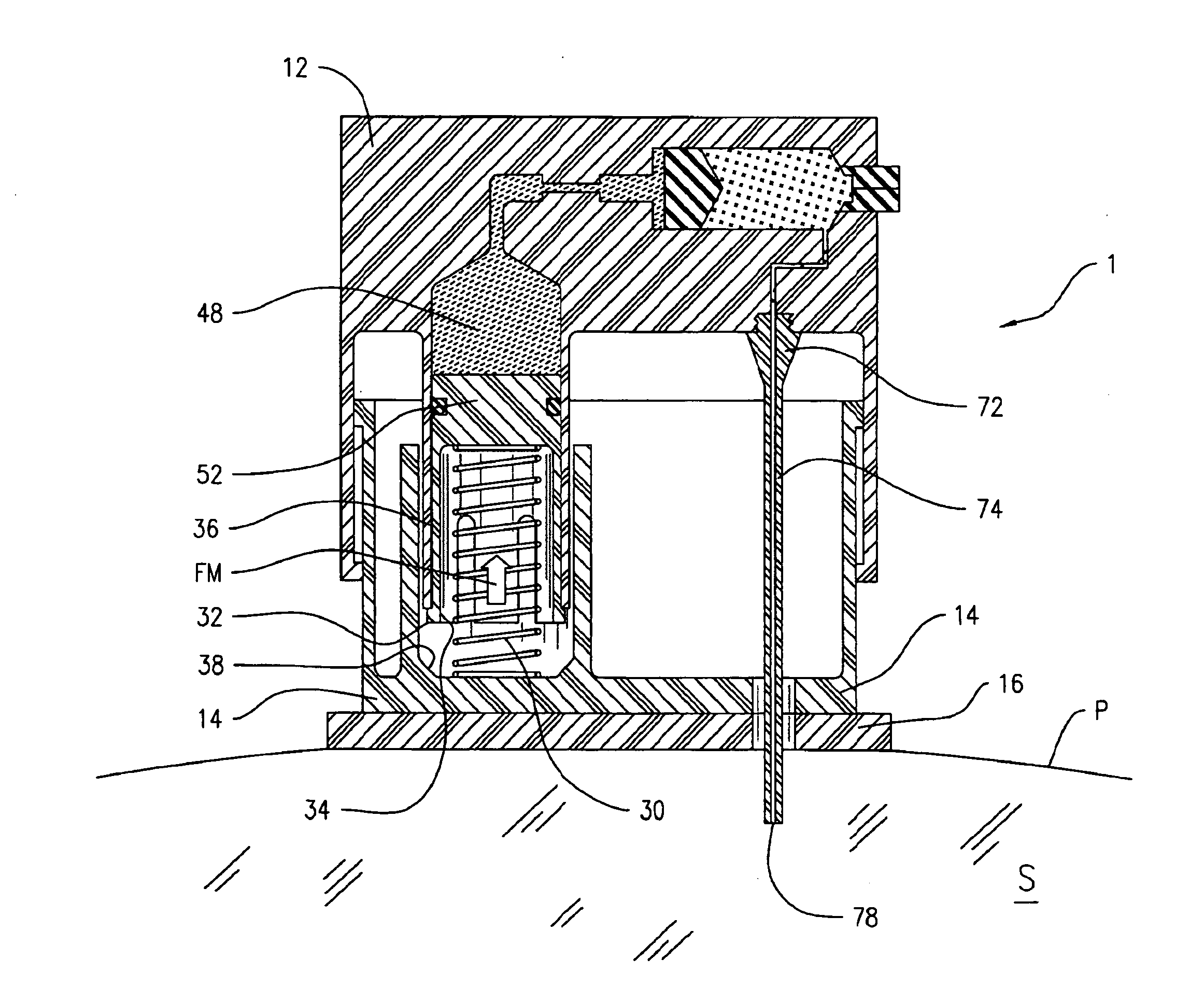

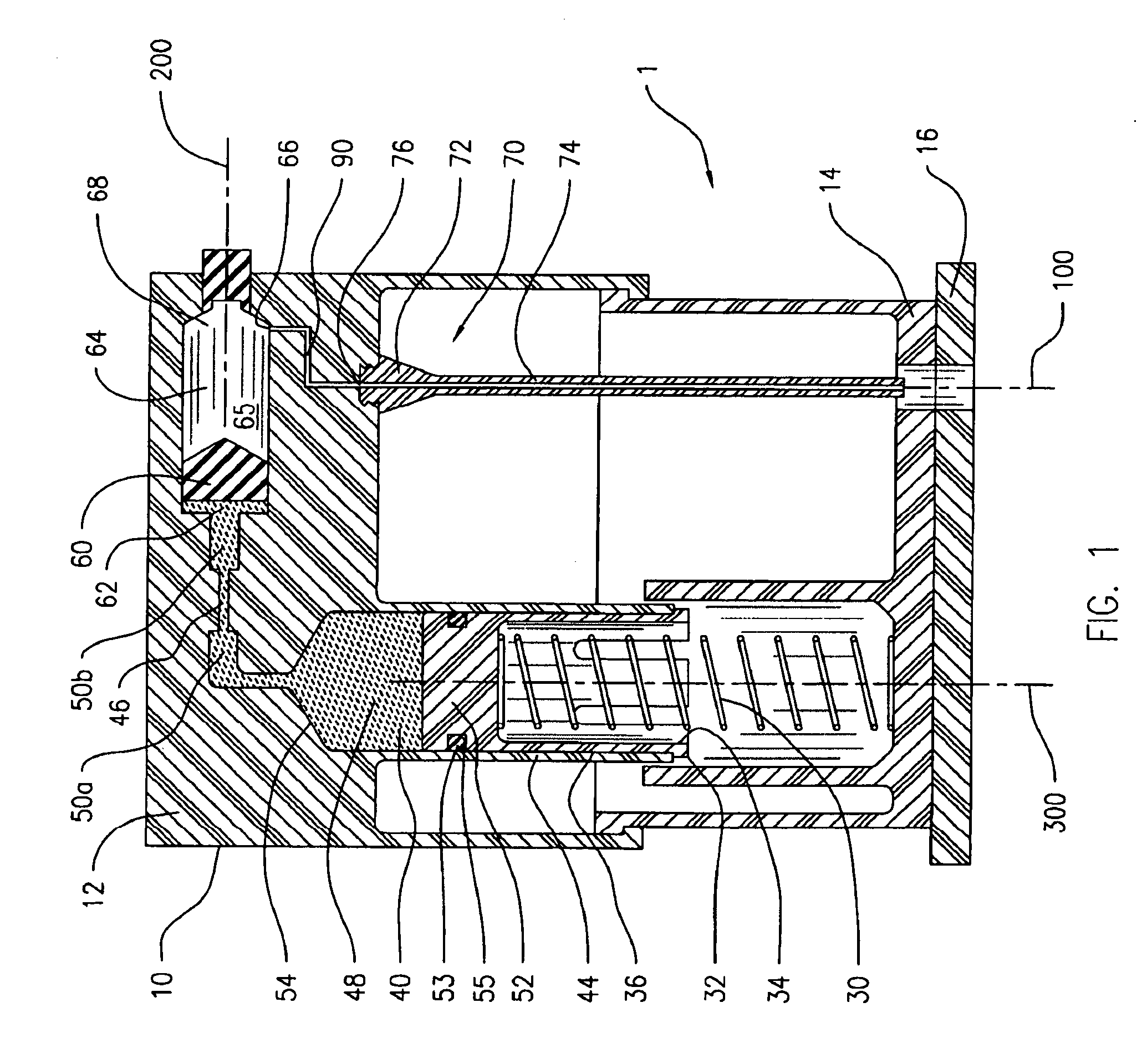

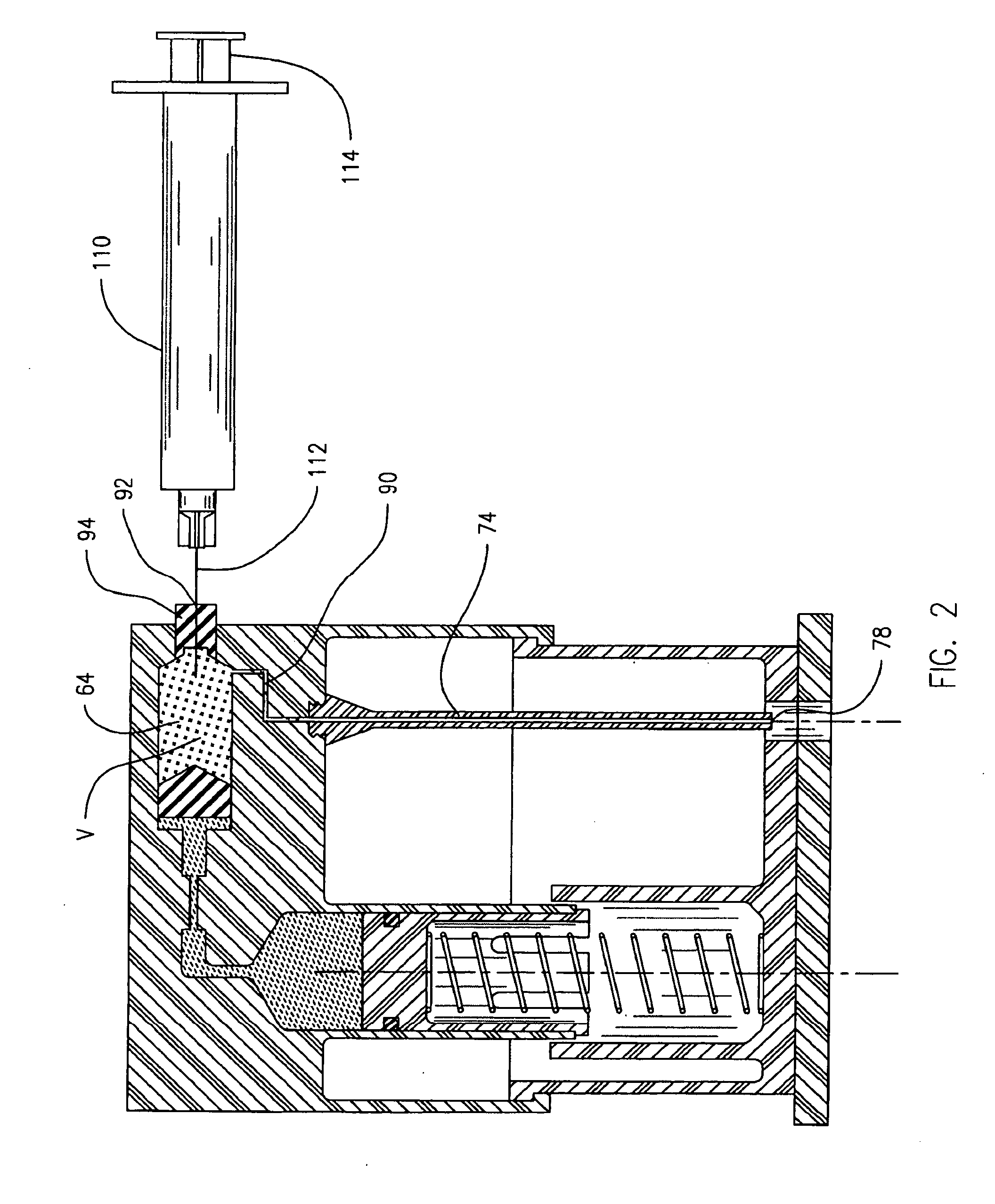

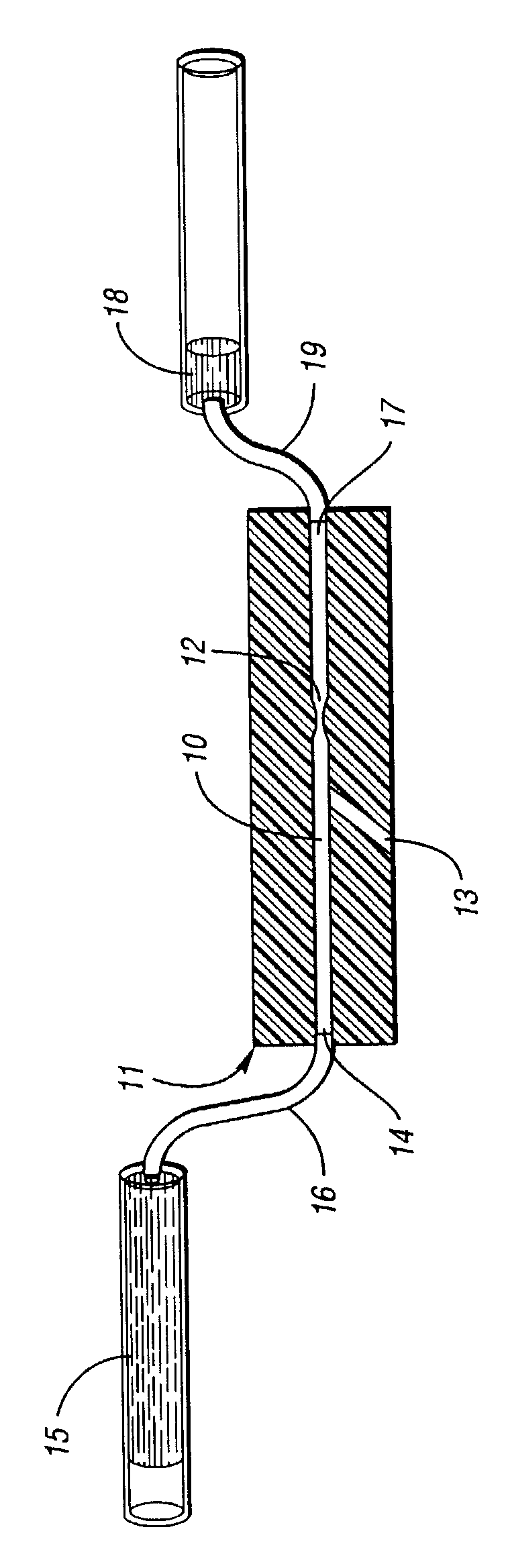

Osmotically Driven Dispense Pump and Related Components for Use in High Pressure Applications

ActiveUS20080269725A1Continuous delivery rateImprove controlPressure infusionPumpsDistortionOsmotic pump

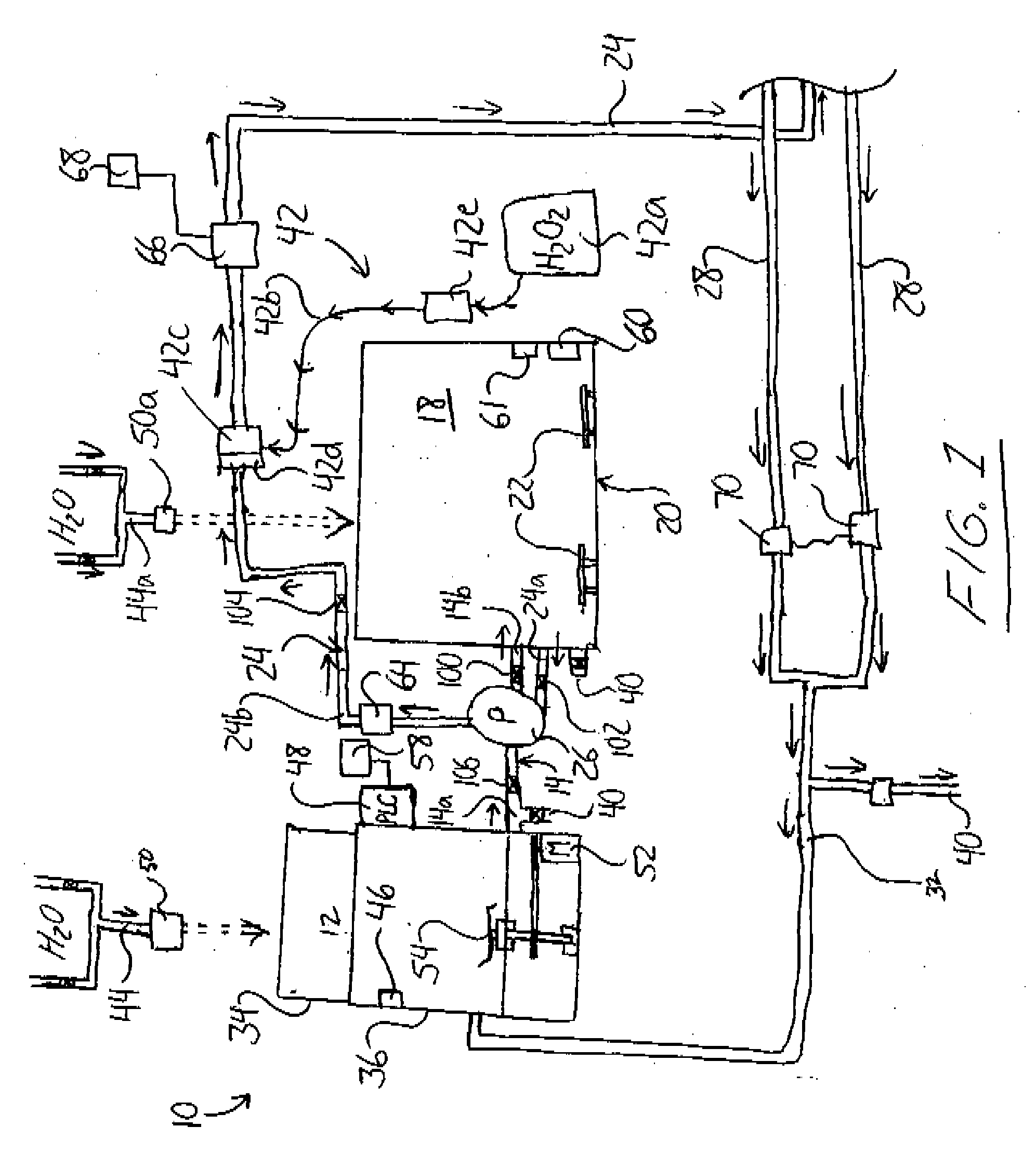

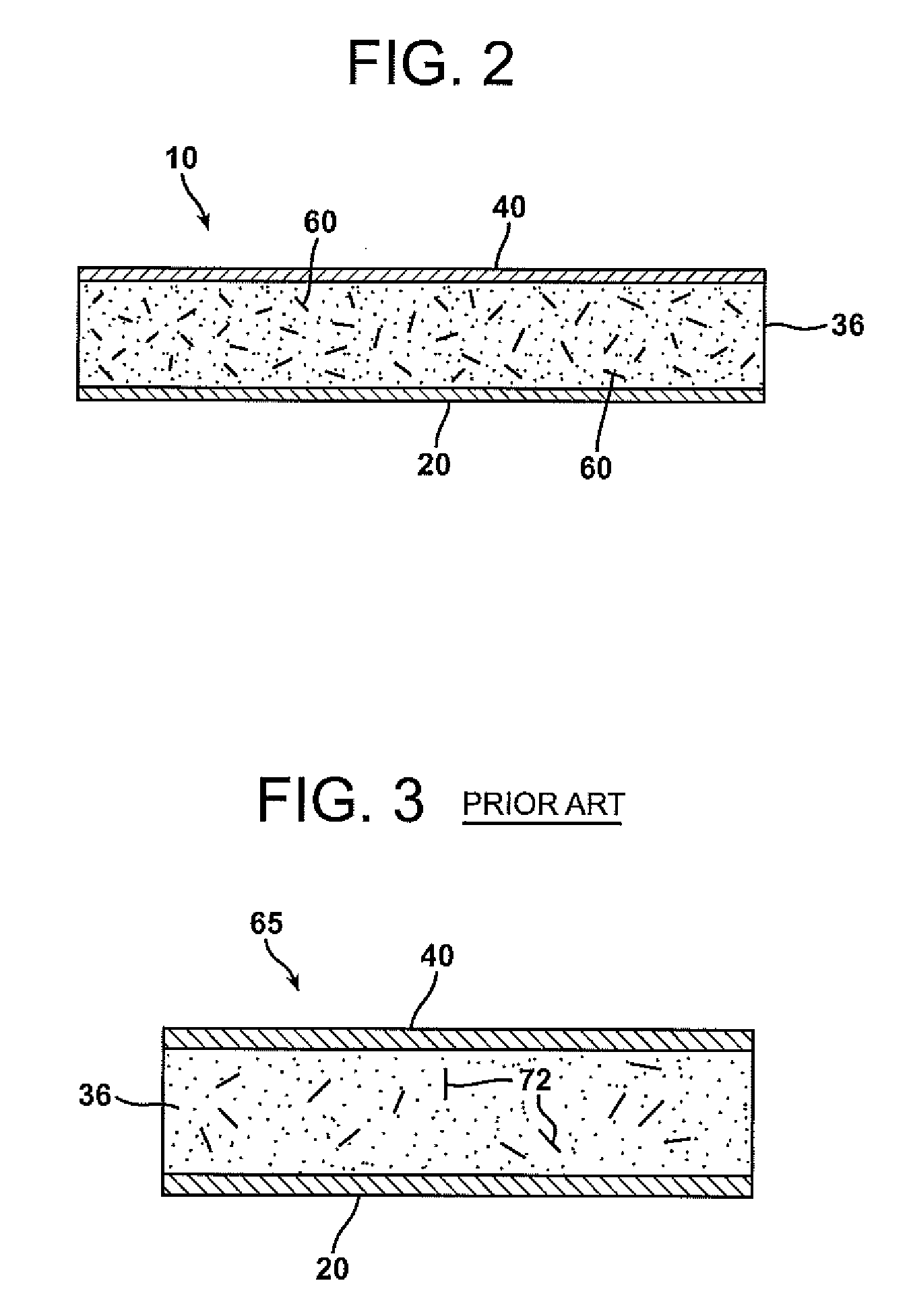

A high pressure osmotic dispense pump (10) having a substantially continuous delivery rate and extended delivery times is described and disclosed. The dispense pump (10) includes a semi-permeable membrane (12) which is substantially free of distortions and lateral stretching stresses. The membrane housing (14) and configuration of the present invention allows for consistent and accurate flow rates at the micro-liter level and improved control of the surface area of the semi-permeable membrane (12). This osmotic pump (10) also includes optional methods for activating and deactivating the osmotic process and / or controlling flow rates. Along with these features, the pump can be amplified or modulated to increase the dispense rate and / or adjust the flow rate during operation.

Owner:UNIV OF UTAH RES FOUND

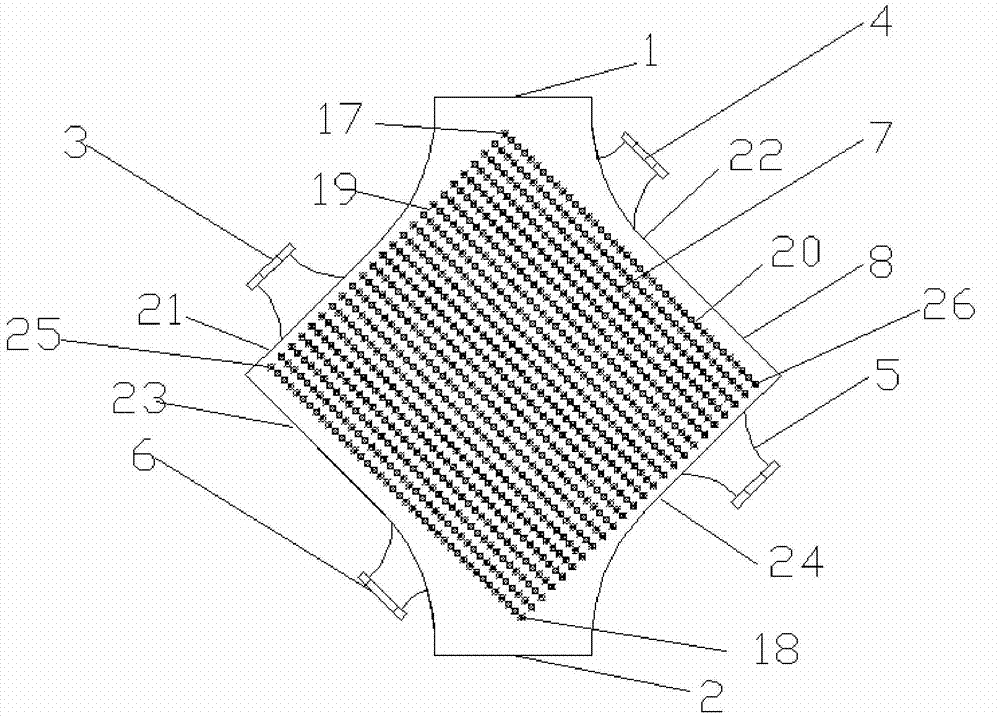

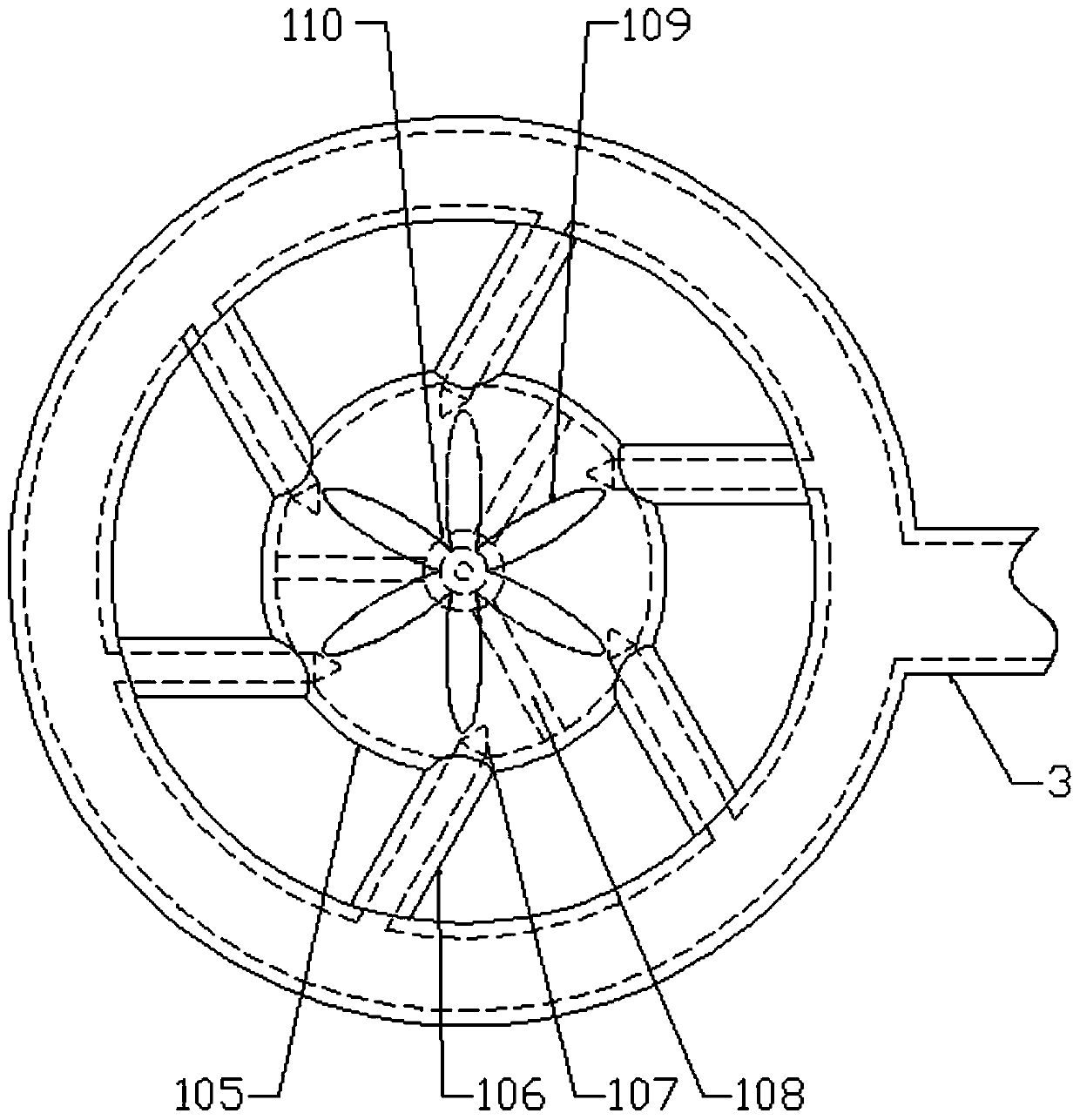

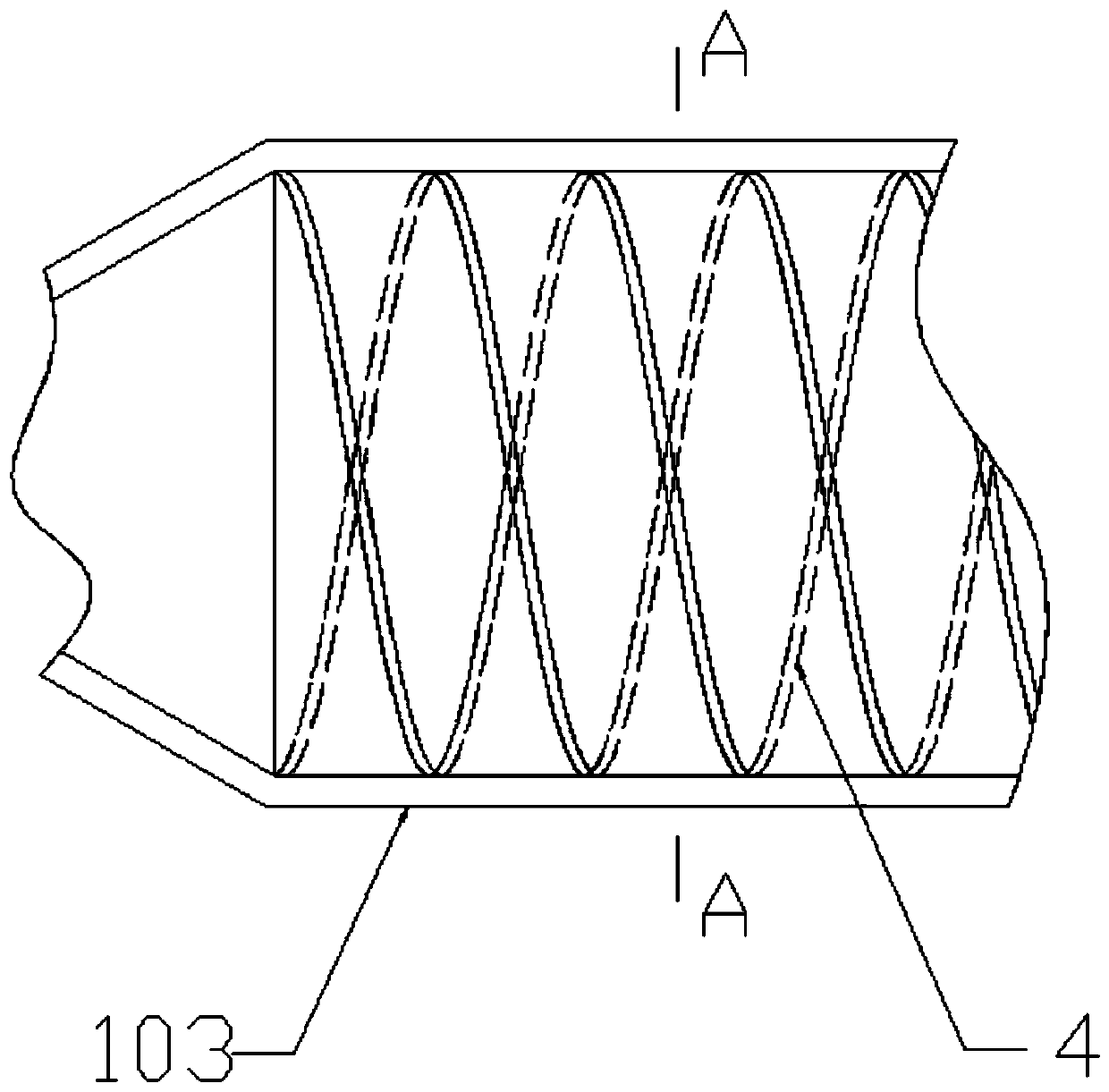

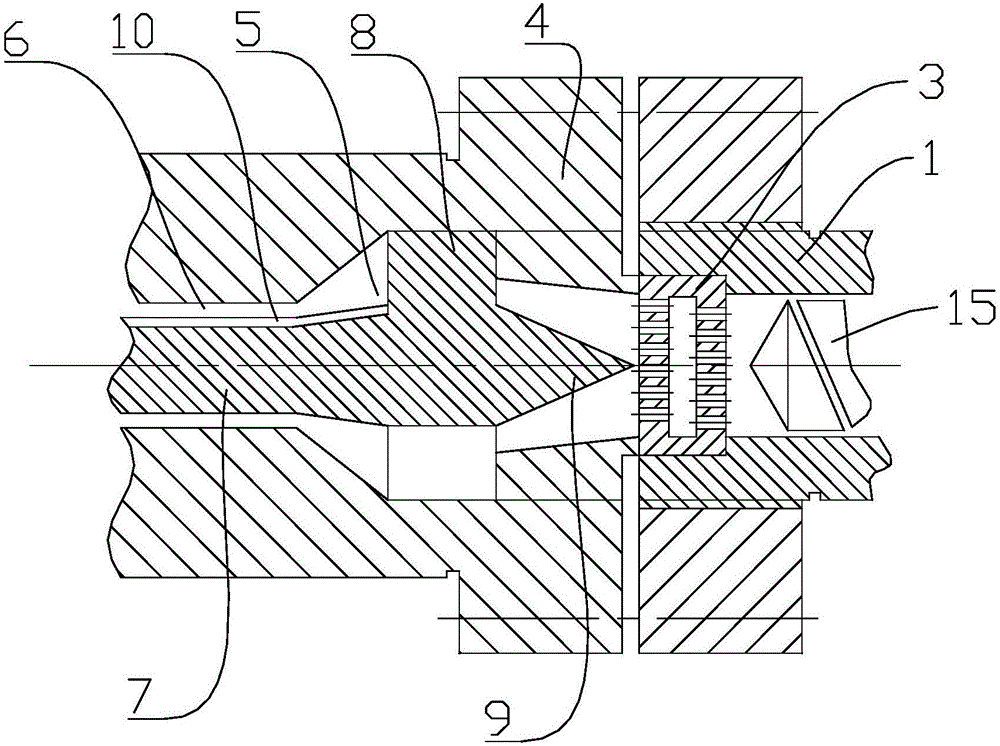

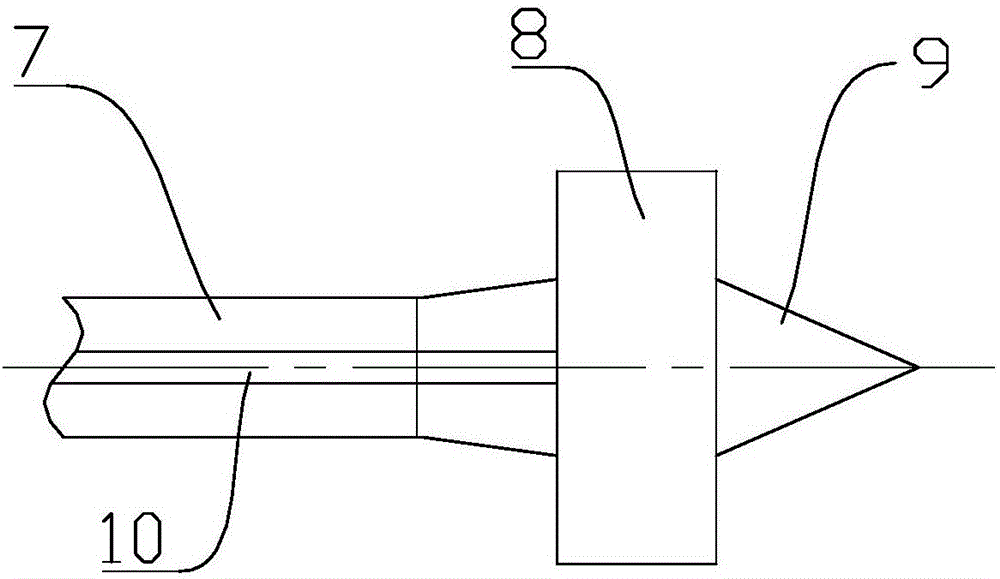

Multi-stage jet-type reaction force disc generating system

InactiveCN101813006AConsistent flow rateReduce kinetic energyHydro energy generationWind motor combinationsCircular discJet flow

The invention relates to a generating technology, in particular to a multi-stage jet-type reaction force disc generating system which mainly comprises a leak-off pipe, a jet-type reaction force disc generating set and a disc shell. The generating system is characterized in that the multi-stage jet-type reaction force disc generating set is arranged on a plurality of sections of the leak-off pipes which are connected. One or more than one jet flow pipe is arranged in a reaction force disc which rotates to generate power through tangential-jet reaction force. The system is powered by water, wind or steam. The invention breaks through the traditional generating technology and applies work by the reaction force of fluid, and meanwhile, the invention keeps original kinetic energy, static pressure energy and potential energy of the fluid undamaged to the largest extent to keep applying work to downstream machines, thereby using the kinetic energy, static pressure energy and potential energy of the fluid to apply work again and again; and therefore, by the invention, it is possible that more generating sets can be installed in the same leak-off pipe.

Owner:李贵祥

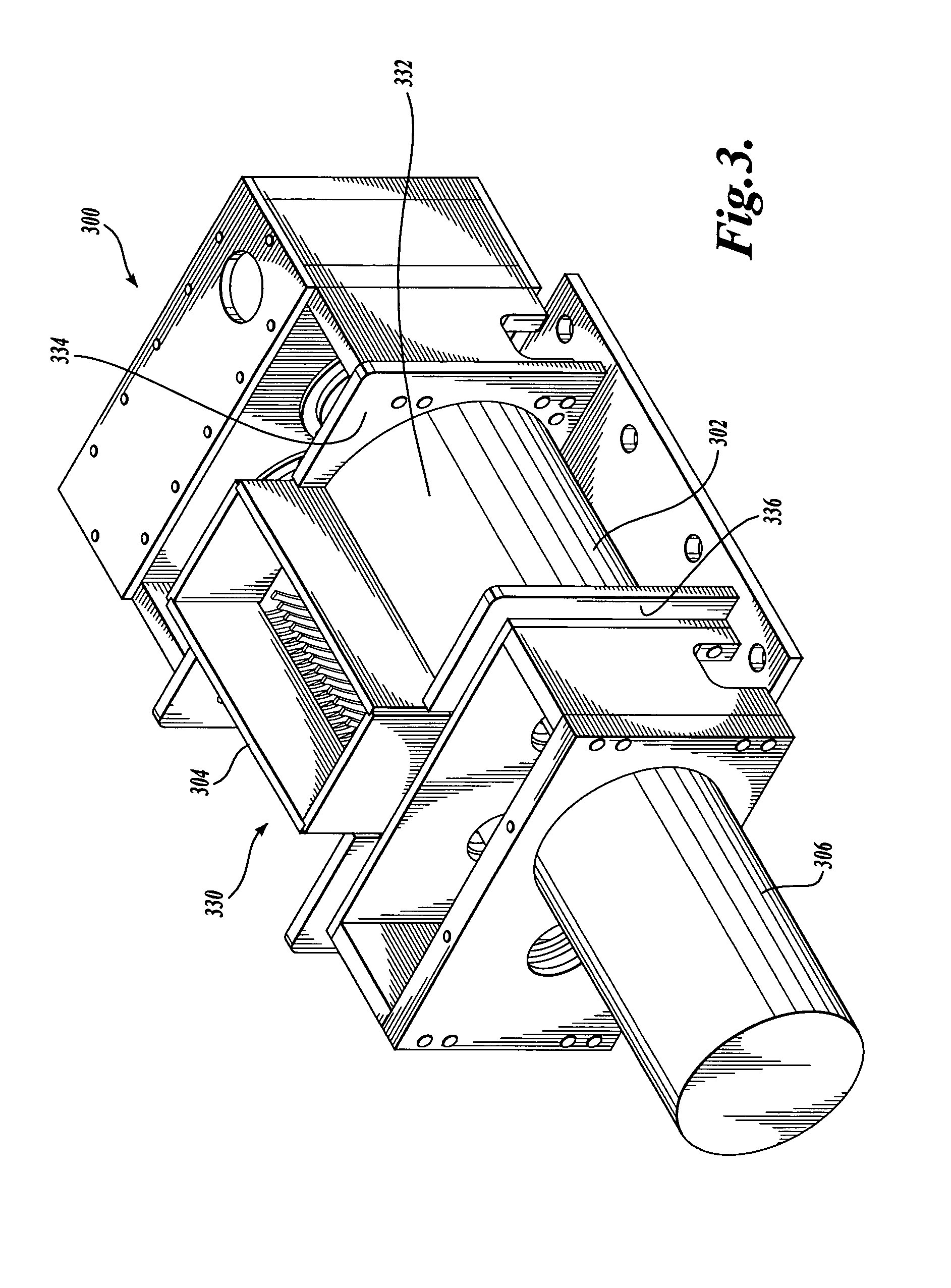

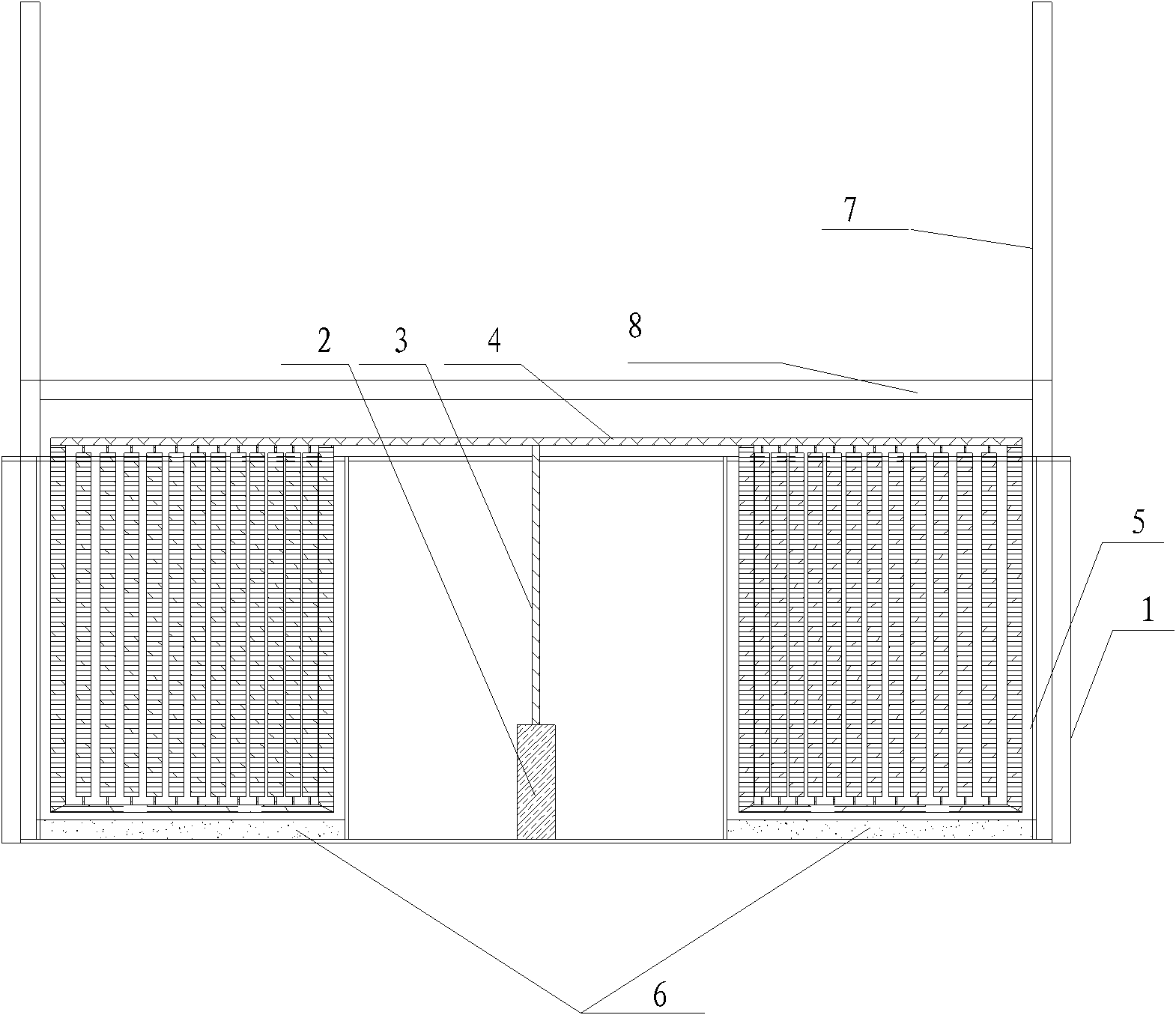

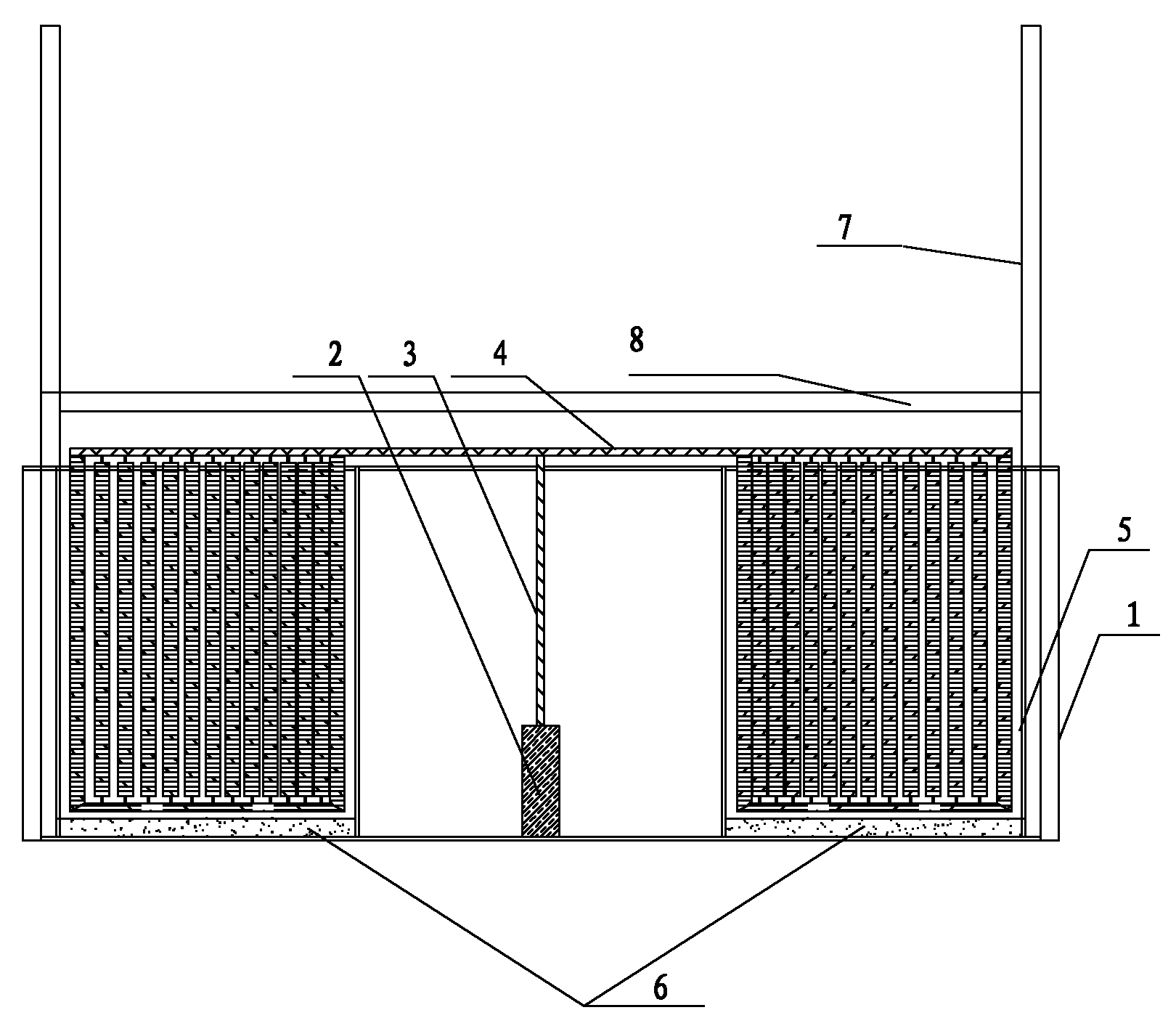

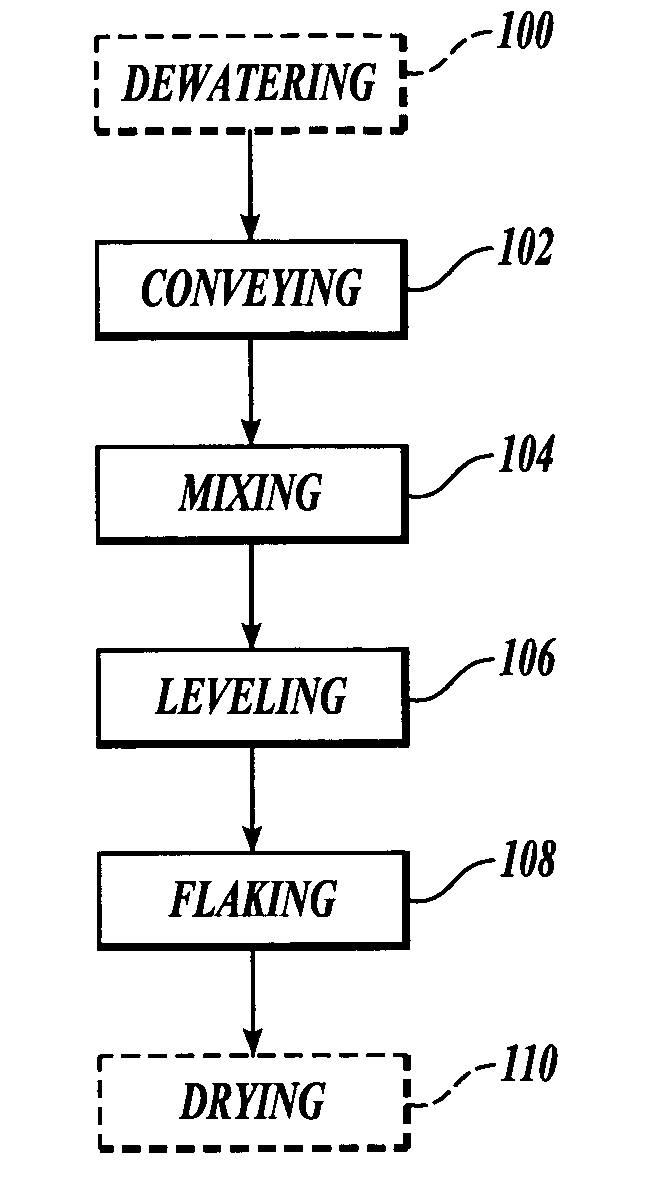

Pulp flaker

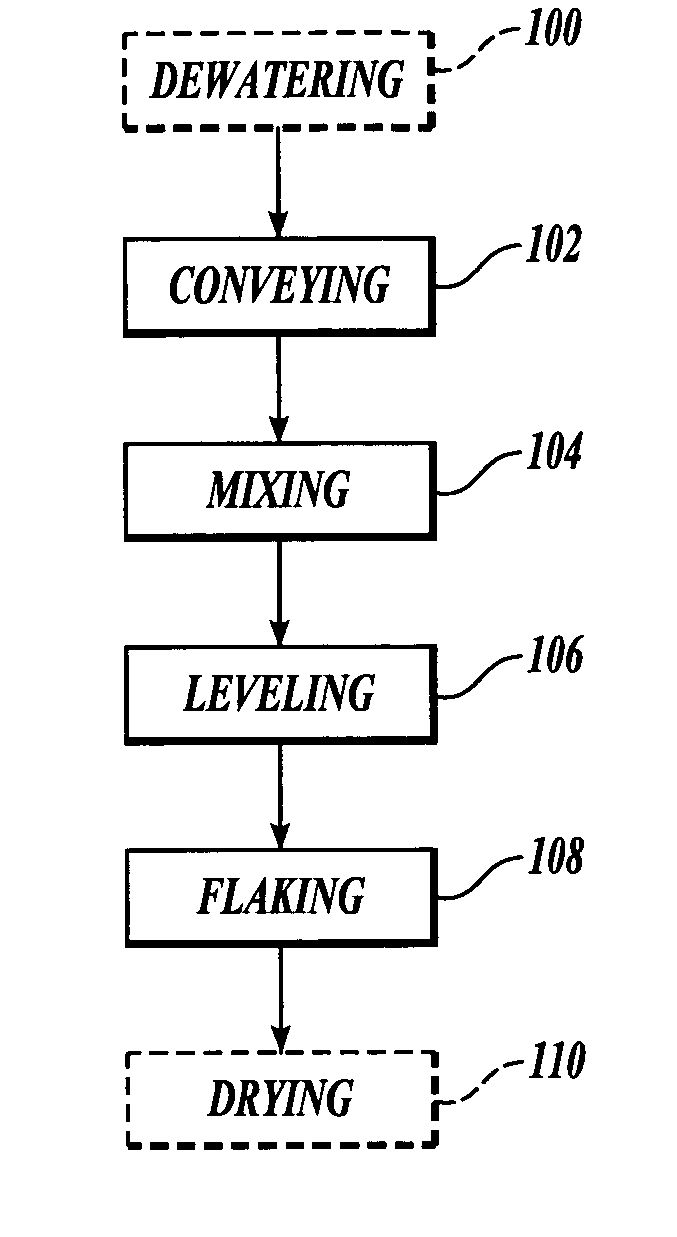

InactiveUS7291244B2Small sizePrevents scattering of the pulpDrying using combination processesDigestersPulp and paper industryMoisture

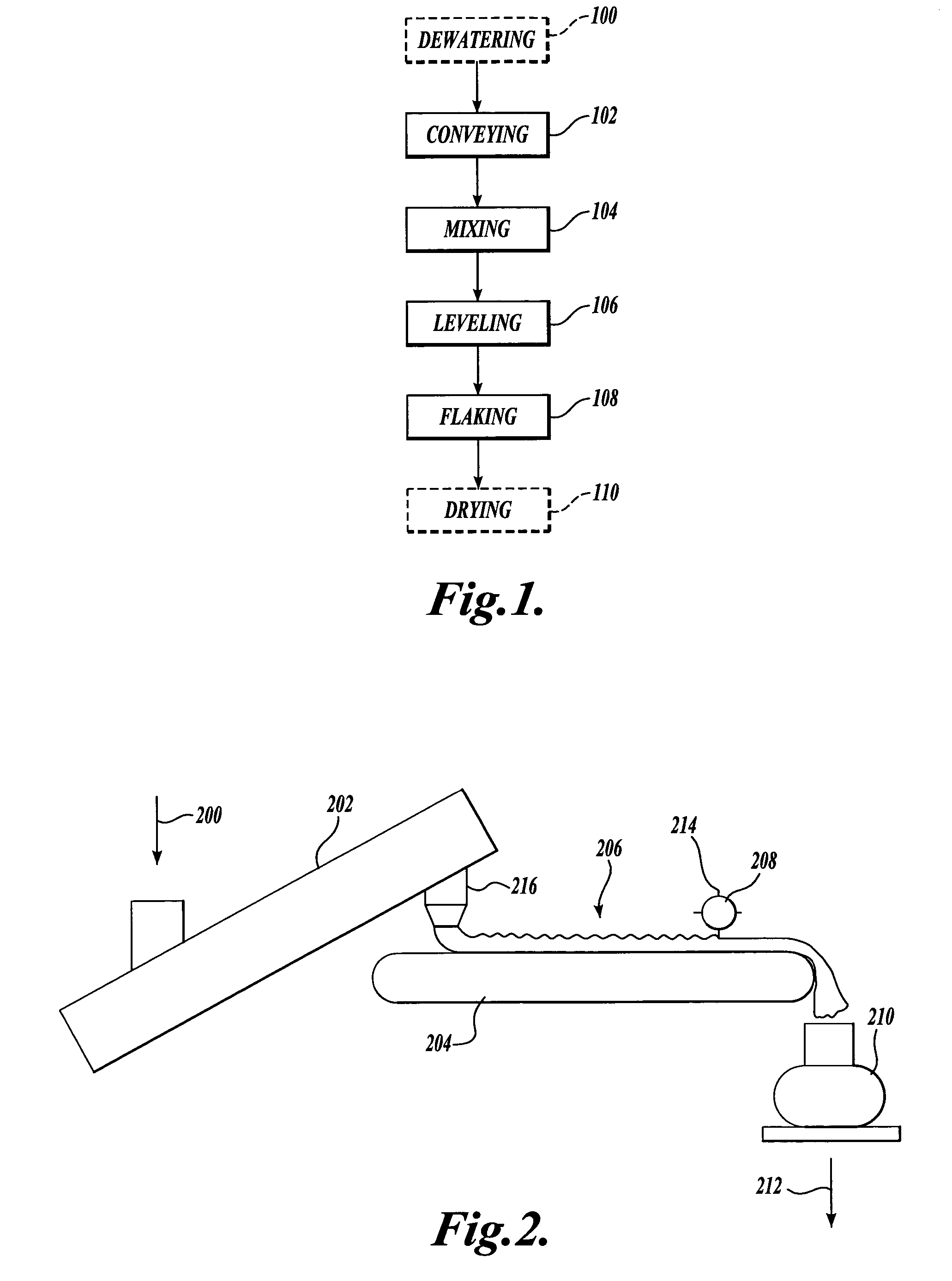

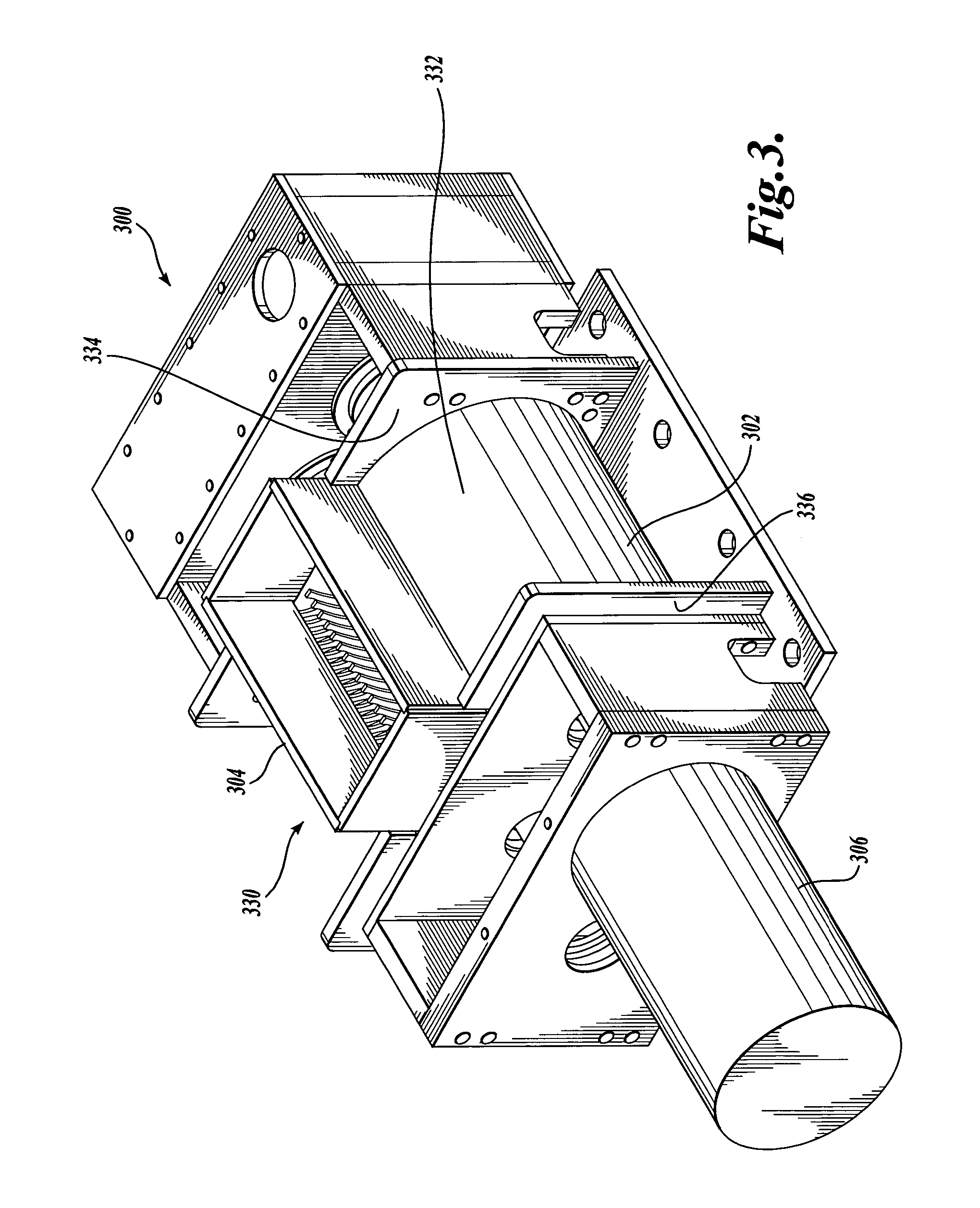

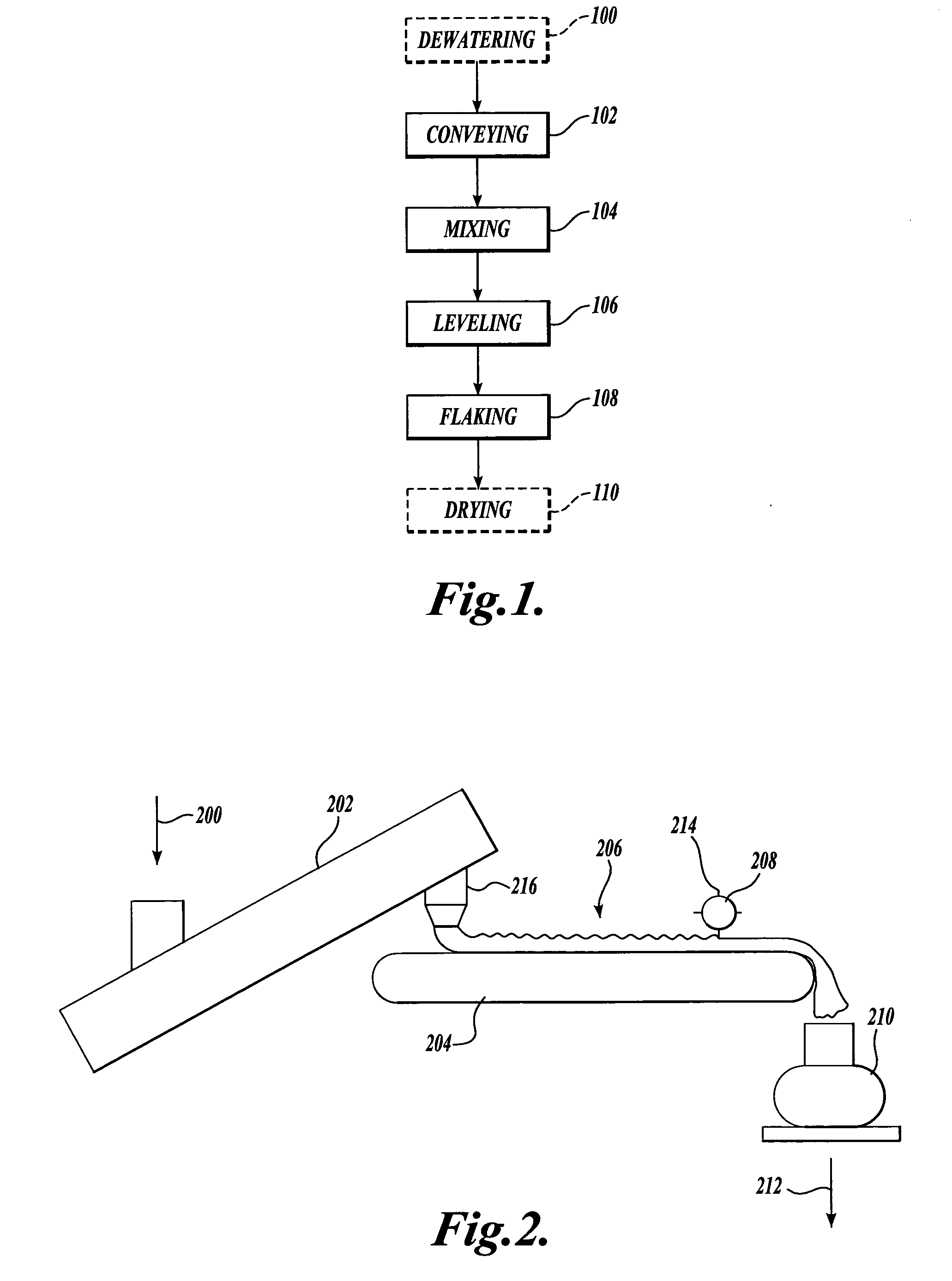

Methods for conveying, mixing, leveling, and flaking dewatered pulp to produce pulp flakes suitable to be used in a dryer. Methods for producing a consistent flow rate of pulp, and, for producing uniform pulp flakes in terms of pulp flake size and pulp flake moisture content. A method includes introducing a dewatered pulp to a rotating shaftless screw conveyor. The pulp is deposited from the screw conveyor onto a moving belt conveyor through a chute. The pulp is leveled with a rotary doctor located above the belt conveyor to produce a substantially even rate of mass flow of pulp along a length of belt conveyor. Uniform and consistent quantities of pulp per unit time can then be fed from the belt conveyor to a pulp flaker that then translates into an even rate of pulp mass flow to the dryer.

Owner:WEYERHAEUSER CO

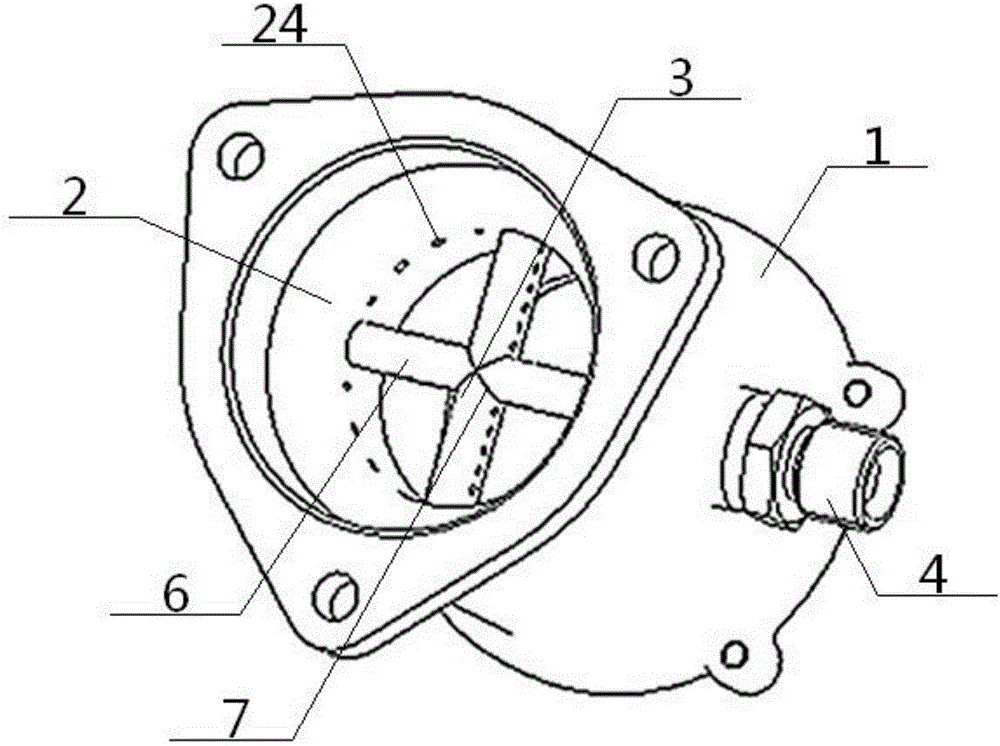

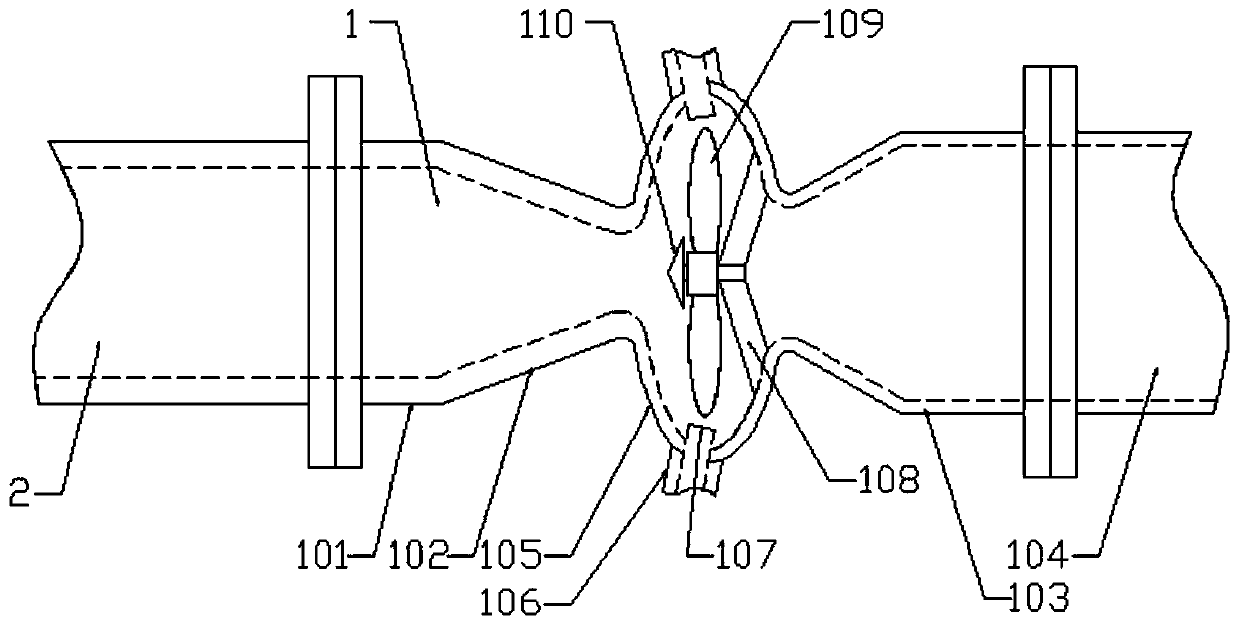

Natural gas mixer

ActiveCN106438115AEvenly distributedEasy to moveInternal combustion piston enginesFuel supply apparatusEngineeringGas chamber

The invention relates to a natural gas mixer which comprises an outer shell, an inner chamber and a gas chamber, wherein the inner chamber is coaxially arranged in the outer shell; the gas chamber is arranged in the inner chamber; the inner chamber has a hollow waist-shaped structure; the inner chamber comprises an air inlet part, a mixing part, a mixed gas outlet part which are successively communicated with each other from bottom to top; a natural gas pressure-stabilizing chamber is encircled by the air inlet part, the mixing part, the mixed gas outlet part and the inner wall of the outer shell; the gas chamber comprises a connecting plate and a gas chamber gas-inlet pipe corresponding to the plate; the outer end of the gas chamber gas-inlet pipe penetrates through a connecting hole of the gas chamber and then extends into the natural gas pressure-stabilizing chamber; a cross section of the gas chamber gas-inlet pipe has a water drop shaped structure with wide top and narrow bottom; an anti-tailing structure is arranged an upper arc part of the outer end. The natural gas mixer has the advantages of larger space of the pressure-stabilizing chamber, smooth mixed gas flow, high mixing uniformity, better mixing effect and higher stability.

Owner:DONGFENG COMML VEHICLE CO LTD

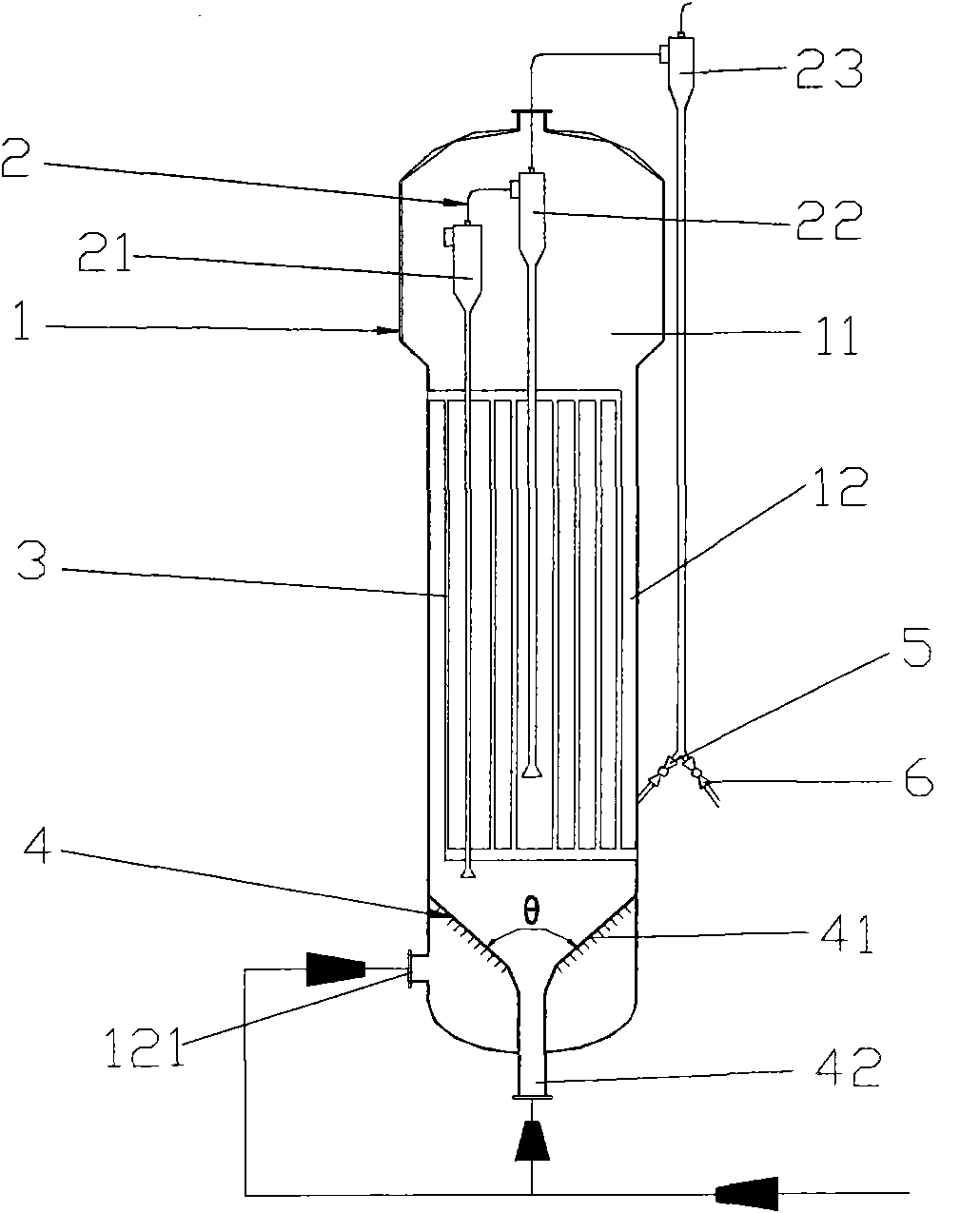

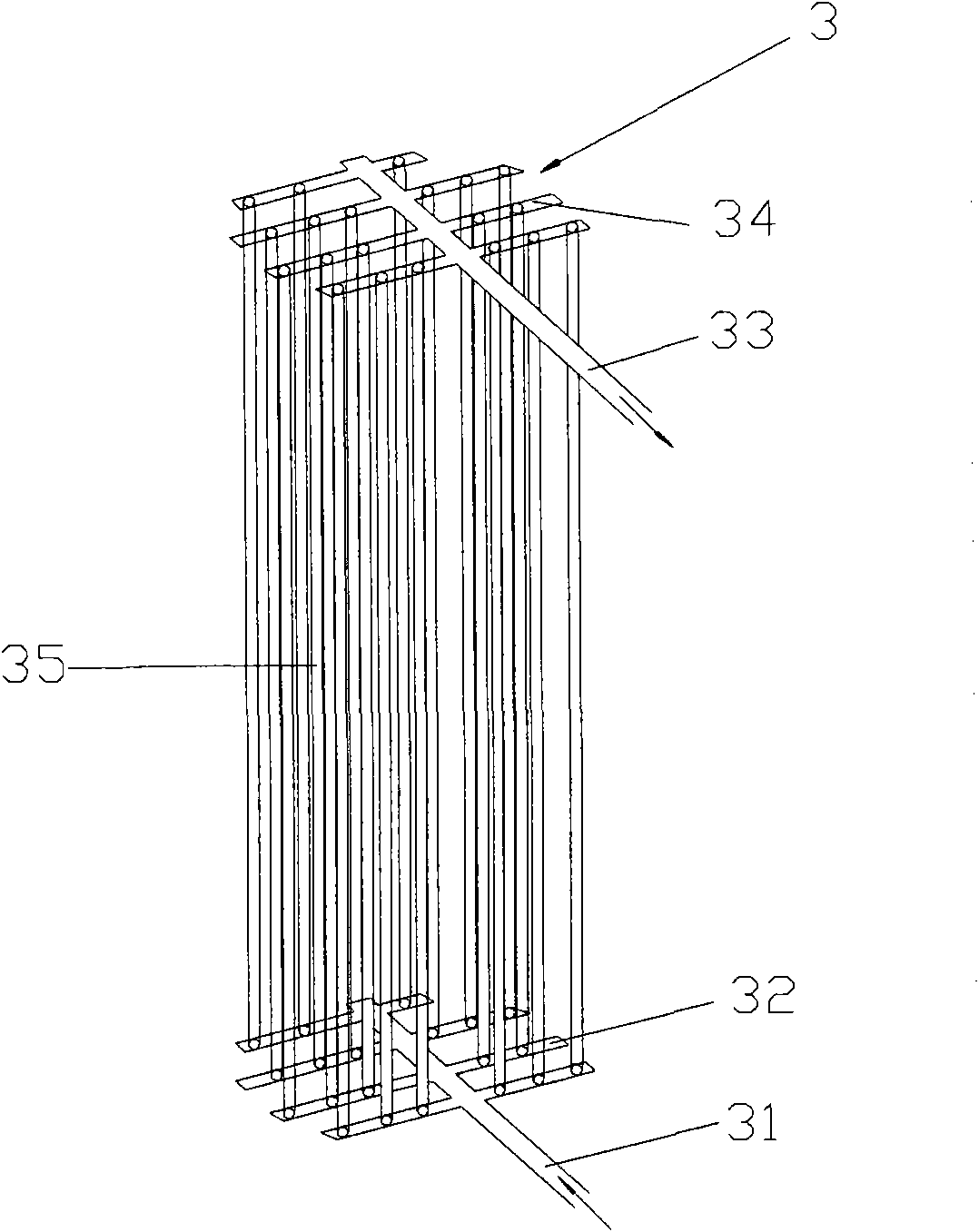

Spout type fluidized bed reactor for synthesis of organic silicon

ActiveCN102078784AUniform heat exchangeAxial temperature difference is smallGroup 4/14 element organic compoundsChemical/physical processesCycloneFluidized bed

A spout type fluidized bed reactor for synthesis of organic silicon comprises a reactor body, an expanded section, tube bore-hole type combination distributors, cyclone separator components, a back-to-bed valve, a powder-ridding tank valve and tubular heat exchangers, wherein the tube bore-hole type combination distributor is arranged at the bottom of the reactor bed body and comprises a conical gas distributor, a straight tube pore-type distributor and a spouted gas tube; the tubular heat exchangers are arranged in the reactor bed body, heat exchange carriers flowing through the heat exchanging tubes from bottom to top, to achieve single-tube pass heat transfer, so that the heat transfer between the tube surfaces and reacting fluid is even, and radial and axial temperature difference aresmall; particles separated by the cyclone separating device are directly returned back to the bed by the inner and external cyclone separating devices in time and not be taken out of the bed or partial particles are taken out, thereby reducing the catalyst content in the bed and the temperature fluctuation and being beneficial to improving reaction efficiency.

Owner:HOSHINE SILICON IND CO LTD

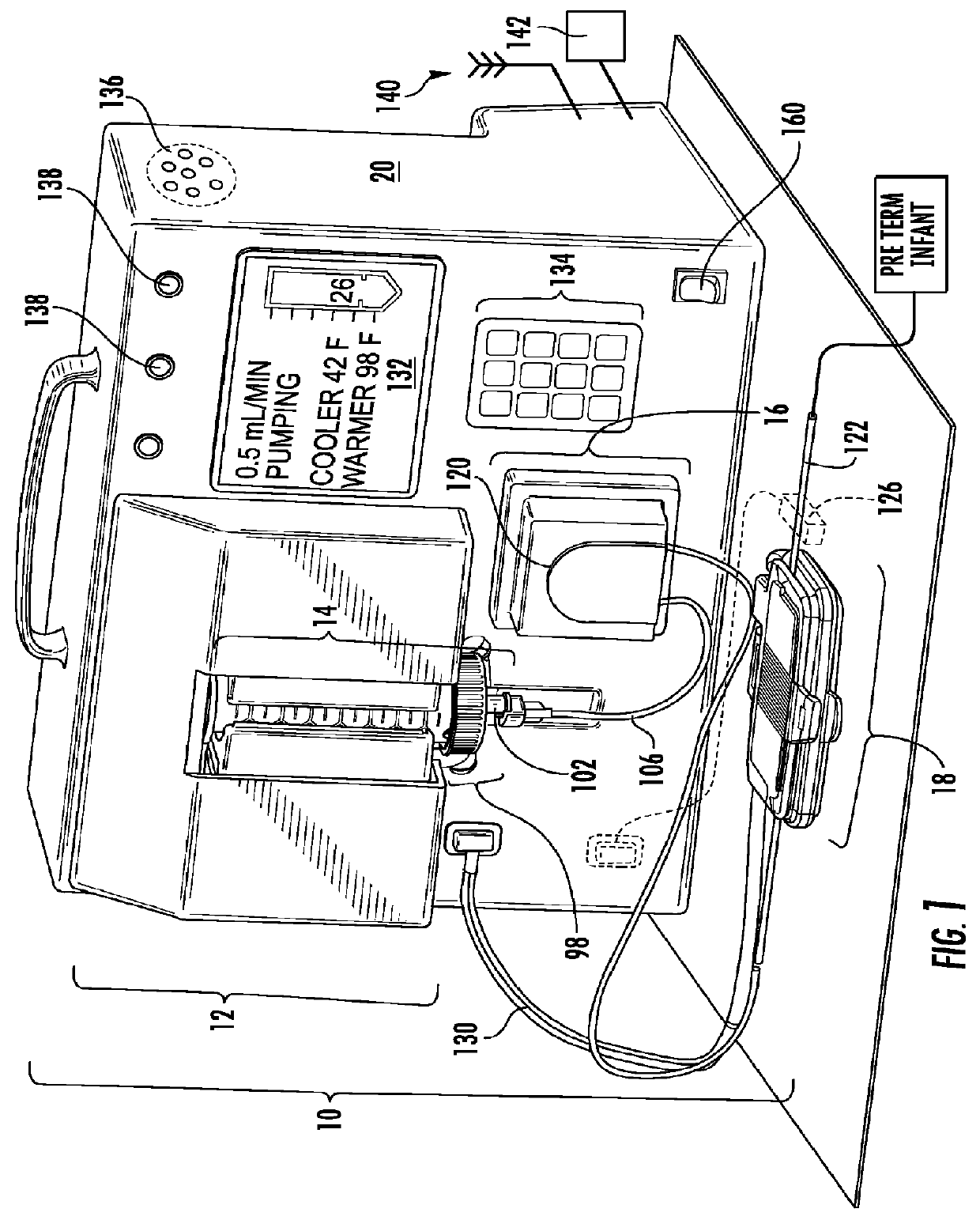

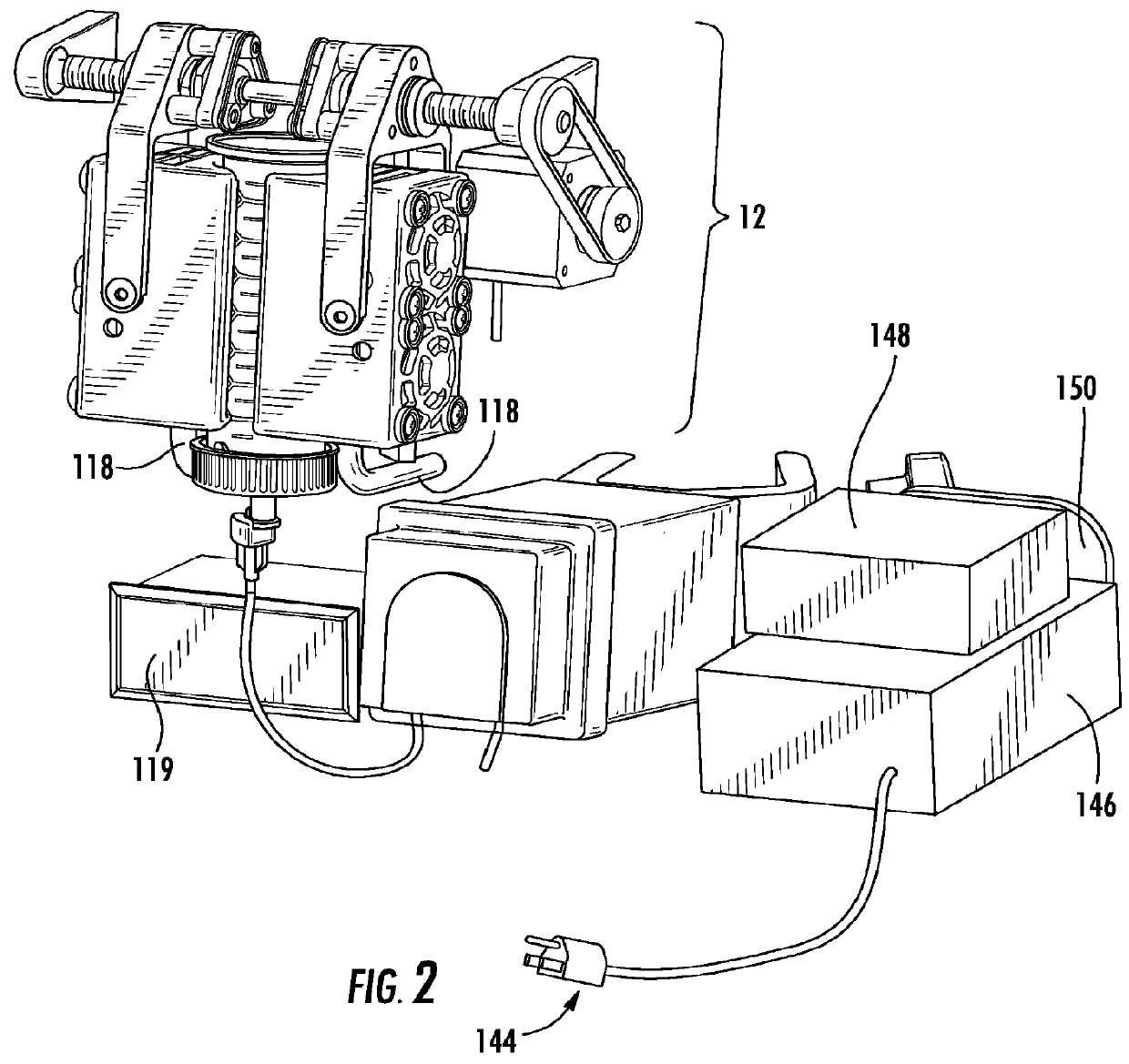

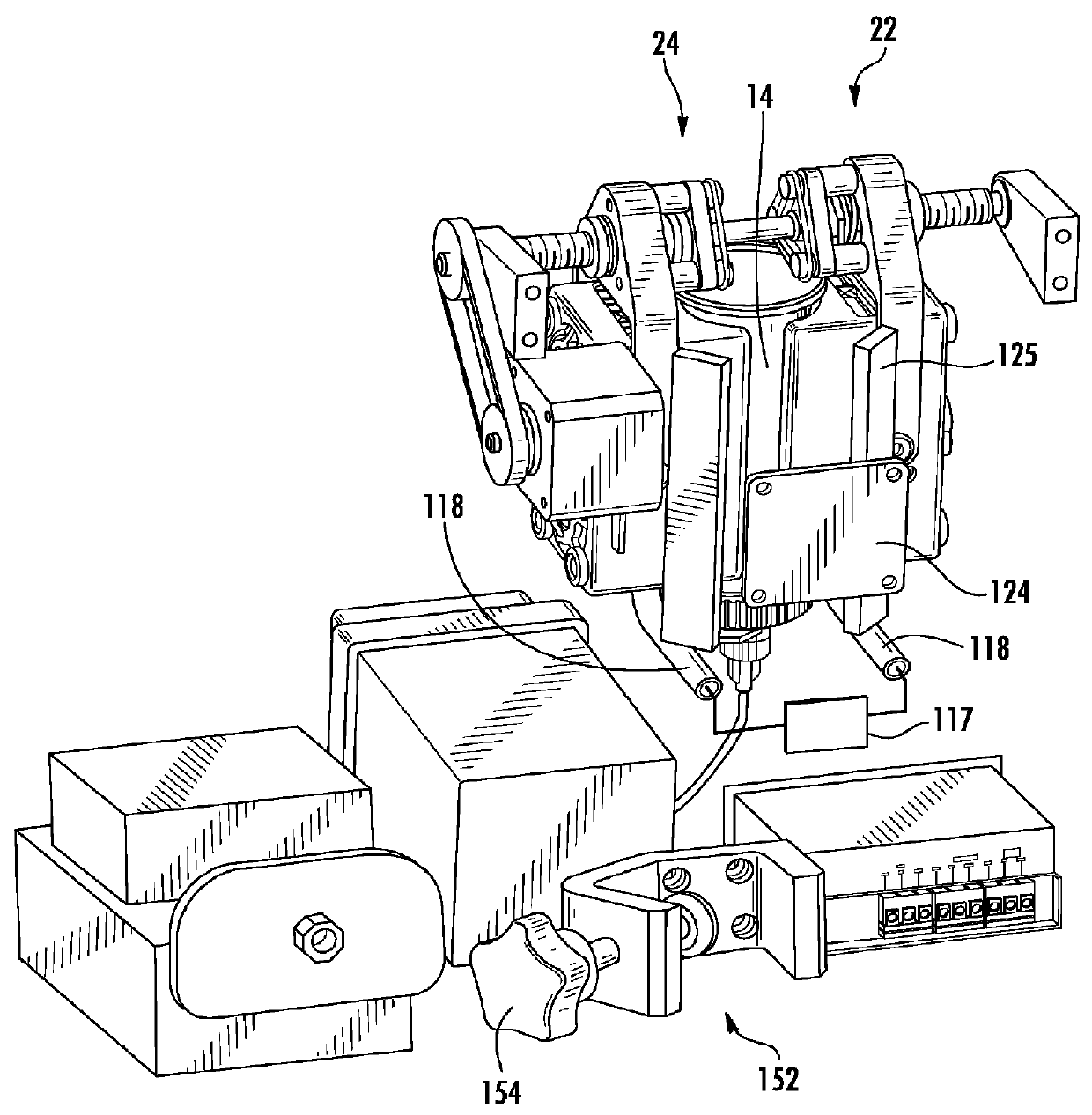

Neonatal enteral feeding system

ActiveUS20160030292A1Prevents feeding delayReduce bacterial growthMedical devicesIntravenous devicesPeristaltic pumpEnteral feedings

A neonatal enteral feeding system for delivering neonate fluid is disclosed. The system includes a cooling unit for cooling the breast milk before, during and after a feeding cycle to mitigate unwanted bacterial growth and reduction of fat content in the breast milk. The system also includes a warming unit for heating the cold breast milk to a temperature above room temperature (preferably, standard body temperature) so that the neonate can focus his or her energy on healing, growth and digestion instead of heat generation. Additionally, the system has a peristaltic pump which draws the breast milk from a bottom side of the container and the container is vented so as to be capable of delivering all of the breast milk in the container to the neonate.

Owner:MEDELA HLDG AG

Hands-free intramuscular injection device

InactiveUS20100185177A1Easy to operateLess fluctuation in rateAutomatic syringesMedical devicesIntramuscular injectionHydraulic circuit

An injection device for hands-free, transdermal injection of a liquid medicament, configured for easy handling and for manipulation by the use of the hand or fingers of the medical technician The device includes a housing having a base for attachment of the housing to the skin of a patient, an injection needle, and a reservoir for containing a vaccine. The device also has a means for expressing the vaccine from the reservoir through the injection needle that includes a mechanical force means for storing potential energy and exerting a mechanical force, and a hydraulic force means for transmitting the mechanical force into a hydraulic force. The hydraulic force is exerted onto the vaccine in the reservoir, thereby pressurizing and passing the vaccine through the injection needle. The mechanical force means is typically a mechanical spring, and the hydraulic force means is typically a closed hydraulic circuit.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

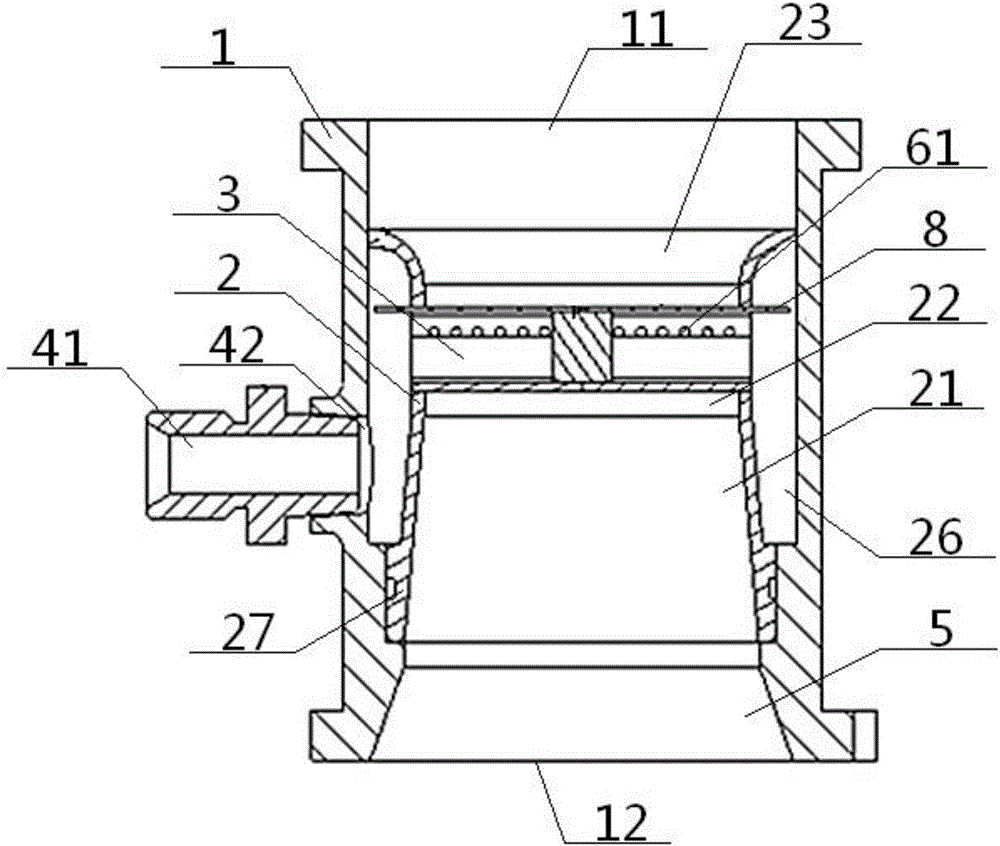

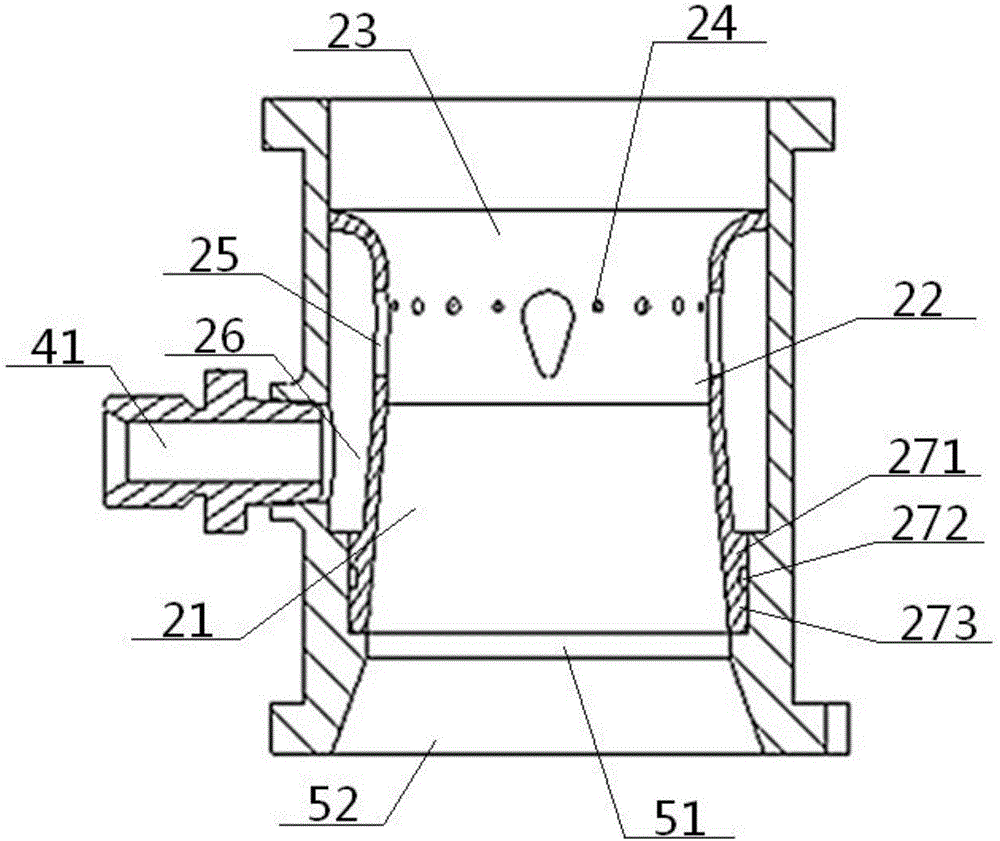

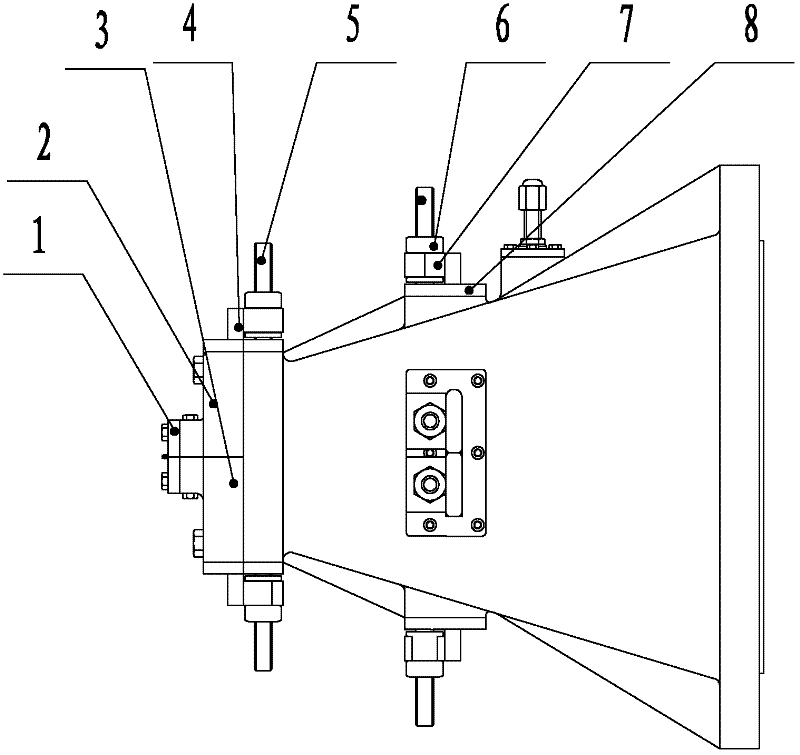

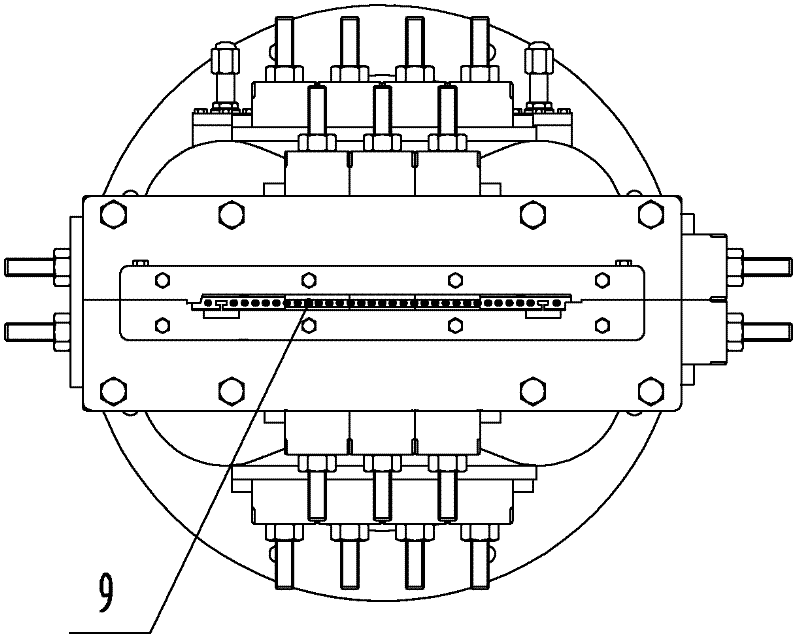

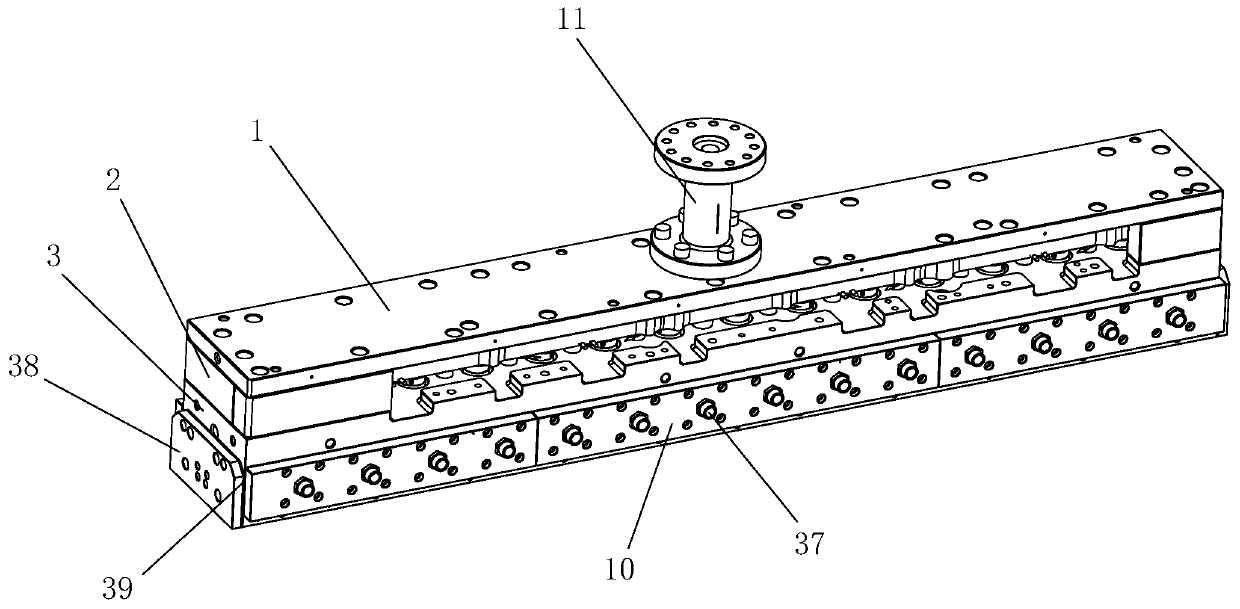

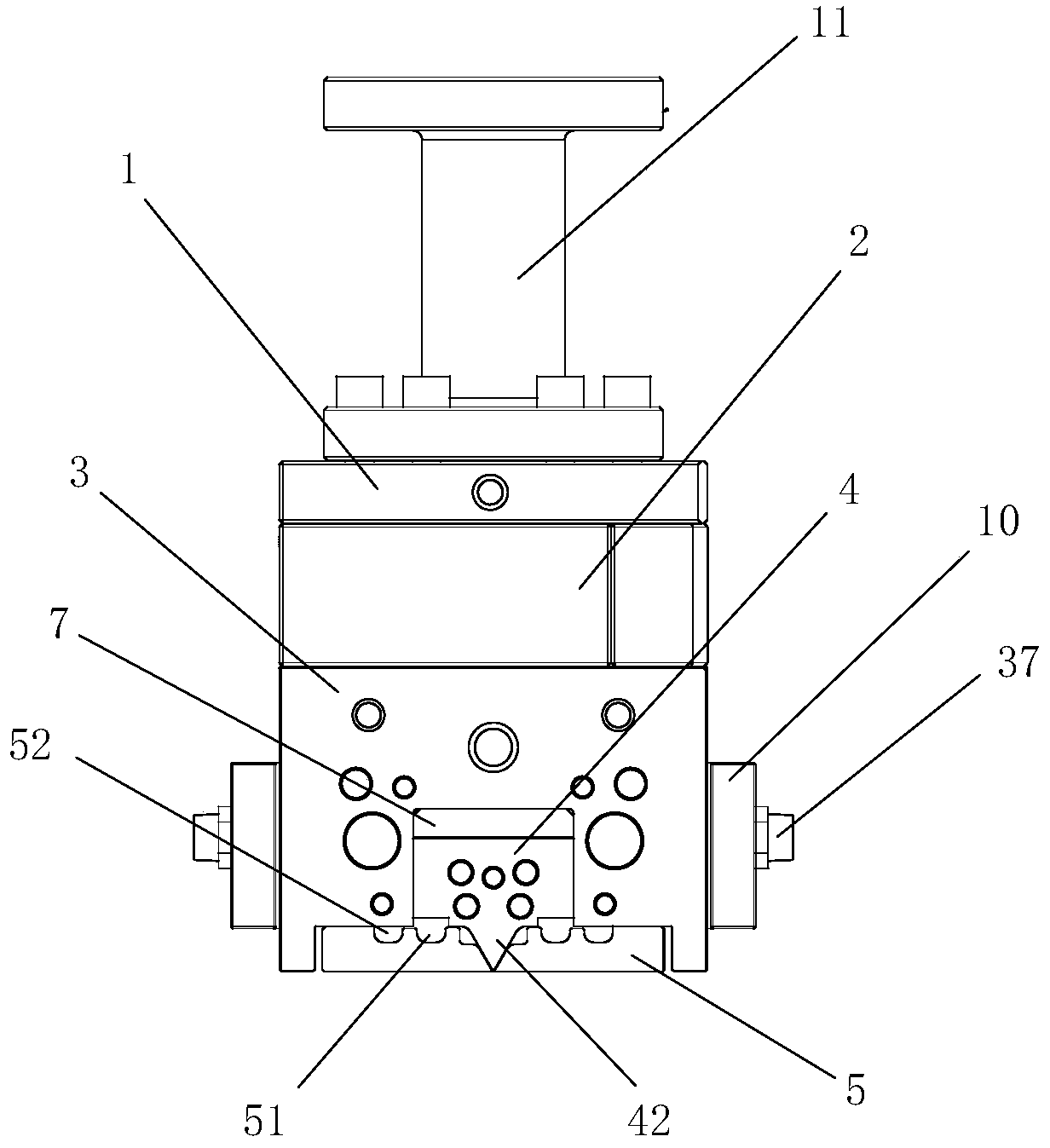

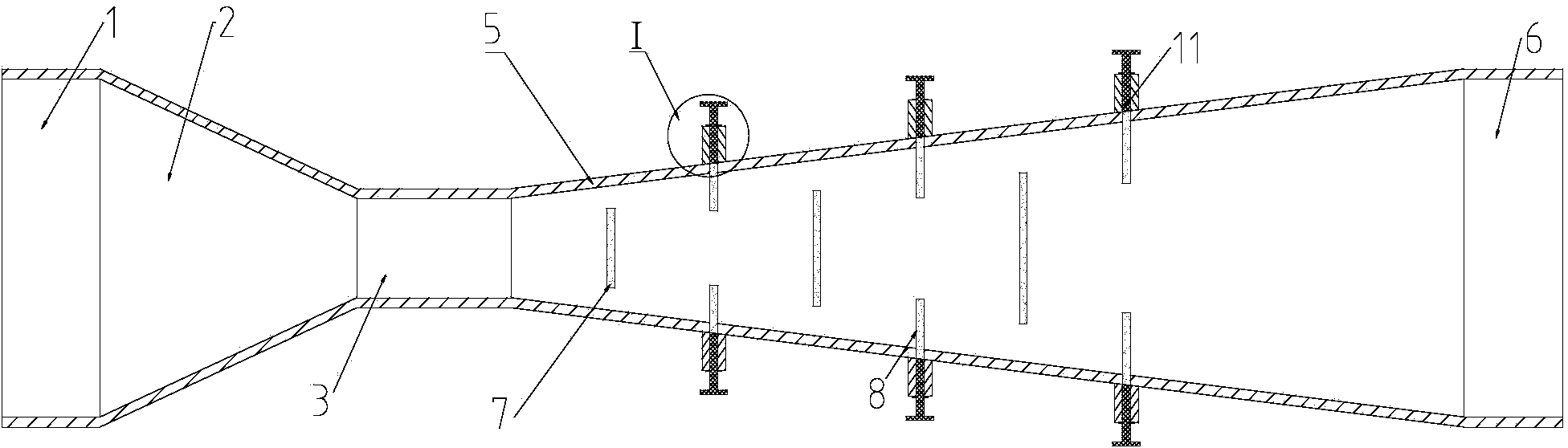

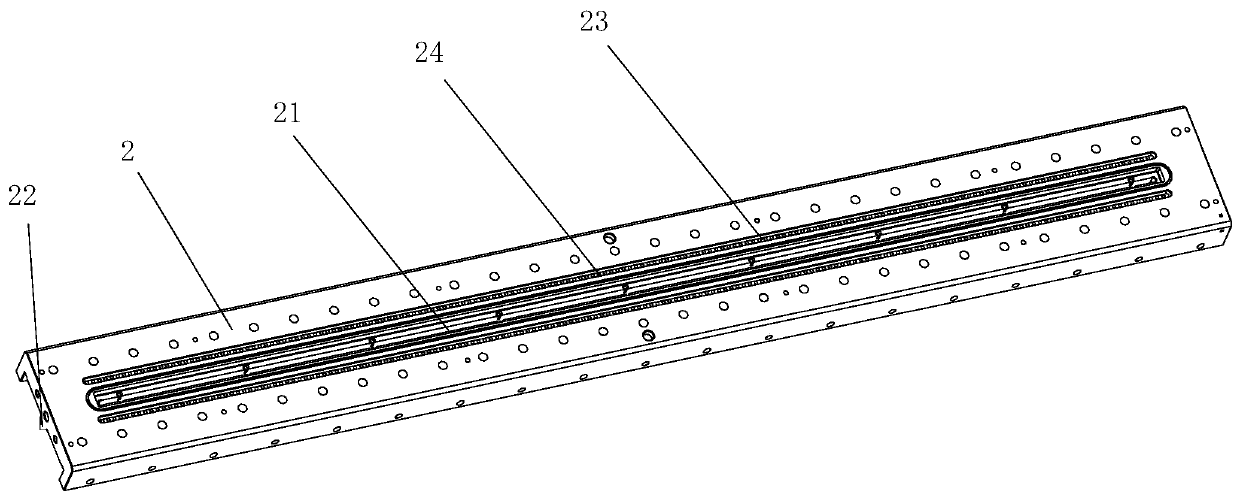

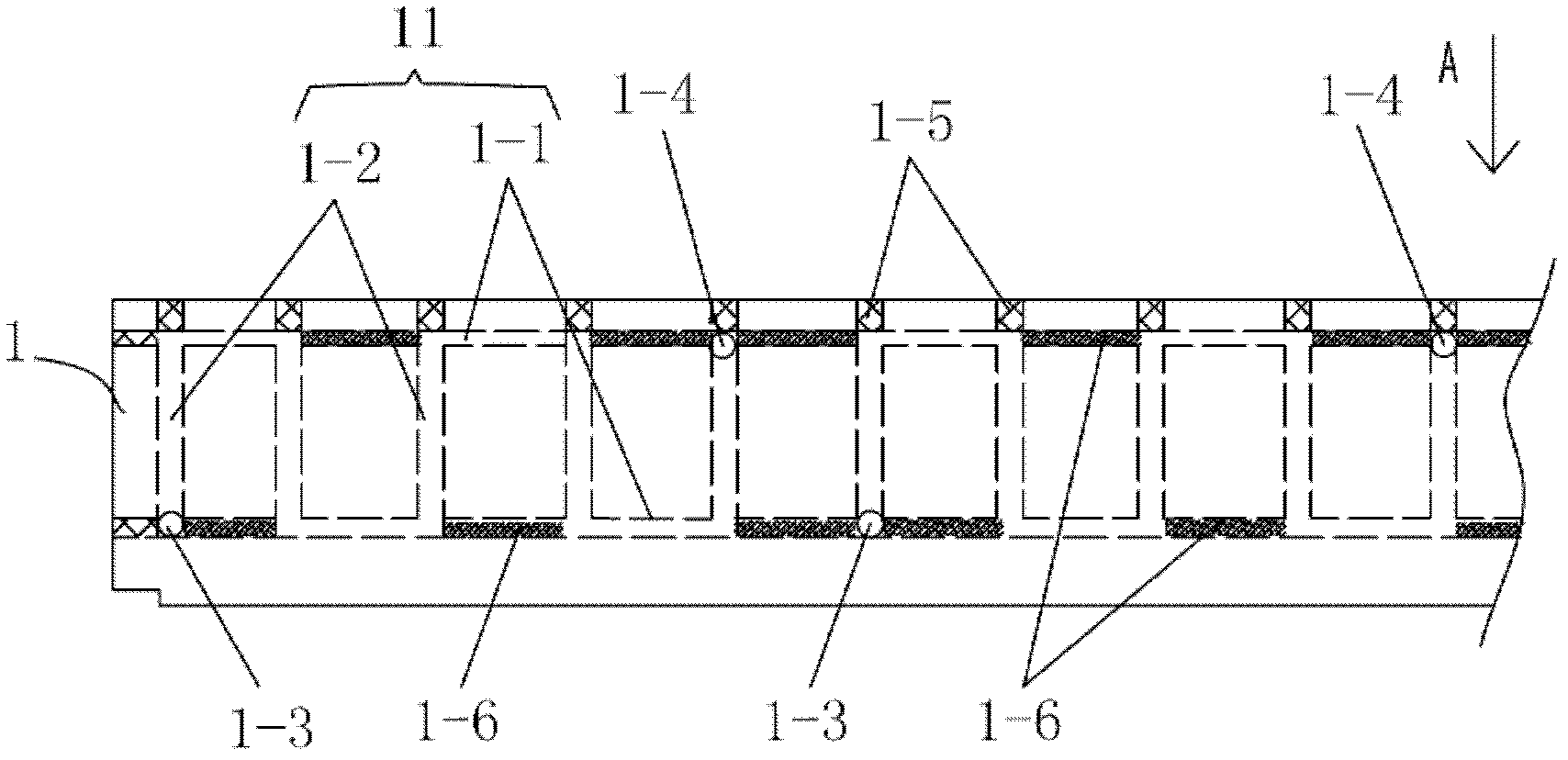

Multifunctional hanging plate and split brick extrusion forming mold

The invention relates to a multifunctional hanging plate and split brick extrusion forming mold. An outlet forming part consisting of upper and lower port plates, an upper machine port and a lower machine port is positioned at the outlet end of a machine head; a front section mud flow adjusting part consists of an adjusting plate and a pressing plate 1; a middle section mud flow adjusting part consists of an adjusting plate 2 and a pressing plate 2; a hole forming core is positioned in a wall consisting of the upper machine port and the lower machine port and connected and fixed through a bolt; and two sets of electronic pressure sensing display devices are arranged at positions above two sides in the rear of the middle section of the machine head. The extrusion forming mold can be matched with large and medium vacuum extruders, raw materials with different parameters, such as pottery clay, shale, coal gangue, fly ash and the like can be used, and the conventional production situation that single pottery clay is used as a raw material is changed; and the extrusion forming mold is technically matched and connected with the large and medium vacuum extruders with extrusion pressure of more than 2.5MPa, a hollow hanging plate and a plurality of split bricks are produced, the product range is further expanded, the requirement of the building industry on specification diversity of wall material products is met, the reformation of wall materials is pushed, the technical level of equipment for producing bricks and tiles in China is greatly improved, and social and economic development is promoted.

Owner:程永科

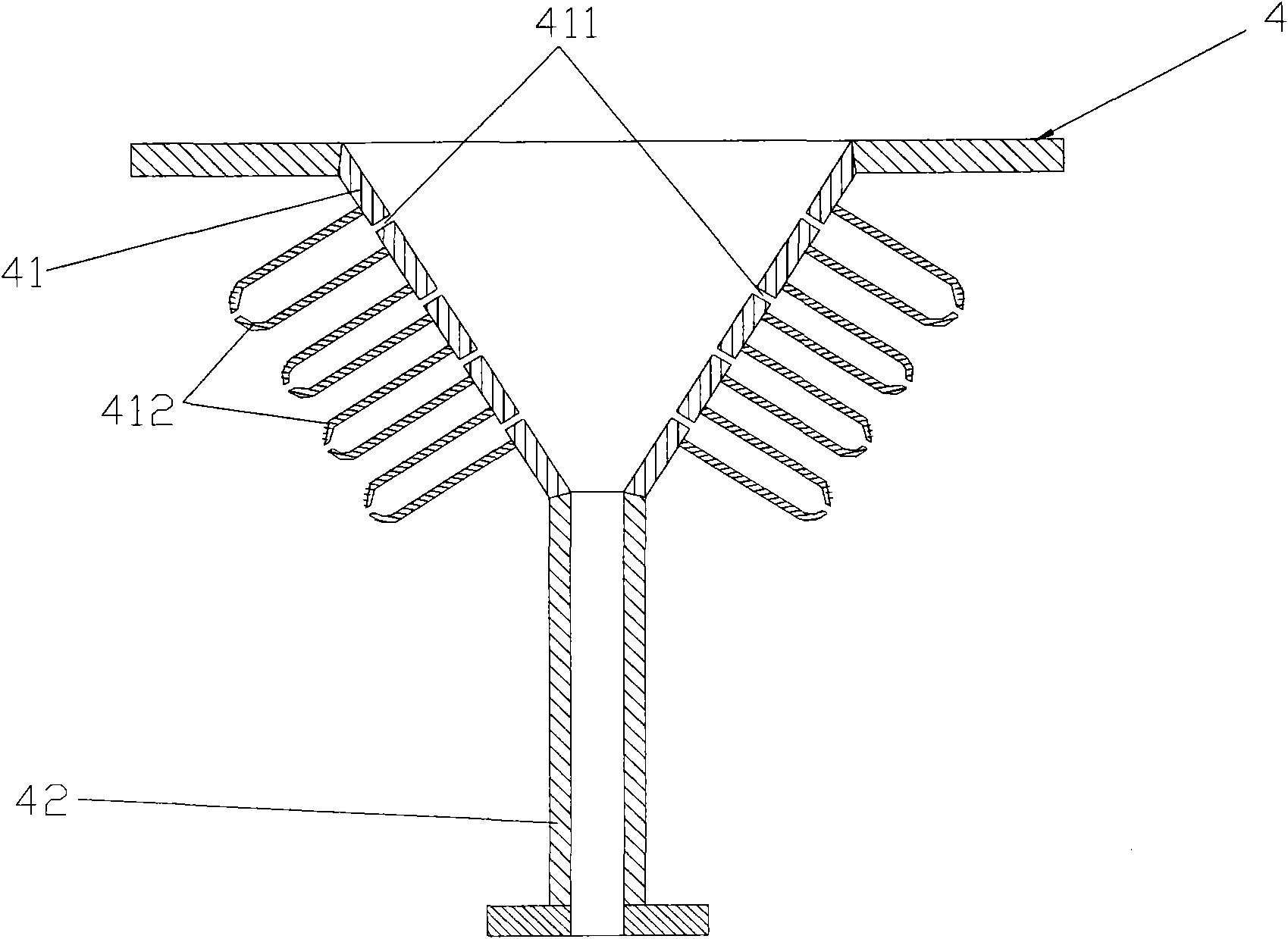

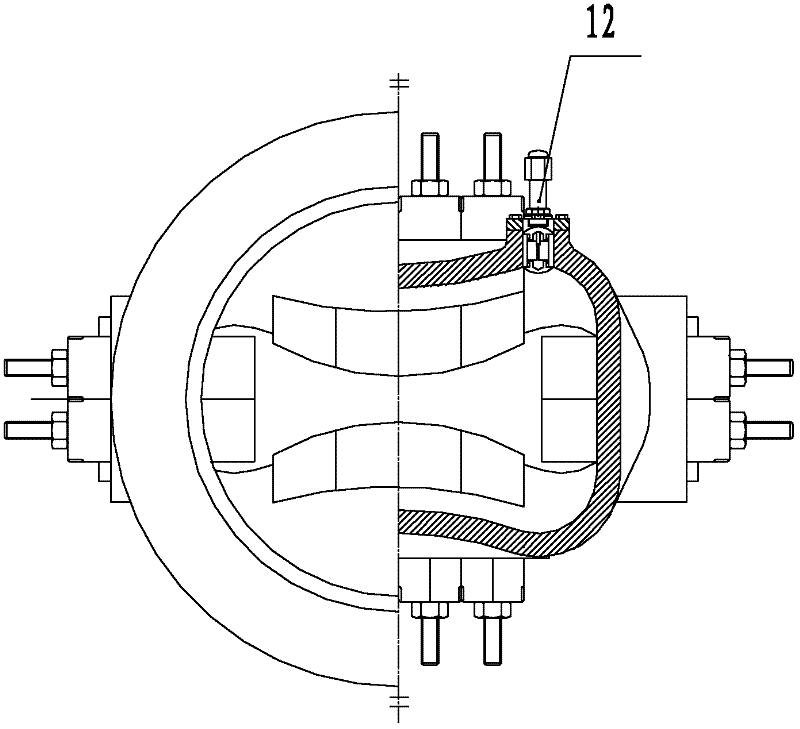

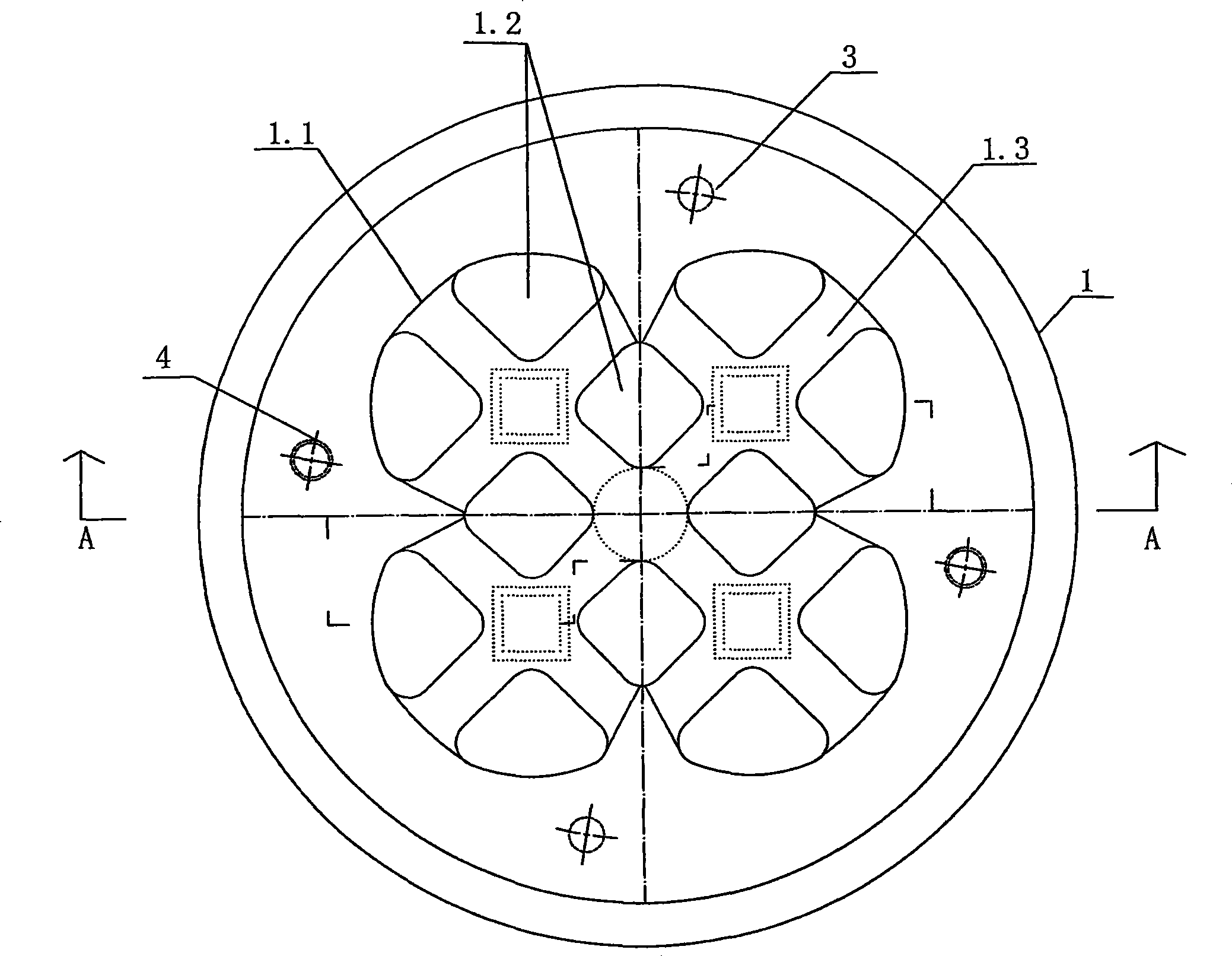

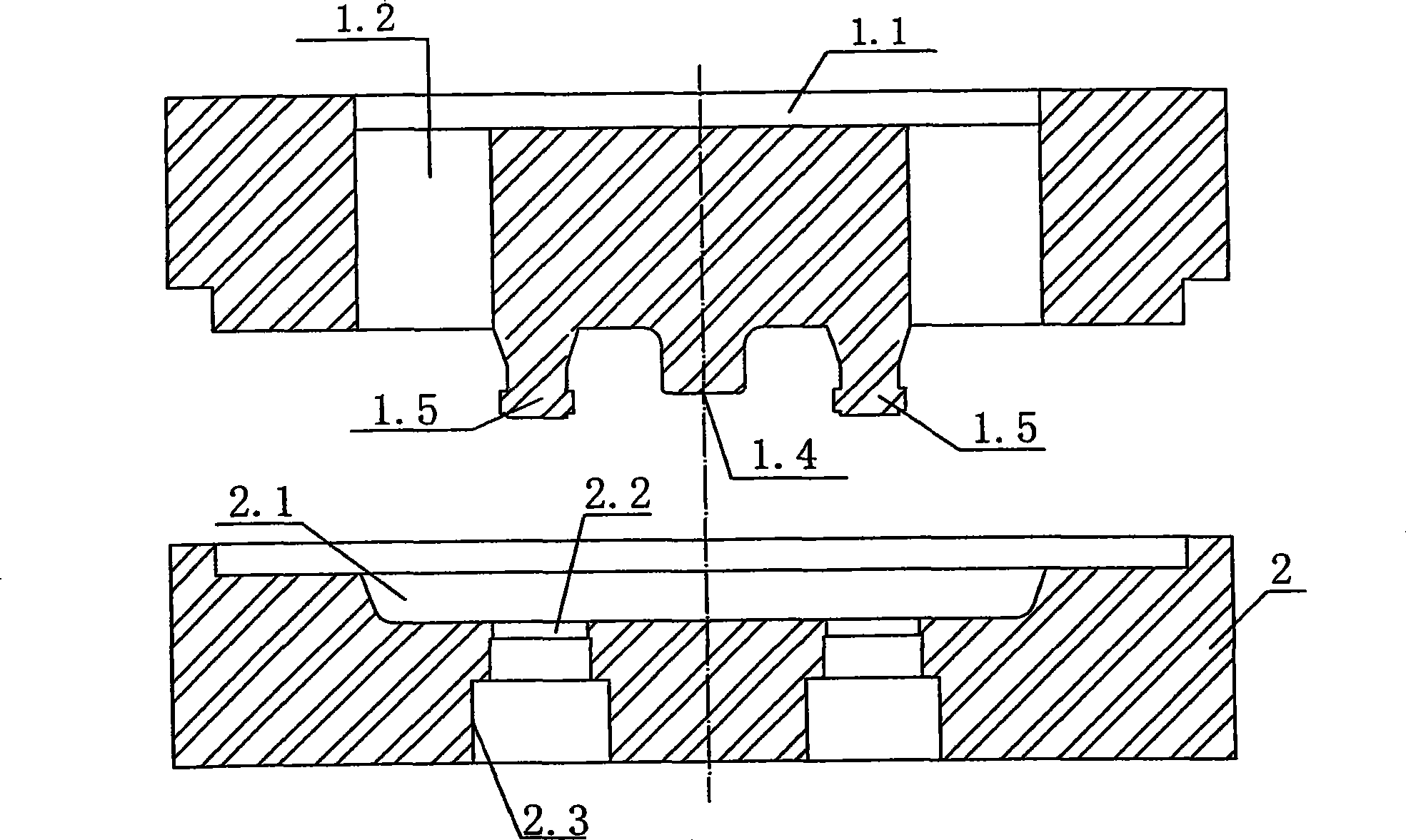

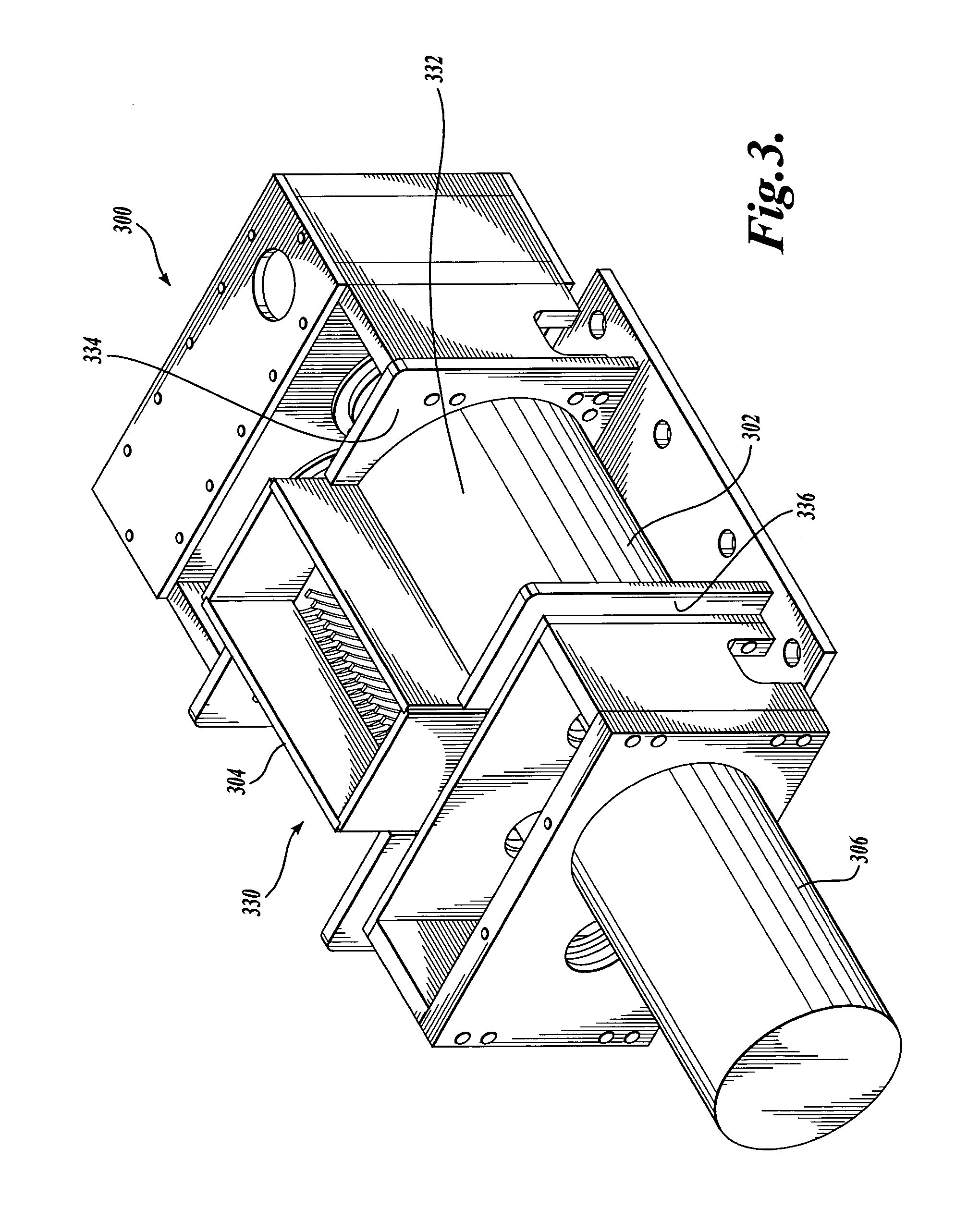

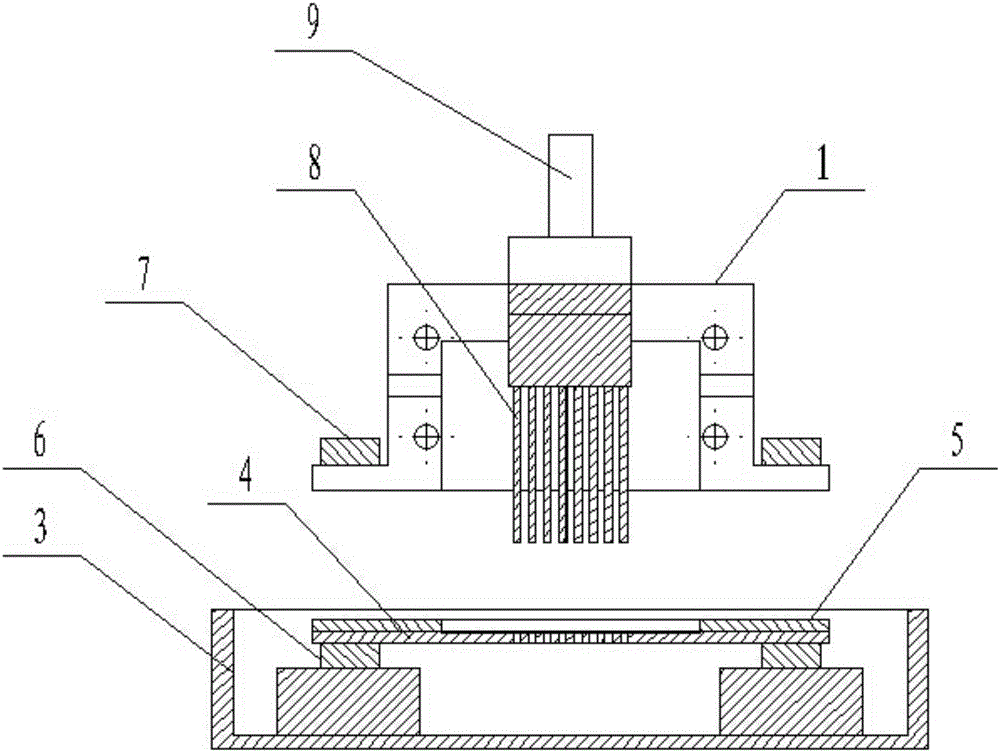

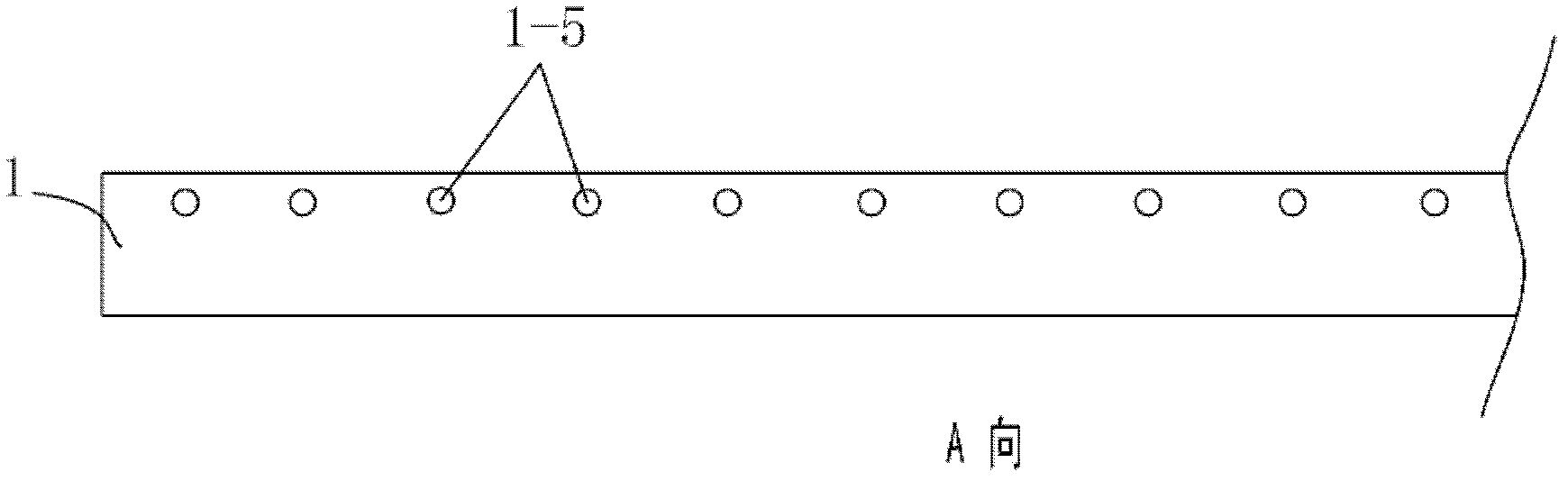

One-die multiple-part aluminium alloy tube hot-extrusion die

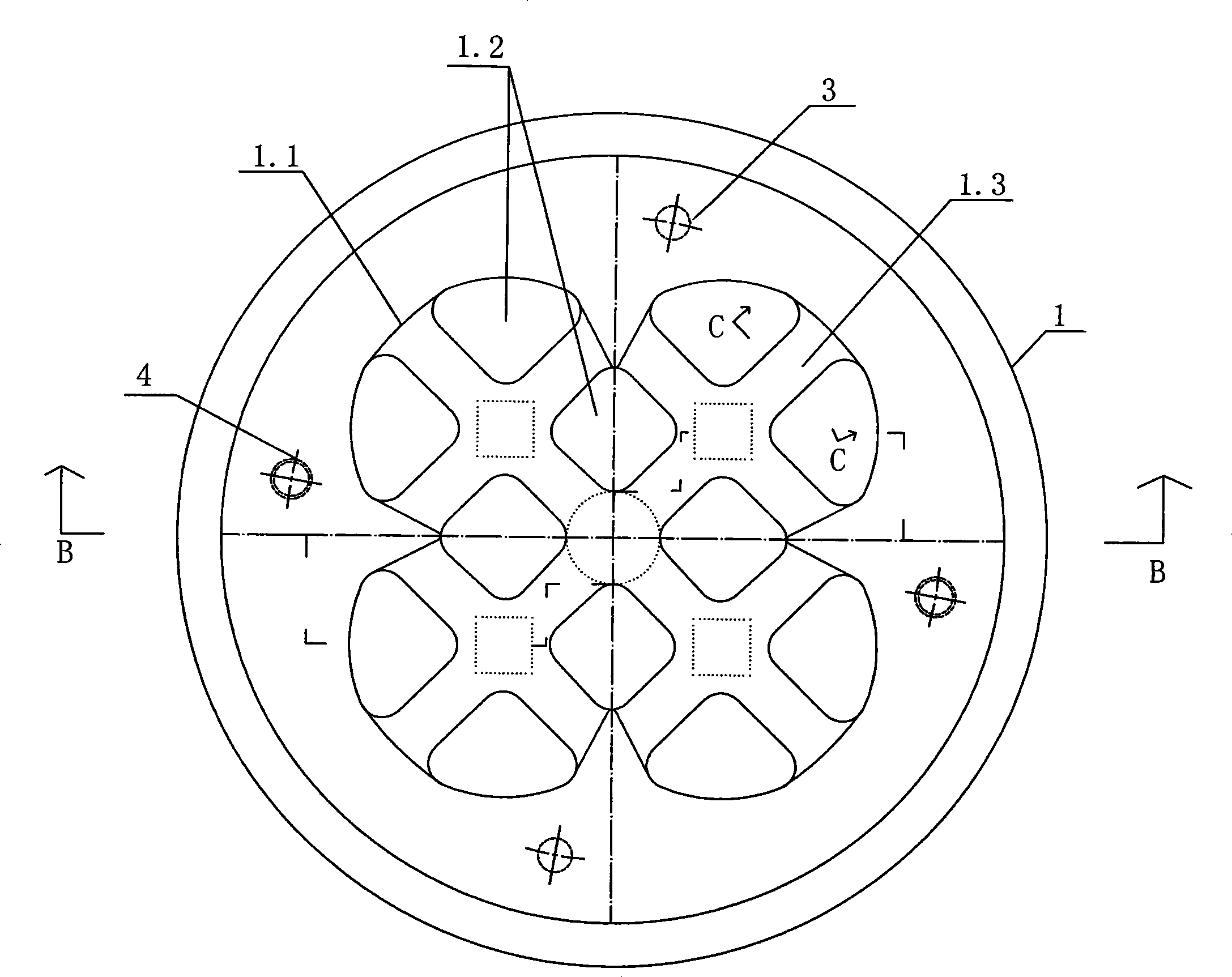

InactiveCN101362163AGuaranteed stabilityAvoid weld linesExtrusion diesDrop structureMaterials science

The invention relates to a hot extrusion die of aluminum alloy pipes with multiple output, in particular to the hot extrusion of the aluminum alloy pipes and is formed by assembling and combining an upper die (1) and a lower die (2), wherein, a feeding end of the lower die (2) is provided with a welding chamber (2.1) and a die cavity (2.2) and a discharging hole (2.3) is processed at a discharging end of the lower die (2); the feeding end of the upper die (1) is provided with a decompress counter bore (1.1), and split flow holes (1.2) of the upper die (1) are distributed in a multiplied way with the die cavity (2.2) of the lower die (2) and are positioned at the circumference of the die cavity (2.2) of the lower die (2); all bridge sites (1.3) of the upper die (1) are processed into water drop structure; the discharging surface of the upper die (1) is provided with a plurality of square head die cores (1.5) which are provided with a support lug boss (1.4) among the square head die cores (1.5), and the lug boss (1.4) is closely and directly attached to the bottom part of the welding chamber (2.1) of the lower die (2); the square head die cores (1.5) and the bridge sites (1.3) are transited smoothly. The hot extrusion die can cause the extrusion products of the aluminum alloy pipes to be uniform in wall thickness, consistent in flow rate and high in rate of finished products.

Owner:JIANGYIN GIANSUN MOLD

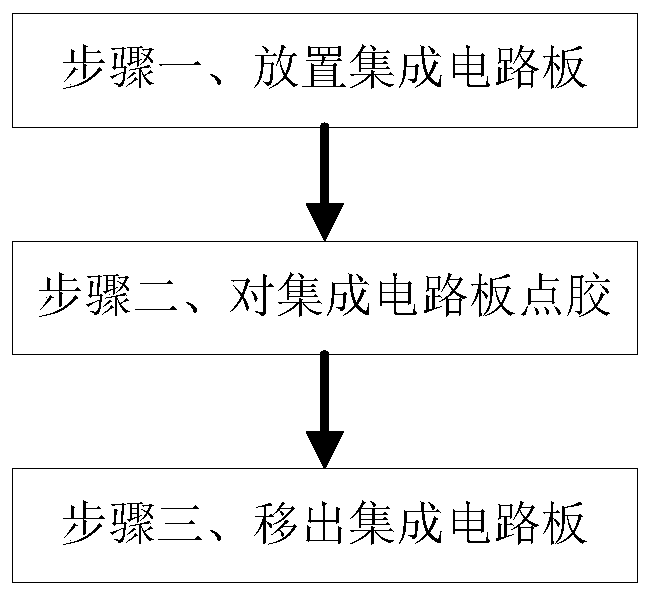

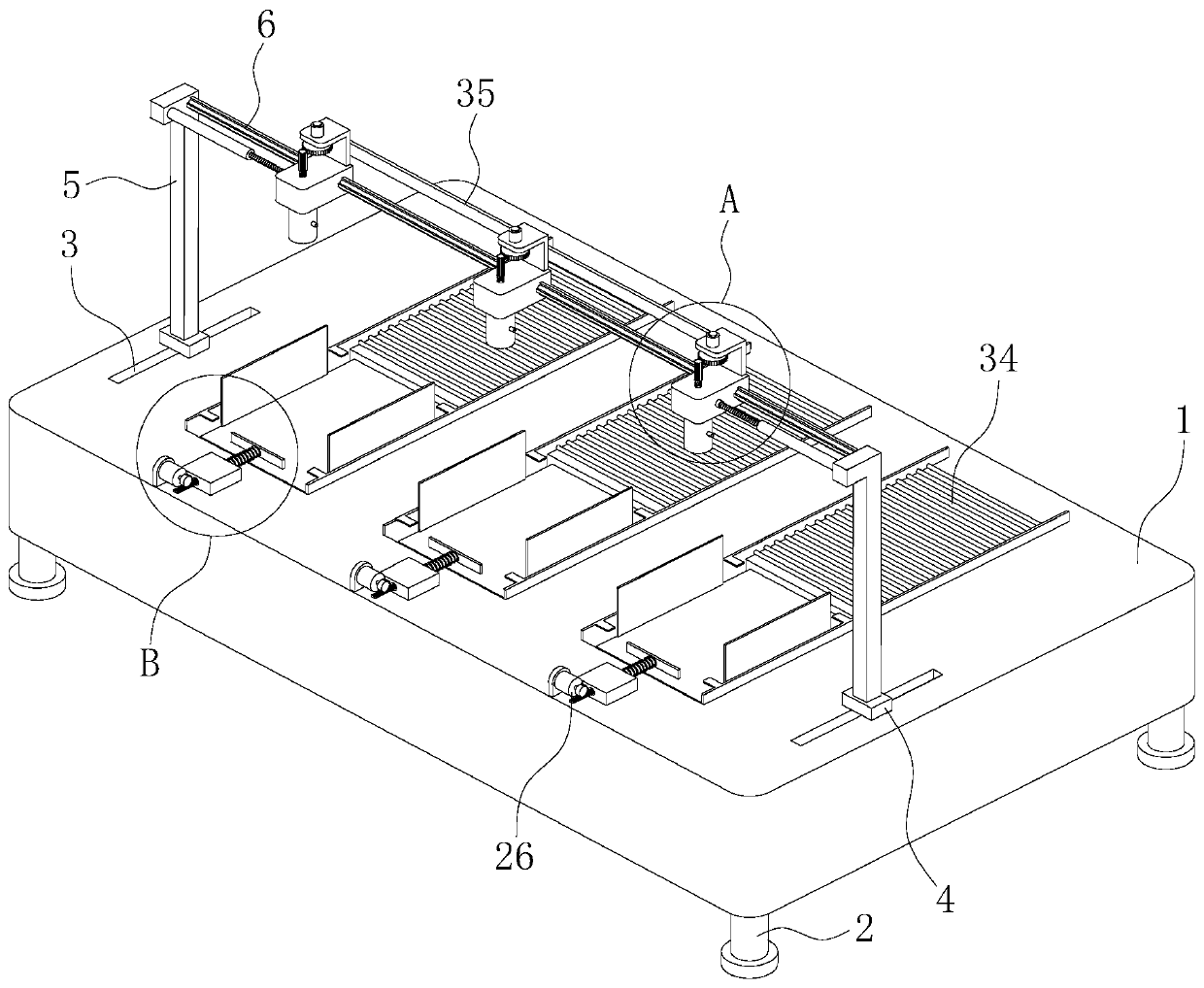

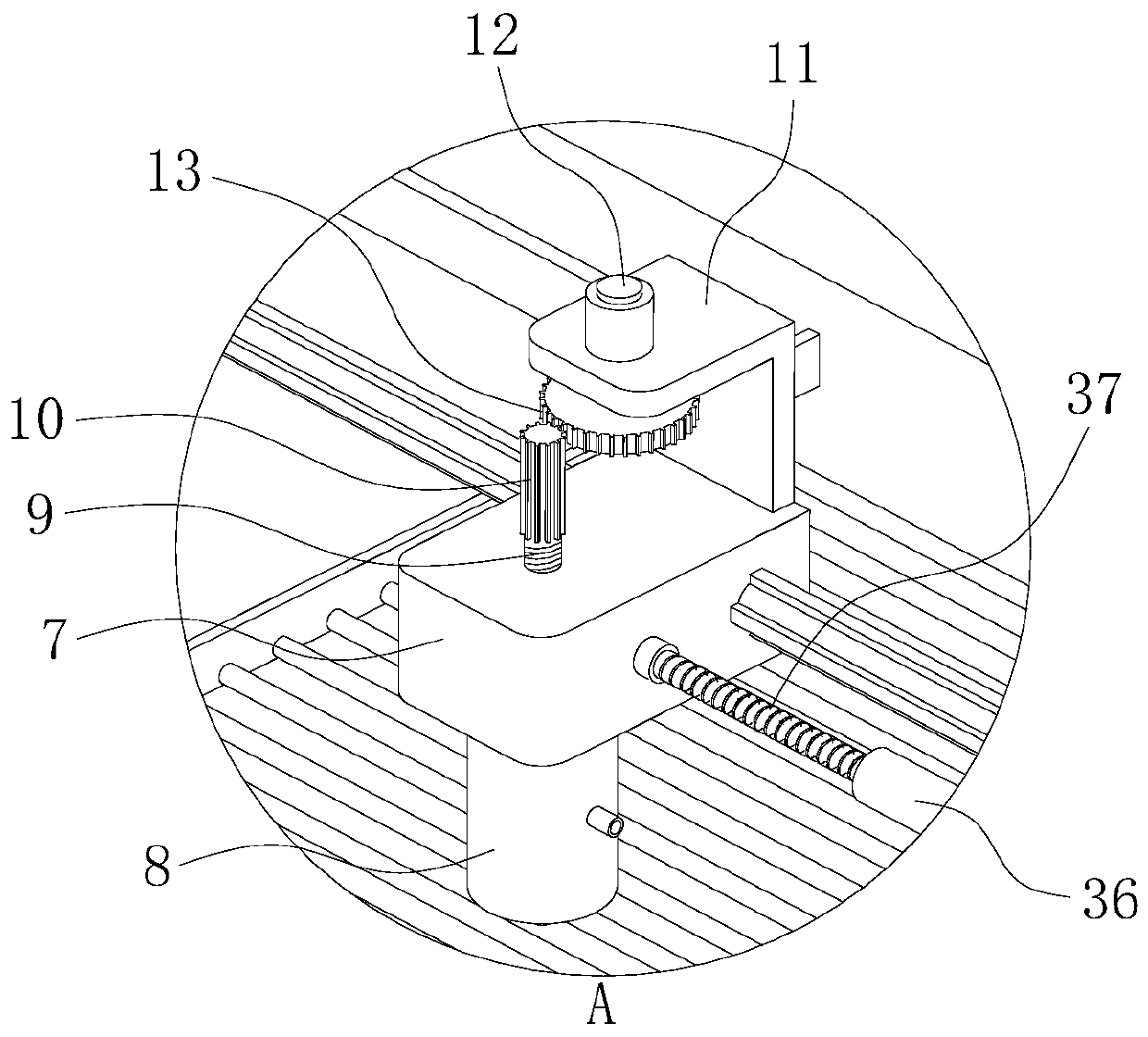

Integrated circuit board manufacturing method

InactiveCN111341702APrecise time controlPrecise control of dispensing volumeSemiconductor/solid-state device manufacturingElectric machineEngineering

The invention belongs to the technical field of integrated circuit boards, and particularly relates to an integrated circuit board manufacturing method. An integrated circuit board manufacturing and processing device is adopted to perform glue dispensing on the surface of a circuit board. The method specifically comprises the following steps: step 1, placing integrated circuit boards: stacking integrated circuit boards on the upper surface of a bearing plate; step 2, dispensing glue onto the integrated circuit boards: aligning a glue outlet with a position to be dispensed on the integrated circuit boards by adjusting the positions of an electric sliding block and a mounting block, and rotating a motor in a reciprocating manner to drive a rubber plug to move upwards so as to enable silica gel in a dispensing head to flow out of the glue outlet and drop onto the uppermost integrated circuit board; and step 3, moving out the integrated circuit board: pushing the integrated circuit board at the uppermost layer out of an accommodating cavity through a pushing mechanism. When the integrated circuit board manufacturing method provided by the invention is adopted to dispense glue on the surface of an integrated circuit board, the glue dispensing amount and the glue dispensing position can be accurately controlled.

Owner:郭东东

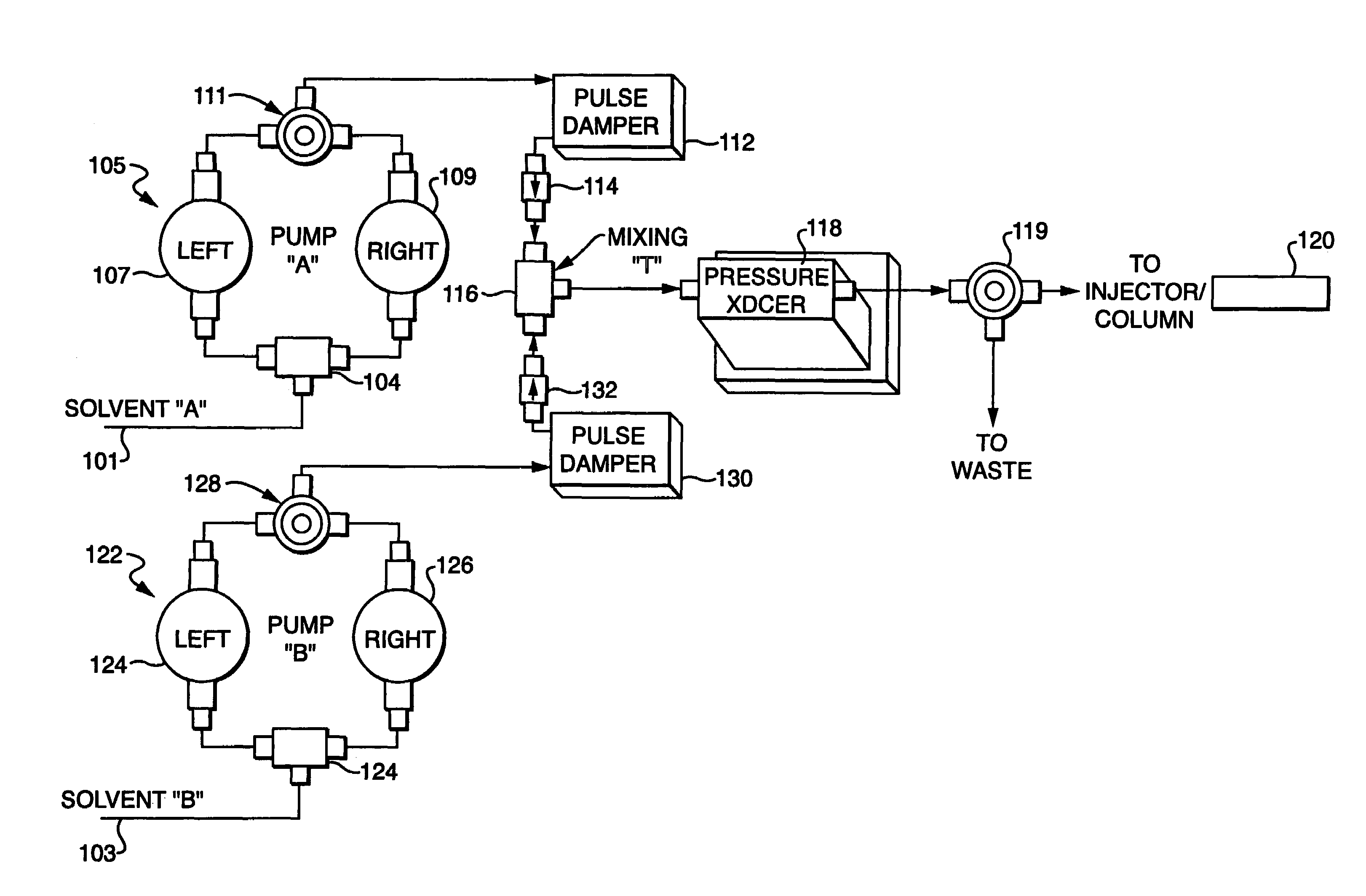

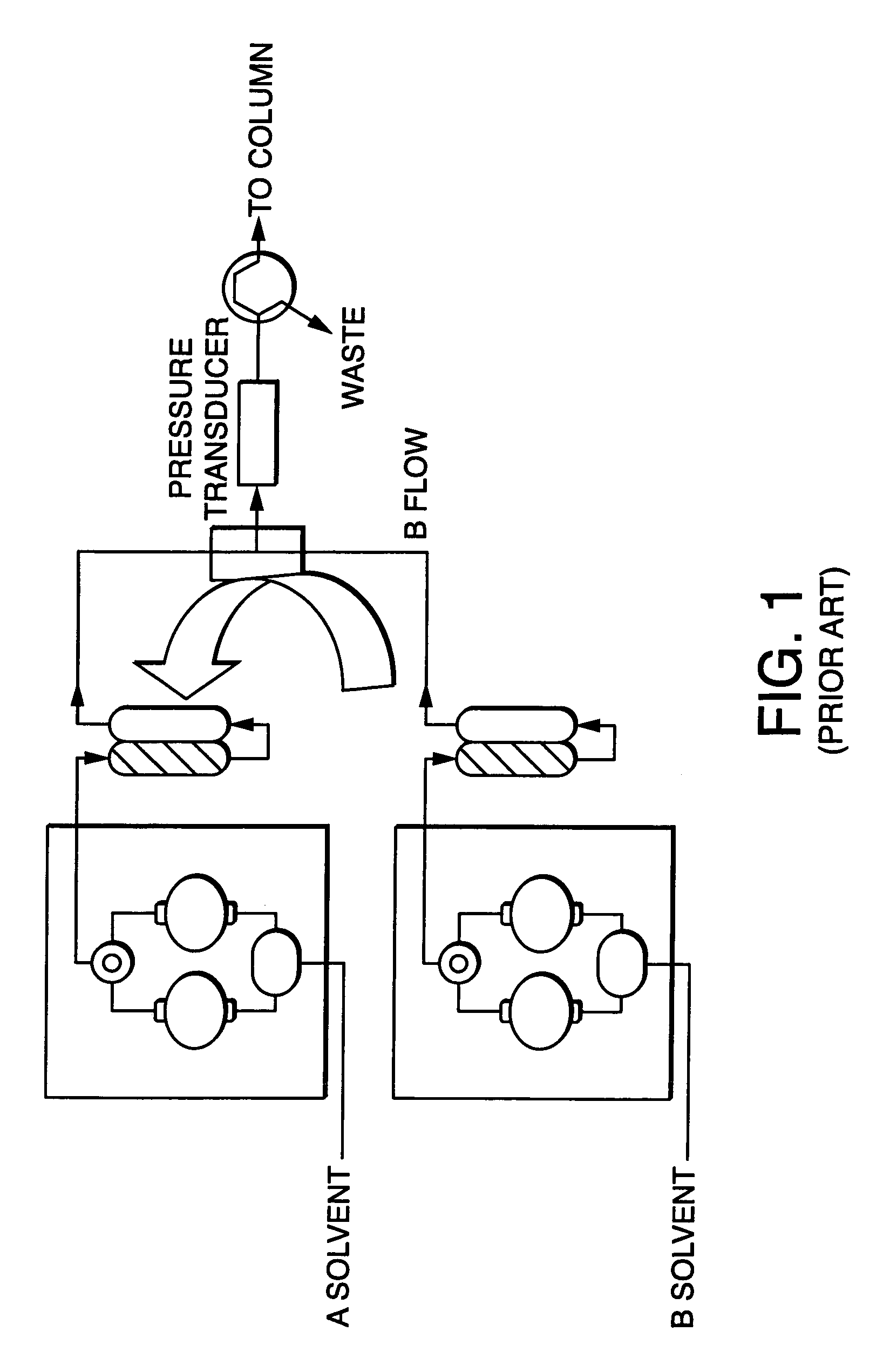

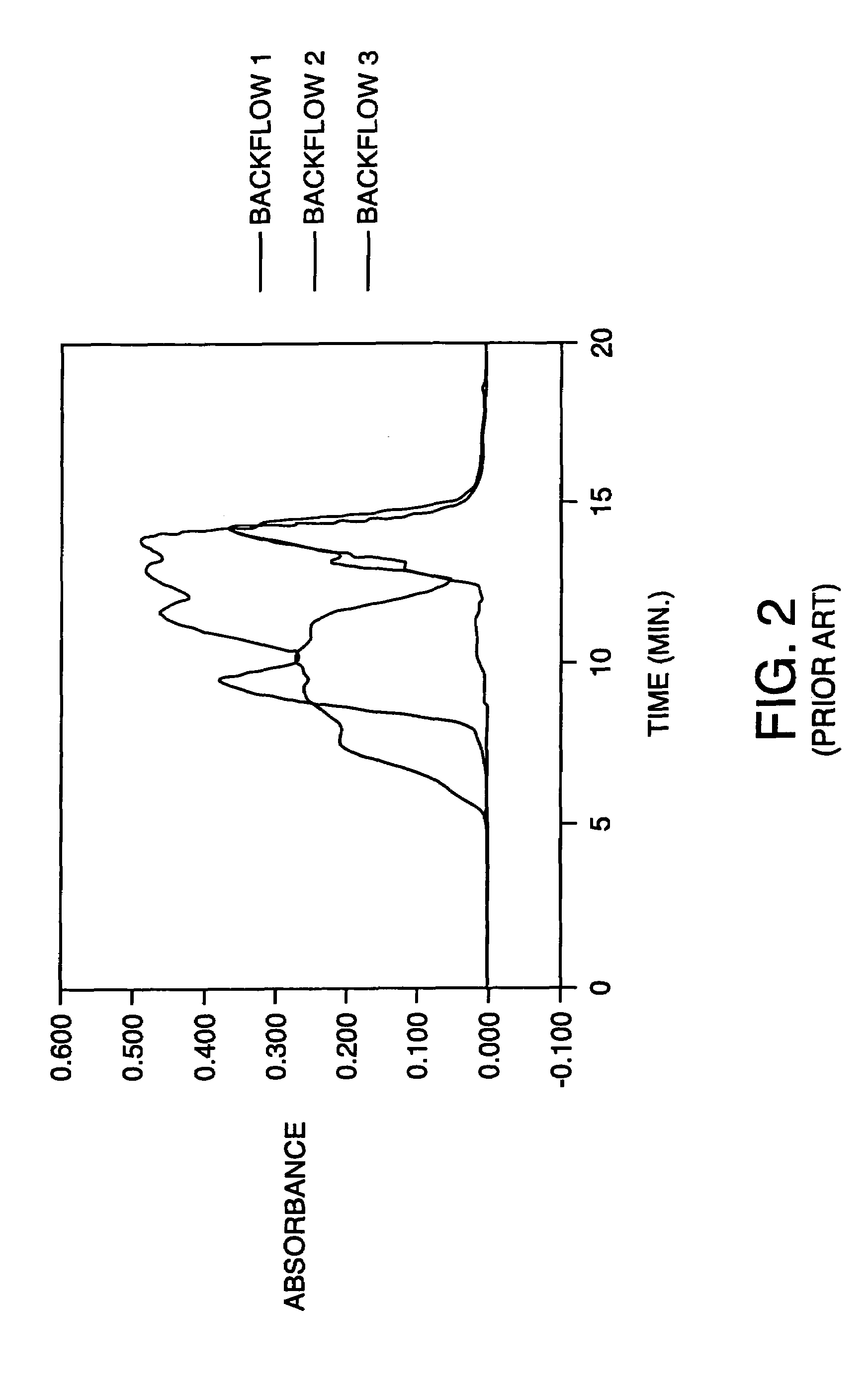

Backflow prevention for high pressure gradient systems

ActiveUS7396469B2Improving compositional accuracyImprove performanceComponent separationIon-exchanger regenerationEngineeringSolvent

Gradient performance with high pressure gradient solvent delivery system is optimized by approximation of infinite stroke volume of high pressure pumps by the addition of pulse dampening with backflow prevention to each high pressure pump. The backflow prevention adds sufficient minimum flow resistance, thereby enhancing the performance of the pulse dampening over a wider range of flow rates resulting in consistent gradient performance.

Owner:WATERS INVESTMENTS

Methods and Systems for Supplying Liquid Feed to Livestock

InactiveUS20090107405A1Reduce feeding costsPrevents gorgingAnimal watering devicesAnimal feeding devicesLine tubingProcess engineering

Methods and systems for providing liquid feed to livestock deliver the liquid feed to a feeding station at a temperature below that of the mother's natural milk to encourage use of the liquid feed by the young as a supplement and not a replacement. A second reservoir expands the capacity of the system without increasing the size of the mixing reservoir. The second reservoir is equipped with selectively operable refrigeration and heating elements to facilitate cooling of the liquid feed or heating of a cleaning solution. A peroxide doser introduces small quantifies of peroxide to clean the liquid feed and prevent gorging. Orifices through which feed is discharged at feeding stations decrease in cross sectional area along the circulation line in the direction of flow to counteract variation in discharge flow rates caused by a pressure differential in the liquid feed along the line.

Owner:HARE JOHN +1

WUCS Fibers Having Improved Flowing And Dispersing Properties

InactiveUS20100055439A1Improve liquidityWeaken energyBuilding componentsConstructions elementsFiberPolyamide

A sizing composition including one or more primary lubricants, at least one secondary lubricant, and at least one coupling agent is provided. The primary lubricant is a fatty amide lubricant that is the condensation product of a saturated fatty acid having at least 16 carbon atoms and a polyamine. Additionally, the primary lubricant acts both as a lubricant and as a cationic surfactant in the size composition when it is neutralized with a weak acid to assist in dispersing the fibers in a gypsum slurry. The secondary lubricant is polyamide or a polyvinyl amine, and acts as a film forming agent in the fiberizing process to protect the glass fibers from interfilament abrasion. The sizing composition provides improved fiber feeding, fiber flow, and fiber dispersion in a gypsum matrix or slurry. The weight ratio by dry solids of primary to secondary lubricant in the size composition is at least 5:1.

Owner:OCV INTELLECTUAL CAPITAL LLC

Waste-heat utilization heat exchanger with constant output fluid temperature

InactiveCN103615919AStable temperatureLow flow resistanceStationary tubular conduit assembliesRecuperatorEngineering

A waste-heat utilization heat exchanger with a constant output fluid temperature comprises heat exchange tube bundles, a shell, an inlet header and an outlet header. The heat exchange tube bundles are arranged in the shell, and the two ends of each heat exchange tube bundle are connected with the inlet header and the outlet header respectively. The inlet header is provided with an inlet pipe, the outlet header is provided with an outlet pipe, and a tail gas inlet and a tail gas outlet are formed in the upper portion and the lower portion of the shell respectively. The inlet pipe is provided with a valve and a temperature sensor, and an outlet temperature sensor is arranged in the outlet pipe. The temperature sensor and the valve are both in communication connection with a central control unit. The waste-heat utilization heat exchanger is an efficient clean type heat reclaim unit and has the advantages of being strong in heat-transfer capability and the like, the outlet water temperature is kept constant by the way of controlling the flow of heat exchange fluid which is input to the heat exchanger, the technical effect that the temperature of output water is constant can be achieved, and therefore intelligent control over the heat exchanger is achieved.

Owner:SHANDONG UNIV

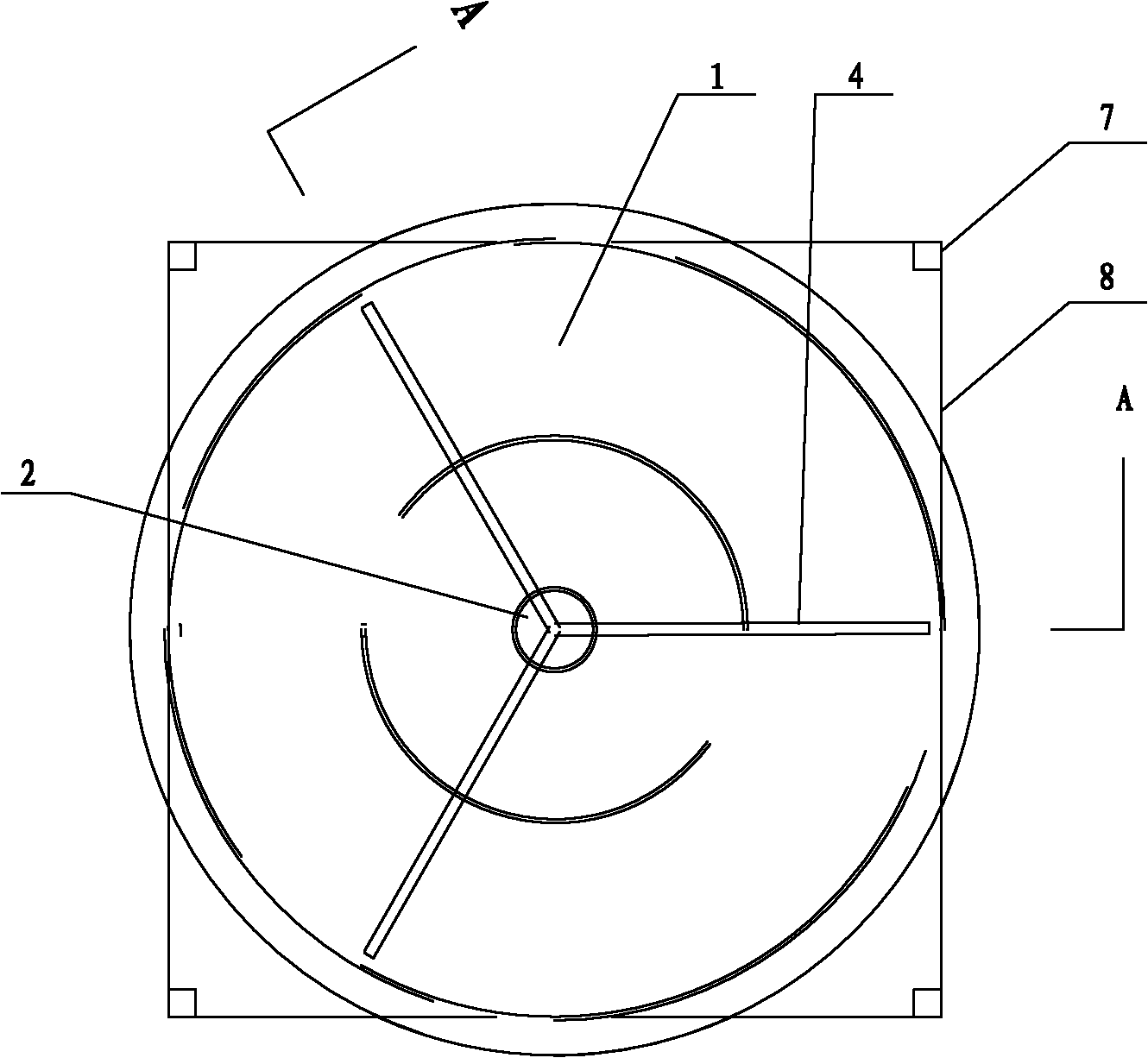

Microcystis aeruginosa research device

InactiveCN102174373AConsistent flow rateAvoid the shortcomings of partial push flow and unstable flow stateBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringLighting system

The invention discloses a microcystis aeruginosa research device which comprises a water tank, a motor and a lighting system, wherein the water tank is in the shape of an annular column with an upward opening; the motor is arranged in the center of circle of the water tank; an output shaft of the motor is provided with vertical supporting beams; the top ends of the supporting beams are provided with horizontal suspension arm beams; water pushing sheets are arranged below the suspension arm beams and extend into the water tank; and the lighting system is arranged at the periphery of the water tank. The device has the characteristic that a water body has basically consistent flow velocity during an experiment.

Owner:北京市水利科学研究所

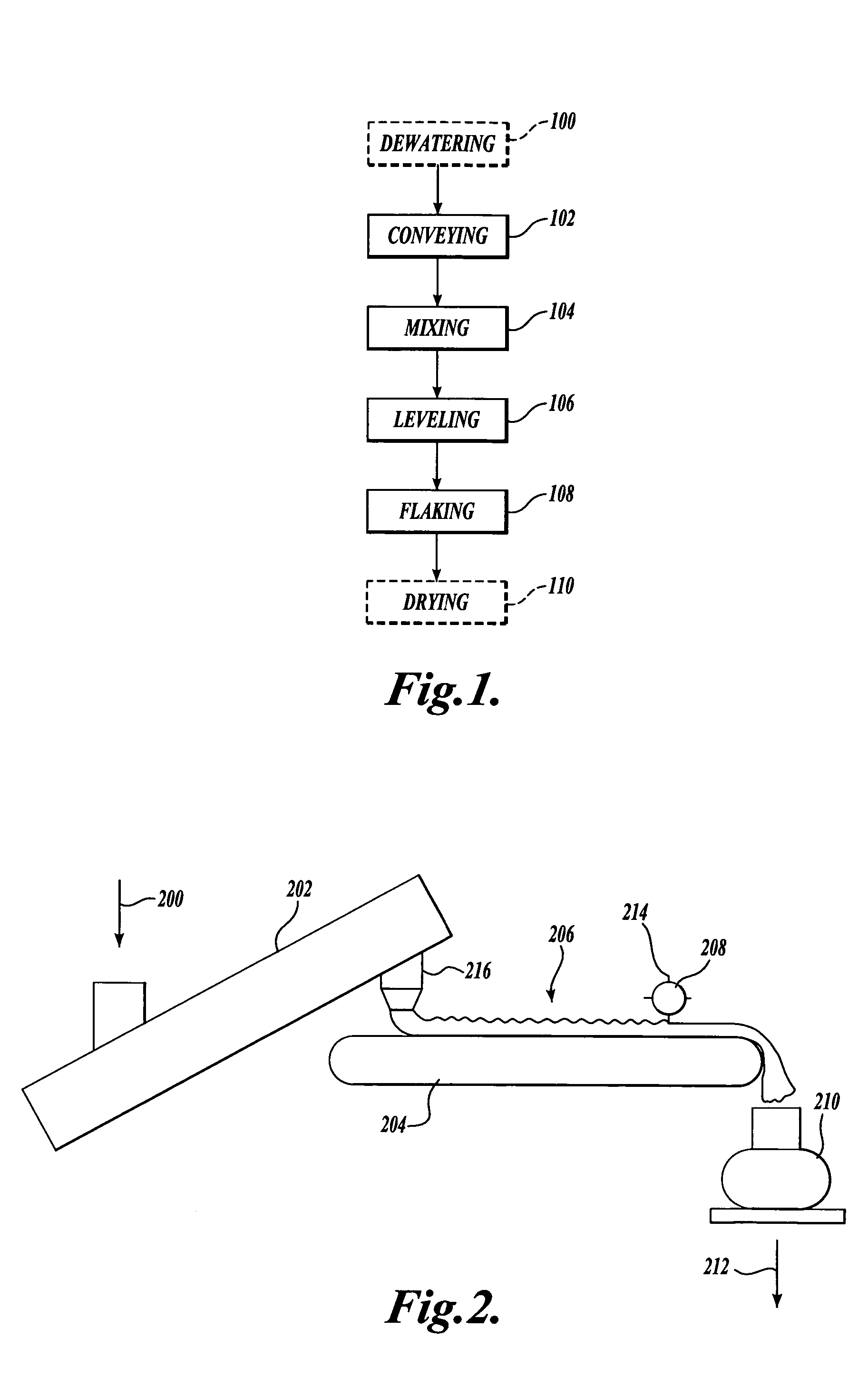

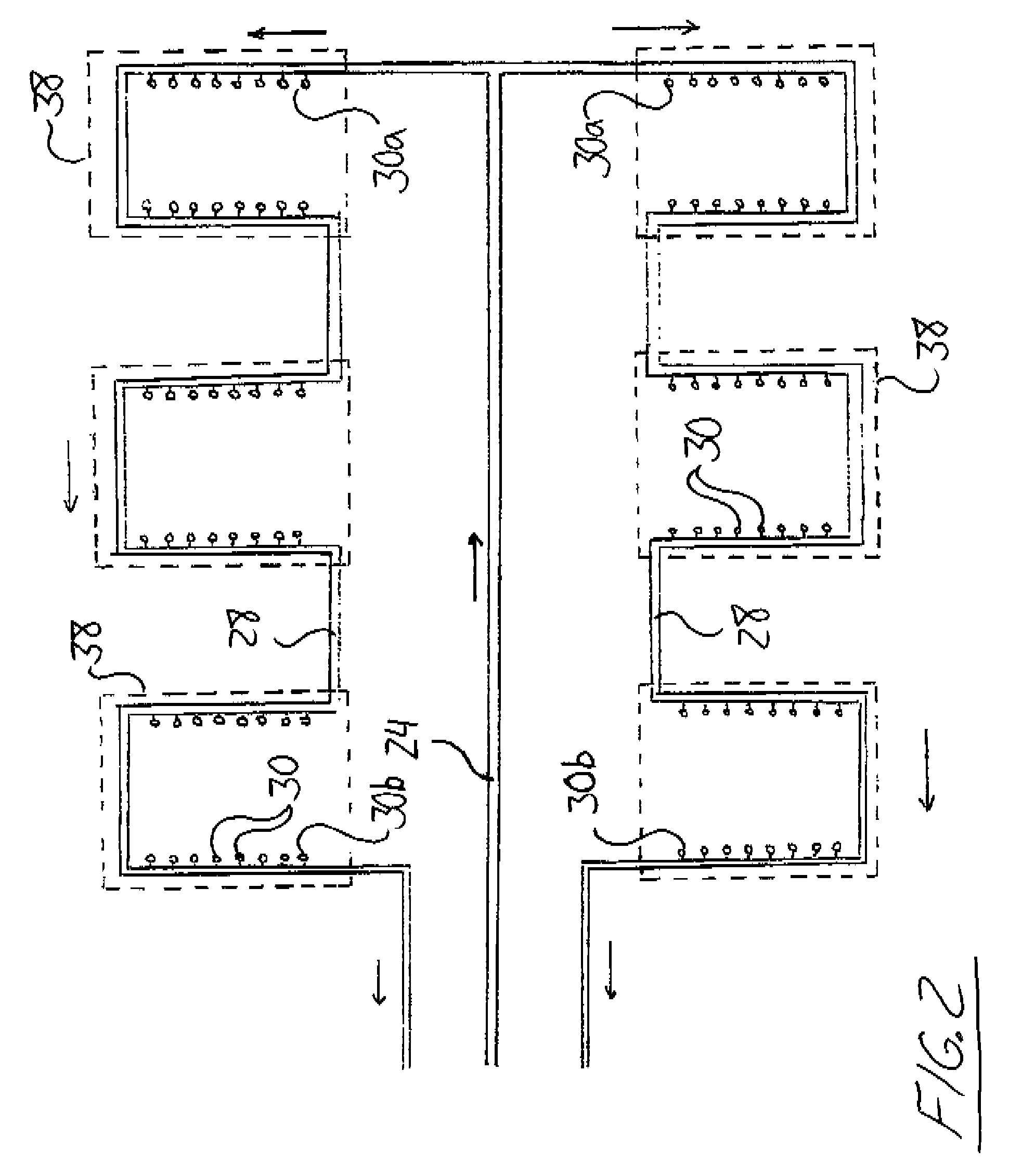

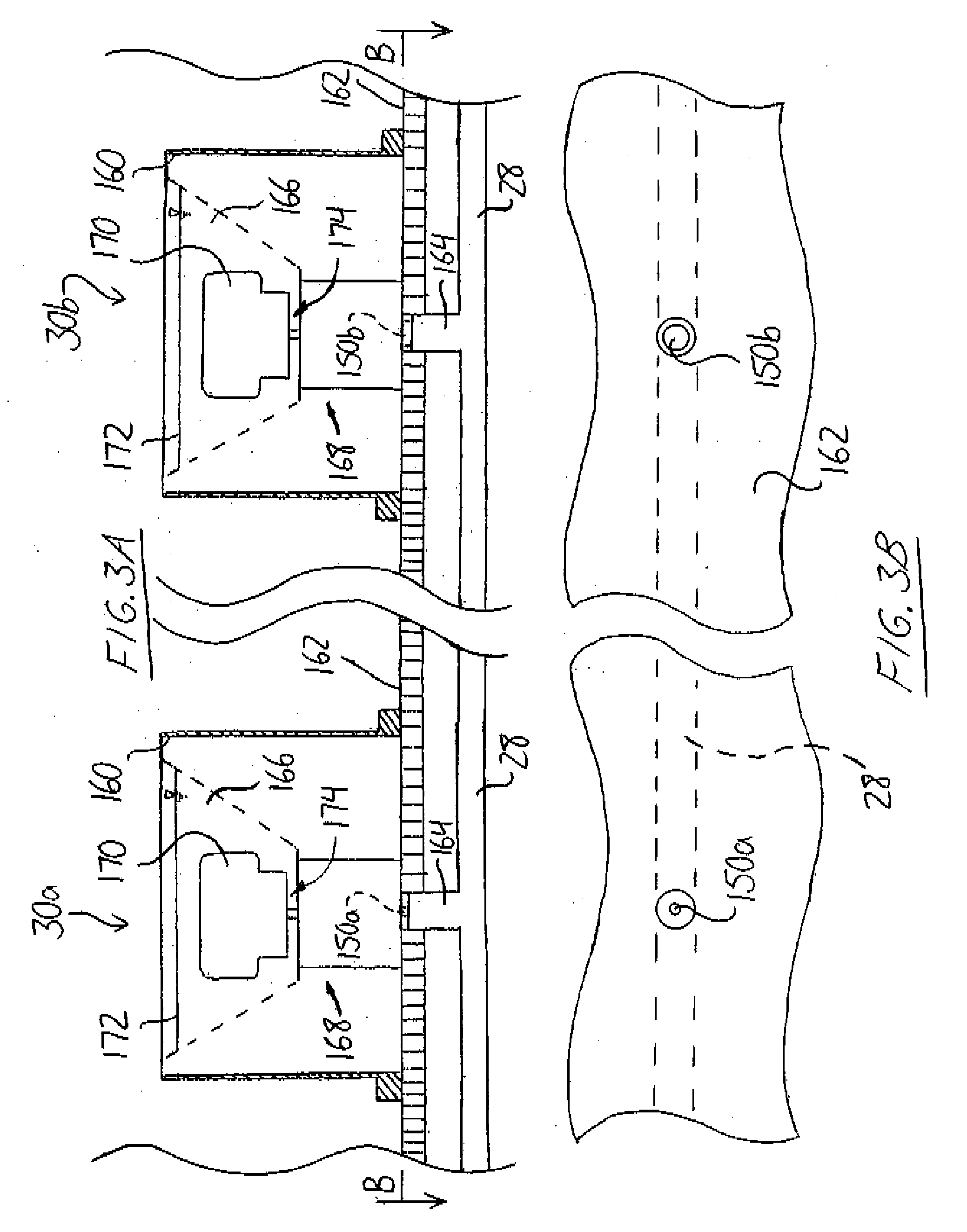

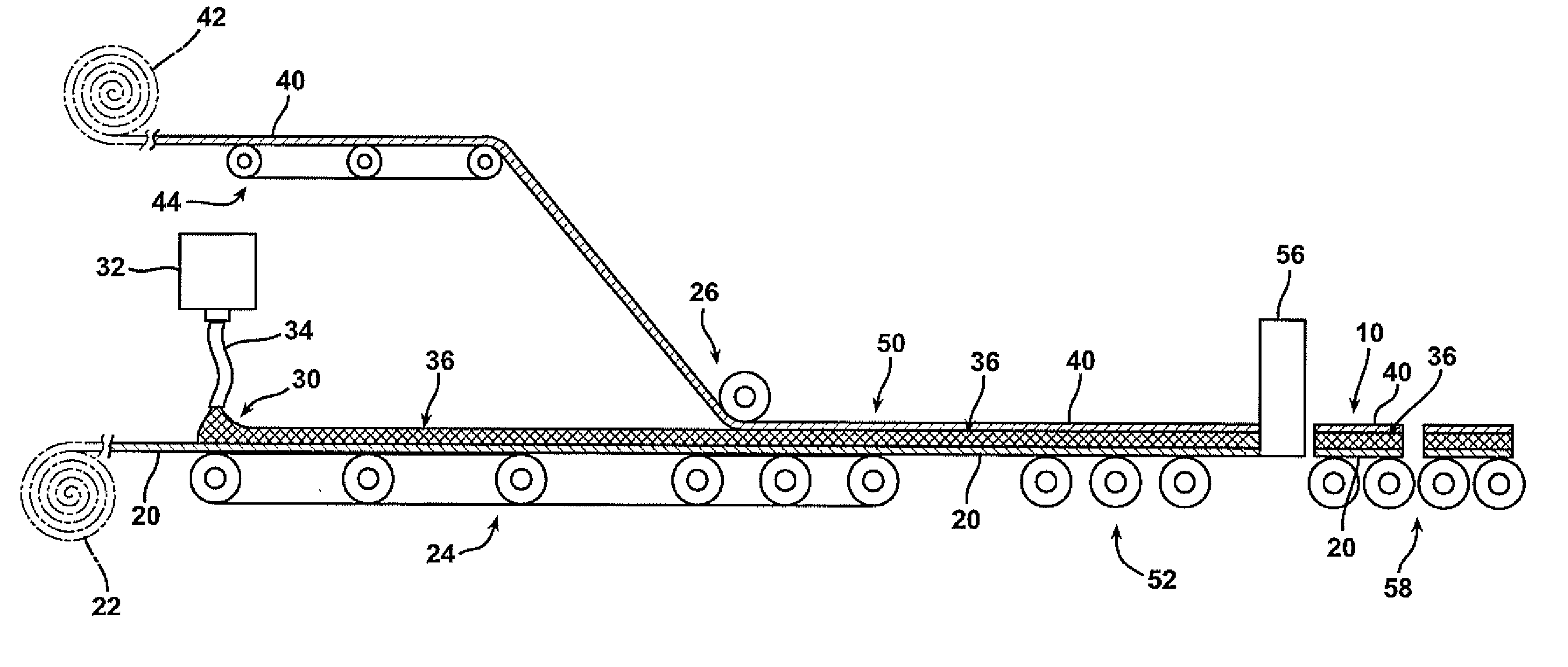

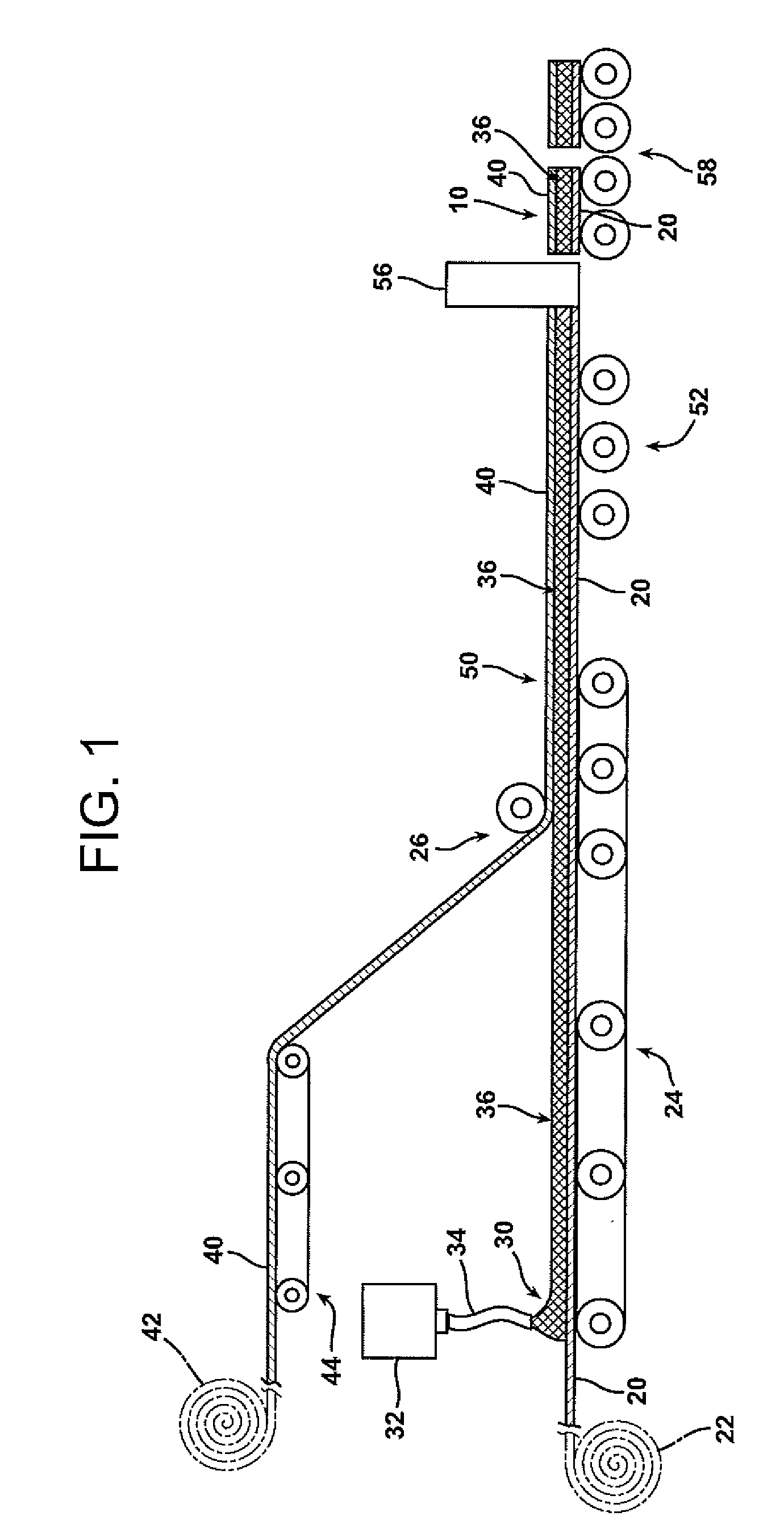

Method for conveying, mixing, and leveling dewatered pulp prior to drying

InactiveUS7396435B2Small sizePrevents scattering of the pulpGlass/slag layered productsWood layered productsPulp and paper industryScrew conveyor

Methods for conveying, mixing, leveling, and flaking dewatered pulp to produce pulp flakes suitable to be used in a dryer. Methods for producing a consistent flow rate of pulp, and, for producing uniform pulp flakes in terms of pulp flake size and pulp flake moisture content. A method includes introducing a dewatered pulp to a rotating shaftless screw conveyor. The pulp is deposited from the screw conveyor onto a moving belt conveyor through a chute. The pulp is leveled with a rotary doctor located above the belt conveyor to produce a substantially even rate of mass flow of pulp along a length of belt conveyor. Uniform and consistent quantities of pulp per unit time can then be fed from the belt conveyor to a pulp flaker that then translates into an even rate of pulp mass flow to the dryer.

Owner:WEYERHAEUSER NR CO

Method for conveying, mixing, and leveling dewatered pulp prior to drying

InactiveUS20050067123A1Prevent from scatterMass flow rateGlass/slag layered productsWood layered productsScrew conveyorMoisture

Methods for conveying, mixing, leveling, and flaking dewatered pulp to produce pulp flakes suitable to be used in a dryer. Methods for producing a consistent flow rate of pulp, and, for producing uniform pulp flakes in terms of pulp flake size and pulp flake moisture content. A method includes introducing a dewatered pulp to a rotating shaftless screw conveyor. The pulp is deposited from the screw conveyor onto a moving belt conveyor through a chute. The pulp is leveled with a rotary doctor located above the belt conveyor to produce a substantially even rate of mass flow of pulp along a length of belt conveyor. Uniform and consistent quantities of pulp per unit time can then be fed from the belt conveyor to a pulp flaker that then translates into an even rate of pulp mass flow to the dryer.

Owner:WEYERHAEUSER NR CO

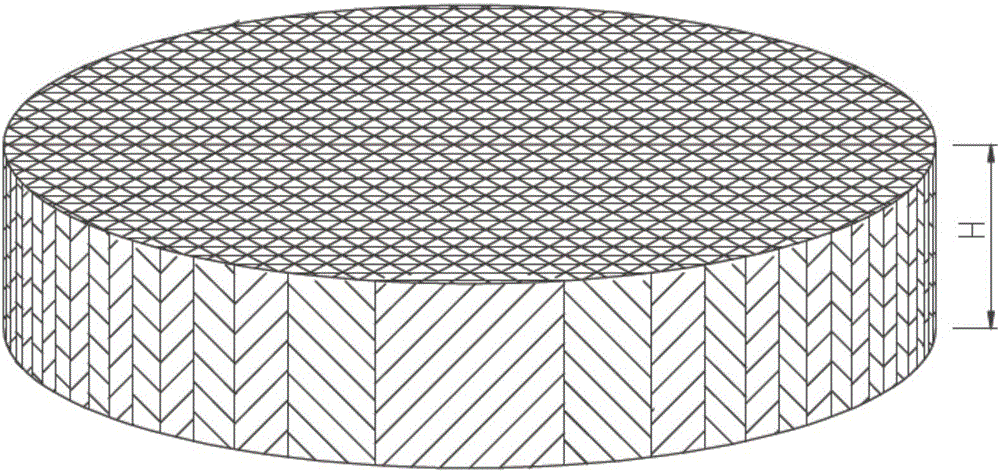

Gas distributor and gas distribution system comprising gas distributor

ActiveCN105944630AConsistent compositionConsistent temperatureChemical/physical processesThermodynamicsDistribution system

The invention provides a gas distributor and a gas distribution system comprising the gas distributor. The gas distributor comprises at least one gas distribution disc; the gas distribution disc is of a disc type structure formed by assembling a plurality of corrugated sheets; corrugated edges of the corrugated sheets are not arranged along the vertical direction; and the inclining directions of the corrugated edges of the two adjacent corrugated sheets are opposite. According to the gas distributor provided by the invention, on one hand, air bubbles with different sizes flow through the gas distributor to from small air bubbles with similar sizes and then the small air bubbles are uniformly distributed on the whole cross section of the equipment, so that the mass transferring speed can be easily improved and the gas distributor provided by the invention has the advantages of uniform air bubble size, uniform distribution and large distribution area; and on the other hand, parameters including the composition, temperature, flow speed and the like of fluid are prone to be consistent in the radial direction of mass transferring equipment, so that the back-mixing the fluid is even avoided.

Owner:BEIJING EDGEIN TECH

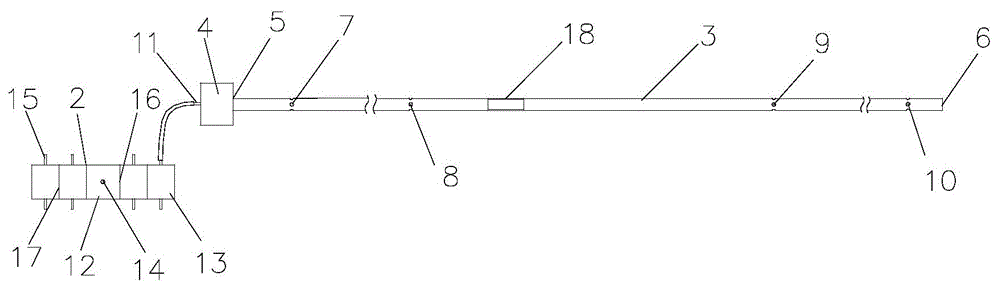

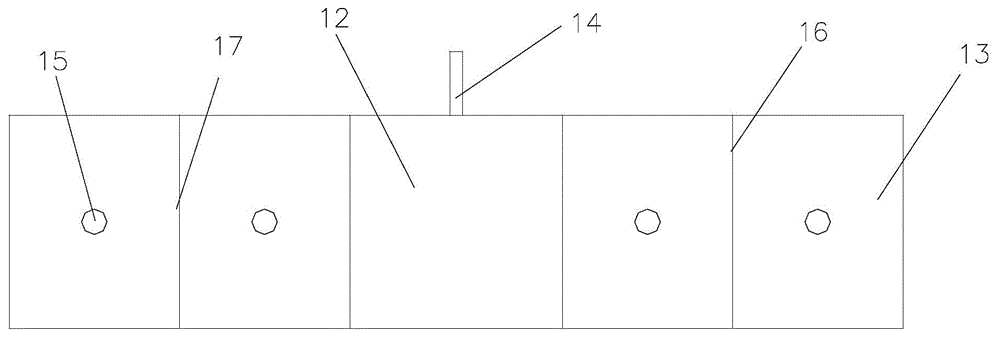

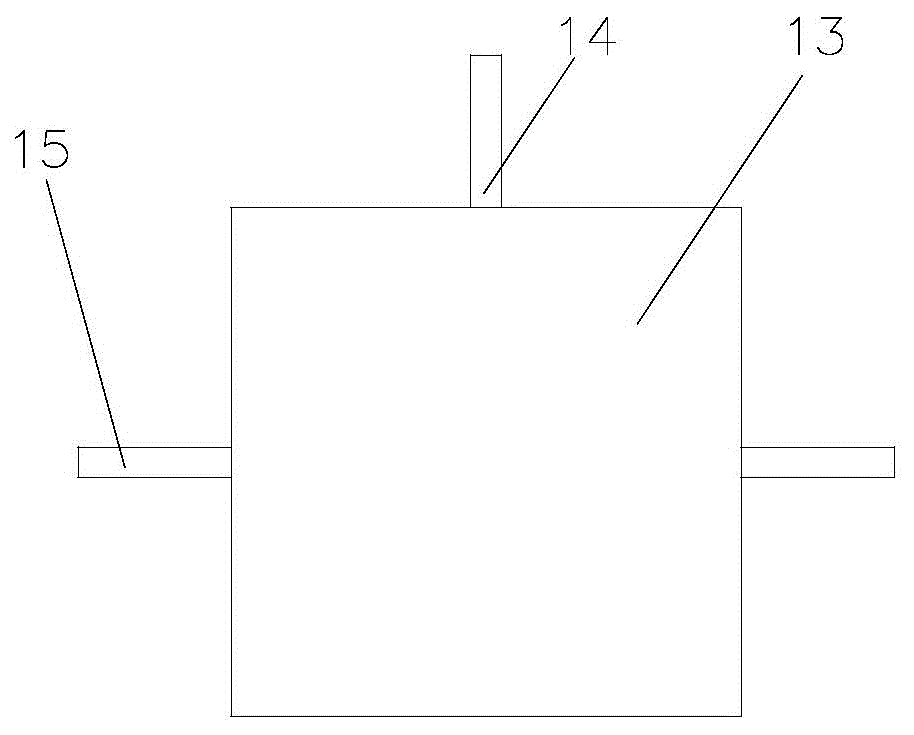

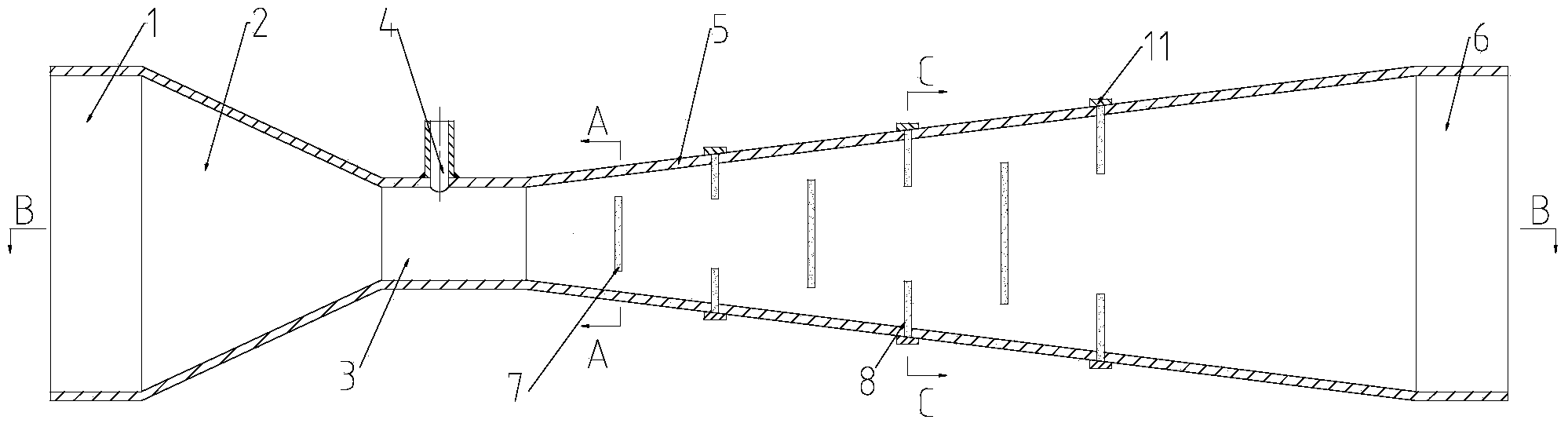

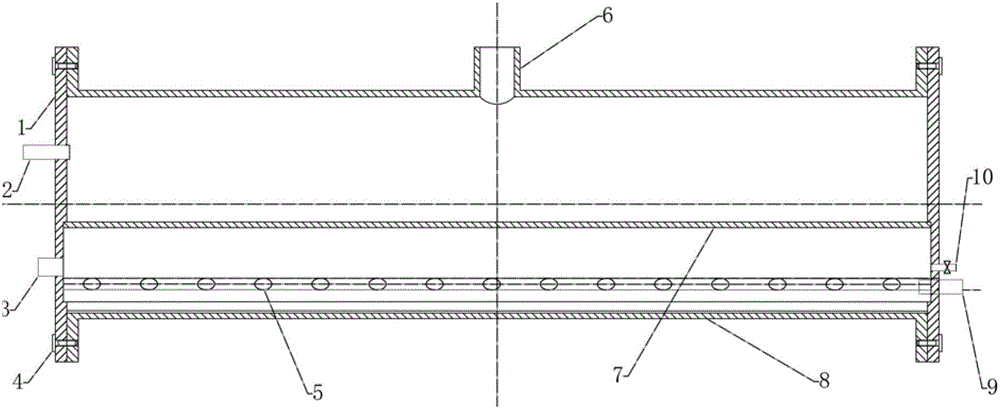

Flue gas sampling and mixing device

InactiveCN104155155AConsistent concentrationConsistent flow rateWithdrawing sample devicesPreparing sample for investigationFlue gasProduct gas

The invention discloses a flue gas sampling and mixing device which comprises a sampling pipe and a flue gas mixer, wherein the sampling pipe comprises a sampling pipe body; one end of the sampling pipe body is an open end and the other end of the sampling pipe body is a sealed end; a plurality of sampling holes are formed in the sampling pipe body at intervals in the axial direction; the pore diameters of the sampling holes are sequentially increased from the open end to the sealed end; the flue gas mixer comprises a plurality of gas mixer chambers separated by porous baffles; one of the gas mixer chambers is provided with a mixing gas outlet; mixing air inlets connected with the open end are formed in the side walls of other gas mixer chambers; the pore diameters of the porous baffles are sequentially decreased in the flue gas flowing direction in the flue gas mixer. The flue gas sampling and mixing device can sample at multiple points and ensures that the sampled flue gas can be mixed uniformly and truly represent the constituent and concentration of the flue gas in a gas duct.

Owner:ZHEJIANG UNIV

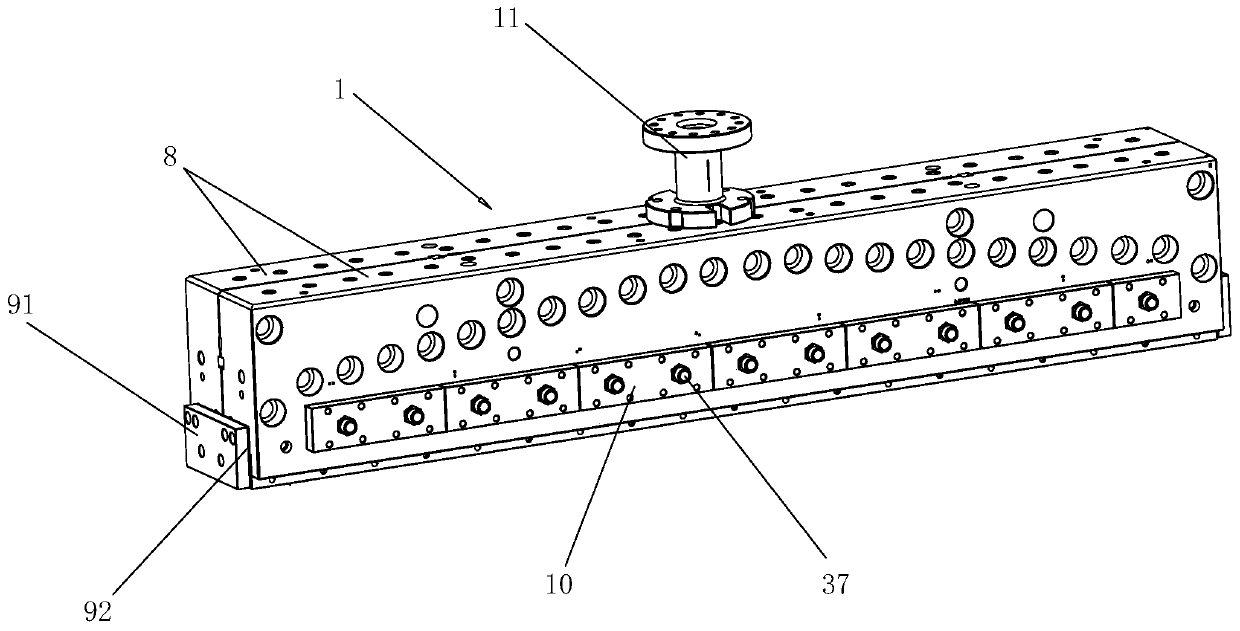

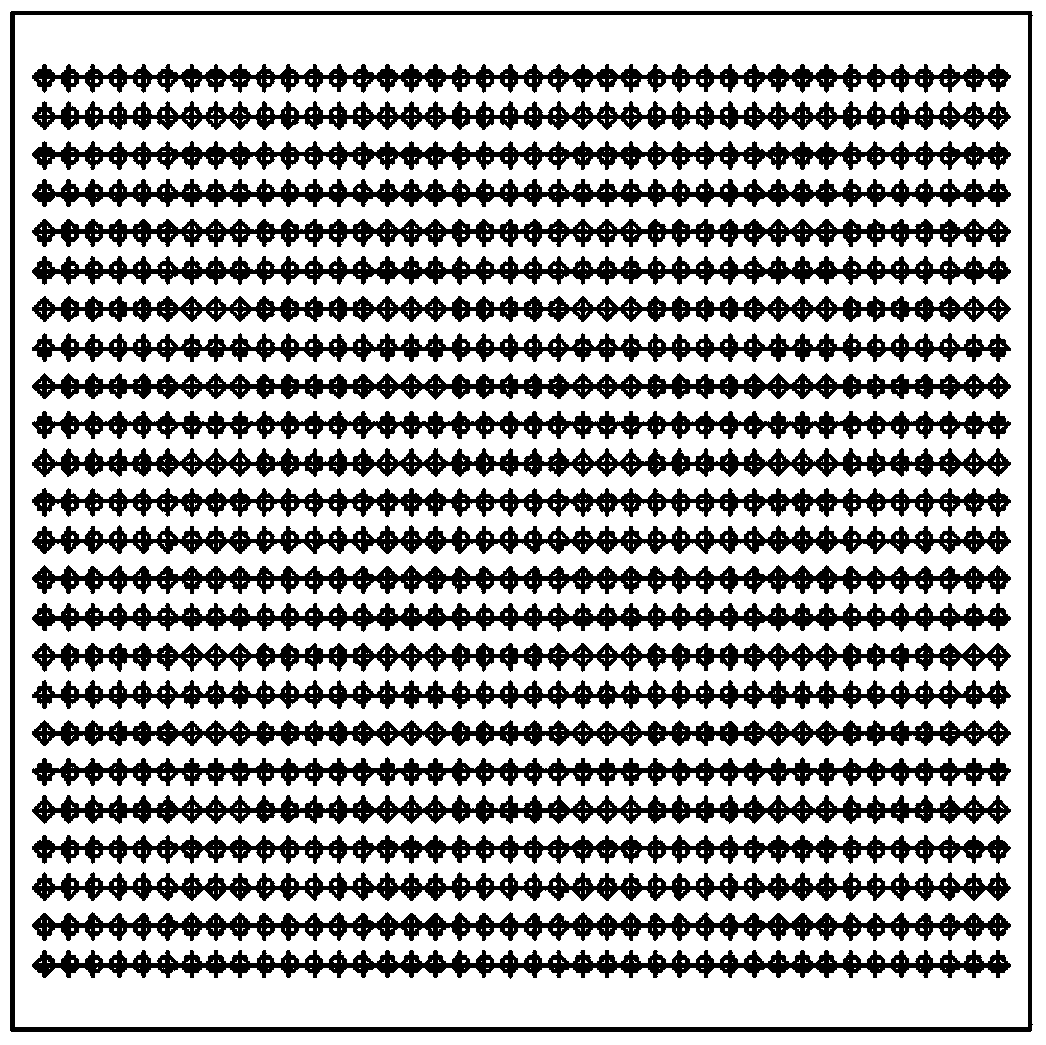

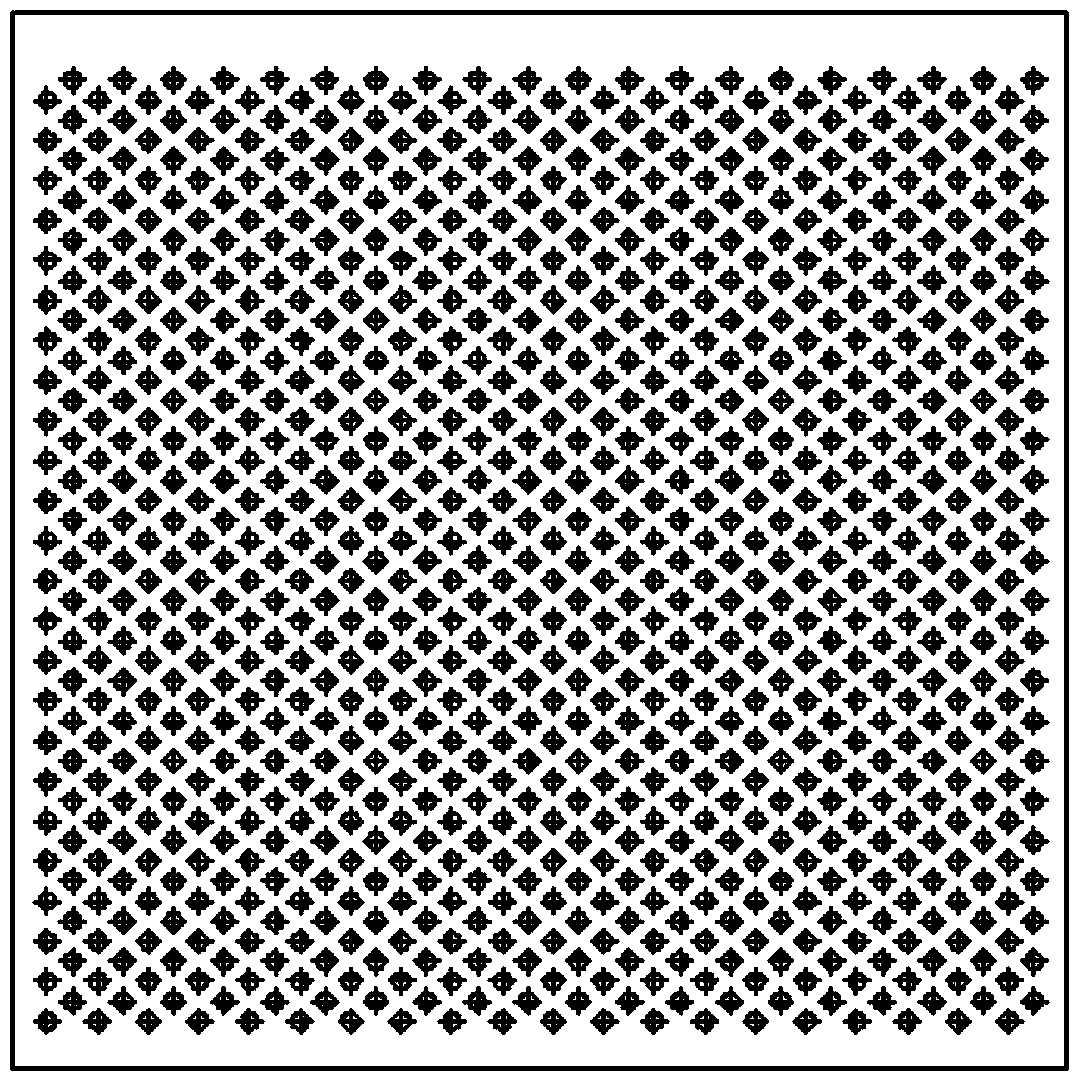

Hot runner type nonwoven melting and spraying die

PendingCN111593485AUniform pressureConsistent flow rateSpinnerette packsMelt spinning methodsHot runnerHeat flow

The invention discloses a hot runner type nonwoven melting and spraying die. The hot runner type nonwoven melting and spraying die comprises a bottom plate, a hot runner manifold, a die head, a spinning plate and two air knives, wherein the bottom plate, the hot runner manifold and the die head are arranged in a transverse direction and are fixedly connected in sequence from top to bottom; a mainhot runner is formed in the hot runner manifold, a sprue bushing is arranged on the bottom plate, the main hot runner communicates with the sprue bushing, and the main hot runner communicates with a bottom groove in the bottom of the die head through a plurality of branch hot runners; the spinning plate is arranged in the die head, a storage tank which corresponds to the bottom groove is arrangedin the spinning plate, and the storage tank communicates with the bottom groove through a shunt filter assembly; a plurality of spinning holes are formed in the bottom of the spinning plate, and the storage tank communicates with the outside through the spinning holes; and the two air knives are located on the front and back sides below the spinning plate. According to the hot runner type nonwovenmelting and spraying die, the bottom groove is uniformly fed through the main hot runner and the branch hot runners in the die head, and the shunting holes are reasonably formed, so that the pressureof hot fluid in the spinning plate is balanced, the flow speed of the spinning holes is consistent, and the nonwoven thickness is uniform.

Owner:青岛海泰科模具有限公司

Venturi mixer with diffuser containing shrinkage cavities

ActiveCN103846027ASevere turbulenceIncrease flow rateFlow mixersMixing methodsMaterials scienceSupport plane

The invention discloses a venturi mixer with a diffuser containing a shrinkage cavity. The venturi mixer comprises a flowing pipeline, a gradual shrinking section, a throat part, the diffuser, an outflowing pipeline and an input pipe as well as the multiple groups of shrinkage cavities in the diffuser, wherein each group of shrinkage cavities comprise a fixed shrinkage cavity and an adjustable shrinkage cavity, and each adjustable shrinkage cavity is composed of two core plates; the fixed shrinkage cavities are welded on the inner wall of the diffuser through multiple support frames, and the adjustable shrinkage cavities are embedded into the diffuser; the fixed shrinkage cavities and the adjustable shrinkage cavities are alternately arranged, and a shrinkage cavity adjusting device can adjust the relative positions of the two core plates in each adjustable shrinkage cavity on line. The venturi mixer provided by the invention has the advantages that the disturbance of a mixing fluid in the diffuser of the venturi mixer is effectively strengthened, the mixing efficiency of the venturi mixer is effectively improved, and a non-uniform mixing phenomenon is avoided.

Owner:度测(上海)科技服务中心

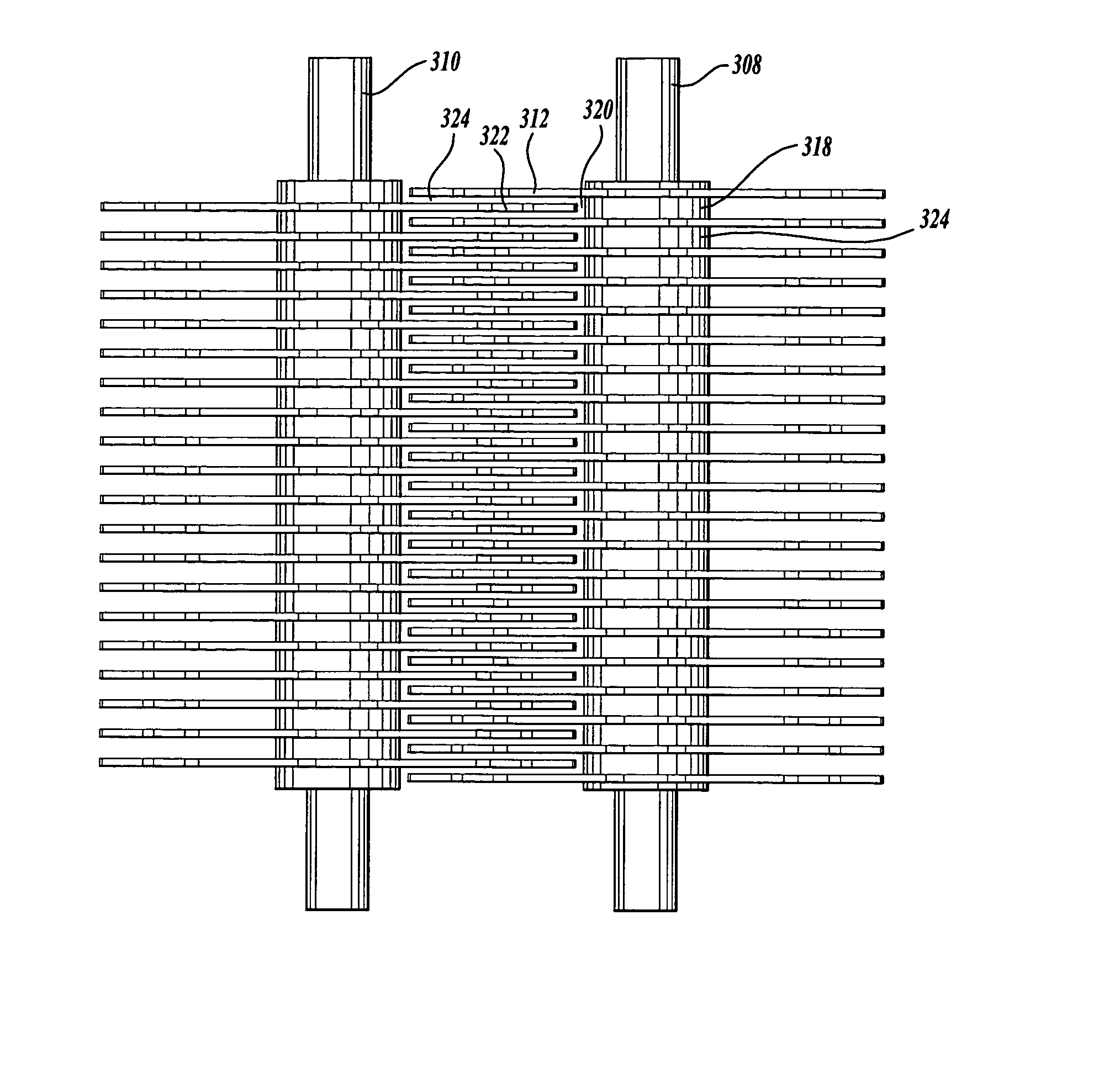

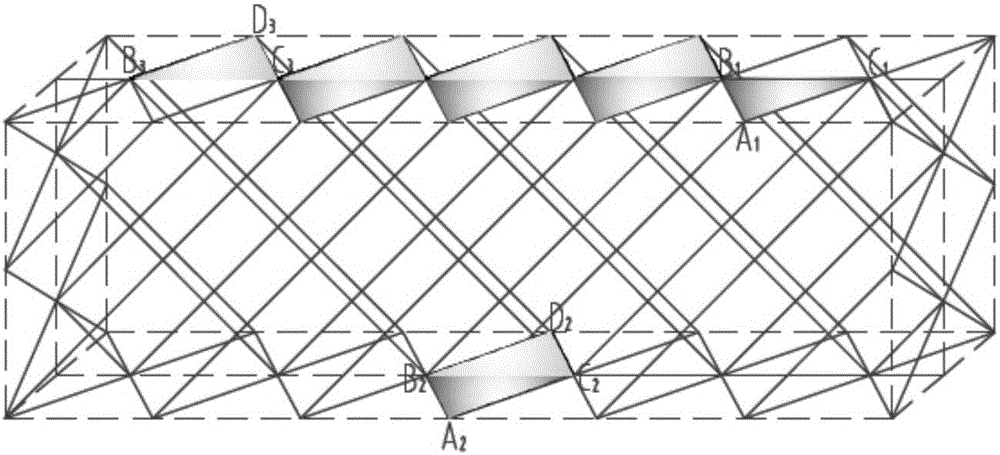

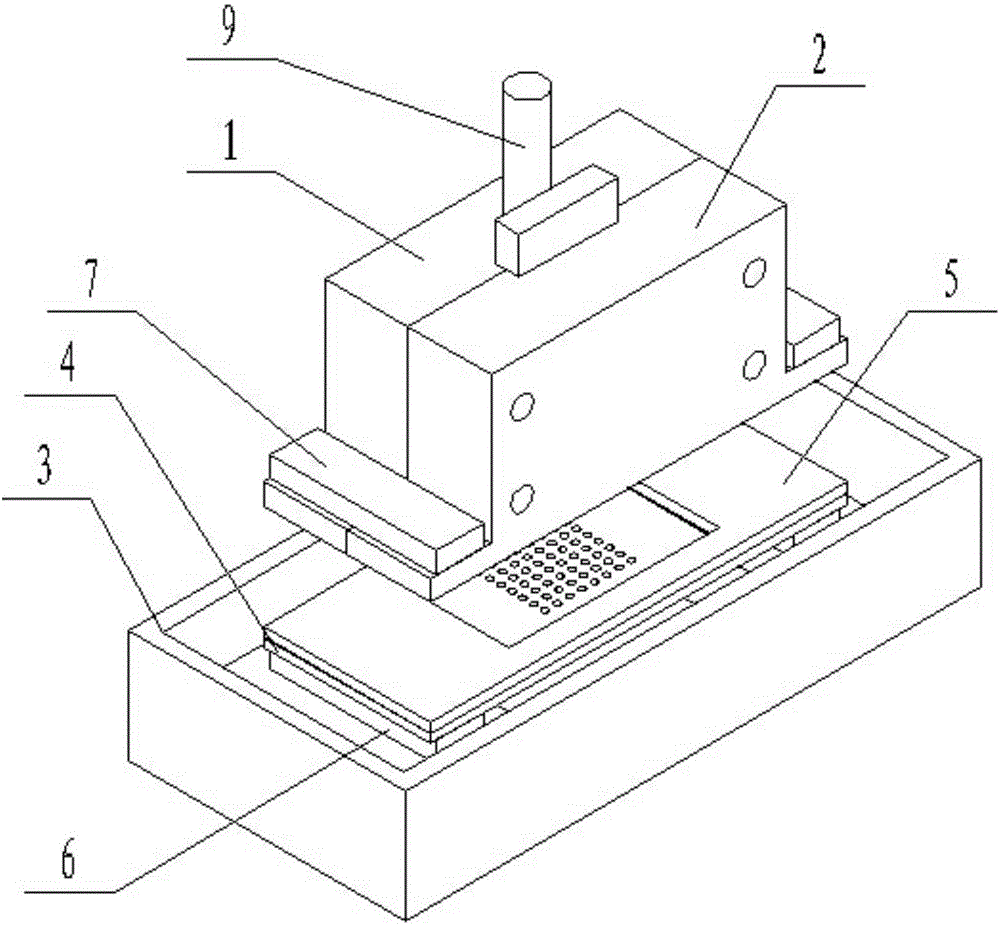

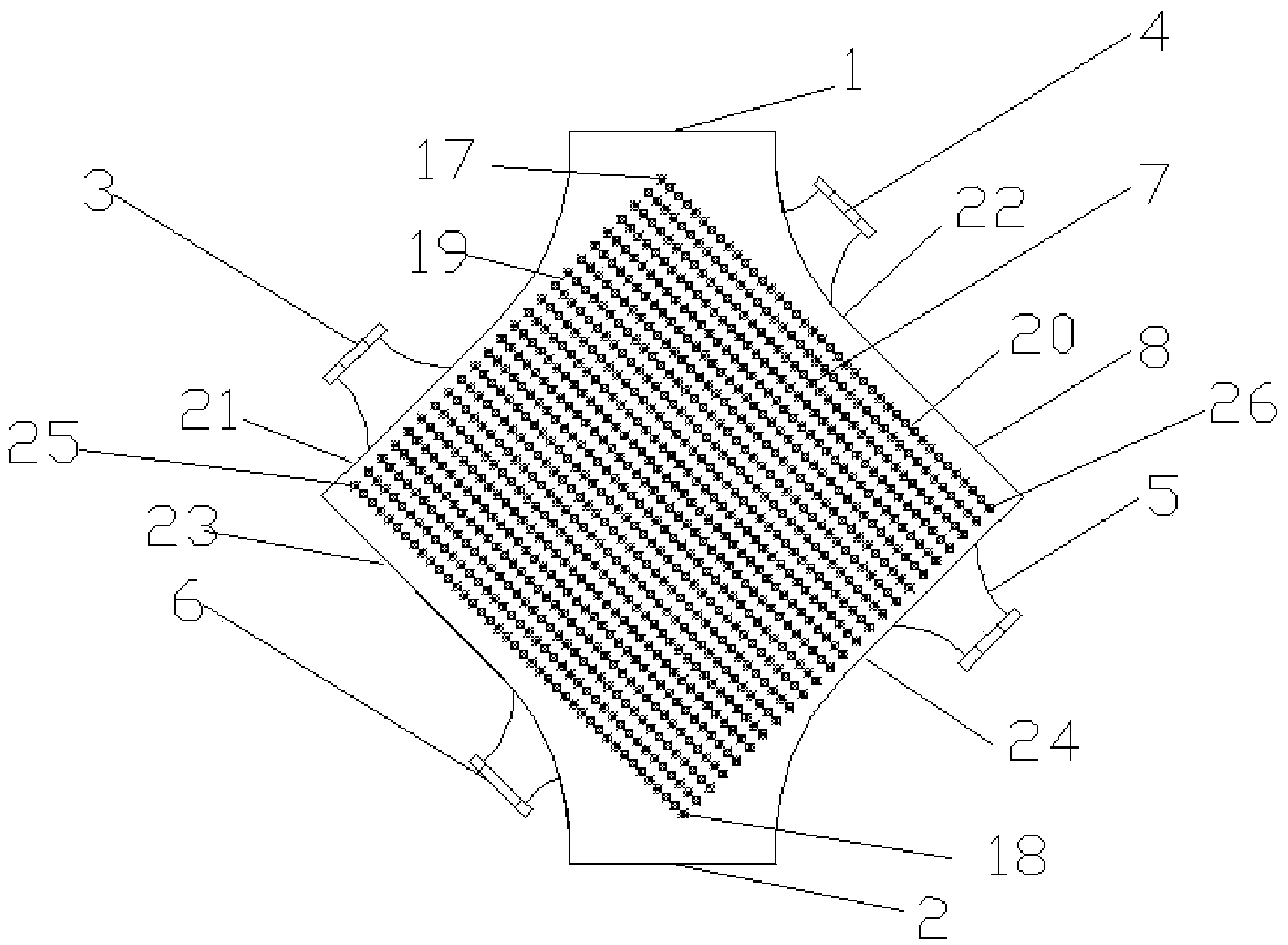

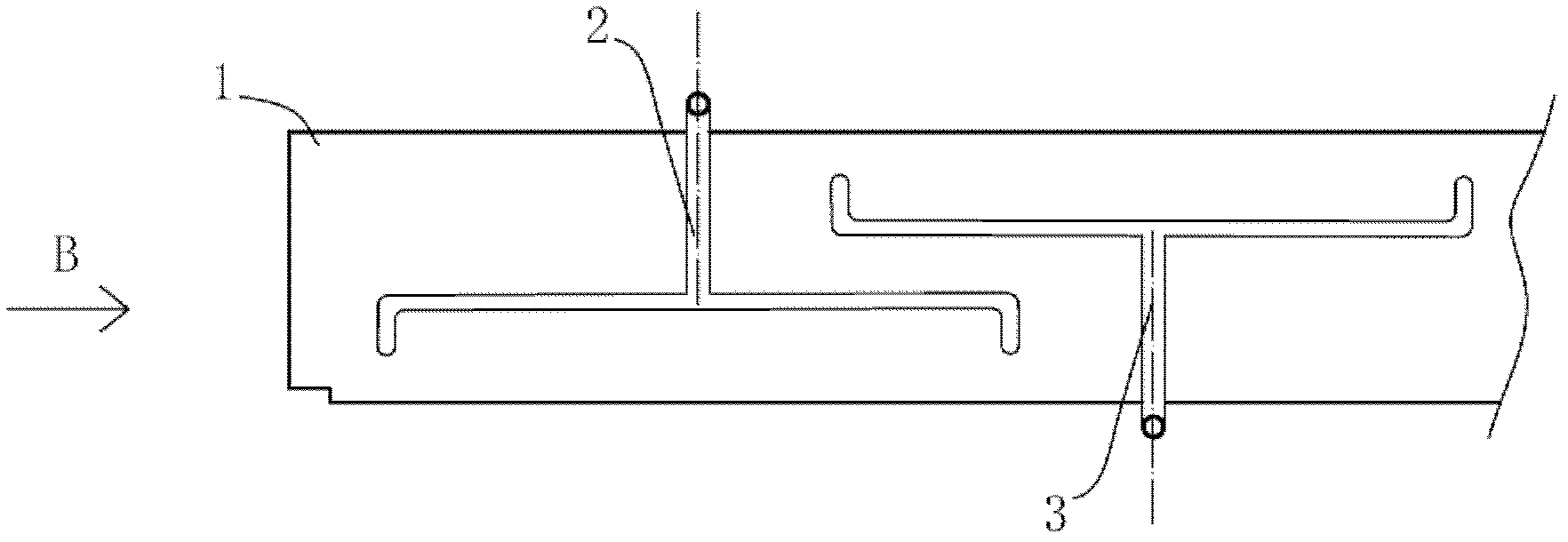

Coaxial electrolyte flushing method and device for array group electrode micro-hole electromachining

ActiveCN105127528AGuaranteed inflowConsistent flow rateElectrical-based auxillary apparatusGroup controlMachine tool

The invention discloses a coaxial electrolyte flushing device and method for array group electrode micro-hole electromachining. The coaxial electrolyte flushing device comprises a sealing cavity, array group electrodes, an electrolyte sealing cavity, an electrolyte groove, an insulating gasket and electromagnetic chucks. When the electrolyte sealing cavity is driven by a machine tool main shaft to move to be attached to the insulating gasket, an insulating cavity composed of the electrolyte sealing cavity, the insulating gasket and a workpiece to be machined is formed through the attraction function of the electromagnetic chucks; and the diameter of a single cathode of the array group electrodes is smaller than the diameter of a single hole in the workpiece to be machined, and an electrolyte sealing flow diversion cavity is formed through the cathodes and the corresponding holes. The coaxial electrolyte flushing method is simple and compact in structure, coaxial machining is conducted on micro holes through the array group electrodes, it is guaranteed electrolytes flow into the machining region along the side walls of the cathodes of the array group electrodes, the flowing speed of the electrolytes at different positions is consistent by keeping the pressure of the electrolyte sealing cavity consistent, machining stability and group control machining consistency can be improved, operation is convenient, and implementation is easy.

Owner:ZHEJIANG UNIV OF TECH

Venturi tube used in plate type absorption tower

The invention relates to the field of desulfurization and denitrification devices and discloses a Venturi tube used in a plate type absorption tower. The Venturi tube comprises a Venturi tube body, wherein the Venturi tube body comprises a gas inlet section, a shrinkage section, a diffusion section and an exhaust section which are mutually connected in sequence from left to right; the gas inlet end of the gas inlet section is connected with the gas outlet end of a flue gas conveying pipeline; the shrinkage section comprises an atomization cavity of a flat spherical cavity structure; a plurality of spray guns are uniformly mounted on the outer side of the atomization cavity; and one end of eachspray gun penetrates through the atomization cavity and extends to the inner wall side of the atomization cavity. A liquid fed into the atomization cavity is instantaneously atomized through an impeller which is driven by high-speed air flows, and the atomized liquid is directly sufficiently mixedwith flue gas inside the atomization cavity along with stirring of the impeller, so that compared with conventional co-spraying of liquids and flue gas, atomization of the liquid of the technical scheme is rapid, the atomizedliquid can be sufficiently mixed with the flue gas, and in addition, the contact time of the atomized liquid with the flue gas is long.

Owner:杭州富阳松连食品有限公司

Pipe extrusion molding machine head

The invention provides a pipe extrusion molding machine head. The pipe extrusion molding machine head comprises a machine head body and a perforated plate, wherein the machine head body and the perforated plate are used for being connected to an extrusion head of a screw-type extruder; a flow divider is installed in the machine head body, a core rod, a support and a flow-dividing cone are sequentially installed on the flow divider, and a mouth mold is installed on the machine head body; the core rod stretches into the mouth mold, the conical tip of the flow-dividing cone is installed towards the perforated plate, and a groove is formed in the outer wall of the core rod in the axial direction; and one end of the groove communicates with the outer end face of the core rod, and the other end of the groove communicates with the side face of the support. By forming the groove in the core rod, stiffeners are generated on the inner wall of a formed pipe, and the perforated plate is improved, so that the flow speed of a plastic fluid tends to be uniform, and the uniform thickness of the pipe wall is guaranteed during forming; and the pipe manufactured through the forming machine head is high in strength, and the thickness of the pipe wall is uniform, so that the service life of the pipe is greatly prolonged.

Owner:泰州市畅通管业有限公司

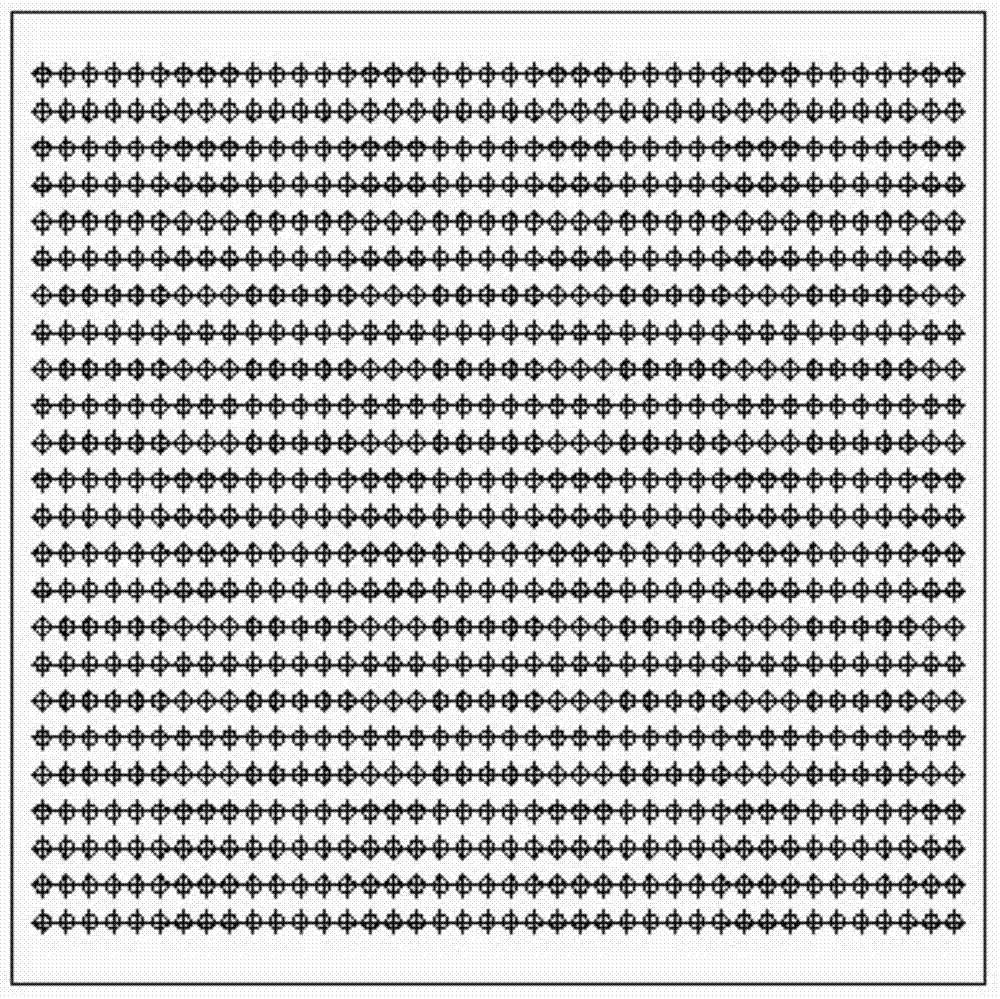

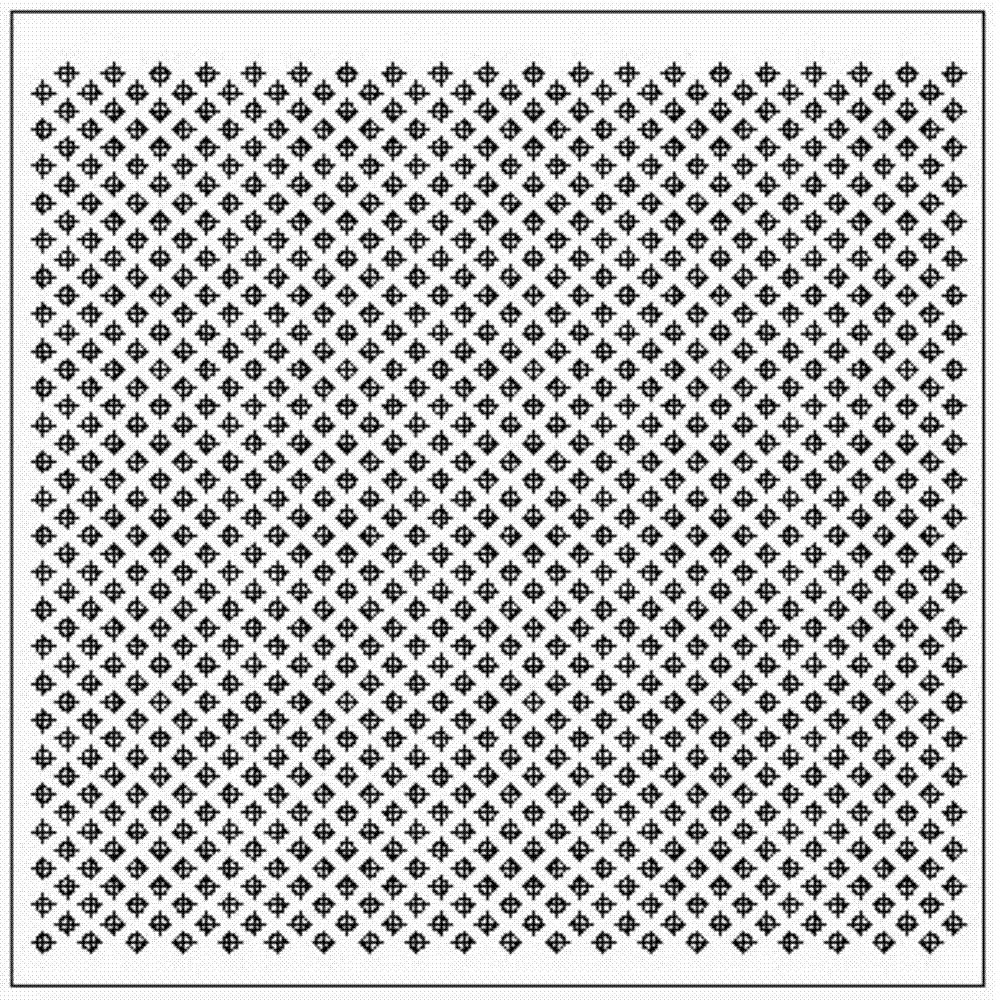

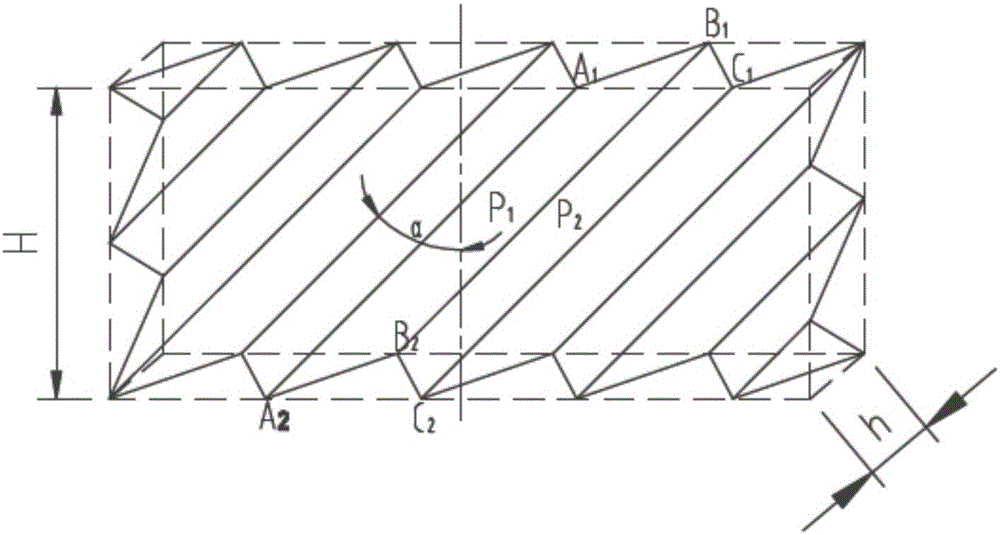

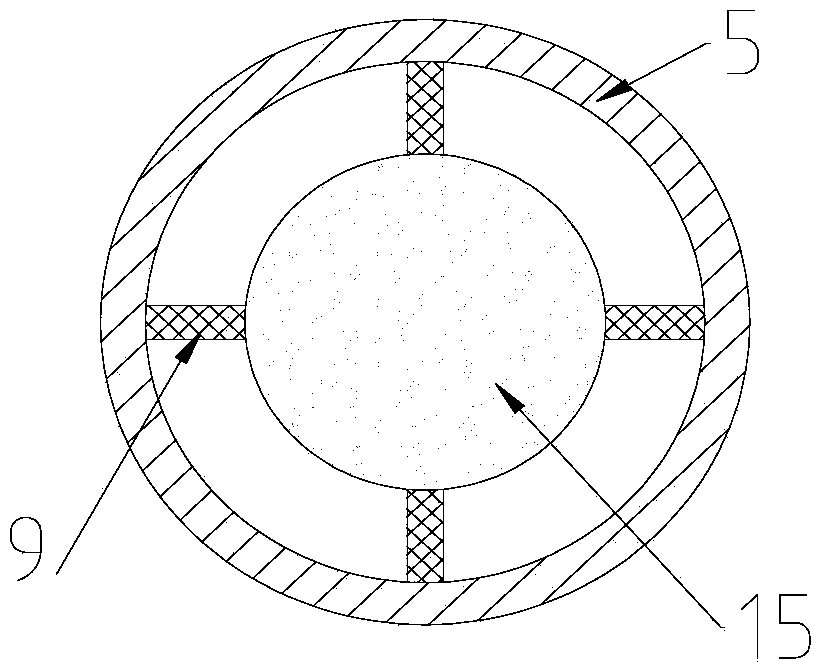

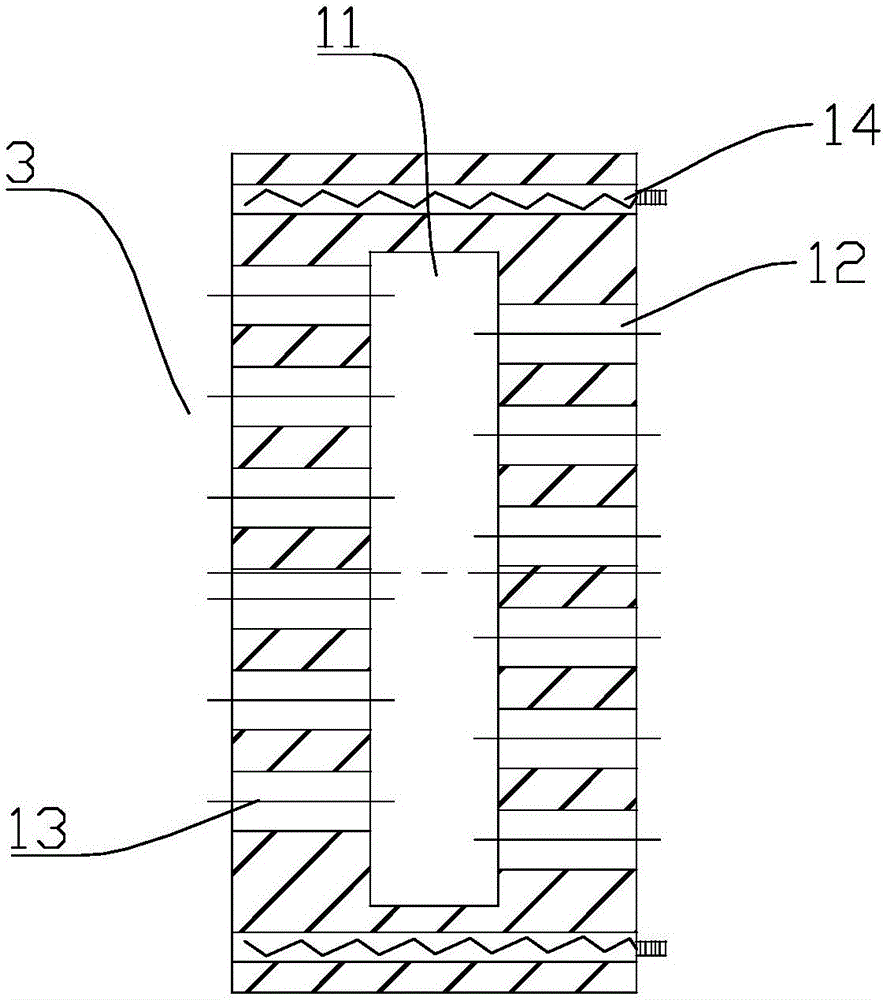

Rolled reverse osmosis membrane element with gradually-reduced inlet channel

ActiveCN102166477AConsistent flow rateReverse osmosisWater/sewage treatment bu osmosis/dialysisWater pipeMembrane configuration

The invention discloses a rolled reverse osmosis membrane element with a gradually-reduced inlet channel, which is formed by winding a pure water guide net, a reverse osmosis membrane and an water inlet guide net around a central water production pipe in a superposition mode, and the inlet water guide net and the pure water guide net are respectively arranged in a water inlet channel formed by aninternal surface of the folded reverse osmosis membrane and a water production channel formed by the adjacent external surfaces of the folded reverse osmosis membrane. The rolled reverse osmosis membrane element disclosed by the invention is characterized in that three folding edges are formed at the side of the central water production pipe after the reverse osmosis membrane is folded, the middle folding edge is embedded into the water inlet channel, so that the water inlet channel is divided into front water inlet sub-channels at the upper and lower layers of the central pipe side and a rear water inlet sub-channel at a concentrated water outlet side, and the water inlet guide net is divided into a large water inlet guide net and a small water inlet guide net, the large water inlet guide net is arranged in one of the front water inlet sub-channels and the rear water inlet sub-channel, and the small water inlet guide net is only arranged at the other front water inlet sub-channel. The rolled reverse osmosis membrane element disclosed by the invention has the advantages of simple manufacturing mode, simpleness in implementation, and capability of realizing mass production.

Owner:A O SMITH (CHINA) ENVIRONMENTAL PRODUCTS CO LTD

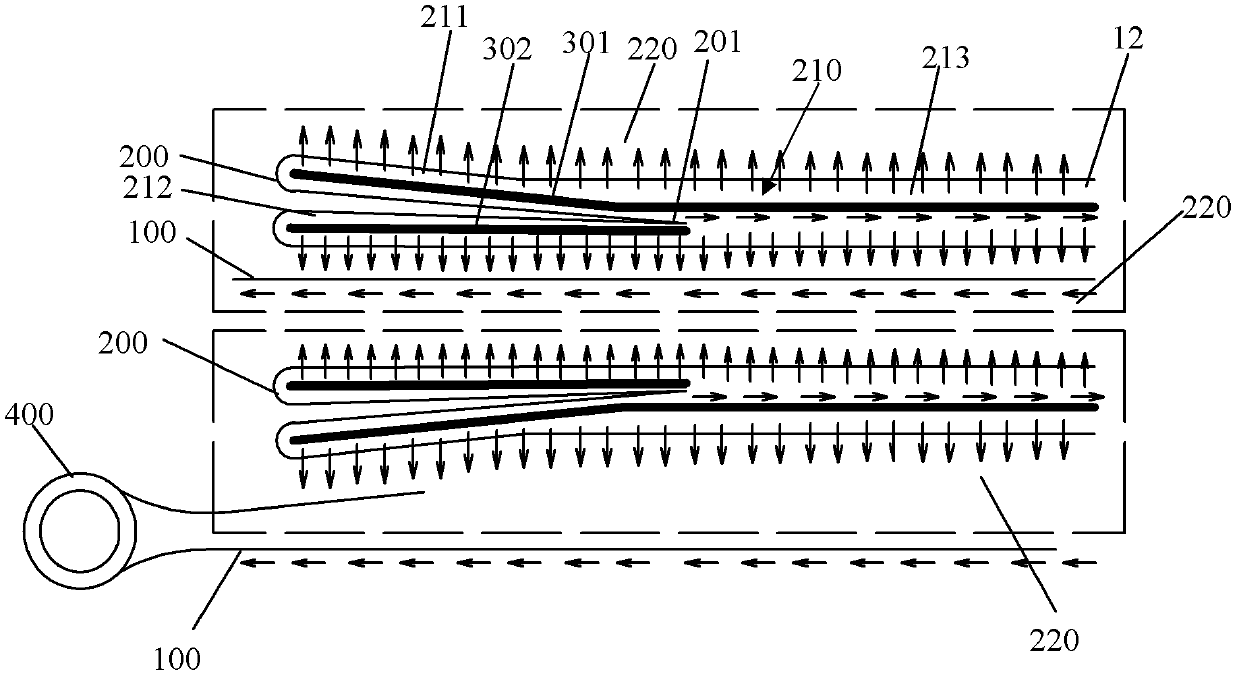

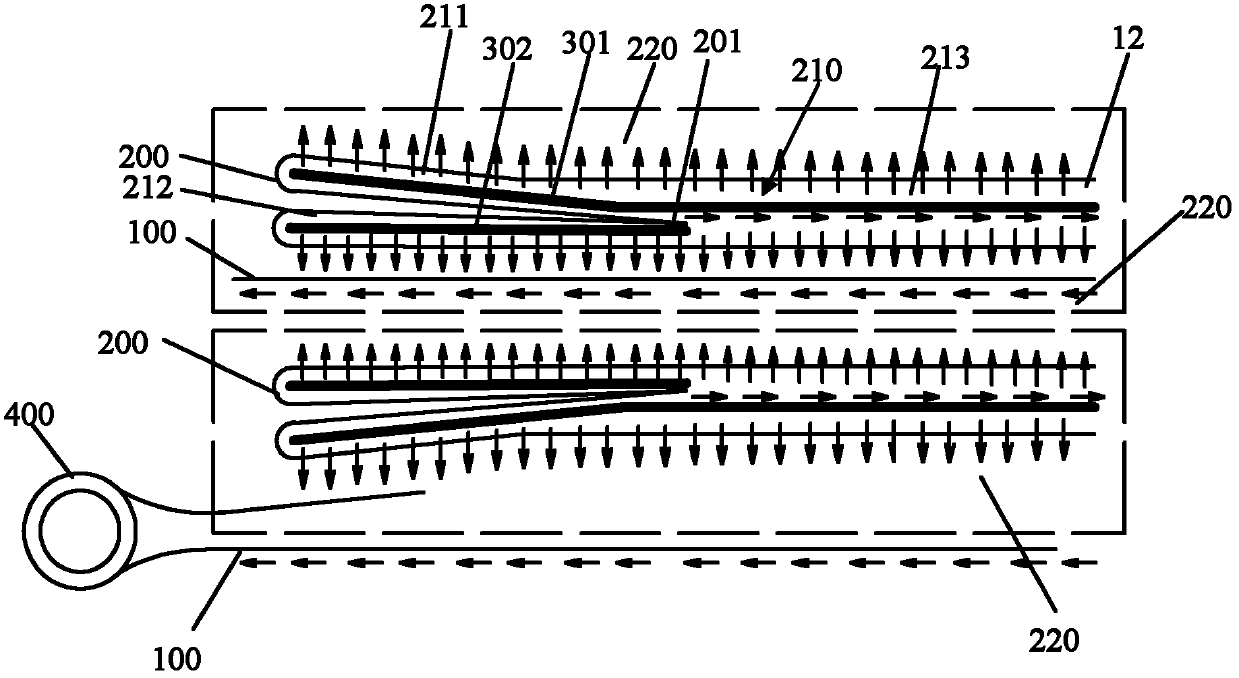

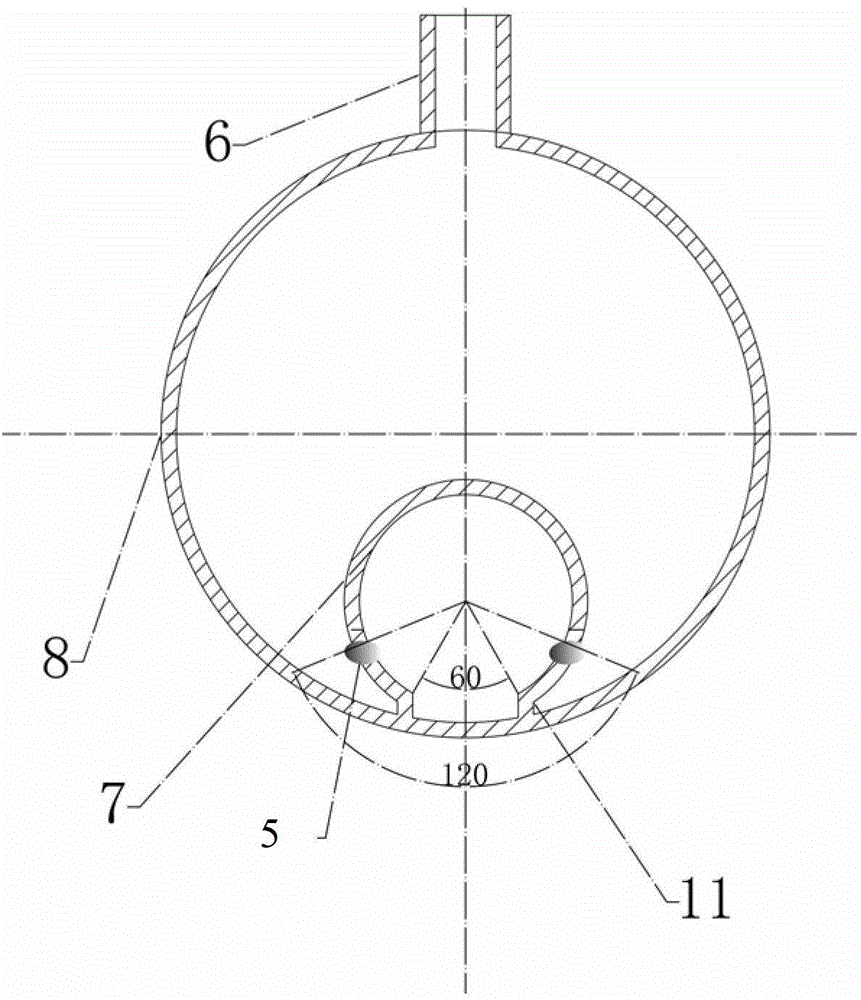

Tangential casing built-in aeration photo-bioreactor applicable to micro algae high-efficiency culture

ActiveCN102911856ALight confinementReduce light areaBioreactor/fermenter combinationsBiological substance pretreatmentsExhaust valveCulture fluid

The invention discloses a tangential casing built-in aeration photo-bioreactor applicable to micro algae high-efficiency culture. The tangential casing built-in aeration photo-bioreactor comprises a transparent tangential casing, a liquid inlet and outlet structure and an air inlet and outlet structure, wherein the transparent tangential casing comprises a transparent outer tube and a built-in transparent perforated aeration tube; the two ends of the transparent tangential casing are provided with flanges; the transparent outer tube and the built-in transparent perforated aeration tube are sealed through the flanges; one end of the transparent outer tube is provided with a liquid inlet, and the other end of the transparent outer tube is provided with a liquid outlet for feeding culture solution into the transparent outer tube and discharging the culture solution out of the transparent outer tube; one end of the built-in aeration tube is provided with an air inlet tube, and the other end of the built-in aeration tube is provided with a high-pressure exhaust valve; the side wall of the built-in aeration tube is provided with aeration holes; and an exhaust tube is arranged above the transparent outer tube. The tangential casing built-in aeration photo-bioreactor has the advantages of a columnar photo-bioreactor; not only the heat transfer and mass transfer are enhanced but also light-dark cycle is promoted by using aeration turbulent flow; and the pH (Potential of Hydrogen) of the culture solution is dynamically adjusted through CO2 content in ventilation, so that the culture environment of micro algae is improved.

Owner:TIANJIN UNIV

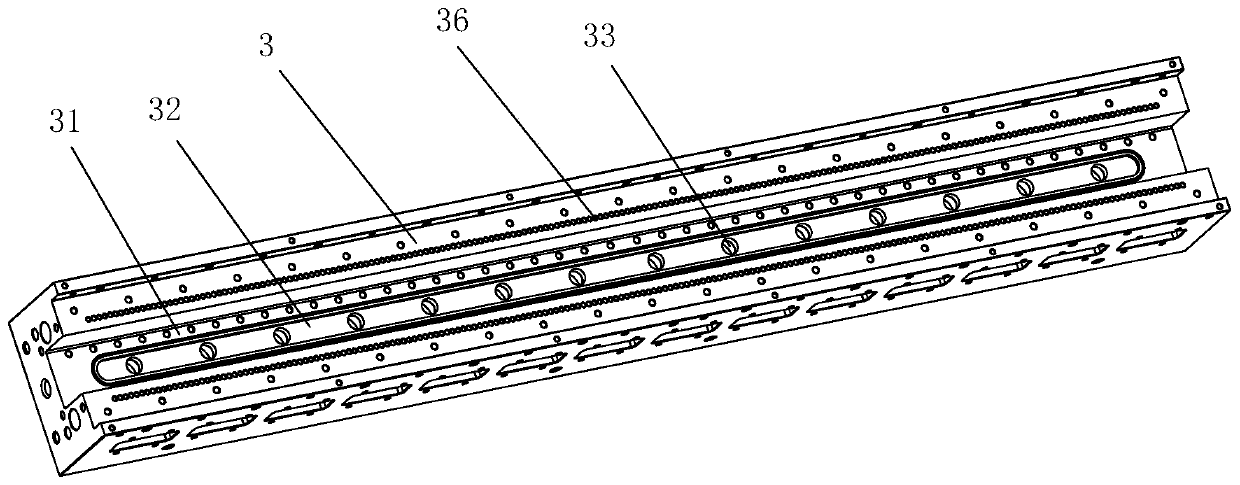

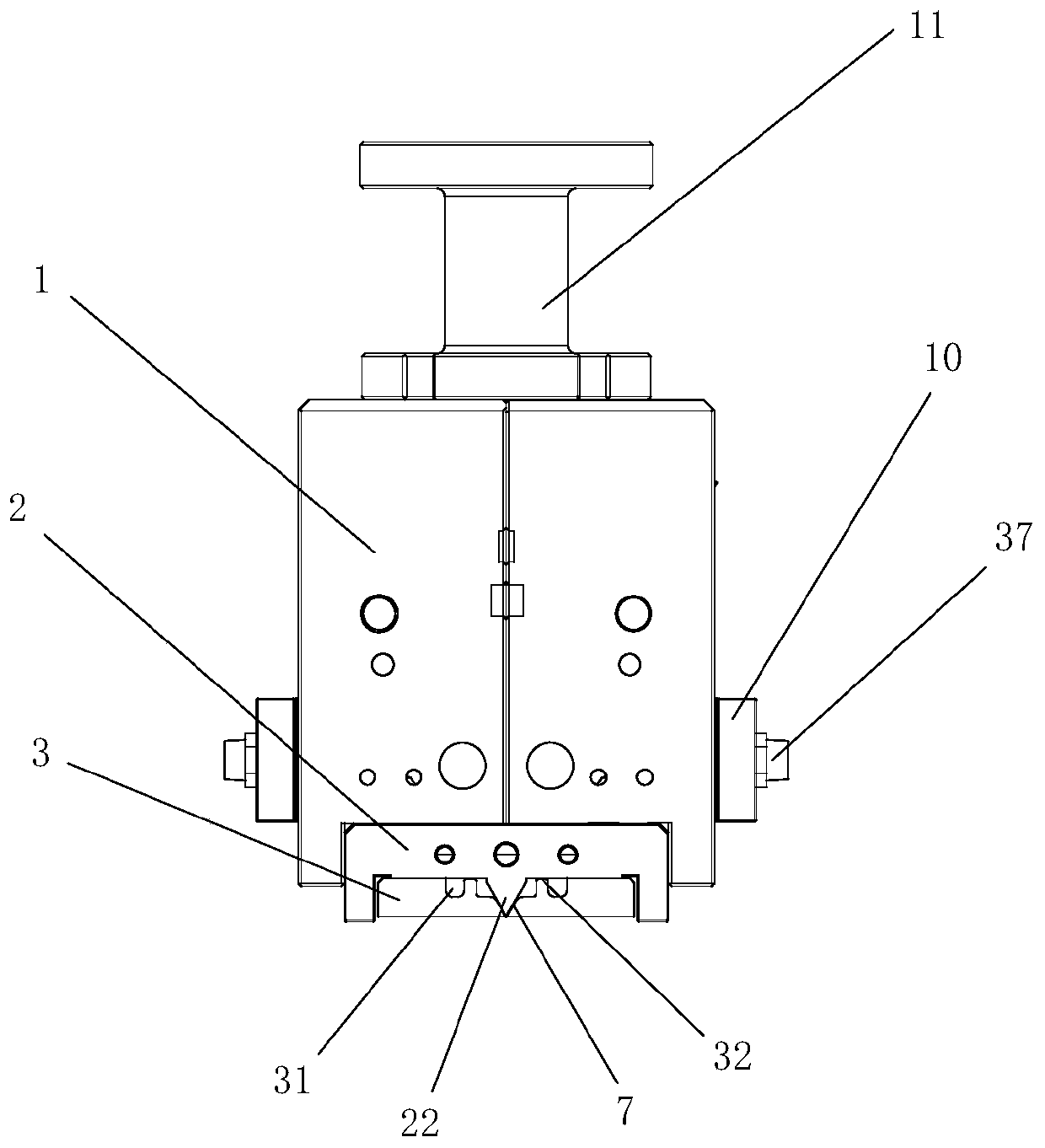

Clothes hanger type non-woven fabric melt-blow mold

PendingCN111575911AIncrease feed resistanceConsistent flow rateSpinning head liquid feederNon-woven fabricsClothes hangerWoven fabric

The invention discloses a clothes hanger type non-woven fabric melt-blow mold which comprises a mold head, a spinneret plate and air knives. The mold head is transversely and horizontally arranged inthe length direction, and the spinneret plate is fixedly mounted at the bottom of the mold head. A feeding cavity of a clothes hanger type structure is formed in the mold head, and a sprue bush communicating with the middle position of the upper end of the feeding cavity is arranged at the top of the mold head. A storage trough is formed in the spinneret plate, a division filter assembly is assembled at the top of the storage trough, and the storage trough communicates with the feeding cavity through the division filter assembly. Multiple spinneret holes transversely and linearly distributed are formed in the bottom of the spinneret plate, and the storage trough communicates with the outside through the spinneret holes. The two air knives are symmetrically arranged on the front sides and the rear sides of the spinneret holes. The feeding cavity of the clothes hanger type structure is adopted in the mold head, the feeding resistance of the middle is increased, so that material flow is evenly diffused towards the two sides, the material flow can evenly distributed in a bottom groove, pressure balance is achieved, the flow speed of the spinneret holes is consistent, the thickness of formed non-woven fabric is uniform, and quality is high.

Owner:青岛海泰科模具有限公司

Waste heat utilization heat exchanger, with different tube bundle intervals and bulge densities, of rotary cement kiln

InactiveCN103629958AConstant speedReduce dust accumulationIncreasing energy efficiencyStationary tubular conduit assembliesEngineeringVolumetric Mass Density

The invention discloses a waste heat utilization heat exchanger, with different tube bundle intervals and bulge densities, of a rotary cement kiln. The heat exchanger comprises a heat exchange tube bundle, a tail gas inlet, a tail gas outlet and a casing, wherein the heat exchange tube bundle is arranged in the casing and is arranged in a diamond way; the casing is provided with a diamond structure matched with the heat exchange tube bundle which is arranged in the diamond way, and is called a diamond casing; the tail gas inlet is formed in a first included angle position of the diamond casing; the tail gas outlet is formed in a second included angle position of the diamond casing; a first included angle and a second included angle of the heat exchange tube bundle arranged in the diamond way are opposite angles; a third included angle and a fourth included angle of the heat exchange tube bundle arranged in the diamond way are opposite angles; heat exchange tube intervals from the tail gas inlet to a connected line between the third angle and the fourth angle are continually reduced; heat exchange tube intervals from the connected line between the third angle and the fourth angle to the tail gas outlet are continually increased. As the heat exchange tube intervals of the heat exchanger from the tail gas inlet to the tail gas outlet are firstly reduced and then increased, the heat exchanger ensures that the tail gas speed keeps constant, reduces the phenomenon of ash deposition, and achieves purposes of environment protection and energy conservation.

Owner:SHANDONG UNIV

Energy-saving type spinning die head for spinning box

ActiveCN102383203BEasy processing and installationFast heat conductionSpinnerette packsSquare waveformHeat conducting

The invention relates to an energy-saving type spinning die head for a spinning box. The spinning die head comprises a pair of die head bodies with symmetrical structures, wherein multiple segments of square wave heat-conducting oil channels are distributed on the inner walls of the die head bodies; and the liquid inflow holes and liquid outflow holes of the square wave heat conducting oil channels are respectively connected with a heat conducting oil inflow pipe and a heat conducting oil outflow pipe. The spinning die head for the spinning box provided by the invention has the advantages that multiple segments of square wave heat-conducting oil channels are arranged on the inner walls of the die head bodies, so that the die head bodies are directly heated by heat conducting oil, thus the die head has the characteristics of higher heat conduction speed, high heat conduction efficiency and energy conservation; and shorter square wave heat conducting oil channels are suitable for ensuring that the flow rates at the heat conducting oil inflow holes and outflow holes are basically consistent, thus the integral temperature uniformity of the die head is ensured and the production quality of a product is improved.

Owner:CHANGZHOU HUIMING PRECISION MACHINERY

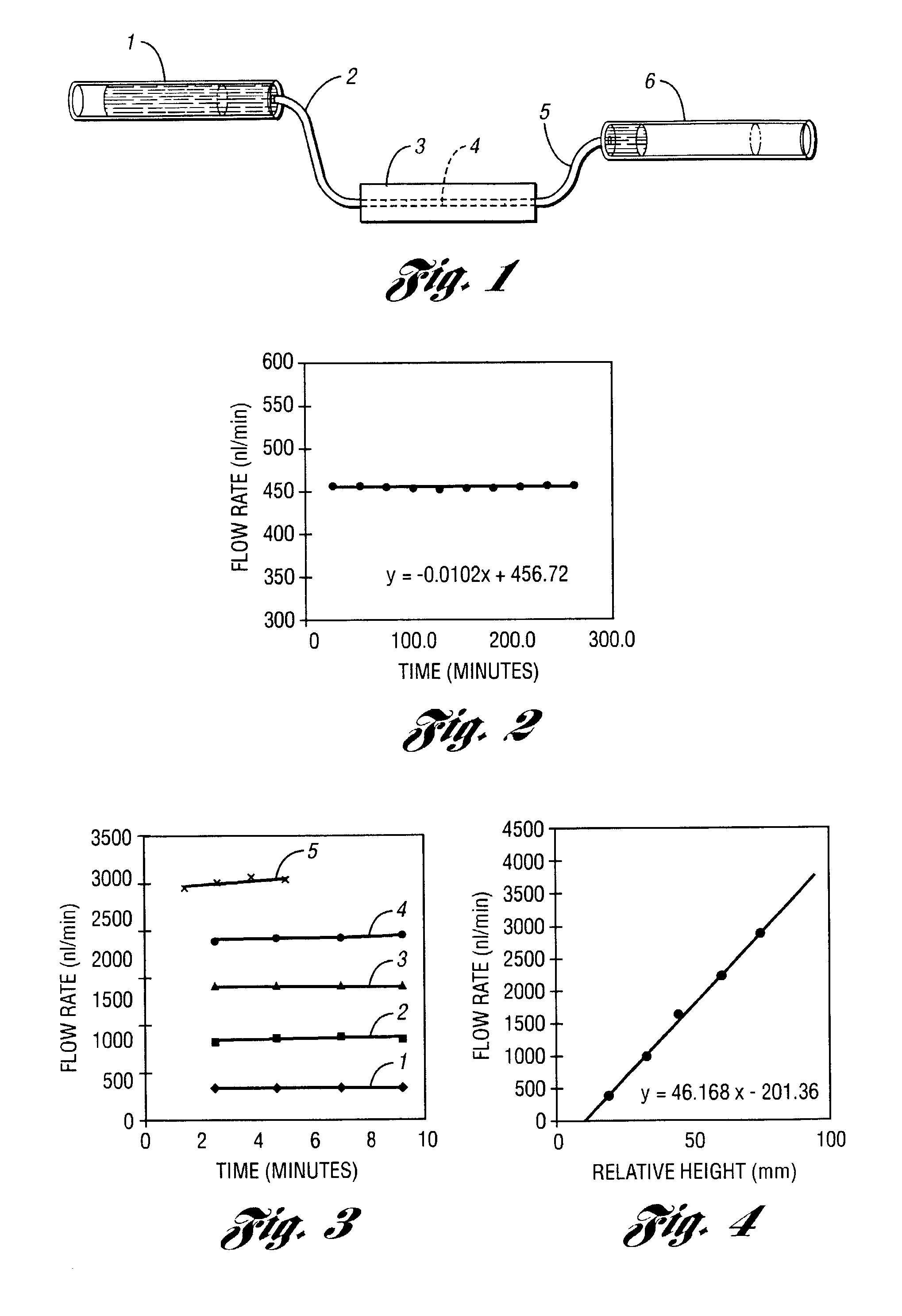

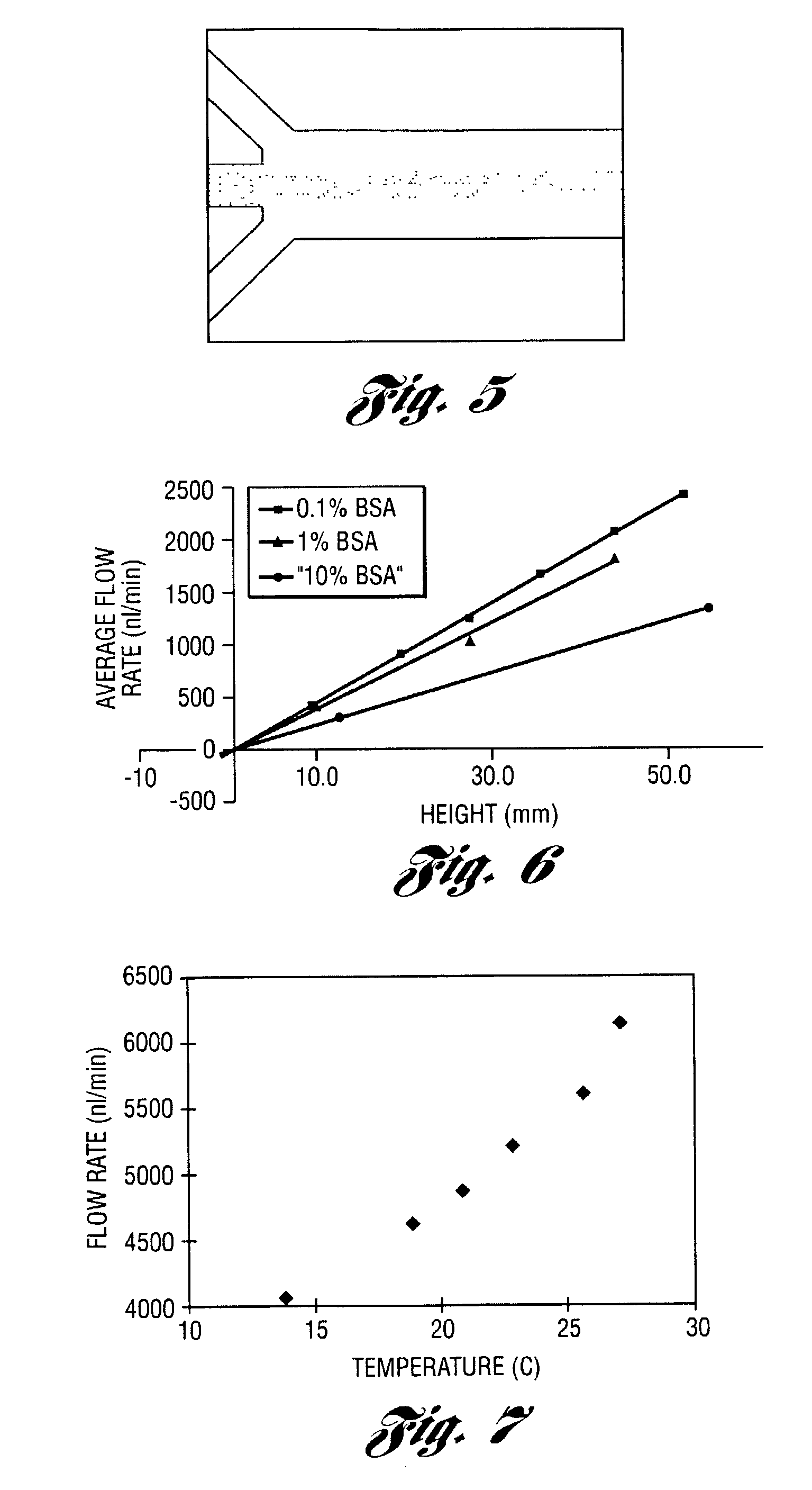

Microfluidic gravity pump with constant flow rate

ActiveUS7704728B2Consistent flow rateBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringInduced stress

A microfluidic system employs a microchannel and a gravity driven pump comprising horizontally oriented fluid supply reservoirs which supplies fluid to the microchannel at a substantially constant rate. The device is useful for numerous microfluidic applications, for example in the culture and / or treatment of biological systems under constant flow-induced stress, cell-size sorting, motile sperm sorting, or embryo culture.

Owner:RGT UNIV OF MICHIGAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com