One-die multiple-part aluminium alloy tube hot-extrusion die

A technology for hot extrusion dies and aluminum alloy tubes, applied in metal extrusion dies and other directions, can solve the problems of uneven wall thickness, large difference in flow rate, and high rejection rate, avoiding welding lines, extending service life, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

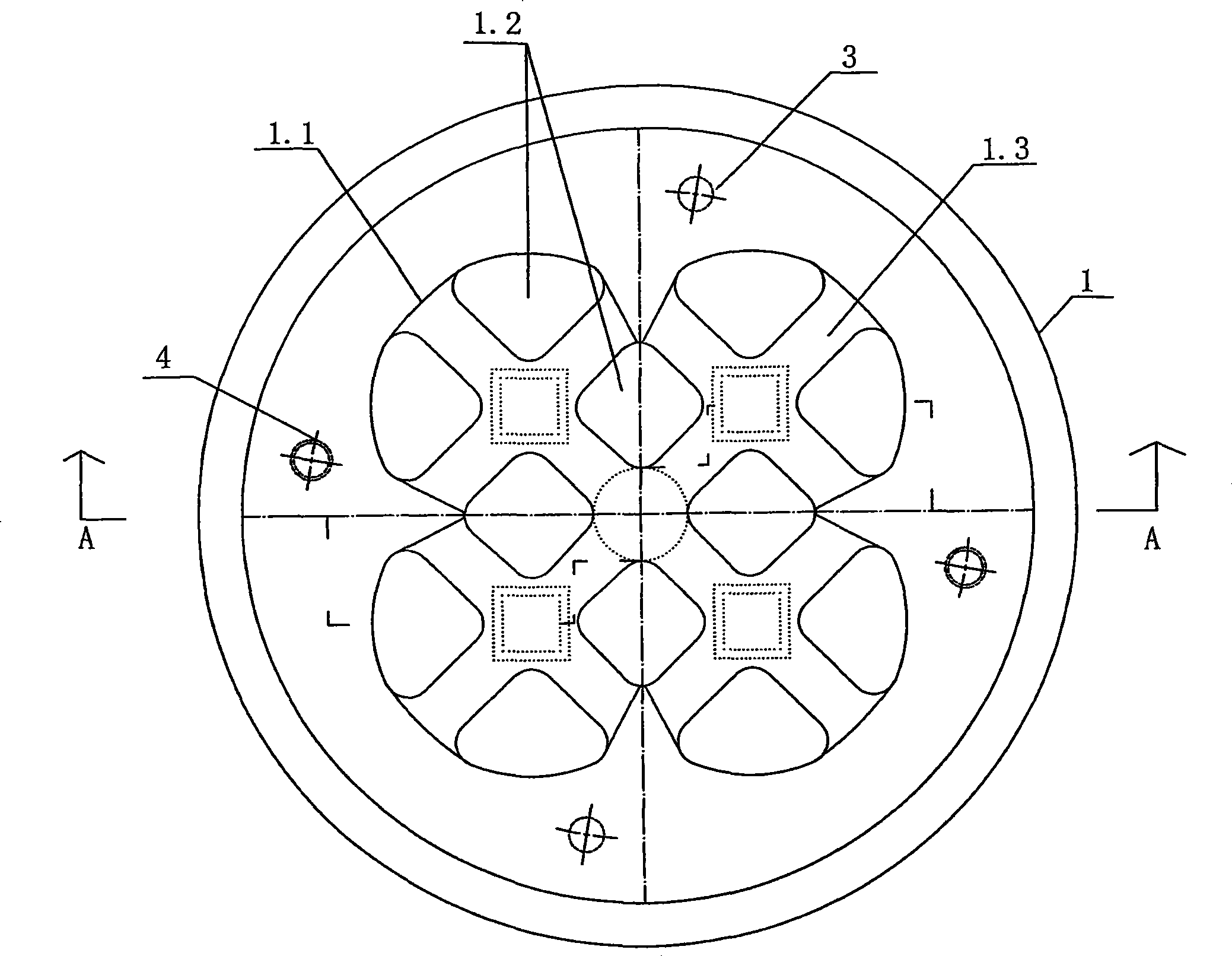

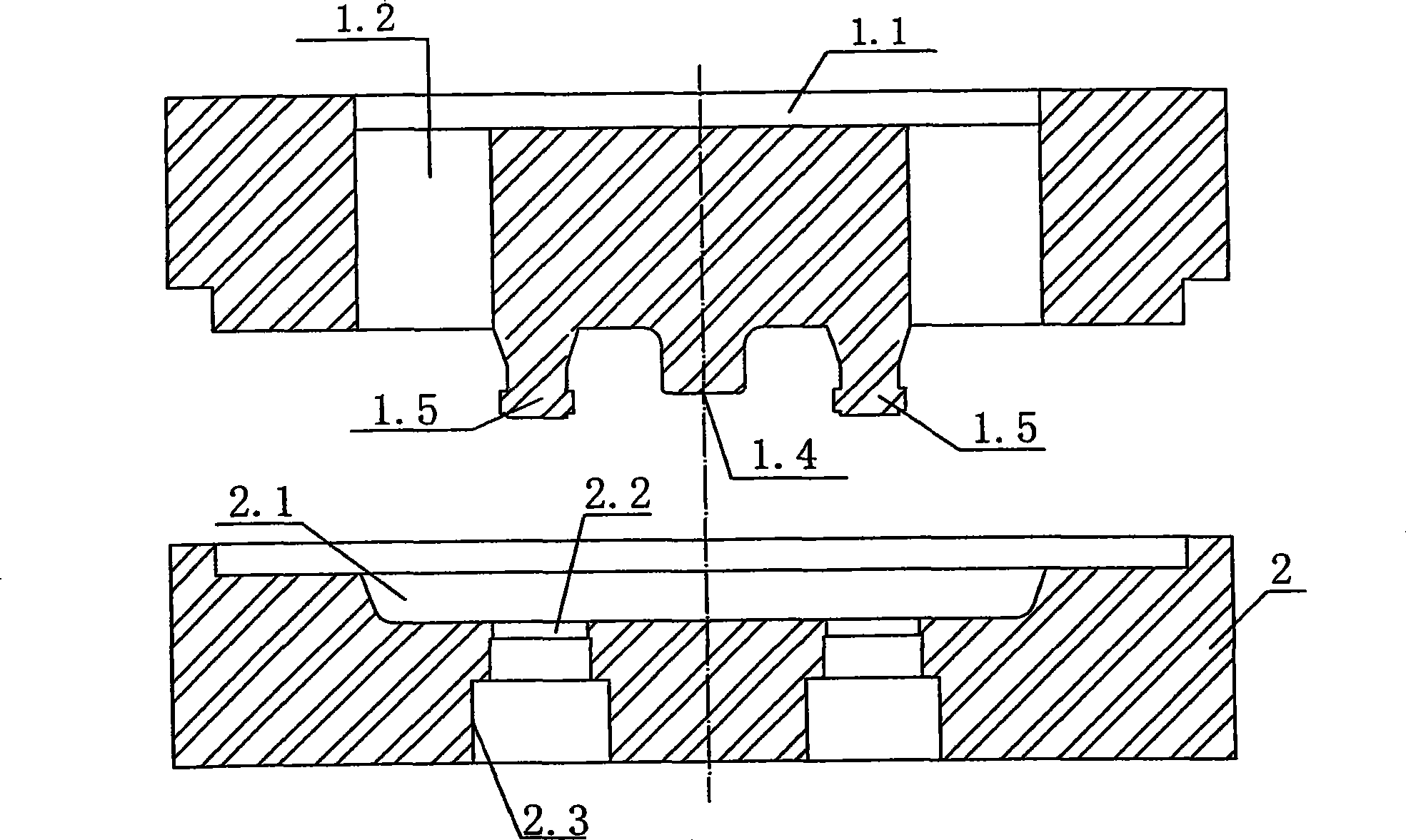

[0020] see Figure 1~2 , the present invention relates to a mold with multiple aluminum alloy pipe hot extrusion dies, which are assembled and combined by an upper mold 1 and a lower mold 2 using pins 3 and screws 4 .

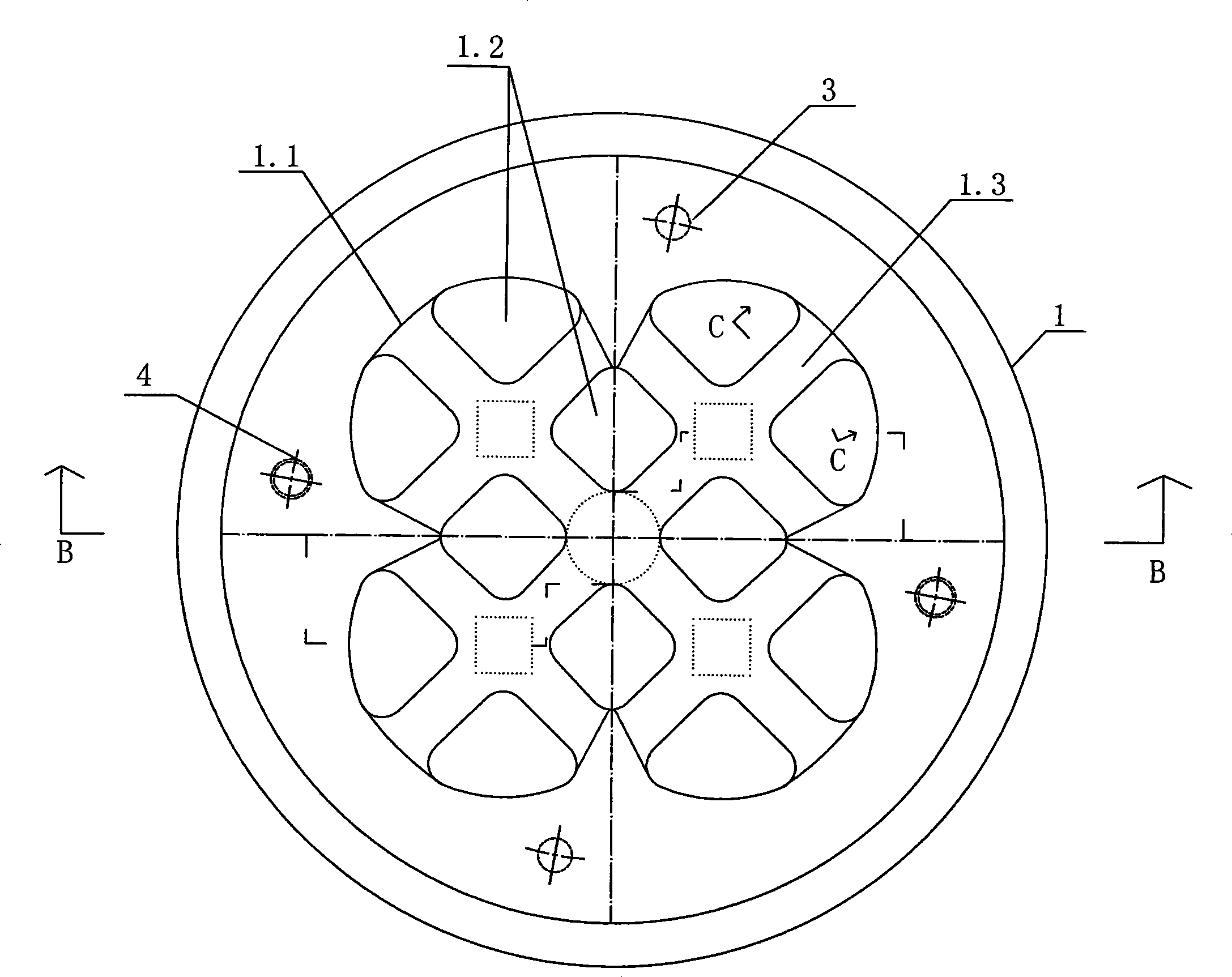

[0021] see image 3 ~5, the feed end of the upper mold 1 is provided with a decompression sink hole 1.1 that sinks 10mm. The distribution holes 1.2 of the upper mold 1 are distributed in multiples of the cavity 2.2 of the lower mold 2 and arranged around the cavity 2.2 of the lower mold 2 . All the bridge positions 1.3 of the upper mold 1 are processed into a drop-shaped structure, as shown in FIG. 5 . The discharge surface of the upper mold 1 is provided with a plurality of square head mold cores 1.5, and support bosses 1.4 are arranged between the square head mold cores 1.5. The square head mold core 1.5 of the upper mold 1 and the bridge position 1.3 transition smoothly.

[0022] Referring to Figures 6-7, the feed end of the lower die 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com