Hot runner type nonwoven melting and spraying die

A hot runner, non-woven technology, applied in the field of mold manufacturing, can solve the problems of poor quality, non-uniform thickness of non-woven fabric, inconsistent injection pressure, etc., and achieve the effect of consistent flow rate, balanced pressure, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail below in conjunction with accompanying drawing:

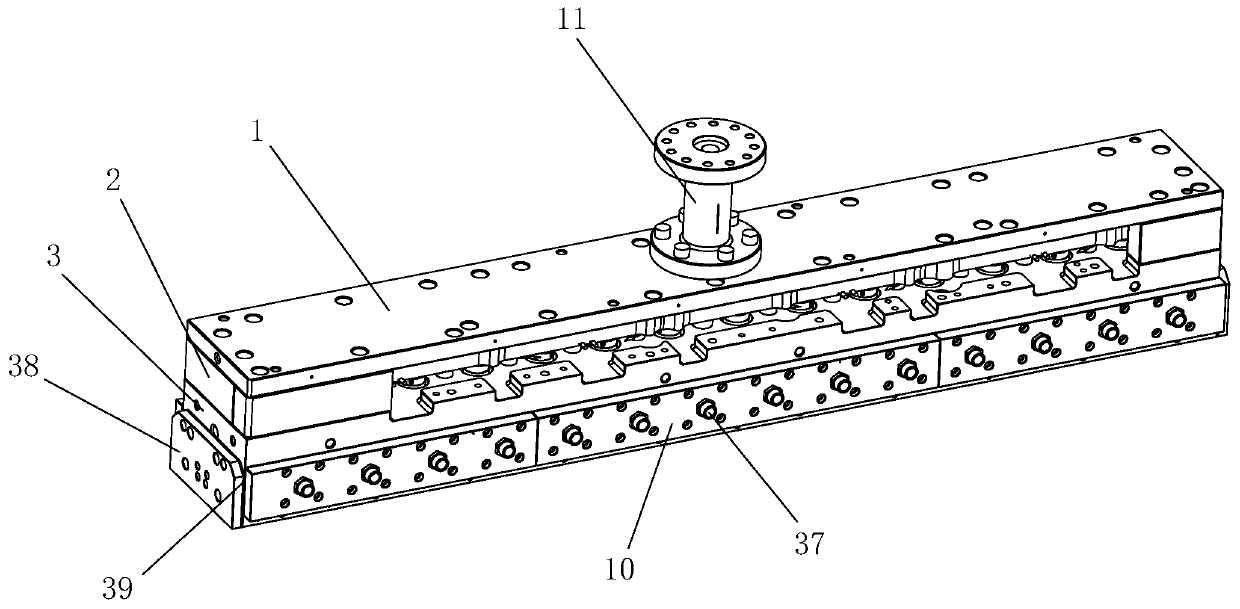

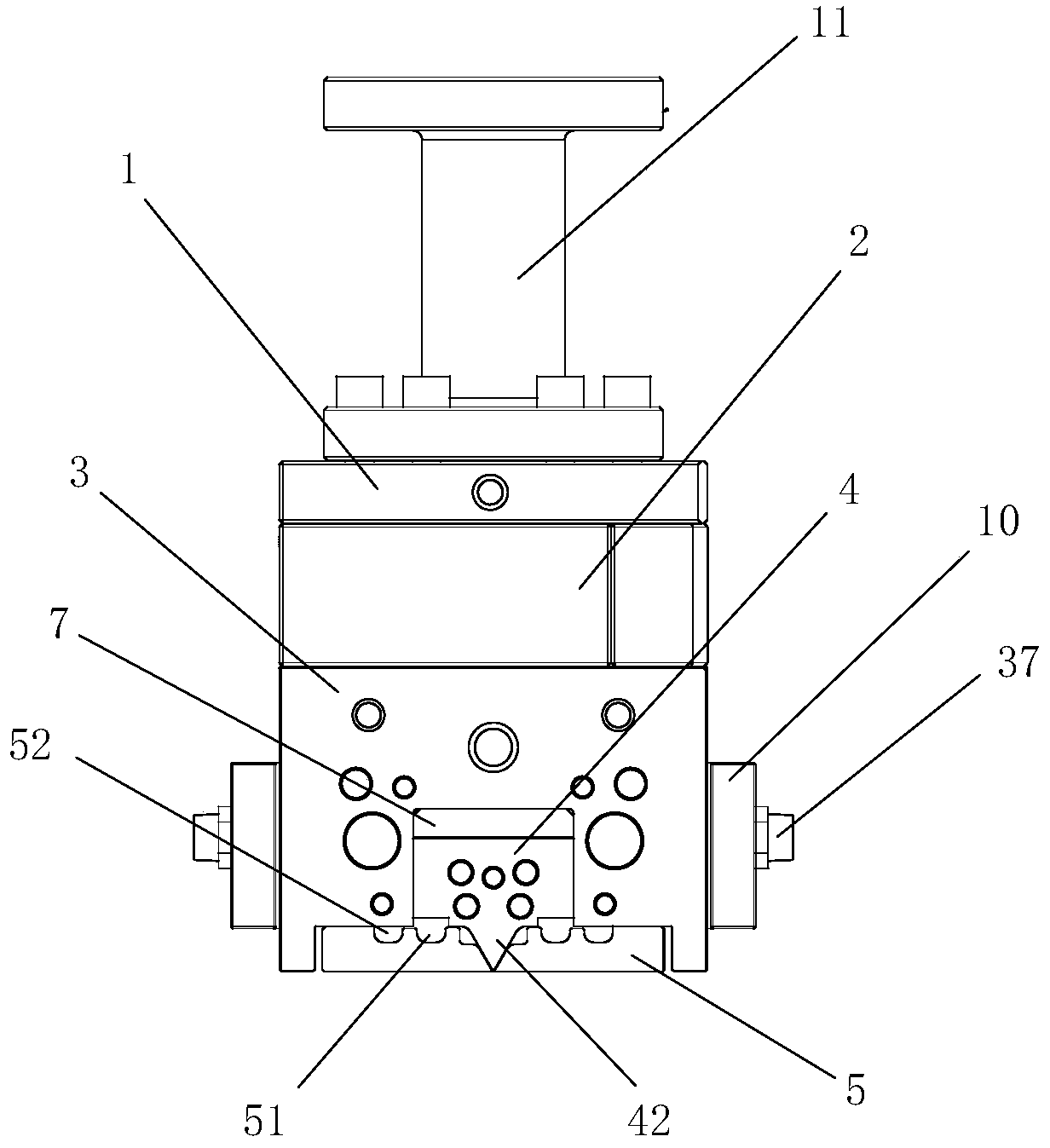

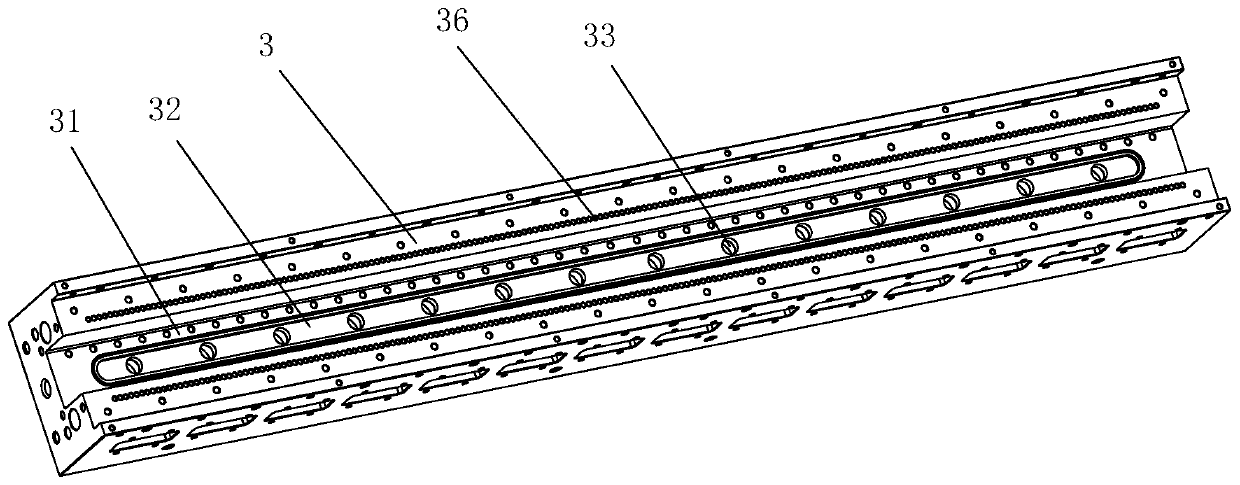

[0038] combine Figure 1 to Figure 8 , a hot runner type non-woven melt-blown mold, including a base plate 1, a hot runner plate 2, a die head 3, a spinneret plate 4 and an air knife 5, and the base plate 1, the hot runner plate 2, and the die head 3 are all horizontal Arranged horizontally and connected in sequence from top to bottom, base plate 1, hot runner plate 2, die head 3, spinneret plate 4 and air knife 5 are all made of metal materials. The inside of the hot runner plate 2 has a main hot runner 21 , and the bottom plate 1 is provided with a sprue sleeve 11 , and the main hot runner 21 is connected to the sprue sleeve 11 . Specifically, the main hot runner 21 is a straight channel with equal cross-section opened horizontally, and the sprue bushing 11 is vertically and fixedly installed on the top of the bottom plate 1 .

[0039] The main hot runner 21 is left-right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com