Oil returning method during heating of multi-split air-conditioning unit

A multi-connected air conditioner and unit technology, which is applied in the direction of compressors, refrigerators, refrigeration components, etc., can solve the problems that users cannot use air conditioners, indoor heating, liquid shock compressors, etc., and achieve good oil return effect, mixing Good effect, avoiding the effect of liquid hitting the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

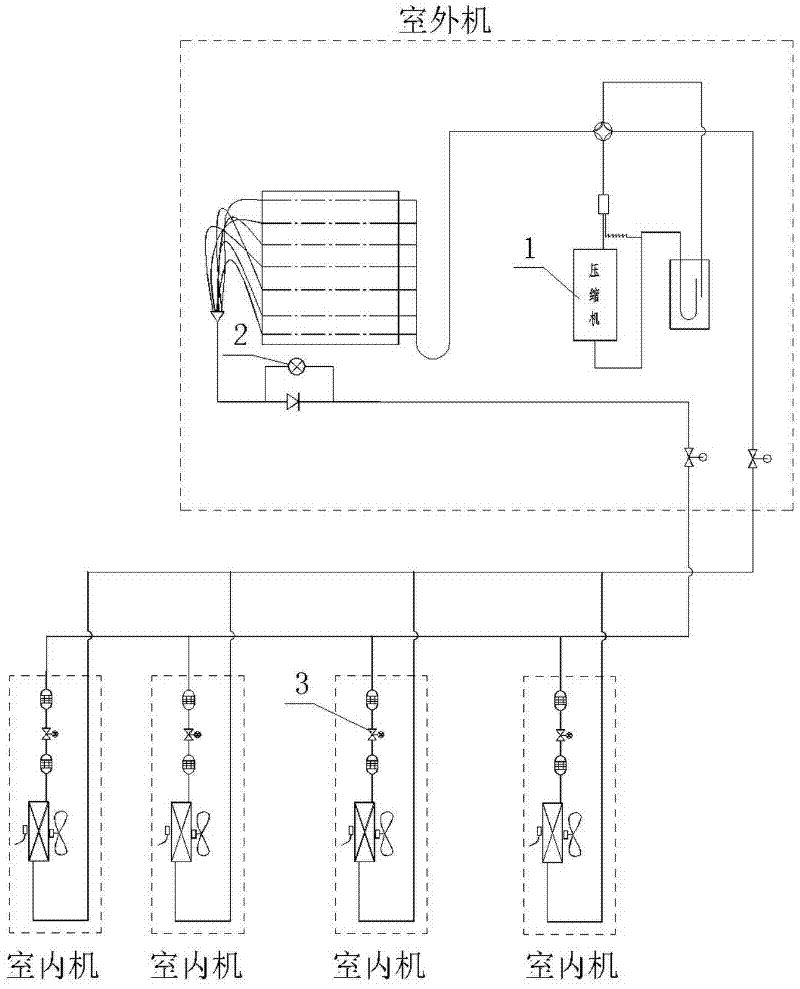

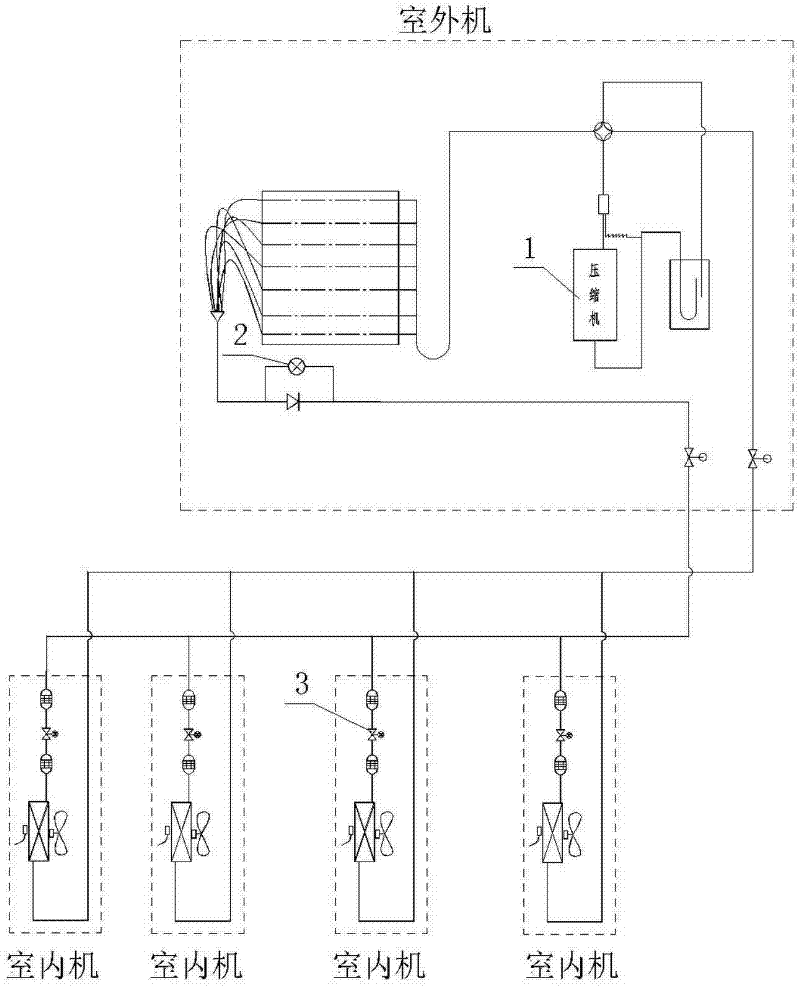

[0029] Such as figure 1 As shown, the oil return method when the multi-connected air conditioner unit of the present invention is heating, it may further comprise the steps:

[0030] a. The multi-connected air conditioner unit is running normally in the heating mode. At this time, the electronic expansion valve 2 of the external unit is the throttling device of the system, and the opening degree is generally about 120 steps. The indoor unit of the indoor unit that is turning on the heating The opening of the electronic expansion valve 3 is generally about 350 steps. The opening of the electronic expansion valve 3 of the indoor unit of the indoor unit that is not turned on and not heating is 0, and the frequency of the compressor 1 is adjusted according to the number of indoor units that are loaded. When the number of indoor units turned on is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com