Method for tempering high temperature slag and mineral cotton production method

A production method and technology of slag wool, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of wasting sensible heat and not saving energy, and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

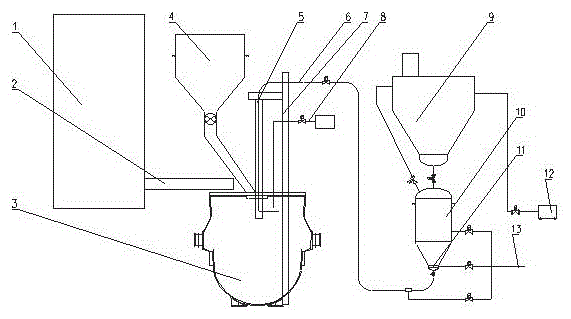

Method used

Image

Examples

Embodiment 1

[0023]Example 1: A company uses silico-manganese furnace slag as raw material, the amount of slag is 6t / h, the water consumption of the original slag flushing water quenching process is 5t water / t slag, the acidity of slag is 2.0, the content of Al2O3>20%, and the viscosity>3(1400 ℃), after using this technology, the water consumption of the water quenching process is reduced by 5t water / t slag, and 100kg dolomite powder / t slag and 40kg SiC powder / t slag are added, the injection conditioner pressure is 0.2Mpa, and the powder injection speed is controlled at 200Kg / min, when the molten slag is discharged, the slag tank will be conditioned, and the slag temperature will basically remain unchanged at 1400°C. After the slag is quenched and tempered, the slag bag will be transported to the slag wool pouring position, and the slag flow will be stabilized at the upper port. Casting and blowing slag wool, the diameter of the blown slag wool fiber is 5um, the content of slag balls is <8%...

Embodiment 2

[0024] Example 2: A company uses ferronickel slag as raw material, the amount of slag is 5t / h, the water consumption of the original slag flushing water quenching process is 5t water / t slag, the acidity of the slag is 1.6, the MgO content is >30%, and the viscosity is >2 (1400°C ), after using this technology, the water consumption of the water quenching process is reduced by 5t water / t slag, 200kg fly ash powder / t slag and 30kgAL powder / t slag are added, the injection conditioner pressure is 0.2Mpa, and the powder injection speed is controlled At 200Kg / min, when the molten slag is discharged, the slag is tempered in the slag tank, and the slag temperature is basically kept at 1400°C. Flow casting, blown slag wool, after measurement, the diameter of the blown slag wool fiber is 4um, the content of slag balls is less than 8%, the thermal conductivity at room temperature is 0.05w / m k, and the density is 150kg / m3. Its products "GB / T11835-2007 performance requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com