Patents

Literature

41results about How to "Solve the temperature drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil gas adsorber

ActiveCN102120121AImproved adsorption conditionsImprove cooling effectDispersed particle separationSorbentEngineering

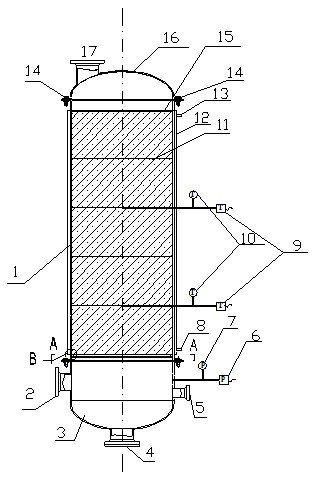

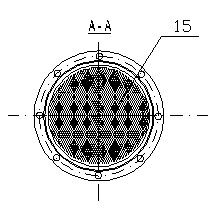

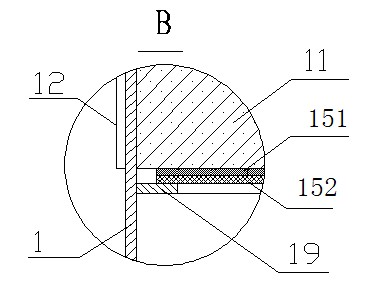

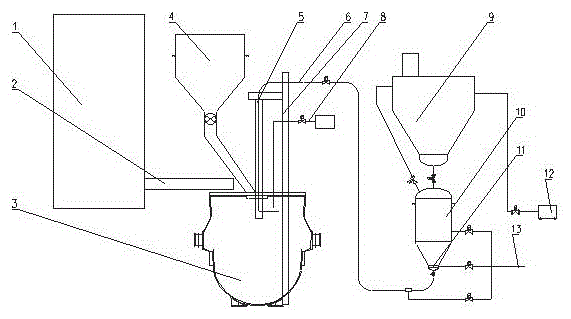

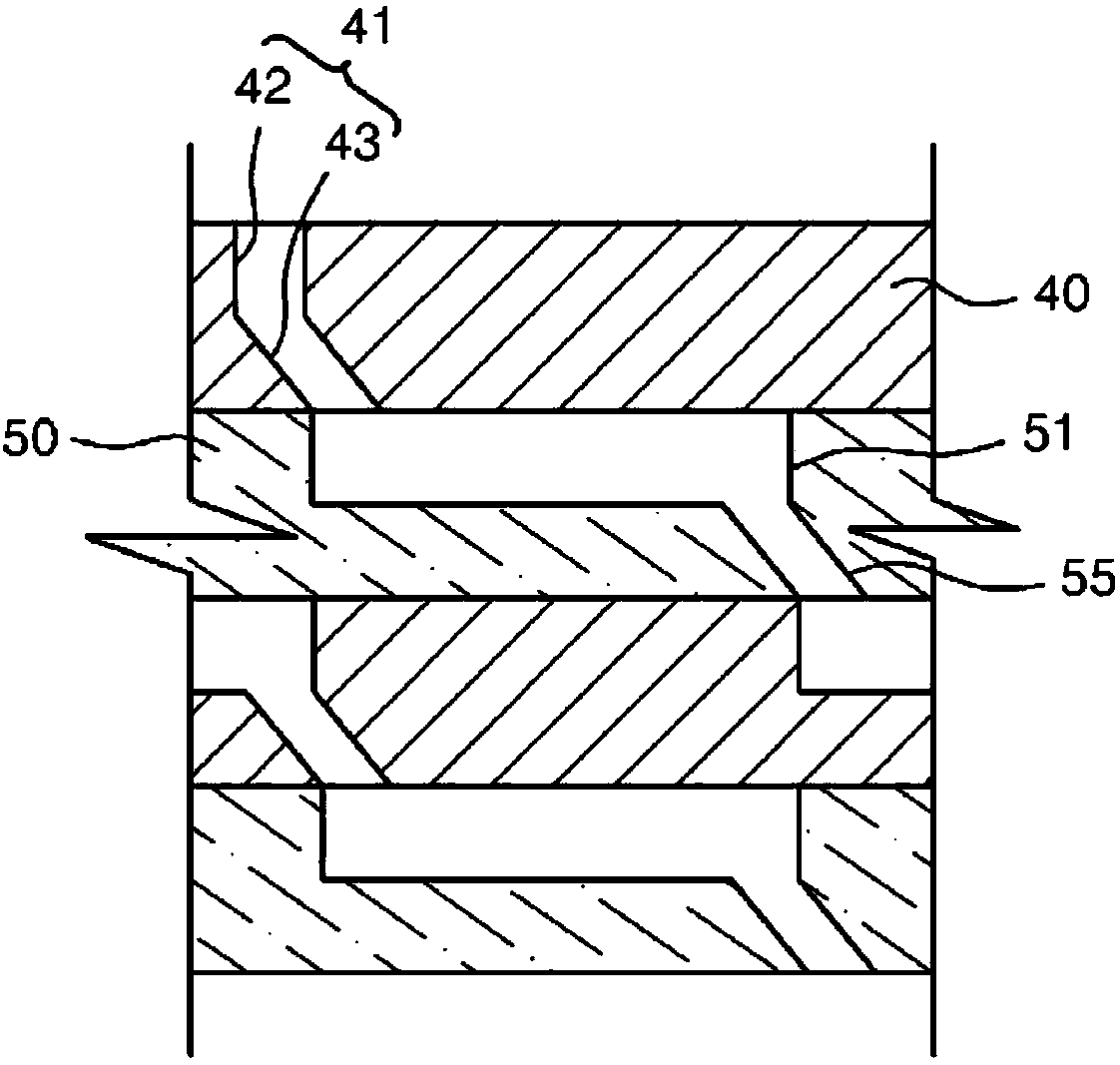

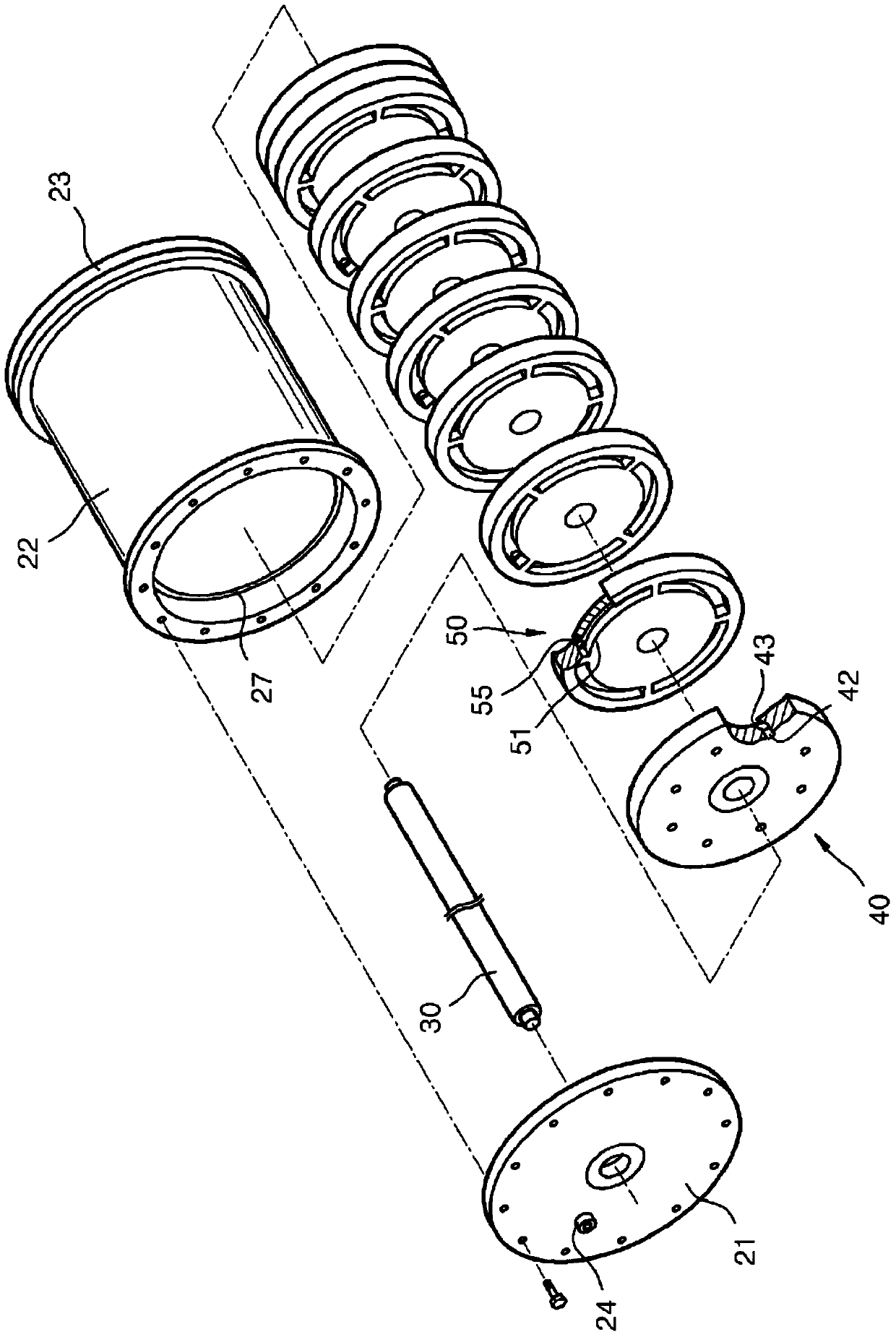

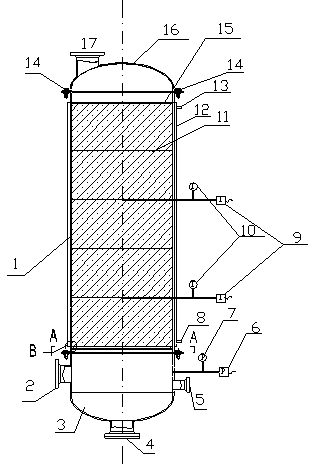

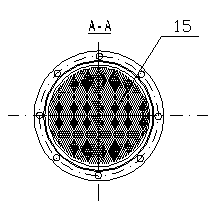

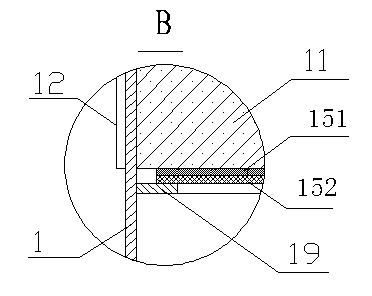

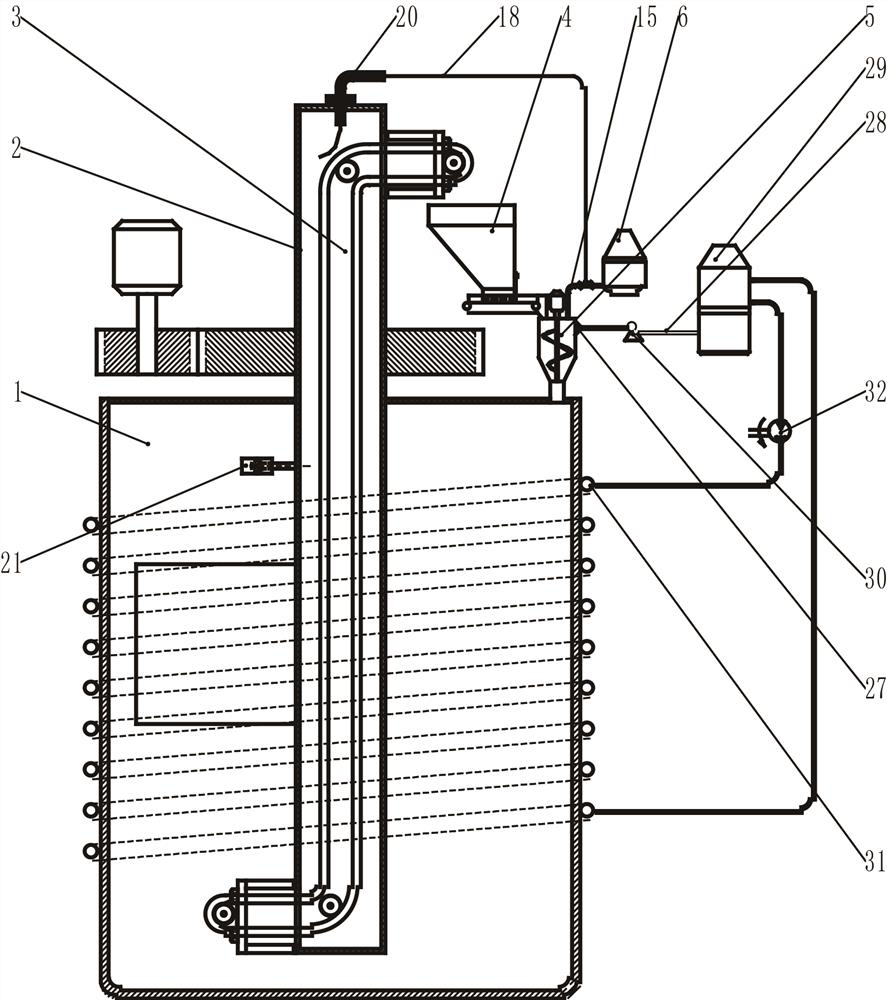

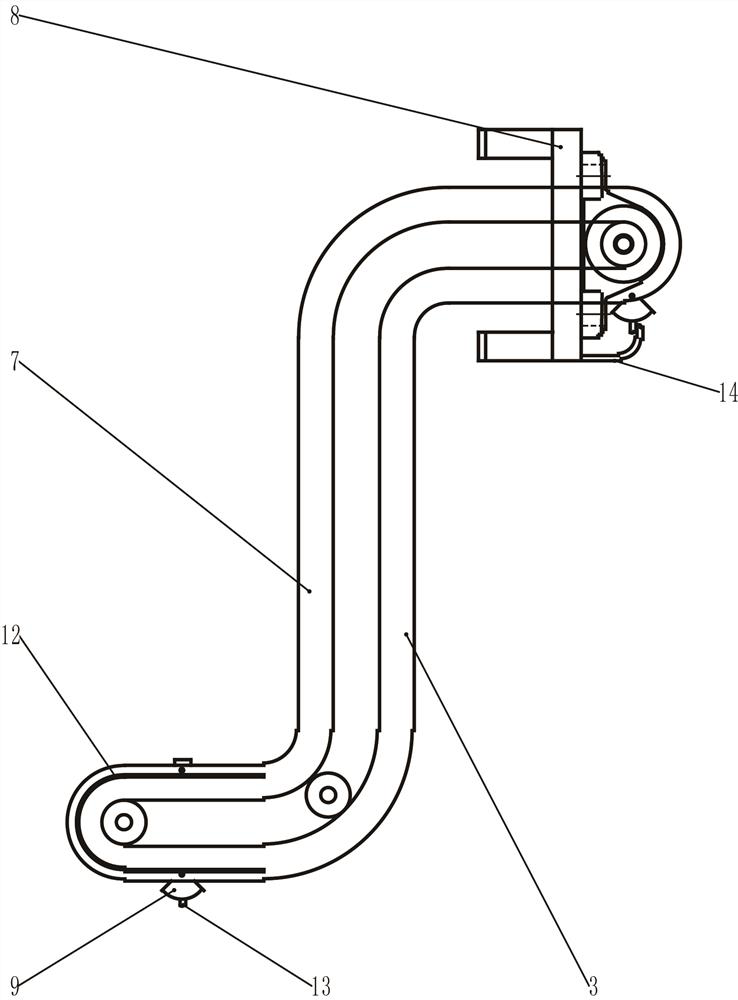

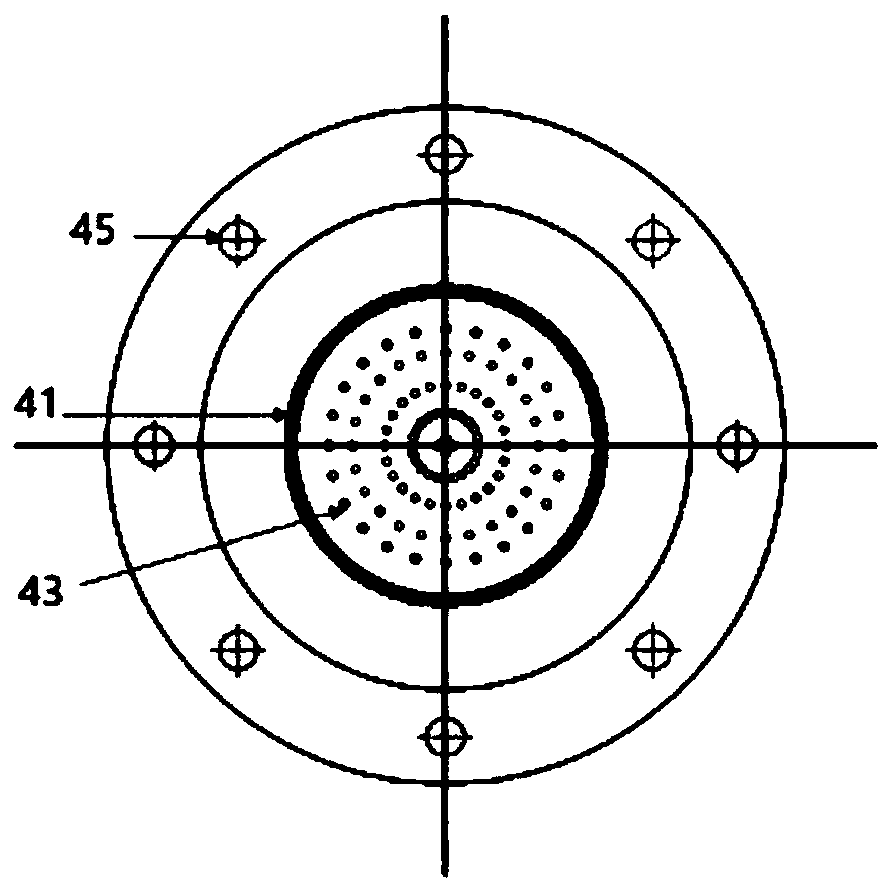

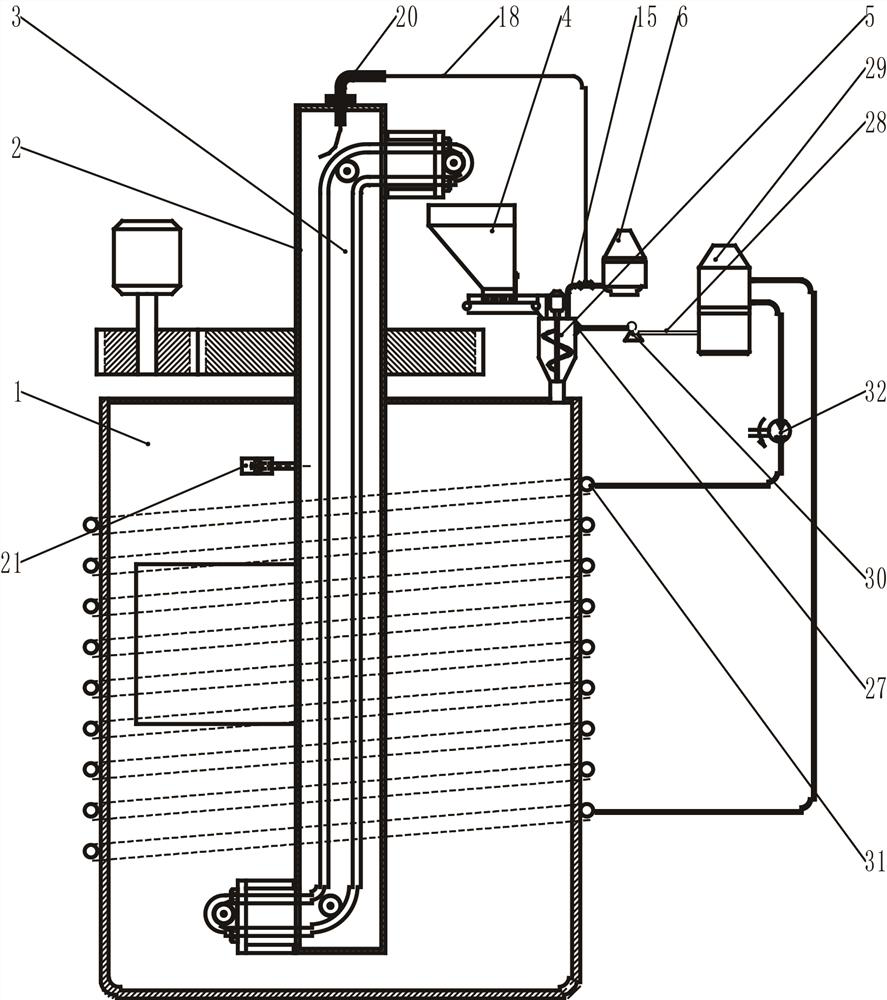

The invention discloses an oil gas adsorber which comprises an adsorber top cover (16), an adsorber main body (1) and an adsorber bottom cover (3) that are connected through bolts (14), wherein the adsorber top cover (16) is provided with an emptying hole (17), and the adsorber main body (1) comprises a composite adsorbing material (11) and a circulating water jacket (12); the circulating water jacket (12) is provided with a circulating water jacket water inlet (8) and a circulating water jacket water outlet (13); the adsorber bottom cover (3) is provided with an oil gas inlet (2), a drain outlet (4), a vacuum pump port (5), a pressure sensor (6) and a pressure meter (7); and the composite adsorbing material (11) is a mixture of foam metal and an adsorbing agent. In the invention, heat radiation is enhanced through the foam metal, the circulating cooling / heating water jackets is additionally arranged outside the oil gas adsorber to enhance heat transfer, thus the temperature rise problem in the adsorber and the temperature drop problem in a desorber can be effectively solved.

Owner:溧阳常大技术转移中心有限公司

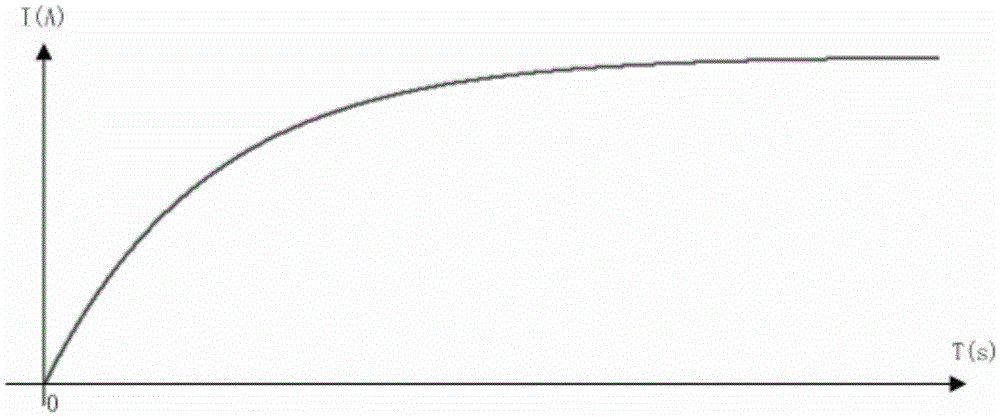

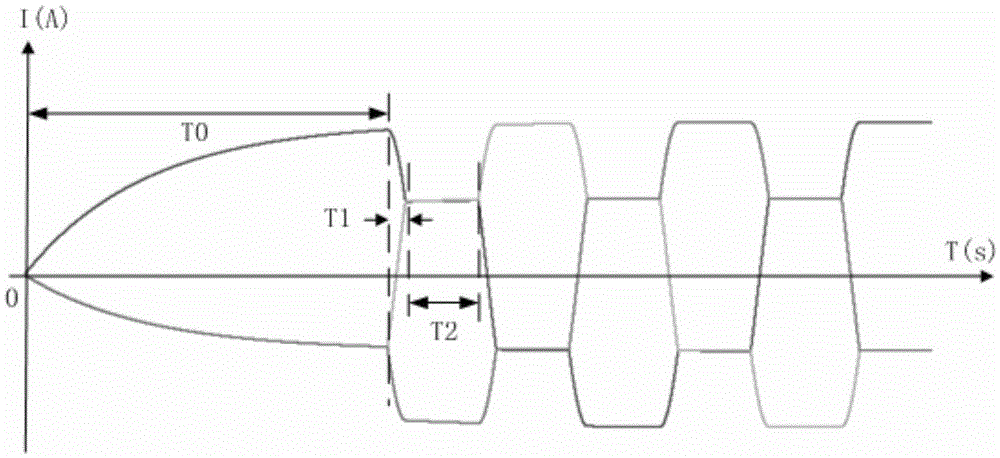

Preheating control method for motor winding

ActiveCN105262385ASolve the temperature dropSolve the noiseAC motor controlVector control systemsFrequency changerPower flow

The invention relates to the air-conditioning control technique, and discloses a preheating control method for a motor winding, which solves the problems in the prior art of the reduced temperature of a motor winding, the over-current shutdown of an IPM and the large noise of the motor during the preheating process based on existing motor winding preheating schemes. During the preheating control process, the current carrier frequency of a frequency inverter is switched into a higher value and then the primary positioning operation is conducted after the frequency switching process. During the primary positioning process, within the time period T0, a motor is positioned at a designated initial position gamma 0, and a current vector is positioned stationary and maintained for a time period T2. The motor winding is energized for the time period T2, and the positioned current vector is rotated with a designated time period T1 and then is prevented from rotating at a next designated position. During the time period T2, the current vector is maintained stationary and the motor winding is kept energized. Upon the closure of the time period T2, the positioned current vector is rotated during the designated time period T1 to reach the next designated position. The above process is repeated in cycles till the pre-heating process is over. Then the carrier frequency of the frequency inverter is recovered and the preheating process of the motor winding is completed. The above method is applicable to the preheating control of the motor winding of an air conditioner.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

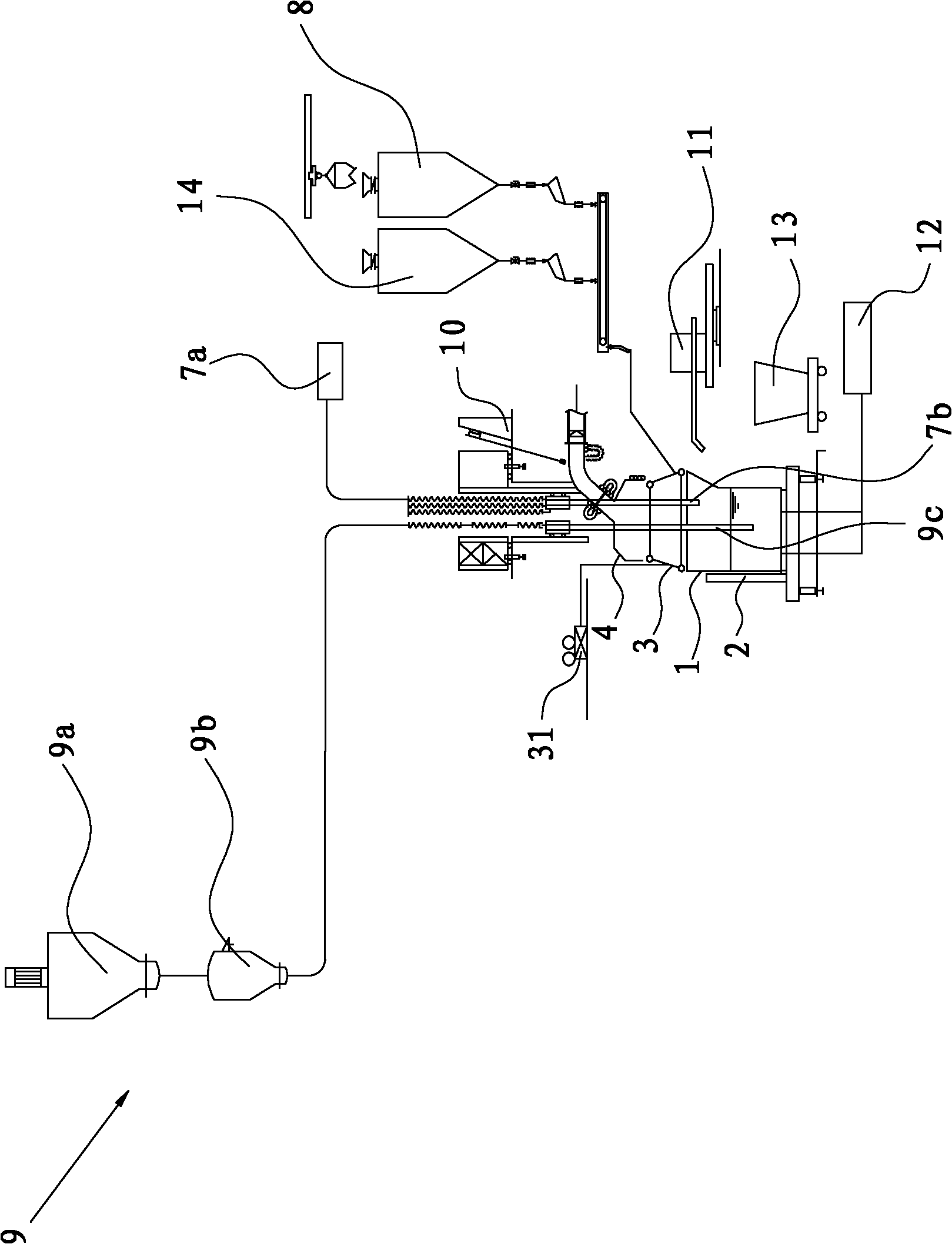

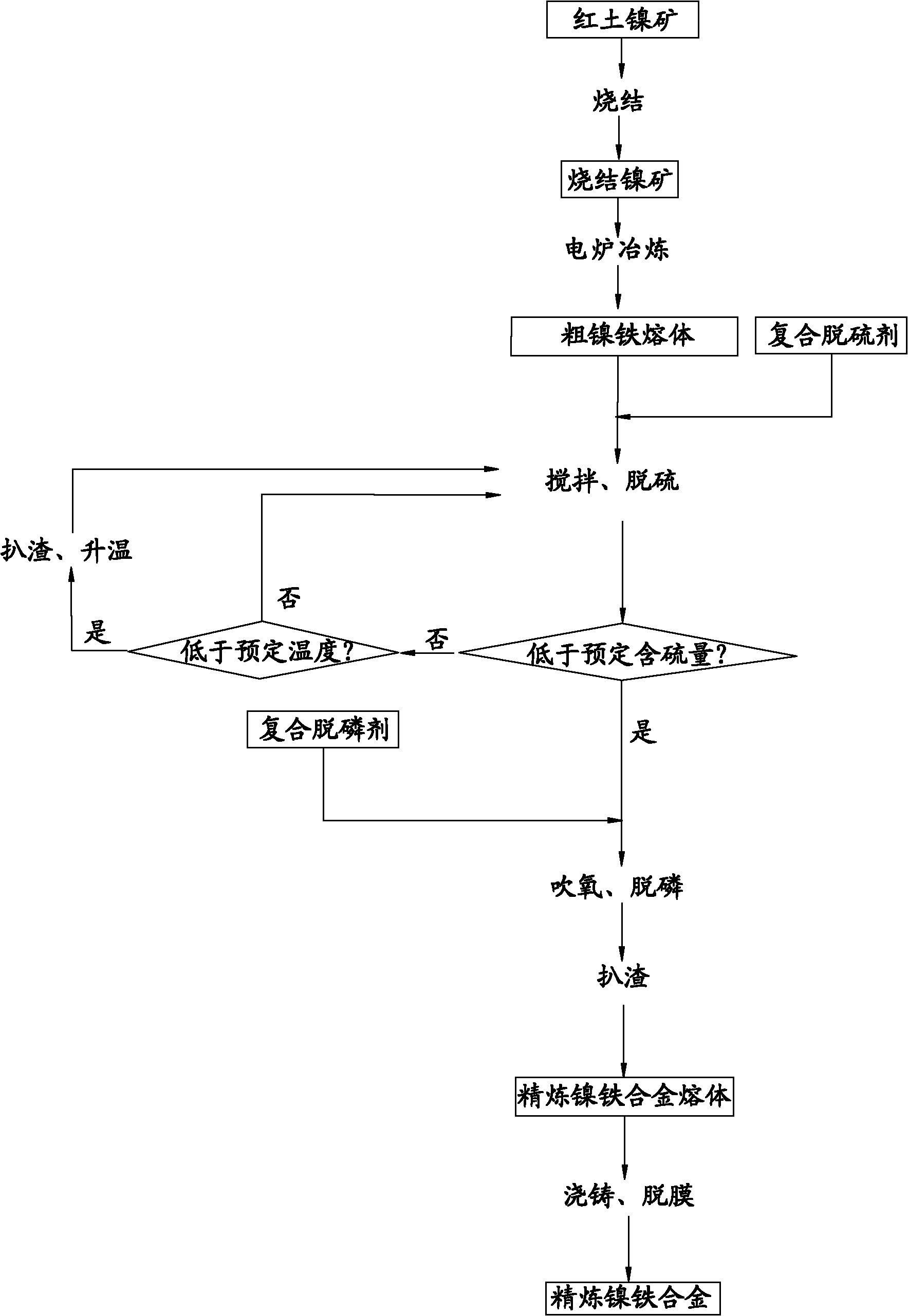

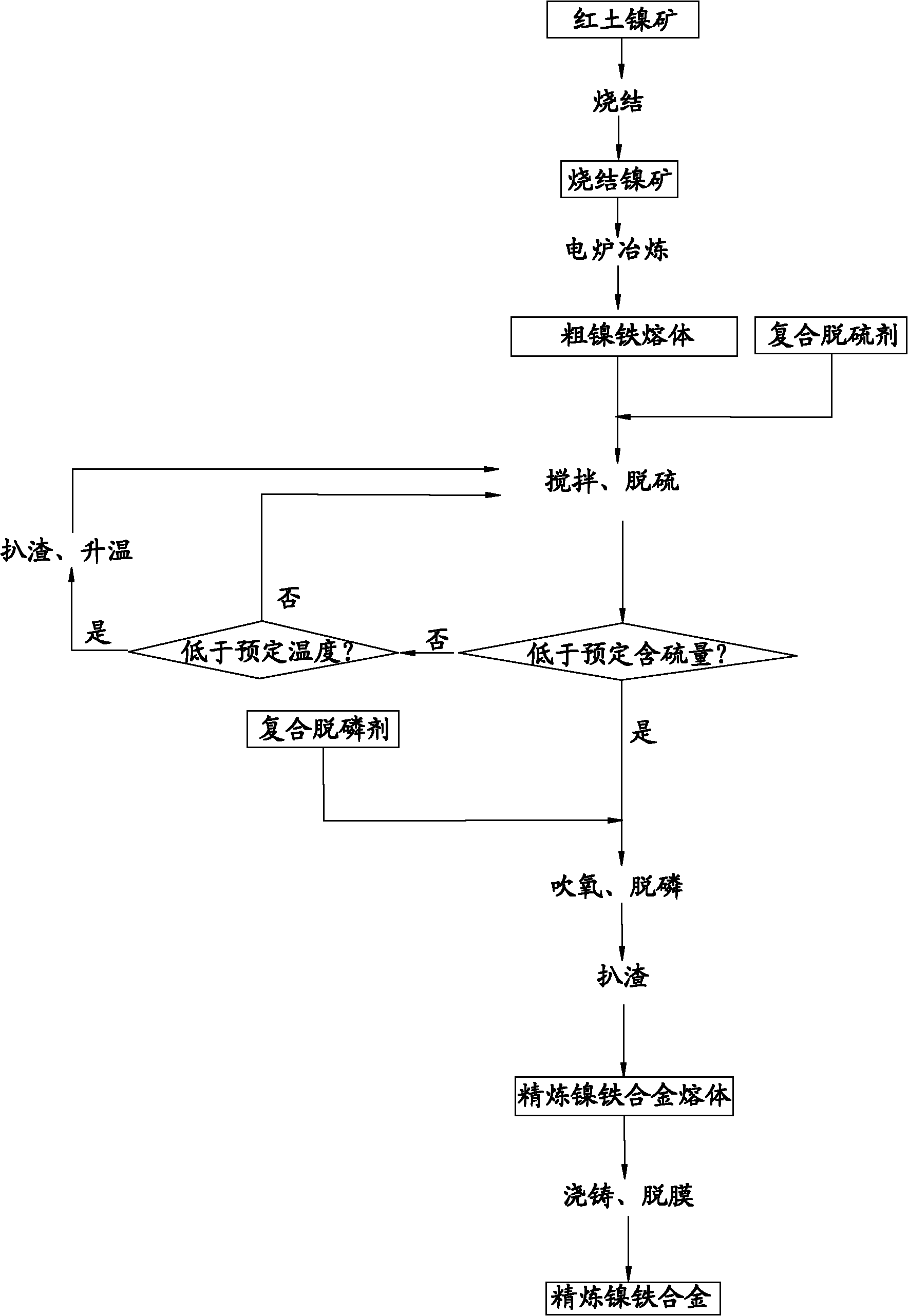

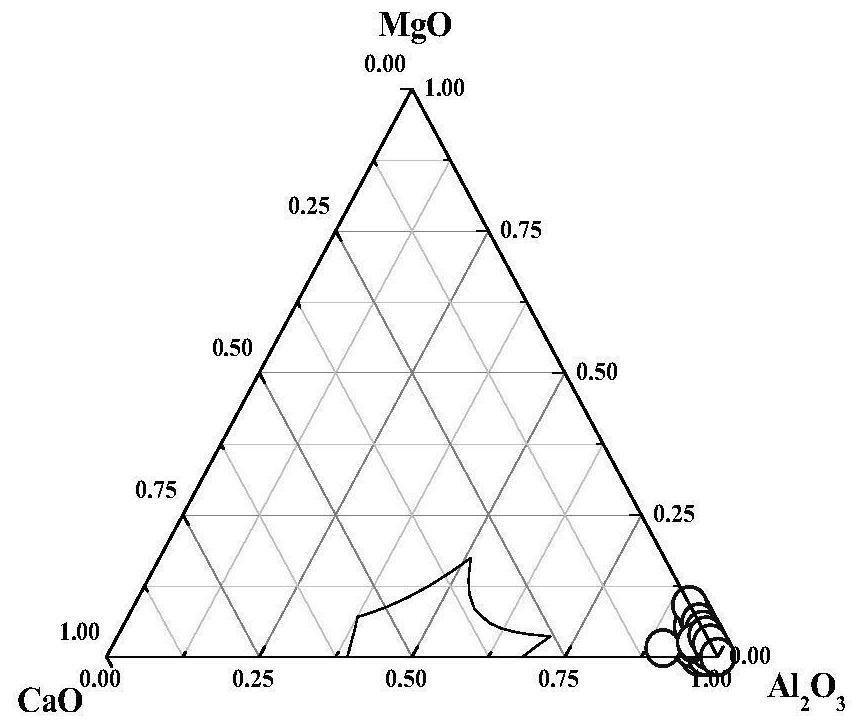

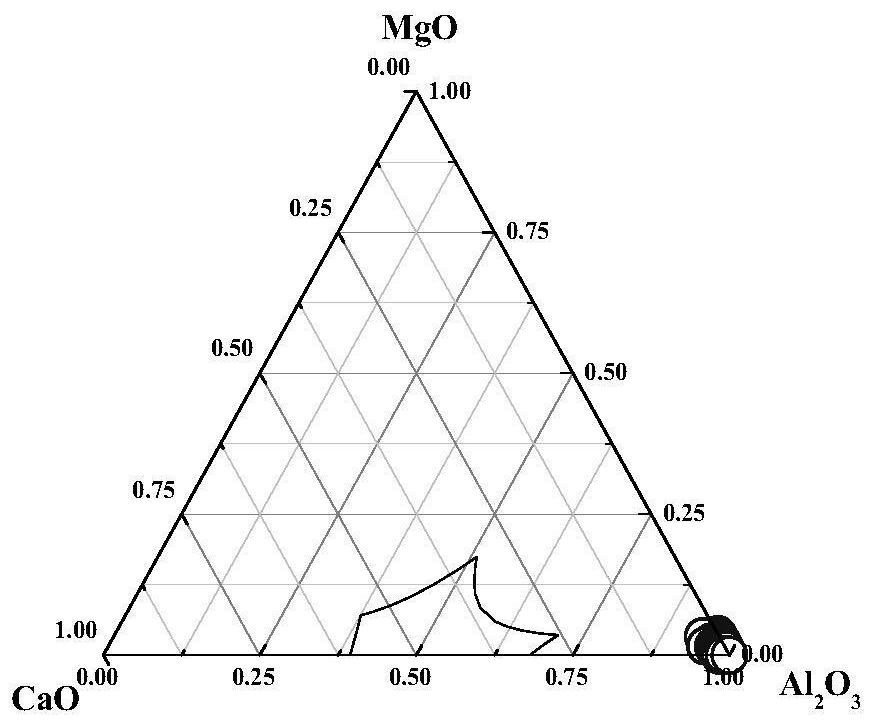

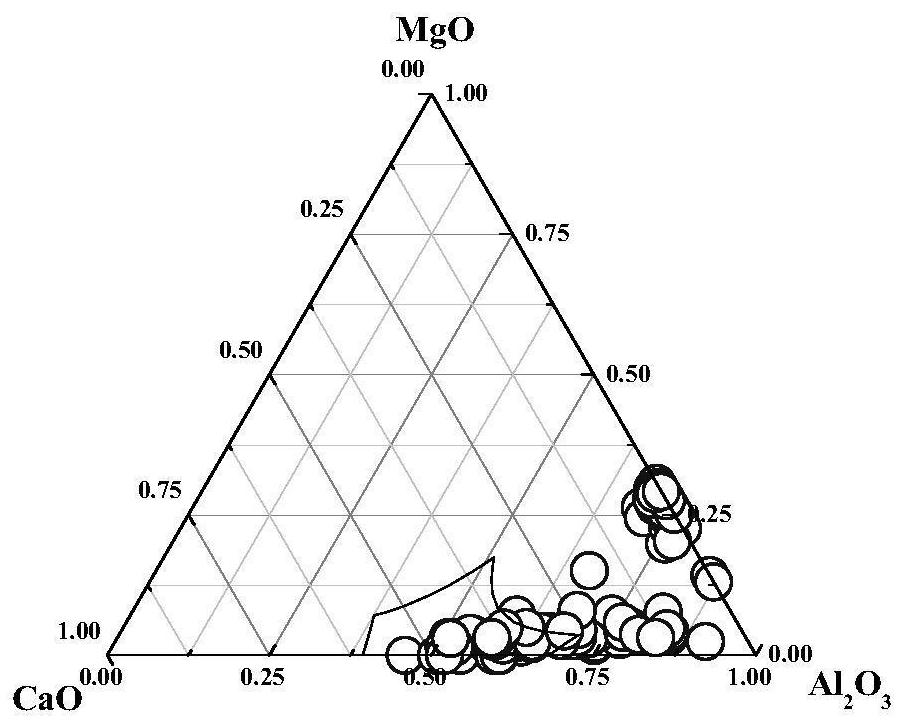

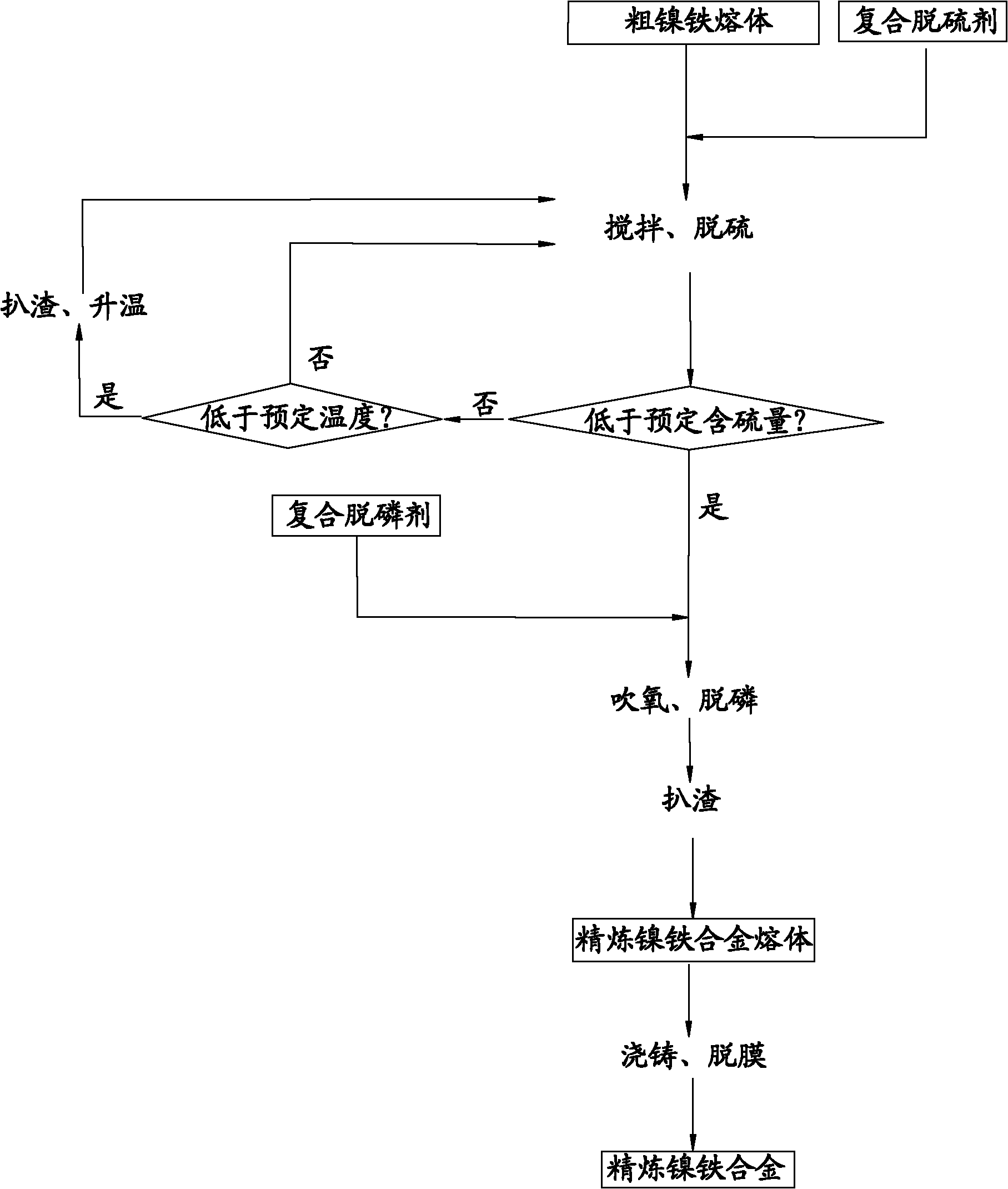

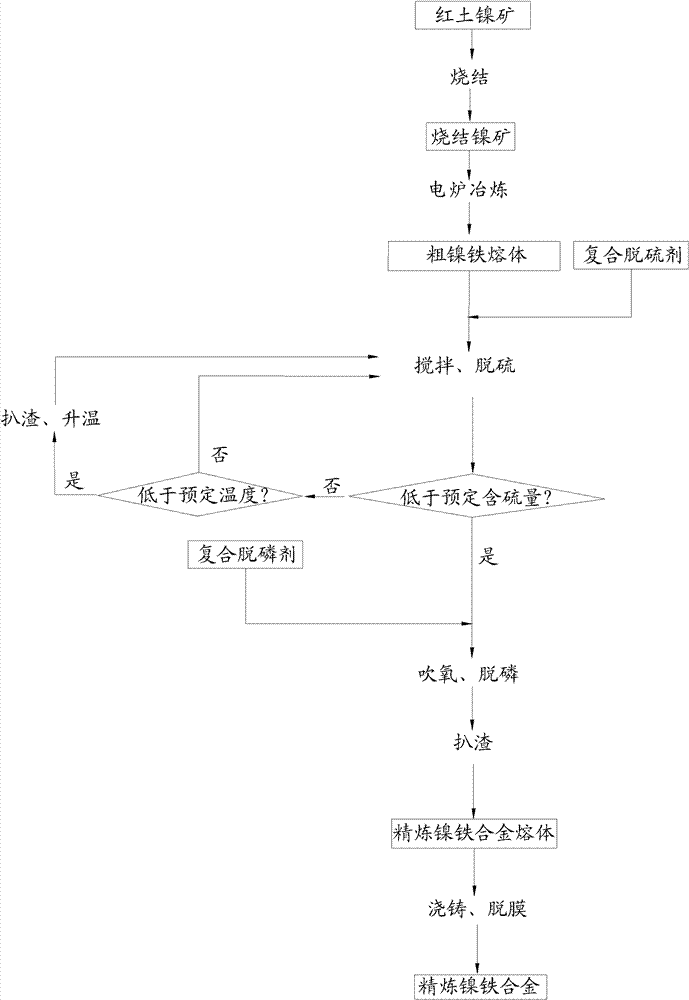

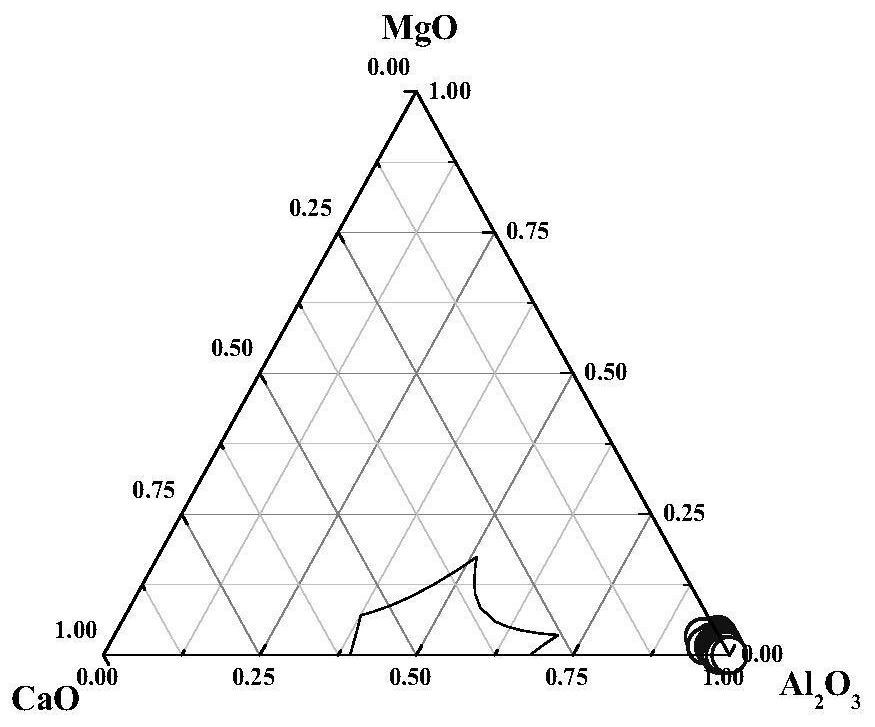

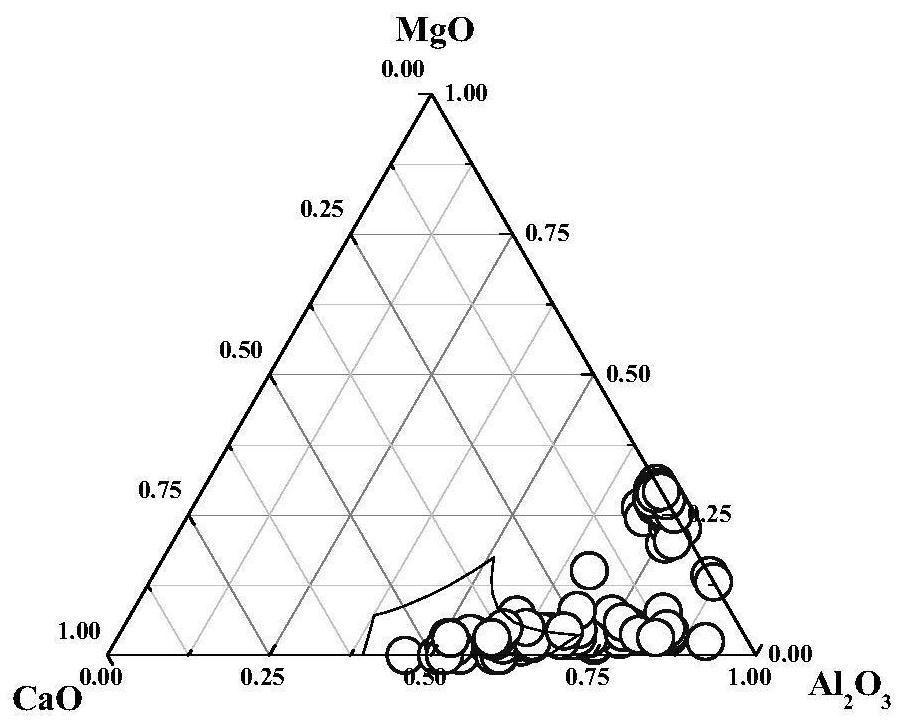

Process for smelting ferronickel from red soil nickel ore

The invention discloses a method for smelting ferronickel from red soil nickel ore, which comprises the following steps of: 1) mixing the red soil nickel ore with coal dust or coke, and sintering for 2 to 8 hours to obtain sintered nickel ore; 2) smelting the sintered nickel ore, a flux and a reducing agent for 2 to 3 hours in an electric furnace to obtain a crude ferronickel melt; and 3) refining the crude ferronickel melt: a) ensuring that the melt temperature is higher than 1,450DEG C; b) adding a complex desulfurizer into the melt for desulfurization; c) detecting the sulfur content of the melt, stopping desulfurization when the sulfur content is lower than a preset value, detecting the melt temperature when the sulfur content is higher than the preset value, slagging off and raising the temperature of the melt and repeating the step b) until the sulfur content is lower than the preset value when the temperature is below 1,350DEG C, repeating the step b) until the sulfur content is smaller than the preset value when the temperature is higher than 1,350DEG C, and slagging off; d) adding a complex dephosphorization agent into the melt for dephosphorization; and e) casting and demolding to obtain the refined ferronickel alloy. The method has the advantages of simple process and low energy consumption.

Owner:CHINA ENFI ENGINEERING CORPORATION

Efficient production process of high-standard bearing steel

ActiveCN111793772ASolve the temperature dropPrevent slaggingManufacturing convertersSteelmakingMolten steel

The invention belongs to the technical field of steelmaking processes, and relates to an efficient production process of high-standard bearing steel, A "BOF-RH-CC" process route is adopted. An alloy is melted by an alloy melting furnace, the problem of the large temperature drop of molten steel caused by the addition of a large amount of ferrochrome and other alloys during a tapping process is ingeniously solved, after the tapping is carried out, the molten steel can be directly subjected to vacuum treatment at a RH station, through the elimination of a LF refining furnace, the production efficiency is improved, the problem of slag entrapment in refining slag is solved, meanwhile, the situation that a slag-steel is reacted in a LF slagging submerged arc heating process, so that Al2O3 inclusions are transformed into calcium aluminates that are not conducive to subsequent control is avoided, the inclusions can be controlled in the whole process to be solid Al2O3 with high removing efficiency, after the RH vacuum is performed, the Al2O3 inclusions are efficiently removed, the total oxygen of the molten steel is controlled to 3.0-4.5 ppm, and meanwhile, because the Al2O3 inclusions inthe steel are controlled, the excessive proportion of calcium aluminate inclusions of the steel type B and type Ds is greatly reduced.

Owner:ZENITH STEEL GROUP CORP +1

Method for tempering high temperature slag and mineral cotton production method

InactiveCN104986961AExcellent performanceTemperature does not dropGlass making apparatusAluminiumOxygen supply

A method for tempering high temperature slag and a mineral cotton production method belong to the metallurgical technical field of steel, ferronickel, ferromanganese, copper and the like. A tempering process is carried out by spraying coal ash, dolomite, aluminum ash and the like by using a heat-resistant spray gun, and the mixture is heated by using a heating agent in an oxygen blowing manner; moreover, by virtue of a sufficient condition of pouring hot slag into a slag tank in kinetics, the used equipment comprises a powder spraying system and an oxygen supply system. According to the components of the hot slag, a corresponding tempering agent is sprayed into the slag and the heating agents such as aluminum ash and the like are added to be in reaction with oxygen; the tempering agent is prompted to be fully mixed with the slag by virtue of flowability of the hot slag pouring into the slag tank so as to quickly form a silicate system; the heating agents are added, so that the slag temperature is not reduced, and a slag tank cover further covers the tank, so that the heat loss is reduced. Thereofe, the component is tempered into the slag blowing slag wool, the temperature of which is proper, and the viscosity is 1-3Pa.s. The problem that the slag is hardly mixed with the tempering agent and a temperature drop happens is solved. A melting furnace (an electric furnace) is not needed for secondary heating, so that the method has a relatively high economical benefit. The slag tank with a top cover is conveyed to a mineral cotton workshop and a travelling crane conveys the slag tank to a pouring site. Then, the slag tank is overturned by using a winch, and a slag fluid in a fixed quantity is controlled to enter a closed and heated blowing tank from an upper opening of the slag tank. The slag fluid in the fixed quantity enters the closed and heated blowing tank from the upper opening of the slag tank, so that the problem that in production of mineral cotton, the slag fluid amount is unstable as the height of the liquid level of a slag tank is different and the pressure of the liquid level is different in a manner that the melt is discharged from the bottom of the tank and the problem that the bottom-discharged slag blowing tank is blocked as the slag temperature is reduced are solved.

Owner:CHINA JINGBLUE BEIJING ENVIRONMENTAL ENG CO LTD

Combined external pressurized flow type steam generation device

ActiveCN106195975ASolve the temperature dropSolve the defect of temperature dropSteam generation heating methodsBoiler controlEngineeringHigh pressure

The invention discloses a combined external pressurized flow type steam generation device. The combined external pressurized flow type steam generation device comprises a basic electromagnetic steam generation unit, one or more additional electromagnetic steam generation units and a pressurization device. The basic electromagnetic steam generation unit comprises one or more first heating inner containers, first coils each wound around the corresponding first heating inner container and a first steam bag used for collecting steam generated by the heating inner containers. Each additional electromagnetic steam generation unit comprises one or more second heating inner containers, second coils each wound around the corresponding second heating inner container and a second steam bag used for collecting steam generated by the heating inner containers. The second steam bags communicate with the first steam bag. The pressurization device communicates with the first steam bag. A steam outlet is formed in the first steam bag. According to the combined external pressurized flow type steam generation device, the multiple sets of electromagnetic steam generation units are arranged in parallel, meanwhile, the pressurization device is additionally arranged, and therefore an electromagnetic steam generator can be applied to occasions needing the high evaporation capacity and high-temperature and high-pressure steam.

Owner:宁波波力维革环保设备科技有限公司

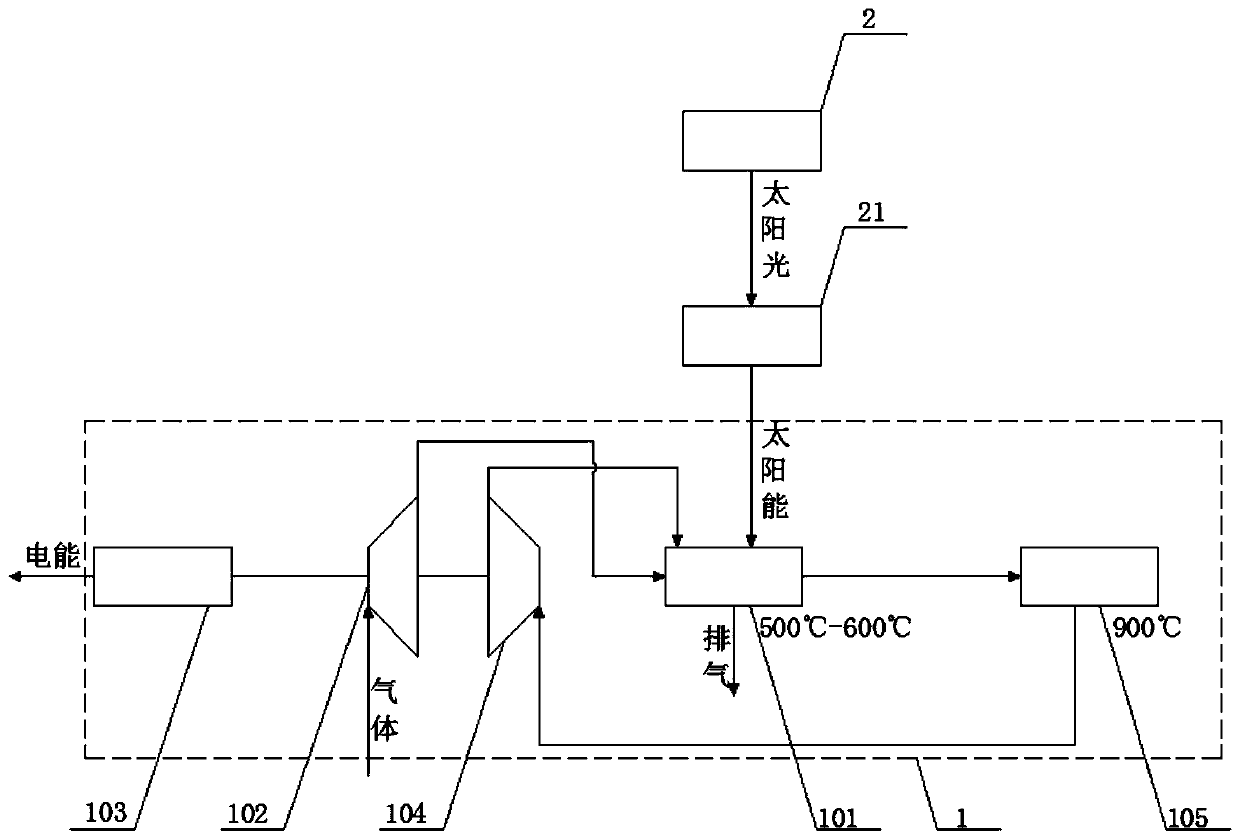

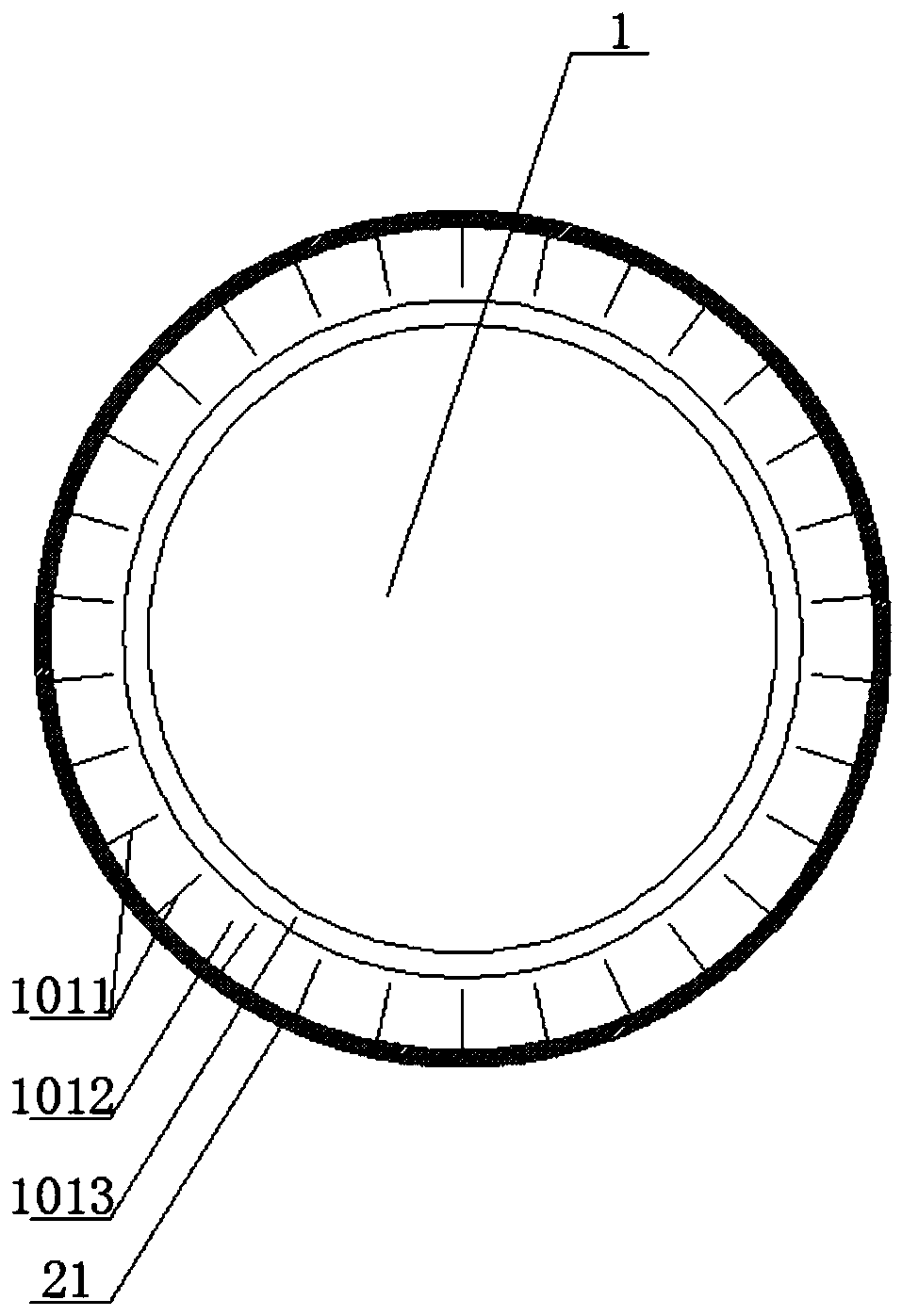

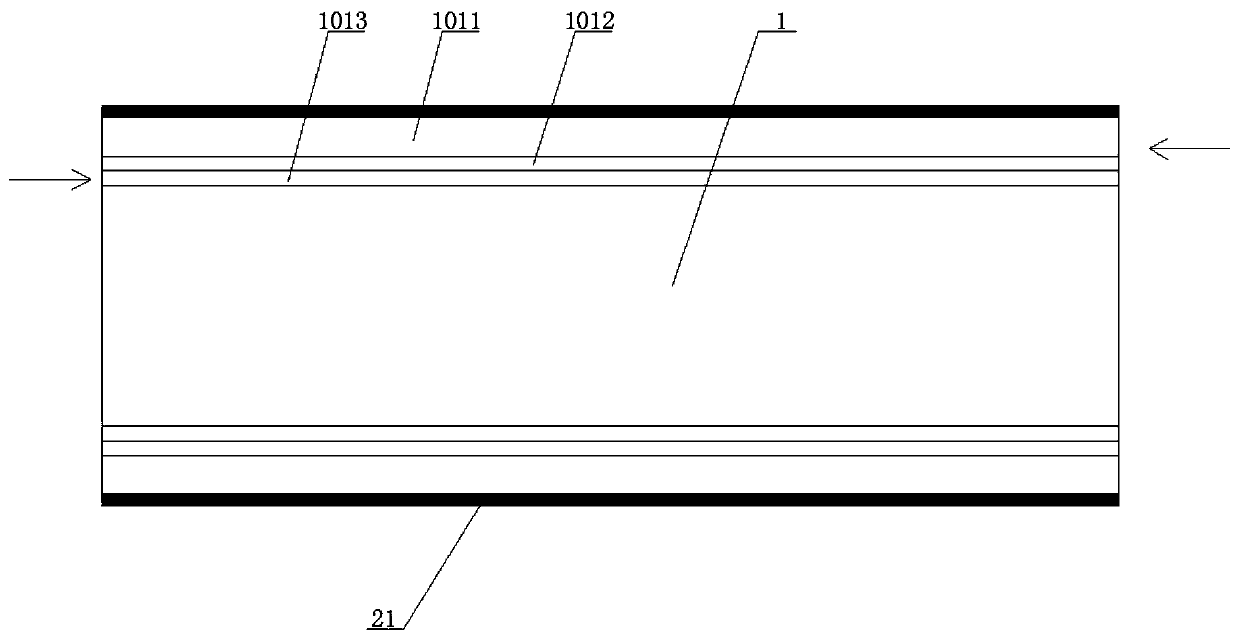

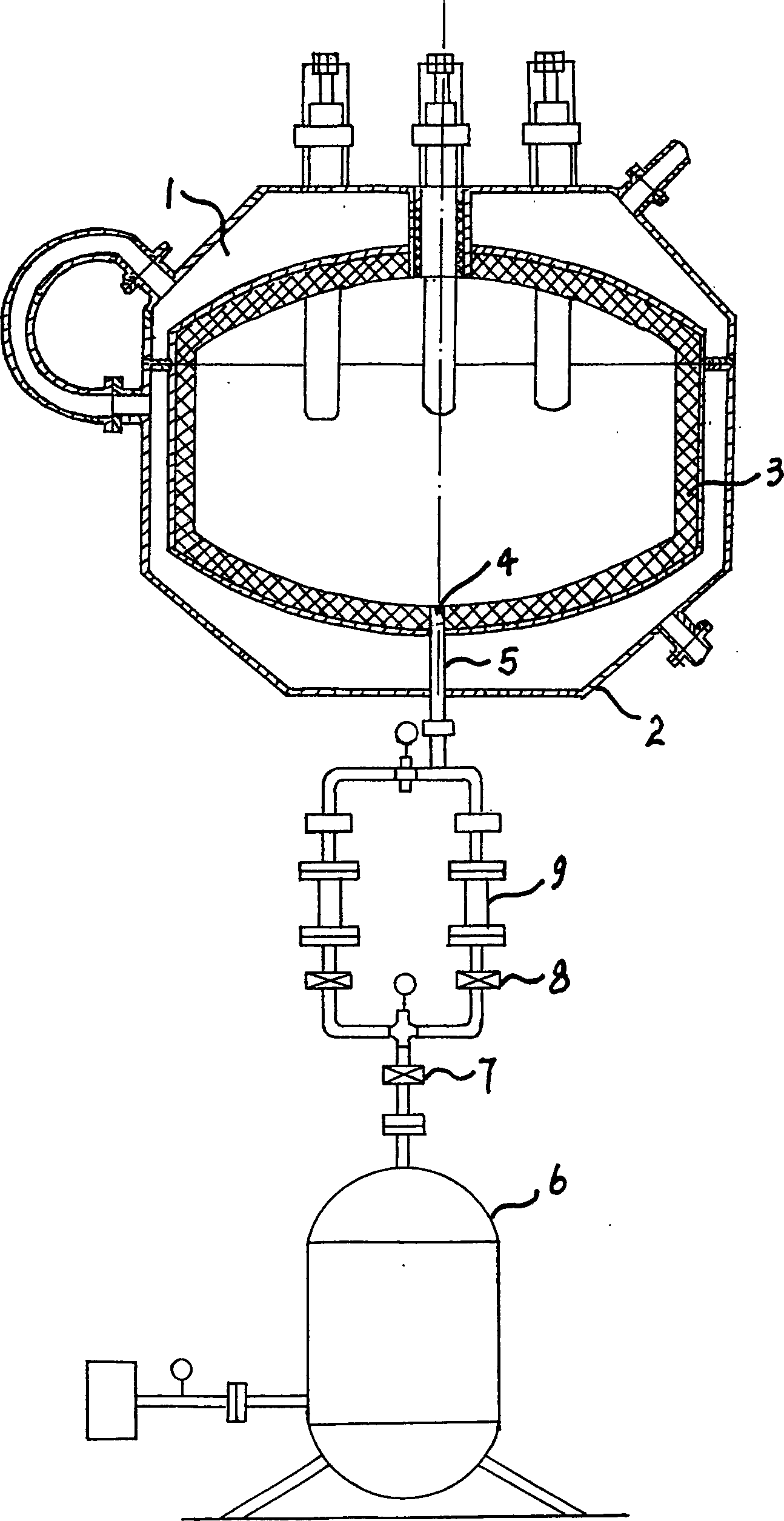

Solar gas turbine power generation system based on photo-thermal principle

PendingCN111156139AImprove utilization efficiencyImprove recycling efficiencySolar heating energyFrom solar energyAir compressionCombustion chamber

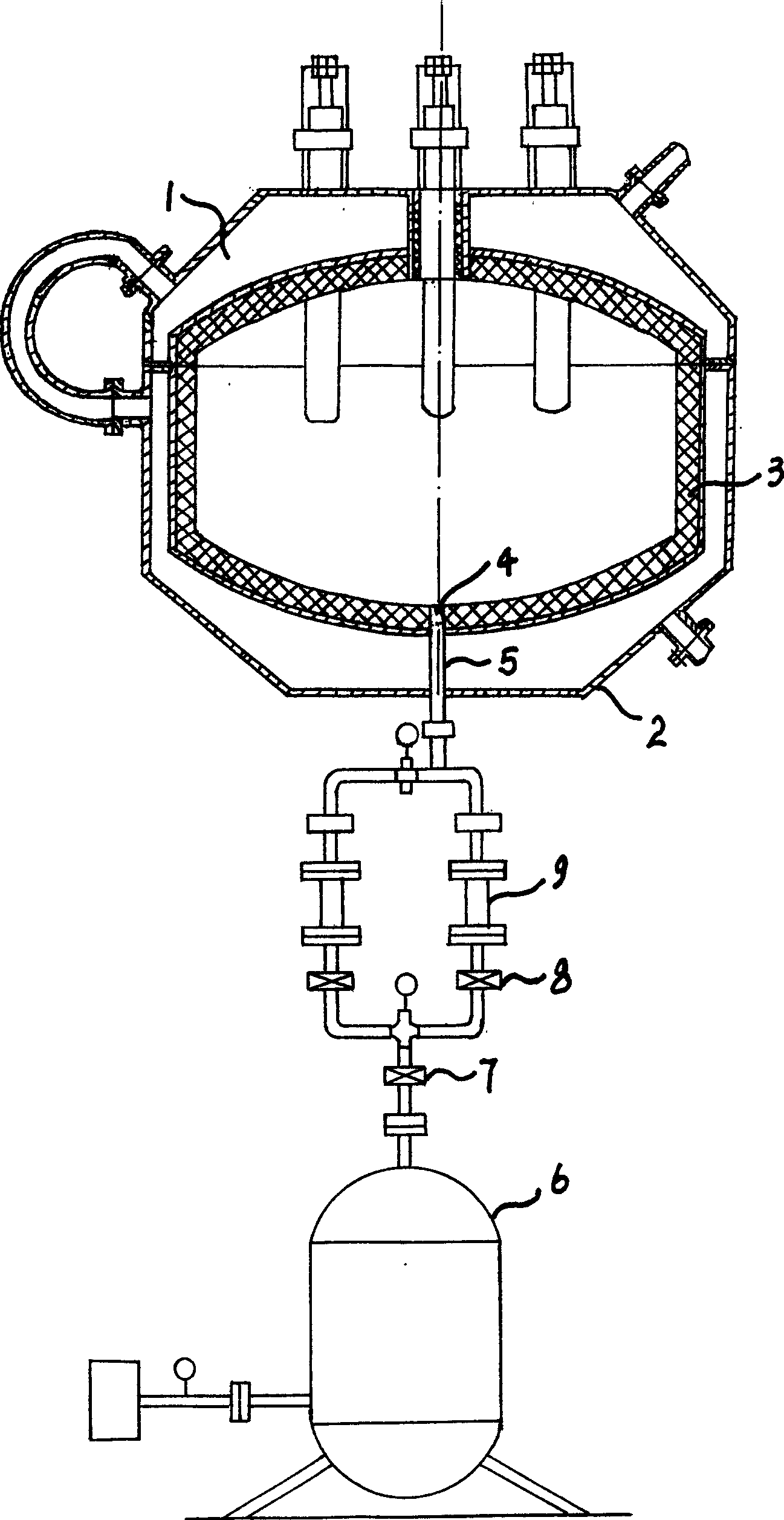

The invention provides a solar gas turbine power generation system based on a photo-thermal principle. The solar gas turbine power generation system comprises a gas turbine, a solar energy collectingdevice and a solar reflector. The gas turbine comprises an air compression impeller, a turbine, a heat regenerator and a combustion chamber, the heat regenerator comprises an outer shell, a middle shell and an inner shell, a low-temperature air inlet channel is formed between the middle shell and the outer shell, and a high-temperature air inlet channel is formed between the middle shell and the inner shell; an inlet and an outlet of the low-temperature air inlet channel communicate with an outlet of the air compression impeller and an inlet of the combustion chamber correspondingly, and an inlet and an outlet of the high-temperature air inlet channel communicate with an outlet of the turbine and the outside correspondingly; and the solar energy collecting device comprises a heat absorbingplate, and a shell of the heat regenerator is wrapped with the heat absorbing plate. By means of the solar gas turbine power generation system, a combined cycle of solar energy and the gas turbine can be achieved, the energy utilization rate is higher than that of single solar power generation or gas turbine power generation, and efficient utilization of energy is achieved.

Owner:刘慕华

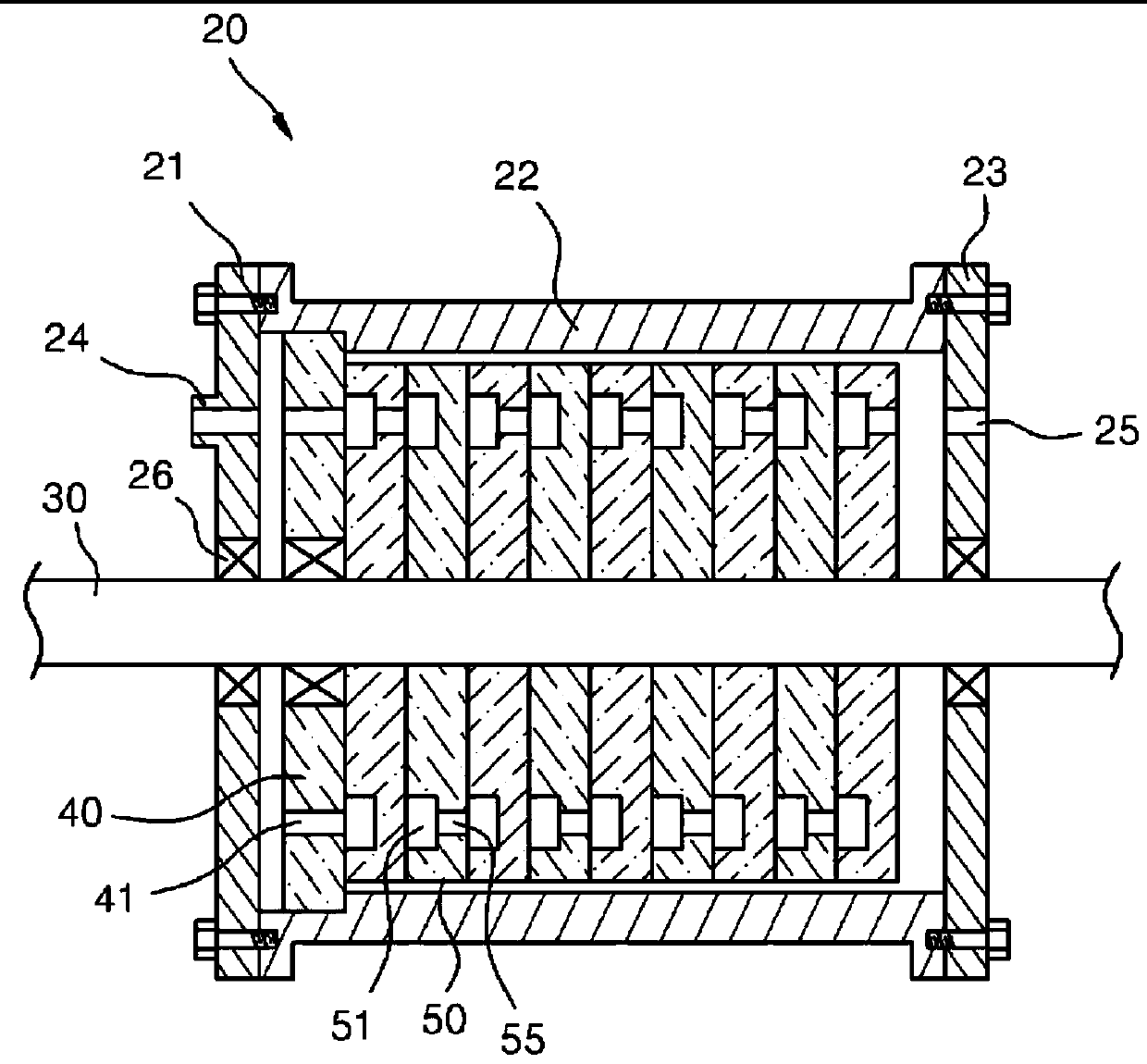

Axial turbine

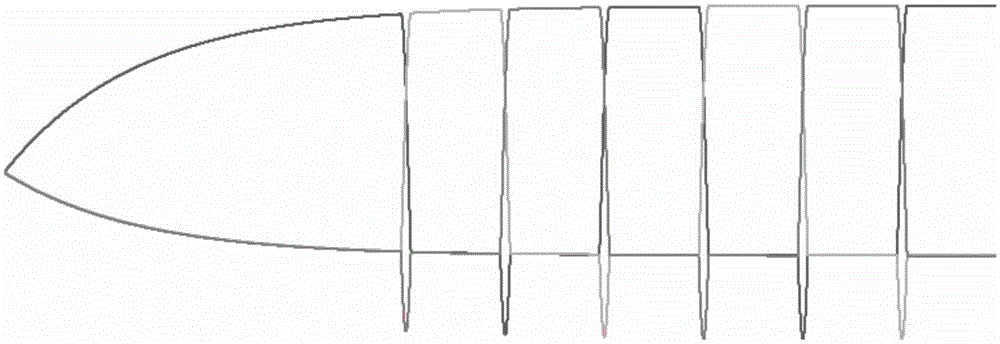

ActiveCN103857879AHigh angular efficiencyAvoid lossBlade accessoriesHydro energy generationHybrid typeHigh pressure

The present invention relates to an improved structure for an axial turbine. To this end, the present invention is provided with a submerged turbine (100) in which a liquid is filled. Also, the present invention is provided with an impulse turbine (200) which spouts high-pressure liquid to rotate blades. The above structure of the present invention has the advantage of being able to selectively use the structure of the turbine to suit the given circumstances when configuring and using a submerged-type turbine, an impulse-type turbine or a hybrid-type turbine (i.e. a combined submerged and impulse turbine). Accordingly, product quality and reliability can be significantly improved, thereby providing satisfaction to the operator.

Owner:崔爀善

Technique of maufacturing electrocast refractories through bubbling method

A technology for preparing the electrosmelting refractory material by bubbling method includes proportionally mixing its raw materials and flux, loading the mixture in electric smelting furnace which has an air tube communicated with compressed air tank, and smelting while introducing compressed air to the furnace. Its advantages are no need of turning off power supply on blowing oxygen, high uniformity and density of refractory.

Owner:侯松发

Casting method capable of effectively improving quality of aluminum alloy casting parts

InactiveCN101239385AAchieve simulation predictabilitySimple designInternal combustion piston enginesCasting safety devicesControl systemThermal insulation

Then invention relates to a casting method for improving aluminum alloy cast quality effectively, pertaining to metal casting technique field, comprising: analog designing product pouring with a computer software, adapted with corresponding heating, cooling solidification control system, thereby selecting optimal pouring technique to solidifying the cast gradually, so that obtaining aluminum alloy casts with little casting flaw and good surface quality. According to the invention, the pouring mould varies the tilt state of the thermal insulation pouring box and the pouring mould continuously, and the mould cavity is filled along with the variety of the tilt state to implement the pouring process according to the control instruments sent by the computer control chip. The invented method is suitable for production of vehicle aluminum alloy parts and premium castings without shrinkage cavity areosis phenomena can be obtained.

Owner:SHANGHAI UNIV

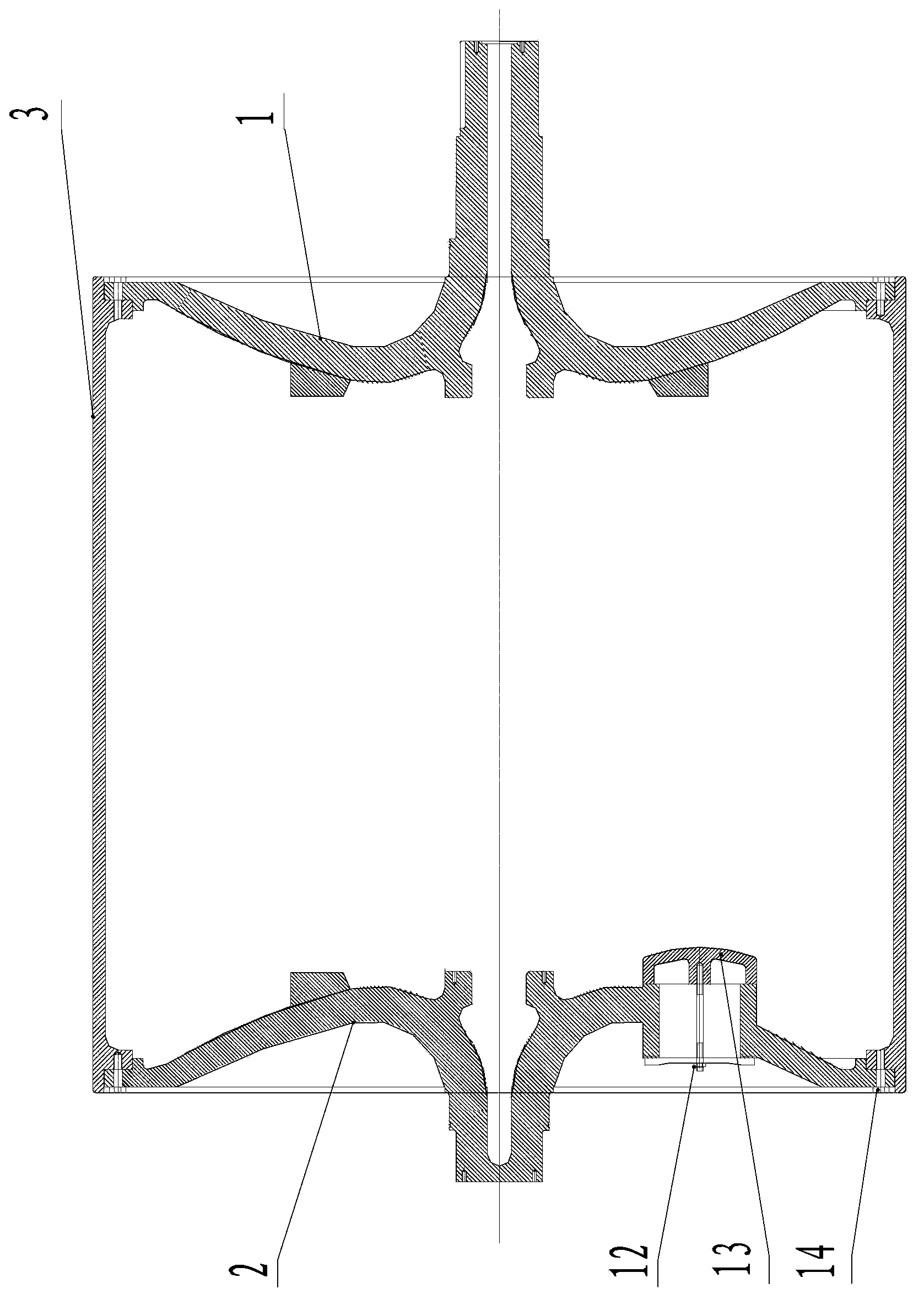

Oil gas adsorber

ActiveCN102120121BImproved adsorption conditionsImprove cooling effectDispersed particle separationSorbentEngineering

The invention discloses an oil gas adsorber which comprises an adsorber top cover (16), an adsorber main body (1) and an adsorber bottom cover (3) that are connected through bolts (14), wherein the adsorber top cover (16) is provided with an emptying hole (17), and the adsorber main body (1) comprises a composite adsorbing material (11) and a circulating water jacket (12); the circulating water jacket (12) is provided with a circulating water jacket water inlet (8) and a circulating water jacket water outlet (13); the adsorber bottom cover (3) is provided with an oil gas inlet (2), a drain outlet (4), a vacuum pump port (5), a pressure sensor (6) and a pressure meter (7); and the composite adsorbing material (11) is a mixture of foam metal and an adsorbing agent. In the invention, heat radiation is enhanced through the foam metal, the circulating cooling / heating water jackets is additionally arranged outside the oil gas adsorber to enhance heat transfer, thus the temperature rise problem in the adsorber and the temperature drop problem in a desorber can be effectively solved.

Owner:溧阳常大技术转移中心有限公司

Membrane concentrated solution treatment system and production process thereof

ActiveCN112979046ASave resourcesSolve liquid temperature dropMultistage water/sewage treatmentTreatment involving sedimentationInorganic saltsLiquid storage tank

The invention discloses a membrane concentrated solution treatment system which comprises a mixing tank and a stirring shaft, wherein a lifting device is fixedly arranged in the stirring shaft, the two ends of the lifting device are arranged on the outer side of the stirring shaft, the upper end of the lifting device is connected with a feeding device, a discharging port of the feeding device is connected with a mixing device, the other side of the mixing device is connected with a liquid storage tank; the lower end of the lifting device is arranged at the bottom of the mixing tank and used for extracting metal impurities in the mixing tank; the mixing device is used for mixing the metal impurities with dilute sulphuric acid to react to generate inorganic salts and injecting the inorganic salts into the mixing tank. Through the device, resources can be greatly saved, and the treatment efficiency of the concentrated solution is improved.

Owner:ZHEJIANG HONGDIAN ENVIRONMENTAL PROTECTION & TECH CO LTD

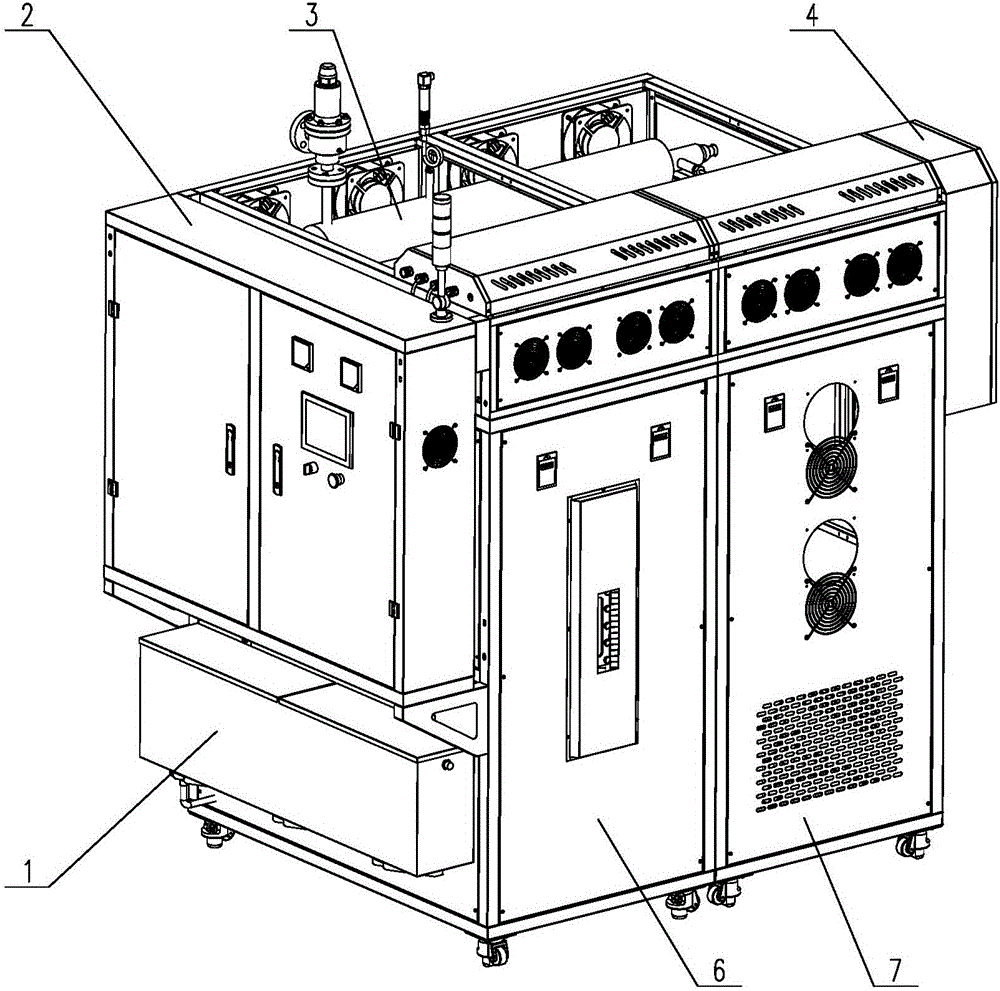

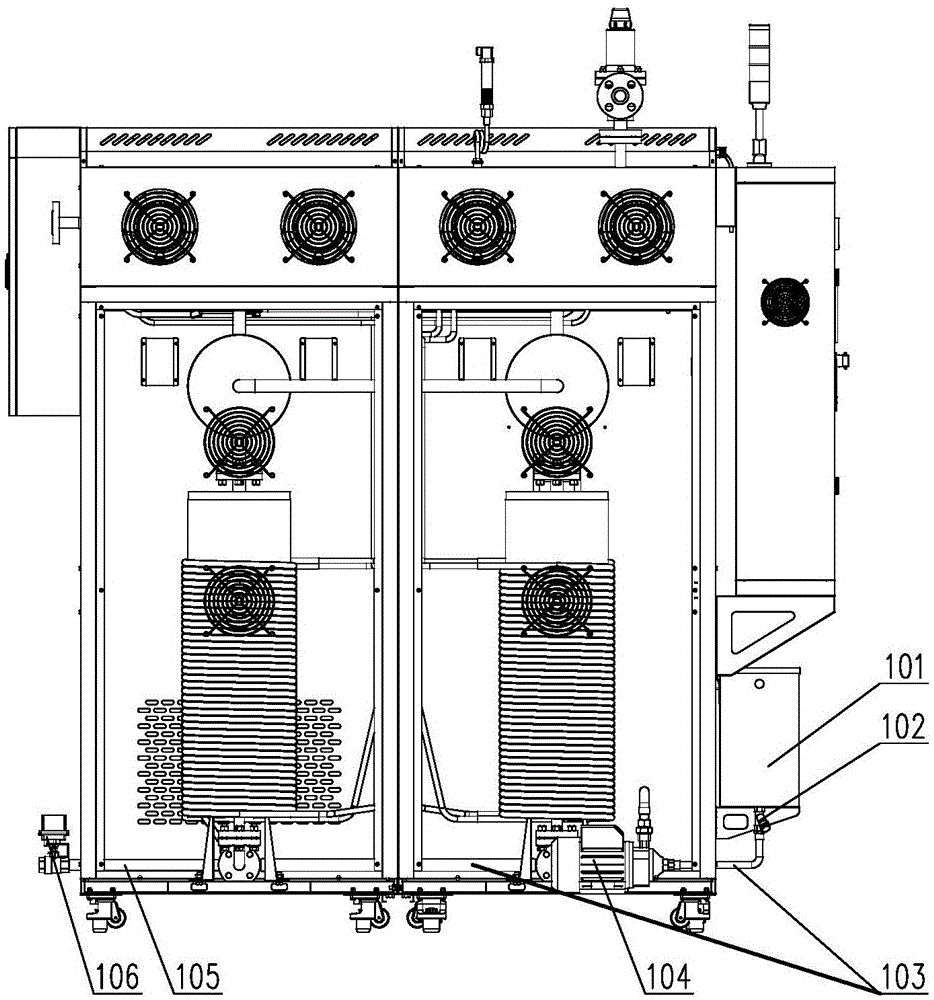

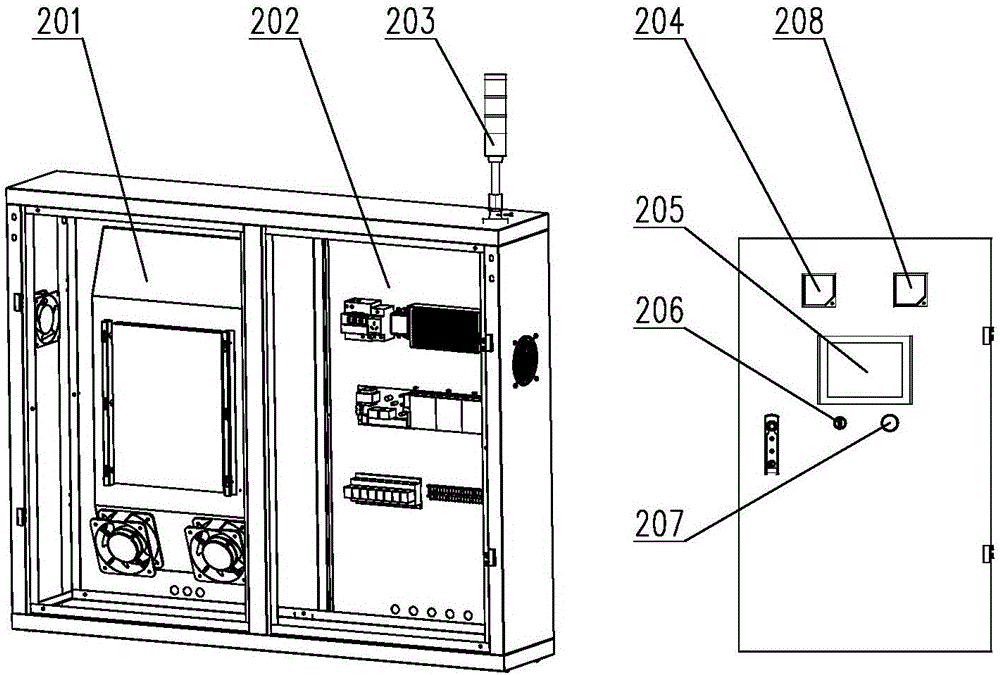

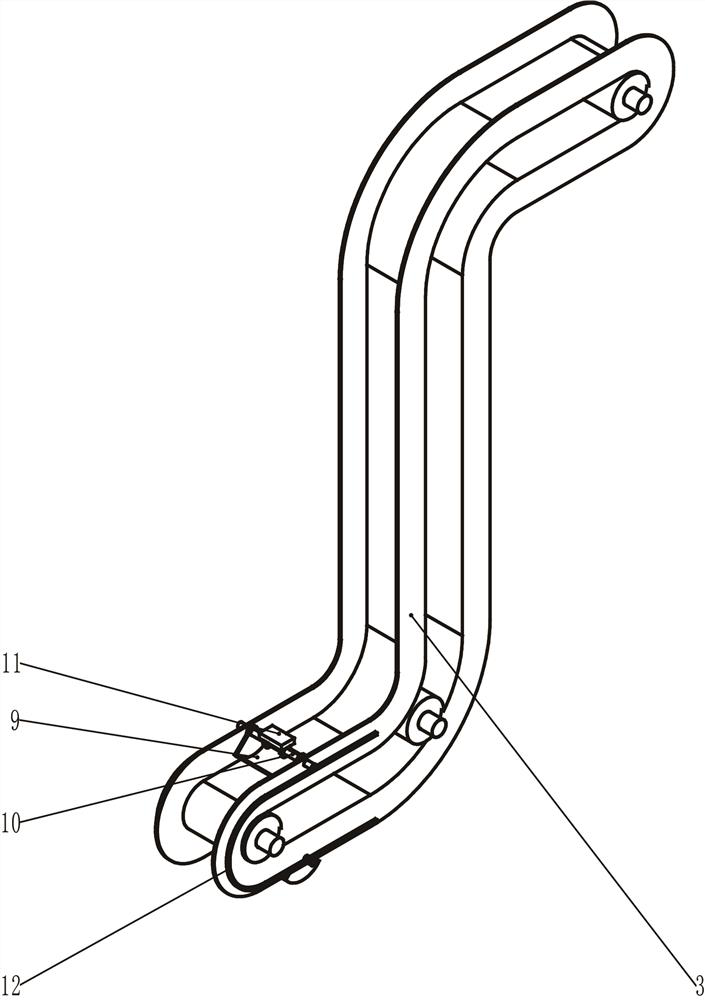

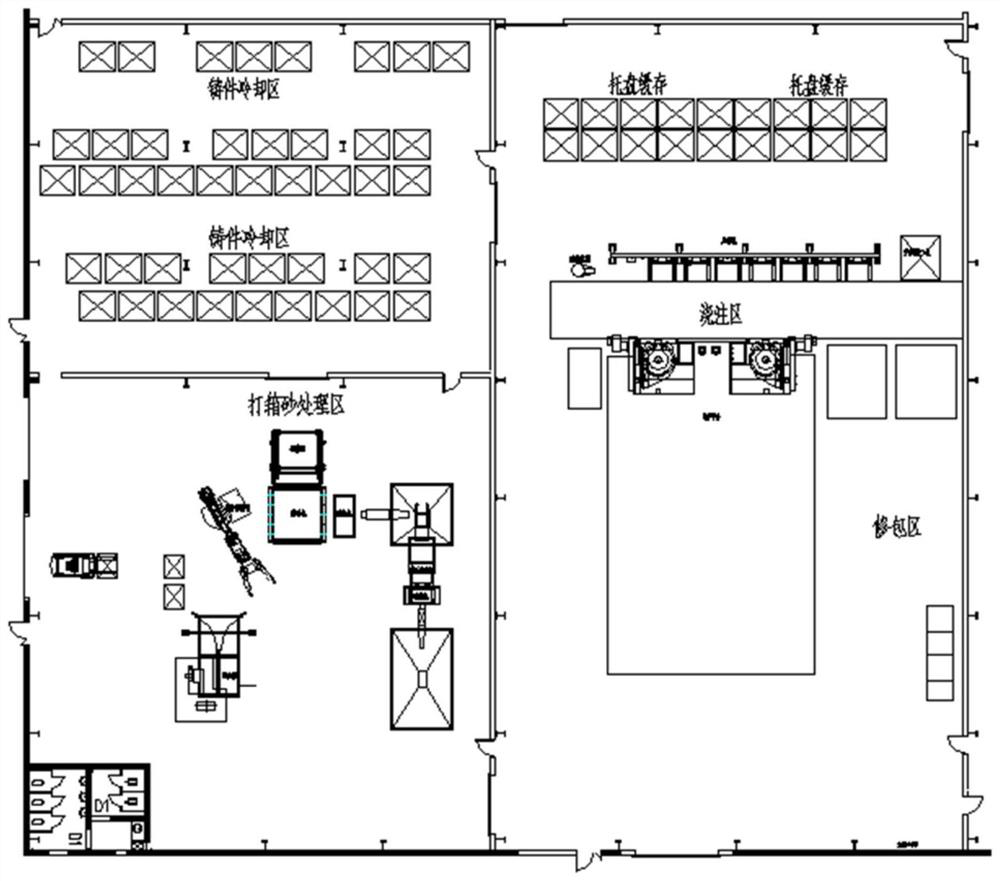

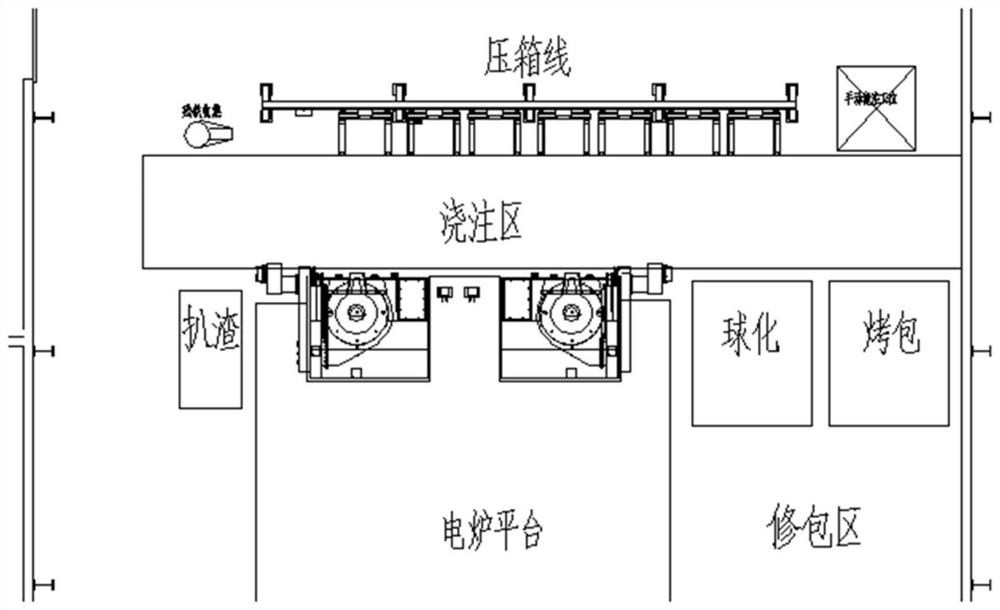

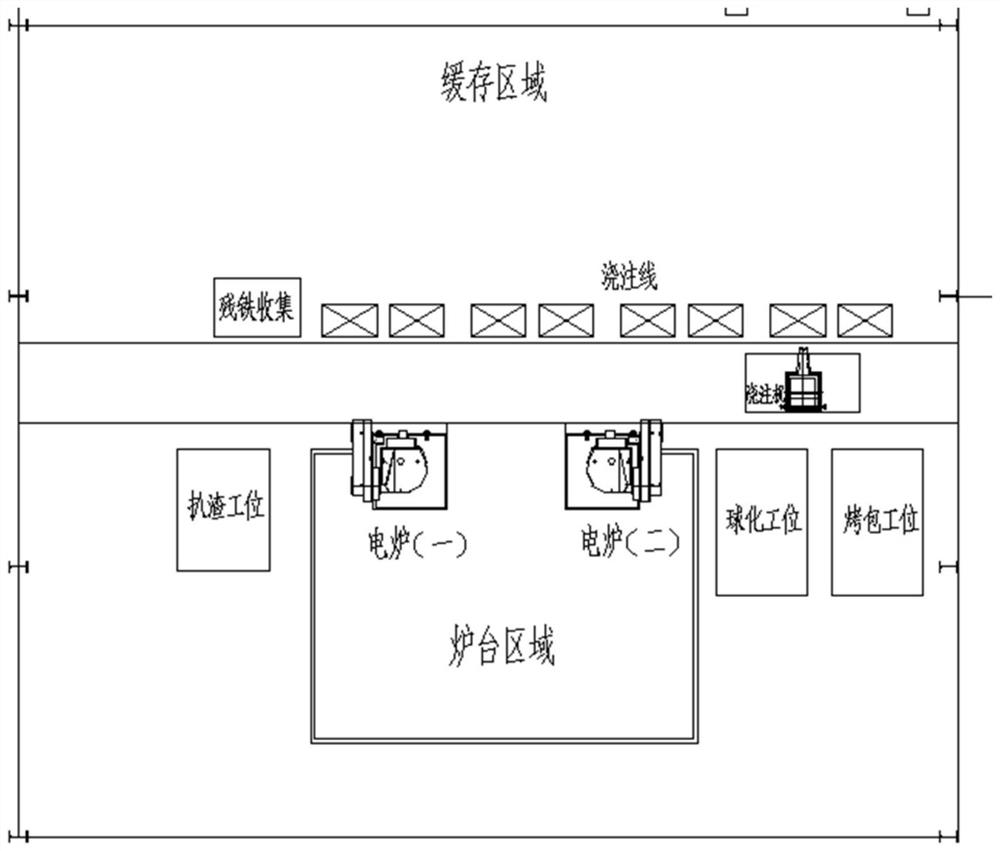

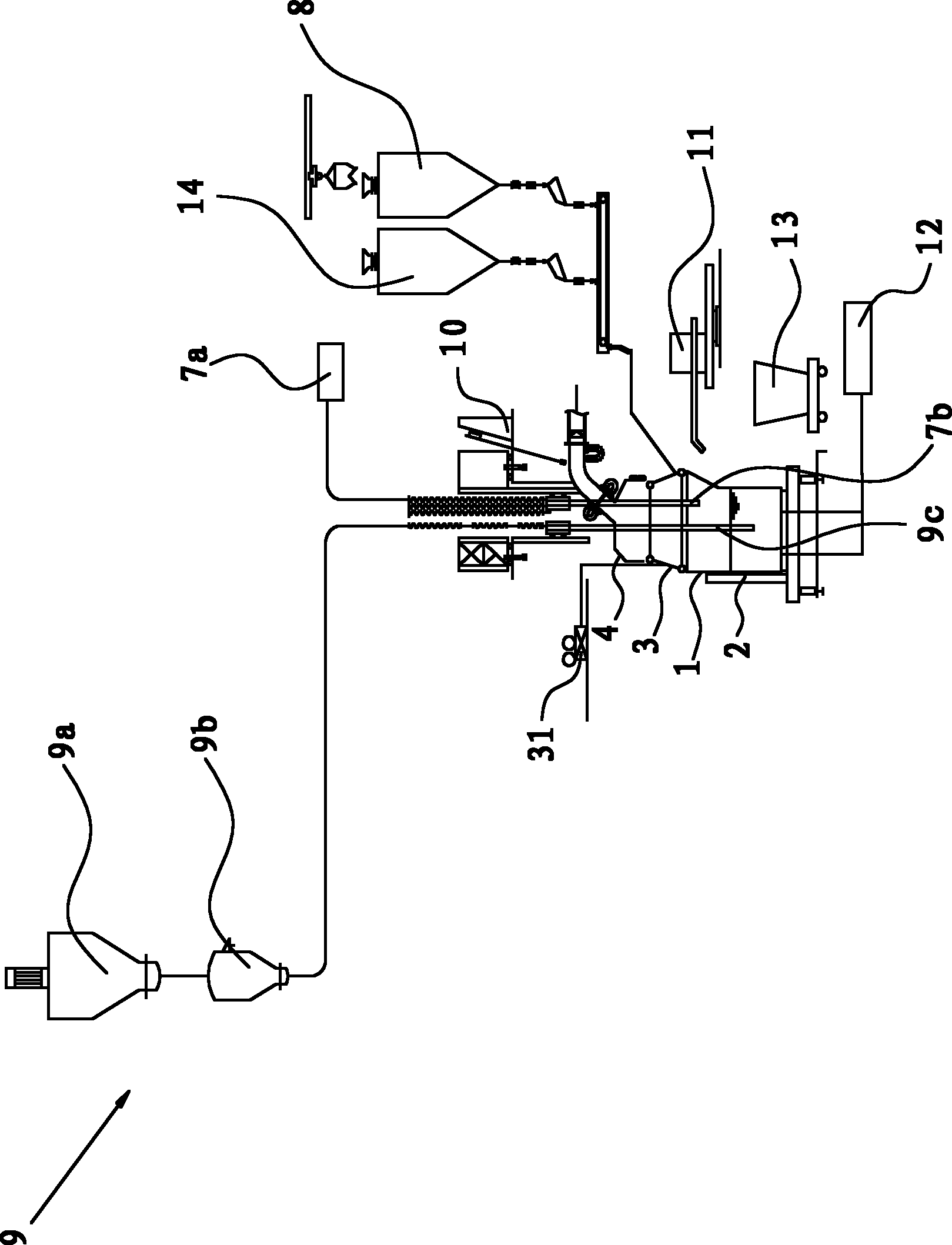

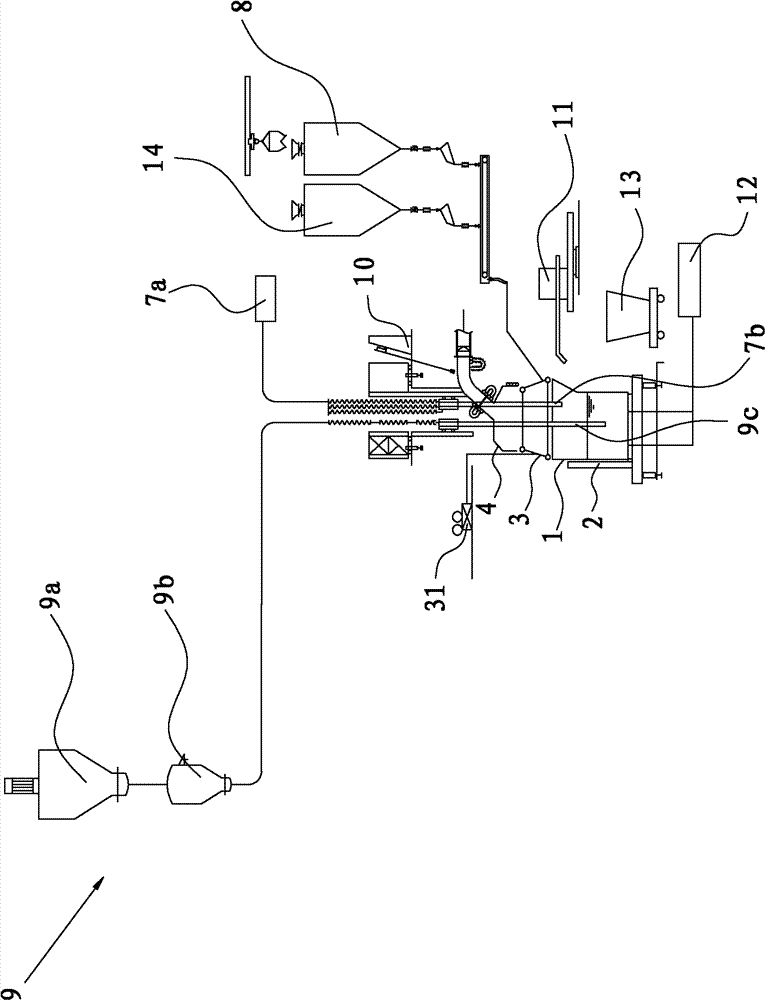

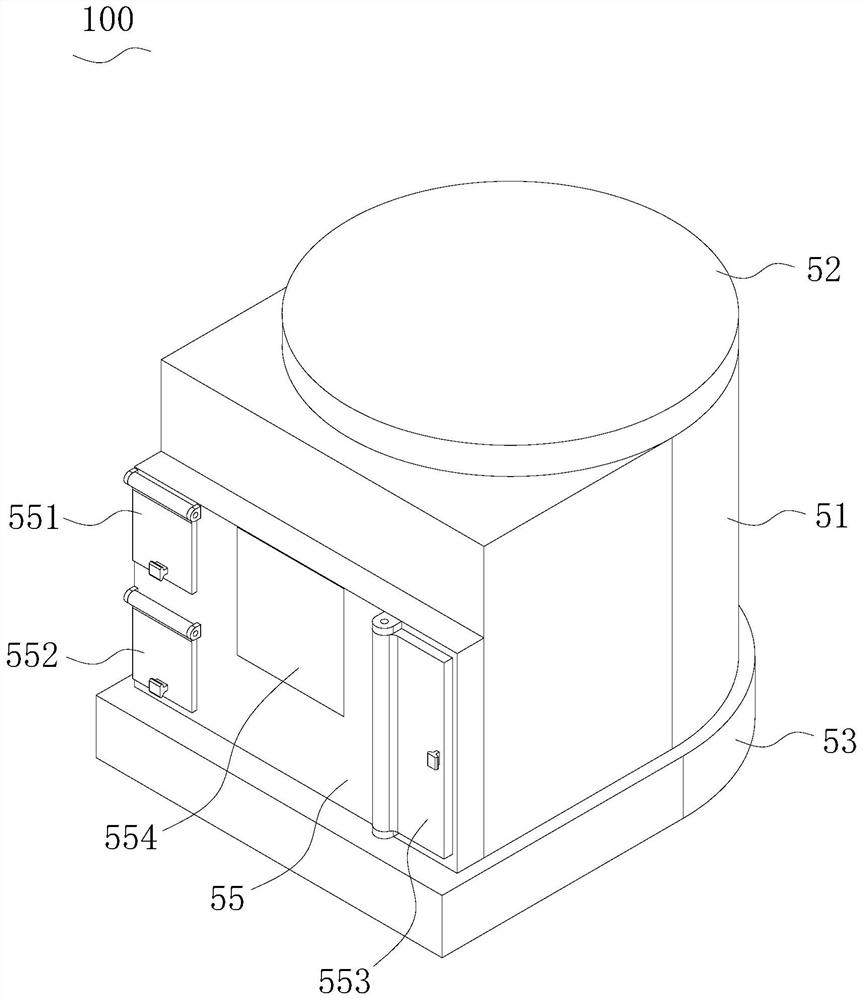

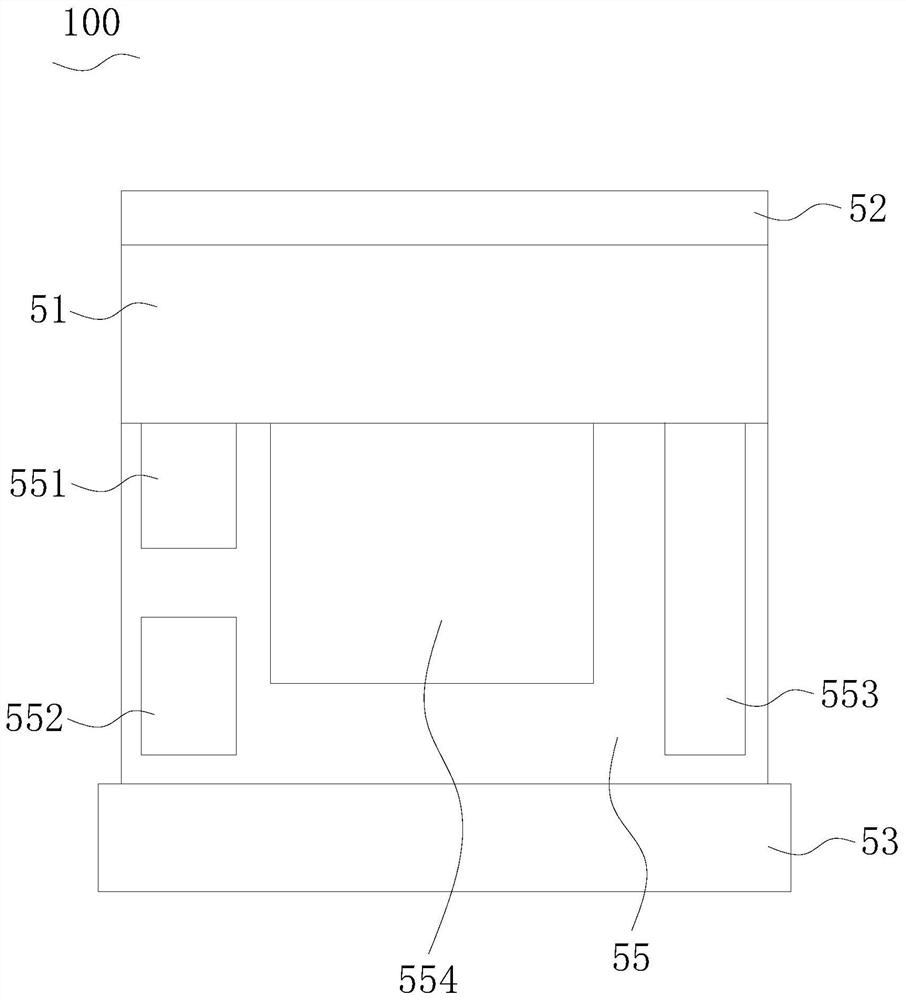

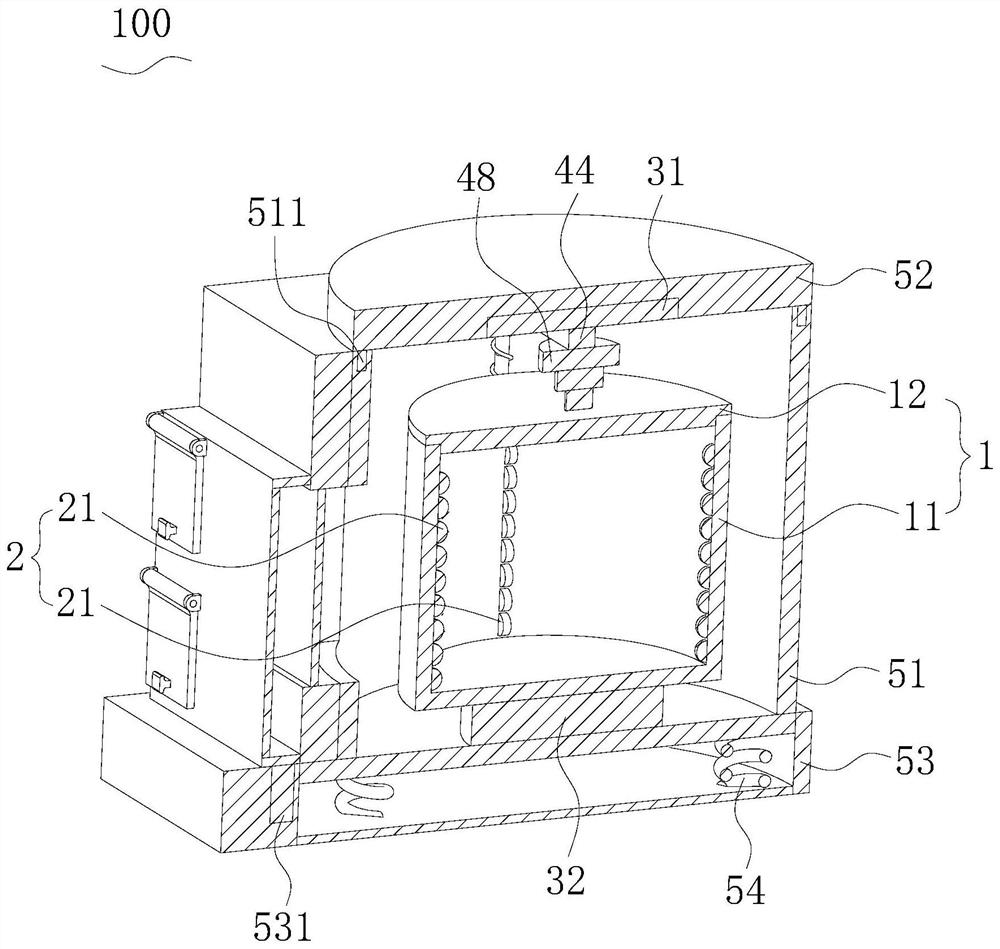

Intelligent smelting system and operation method thereof

PendingCN113523265AReduce in quantityShort process routeCasting plantsProcess engineeringElectric cables

The invention discloses an intelligent smelting system and an operation method thereof, and relates to the technical field of casting. The system comprises AGV transfer equipment, automatic pouring equipment, automatic box pressing equipment, a spheroidizing baking ladle, automatic box turning equipment, casting head removing equipment, shakeout equipment, shot blasting equipment and power and free equipment. The interior of the automatic pouring equipment comprises a barrel-shaped pouring ladle, a tilting mechanism, a transverse moving mechanism, a lifting mechanism, a pouring vehicle body, a rail system, a control and operation system, a safety system and a cable device, and the interior of the automatic box pressing equipment comprises a stand column, a cross beam, a lifting mechanism, a box pressing mechanism, a transverse moving mechanism and a lifting and transverse moving driving mechanism. The production area is compactly arranged, so that equipment is reasonably arranged, the number of production equipment can be reduced, the process route can be shortened, and the requirements of efficiency improvement, cost reduction and environment-friendly production are met.

Owner:烟台冰轮智能机械科技有限公司 +1

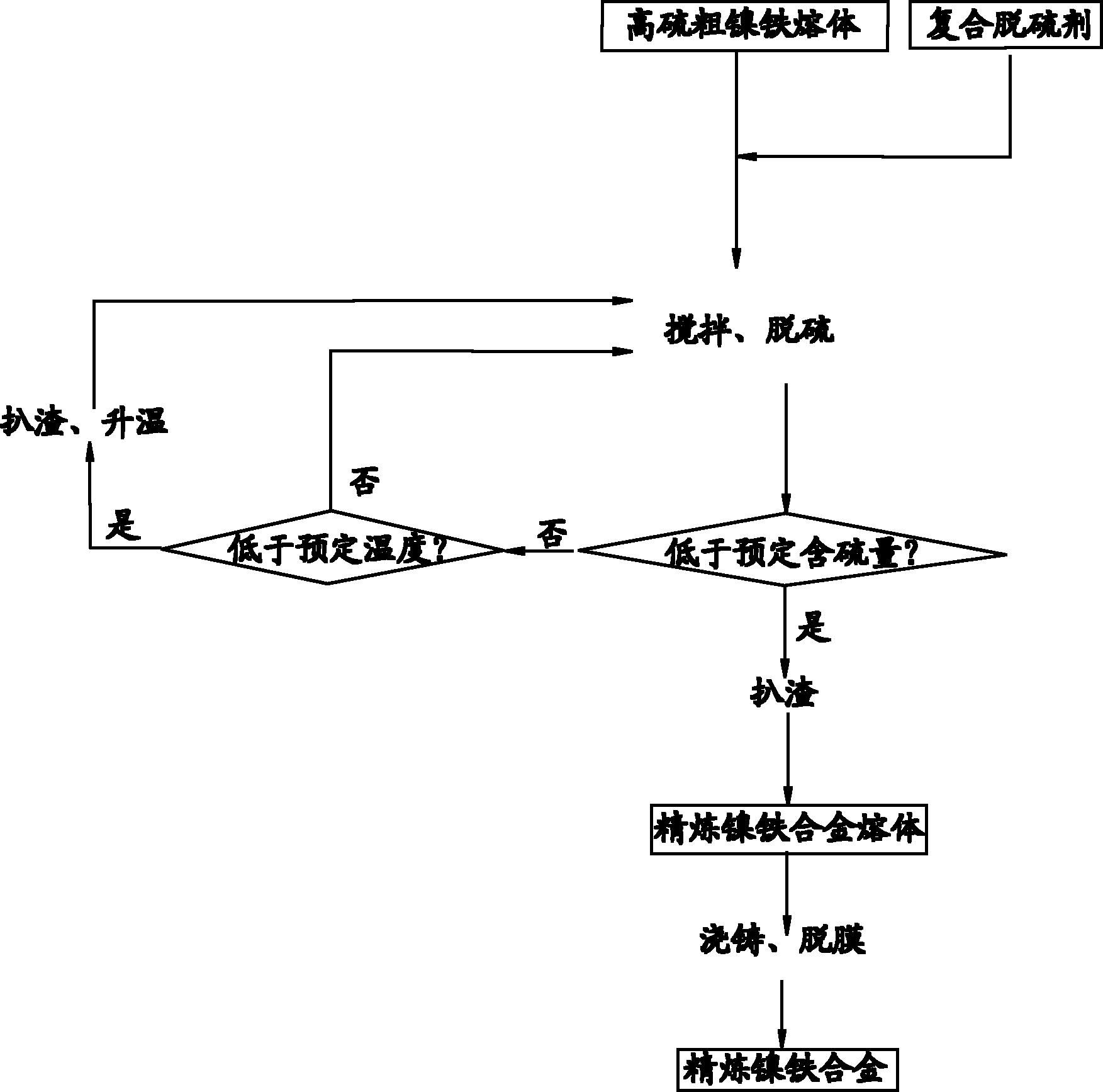

Desulfuration refining process of high-sulfur crude ferronickel

The invention discloses a desulfuration refining process of high-sulfur crude ferronickel. The desulfuration refining process comprises the following steps of: (1) providing a fusant of the high-sulfur crude ferronickel with an initial temperature of more than 145 DEG C; (2) adding a composite desulfurizer to the fusant and introducing a high pressure gas from the bottom for stirring; (3) detecting sulfur content of the fusant, stopping desulfurating when the sulfur content of the fusant is below a predetermined value, detecting the temperature of the fusant when the sulfur content of the fusant is above the predetermined value, slagging off, raising the temperature of the fusant and repeating the step (2) until the sulfur content is below the predetermined value when the temperature is below 1350 DEG C, repeating the step (2) until the sulfur content is below the predetermined value when the temperature is above 1350 DEG C, and slagging off to obtain a refined ferronickel alloy fusant; and (4) casting and cooling the refined ferronickel alloy fusant and demoulding to obtain a refined ferronickel alloy. The desulfuration refining process of the high-sulfur crude ferronickel, whichis disclosed by the embodiment of the invention, can be used for removing high-content sulfur with low energy consumption.

Owner:CHINA ENFI ENGINEERING CORPORATION

High-pressure water dephosphorization machine

ActiveCN112122371AExtended service lifeSolve the phenomenon of splashingWork treatment devicesMetal rolling arrangementsThermodynamicsEnergy absorption

The invention relates to a high-pressure water dephosphorization machine, and belongs to the technical field of mechanical equipment. The dephosphorization machine comprises a dephosphorization machine frame, and a conveying roller way, an upper dephosphorization header, a lower dephosphorization header, a water retaining chain, a water collecting tank and a protective cover body which are arranged on the dephosphorization machine frame. Through the rotation effect of an energy absorption sleeve, the service life of the water collecting tank is greatly prolonged, the phenomenon that oxide scales and dephosphorization water of the dephosphorization machine splash around is effectively avoided, and potential safety hazards are eliminated; and meanwhile, through the design of a flow guide pipe, most of the collected dephosphorization water does not flow onto steel billets, and the problem of temperature drop of the steel billets is solved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

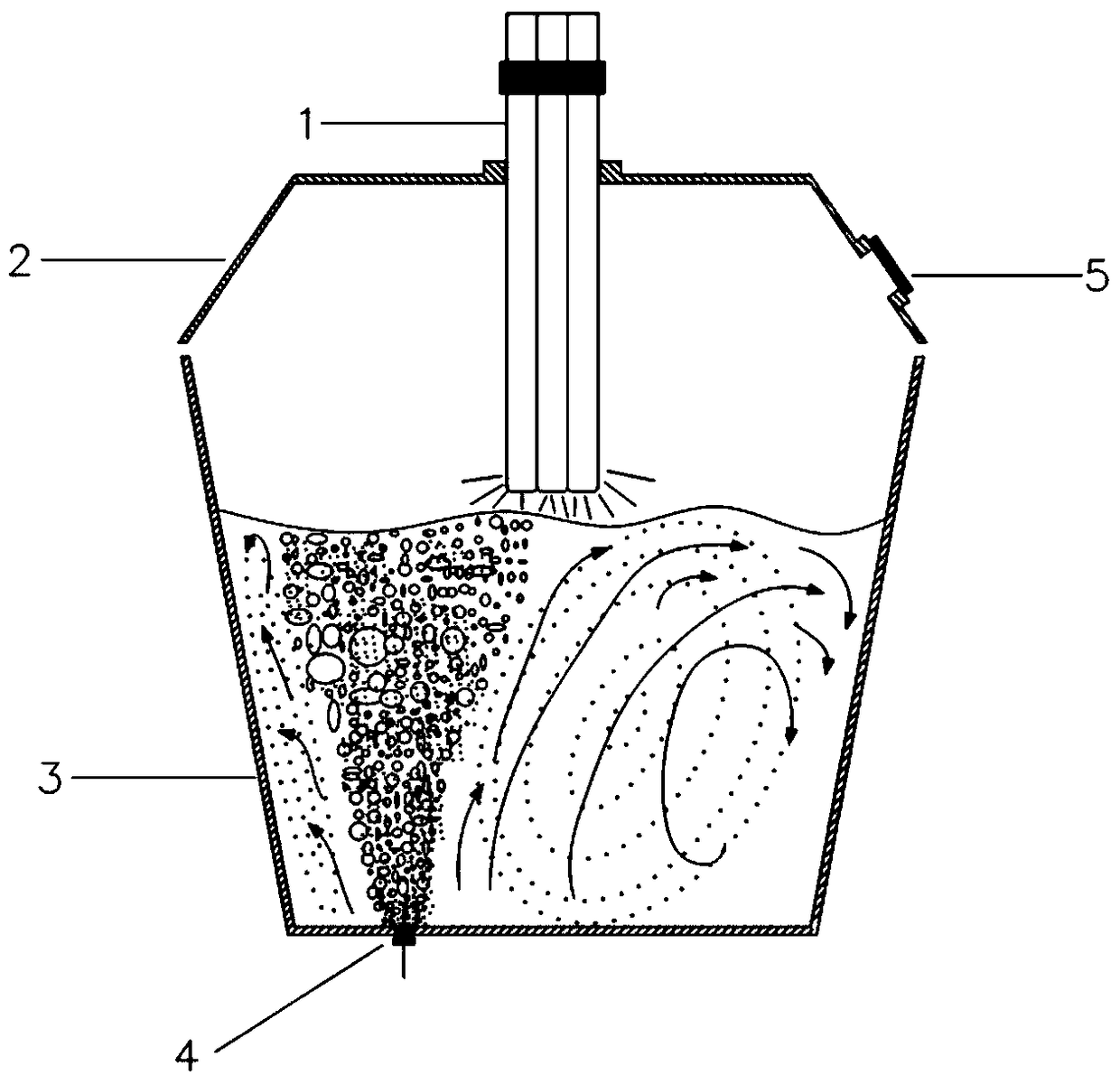

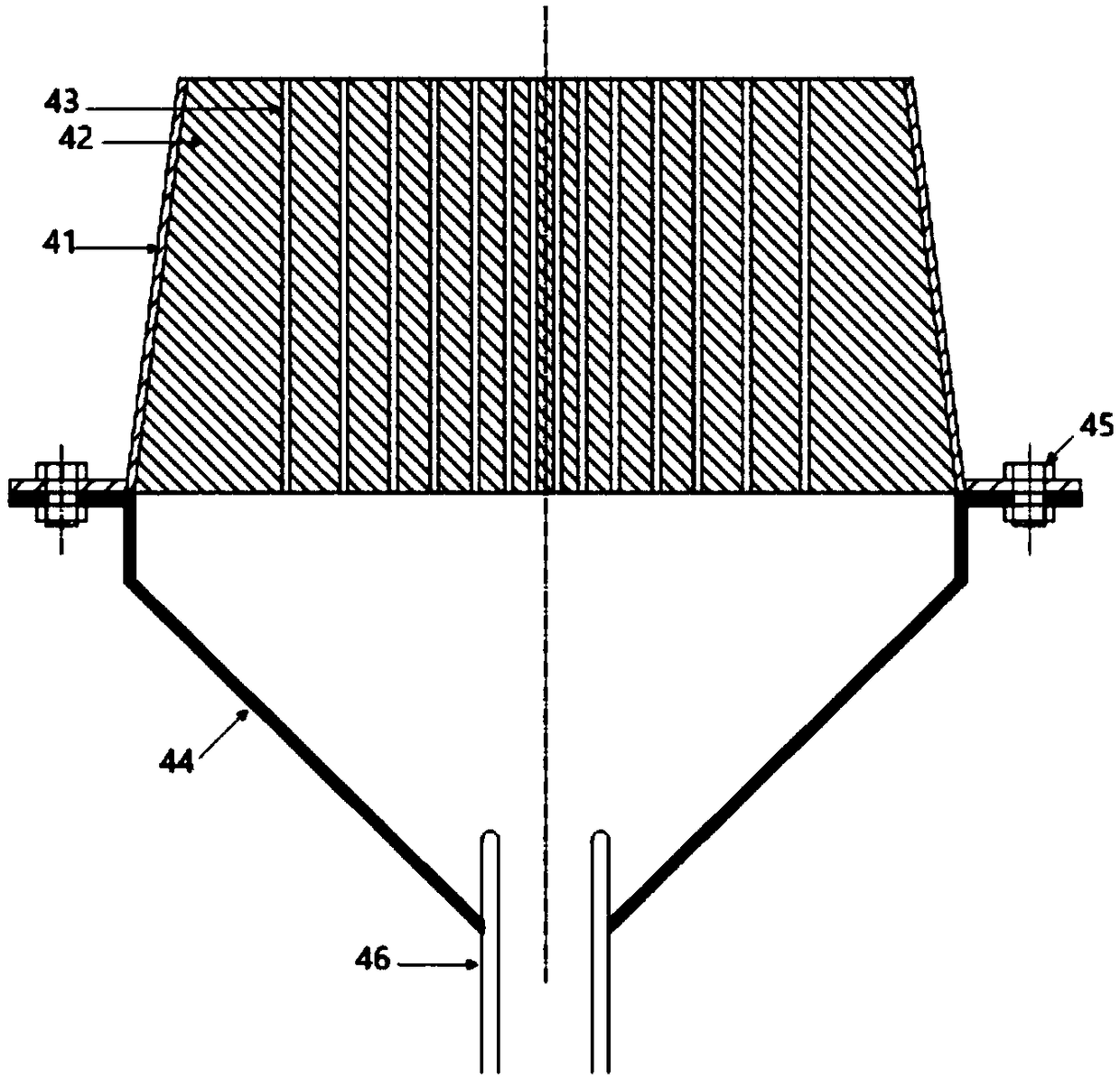

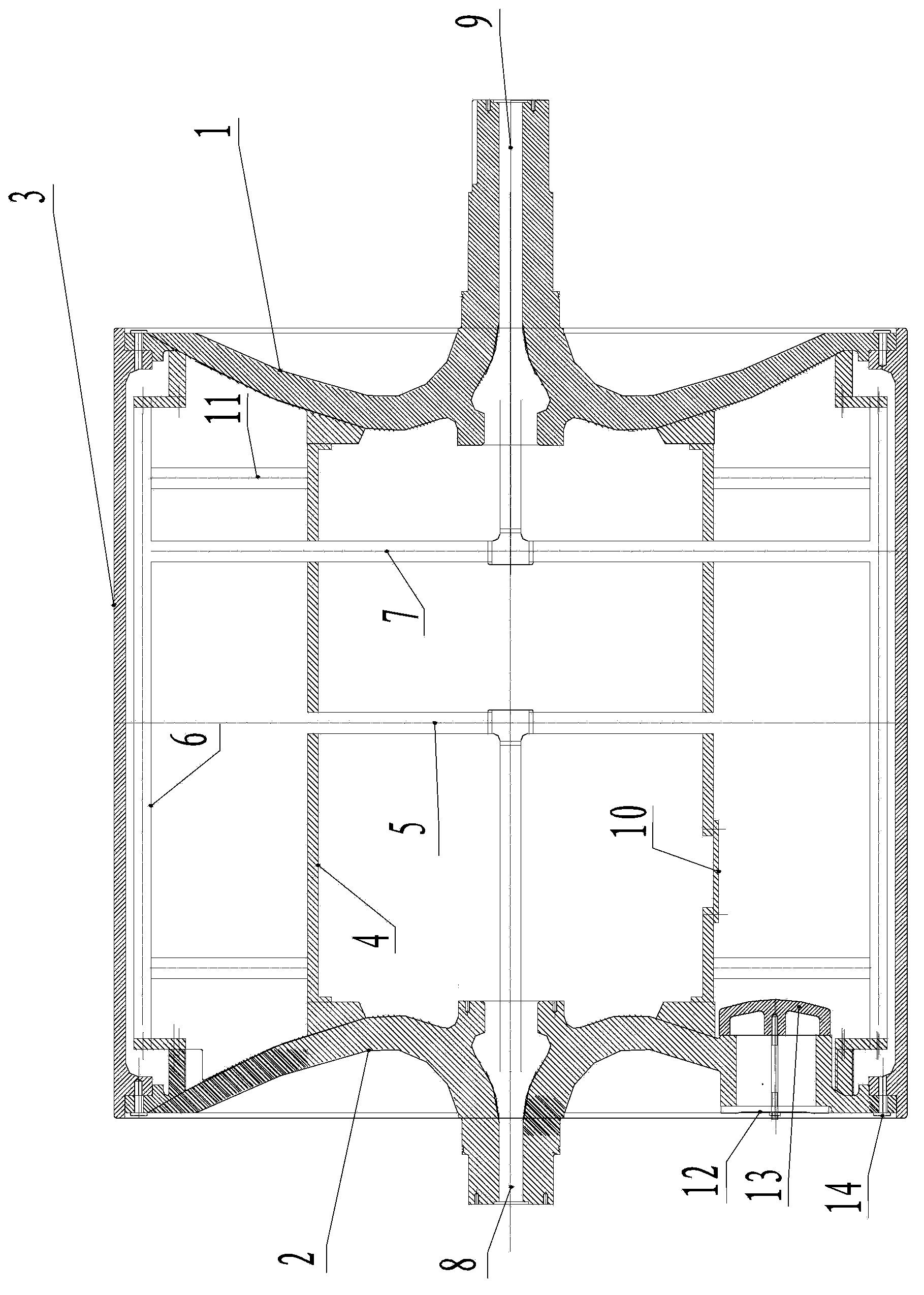

Bottom-powder-spraying molten steel refining device with heating function

InactiveCN108660288AOvercoming poor reaction conditionsSolve the temperature dropElectric energySmelting process

The invention provides a bottom-powder-spraying molten steel refining device with a heating function. The device comprises a steel ladle for refining molten steel, a heating device for heating the steel ladle and a powder spraying device used for introducing gas and powder into the steel ladle. The heating device is arranged inside the steel ladle and located on the upper portion of the molten steel, and the powder spraying device is arranged at the bottom of the steel ladle. According to the molten steel refining device, the powder is pneumatically conveyed from the bottom of the steel ladleinto the steel ladle, therefore, the molten steel in the steel ladle can achieve thorough contact from the bottom to the top, the defects that steel slag reaction conditions are poor and feeding is difficult inside traditional steel ladle heating refining furnaces are overcome, the problem that the temperature is reduced in the steel ladle bottom powder spraying smelting process is solved, the desulphurization efficiency is improved, the steel grade quality is improved, the smelting period is shortened, no splash is produced in the powder spraying process, and refining safety is improved. By the adoption of the molten steel refining device, the refining speed is increased, consumption of electric energy, electrodes and argon is reduced, the production rhythm is improved, the production isincreased, and the cost is reduced.

Owner:NORTHEASTERN UNIV

Process for smelting ferronickel from red soil nickel ore

The invention discloses a method for smelting ferronickel from red soil nickel ore, which comprises the following steps of: 1) mixing the red soil nickel ore with coal dust or coke, and sintering for 2 to 8 hours to obtain sintered nickel ore; 2) smelting the sintered nickel ore, a flux and a reducing agent for 2 to 3 hours in an electric furnace to obtain a crude ferronickel melt; and 3) refining the crude ferronickel melt: a) ensuring that the melt temperature is higher than 1,450DEG C; b) adding a complex desulfurizer into the melt for desulfurization; c) detecting the sulfur content of the melt, stopping desulfurization when the sulfur content is lower than a preset value, detecting the melt temperature when the sulfur content is higher than the preset value, slagging off and raising the temperature of the melt and repeating the step b) until the sulfur content is lower than the preset value when the temperature is below 1,350DEG C, repeating the step b) until the sulfur content is smaller than the preset value when the temperature is higher than 1,350DEG C, and slagging off; d) adding a complex dephosphorization agent into the melt for dephosphorization; and e) casting and demolding to obtain the refined ferronickel alloy. The method has the advantages of simple process and low energy consumption.

Owner:CHINA ENFI ENGINEERING CORPORATION

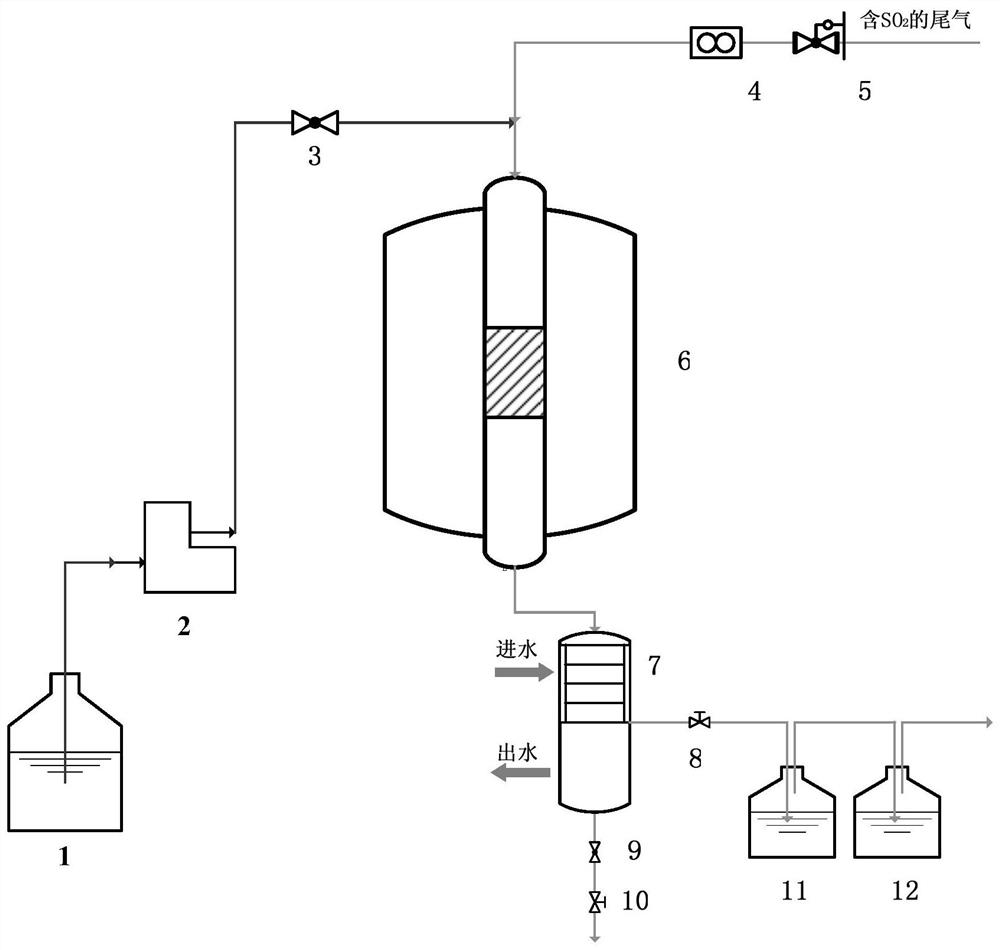

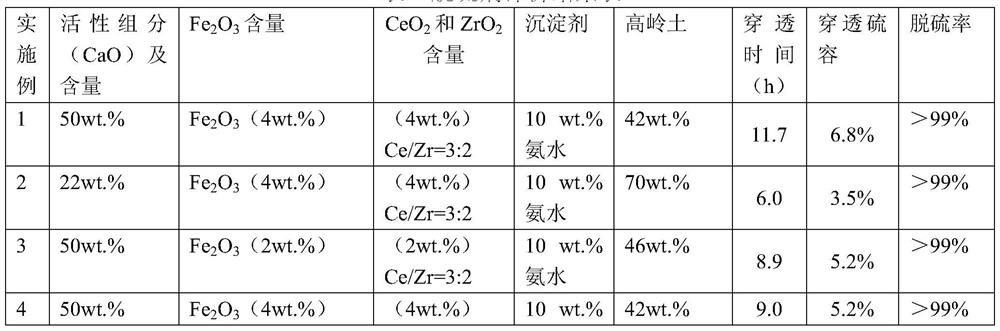

A kind of renewable dry flue gas desulfurizer and its preparation method and application

ActiveCN108722168BHigh sulfur capacityImprove desulfurization effectDispersed particle separationChemical industryFlue gas

The invention discloses a renewable dry-method flue gas desulfurizing agent and a preparation method and application thereof and relates to the field of flue gas desulfurization and purification in coal-fired power plants, heating boilers and metallurgy and chemical industry. The renewable dry-method flue gas desulfurizing agent used for removing SO2 and SO3 components in flue gas comprises activecomponent CaO, an auxiliary and a carrier, wherein the active component is made of cheap quick lime or slaked lime; the auxiliary is the combination of Fe, Ce and Zr oxides; the carrier is kaolin. The renewable dry-method flue gas desulfurizing agent has the advantages that the renewable dry-method flue gas desulfurizing agent is low in raw material cost, good in desulfurizing effect, high in sulfur capacity and good in renewability, the sulfur capacity of the renewable dry-method flue gas desulfurizing agent which is repeatedly used for 10 times is more than 90% of that of the renewable dry-method flue gas desulfurizing agent which is used for the first time, and the renewable dry-method flue gas desulfurizing agent also has a dust removing effect during use.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

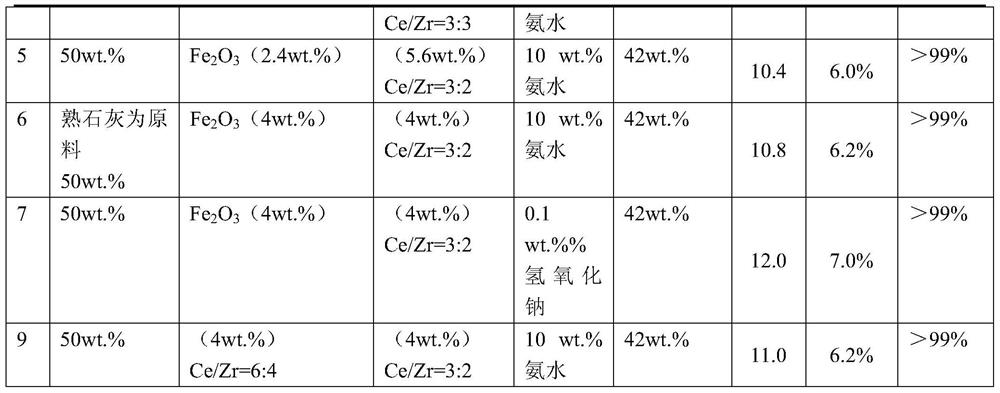

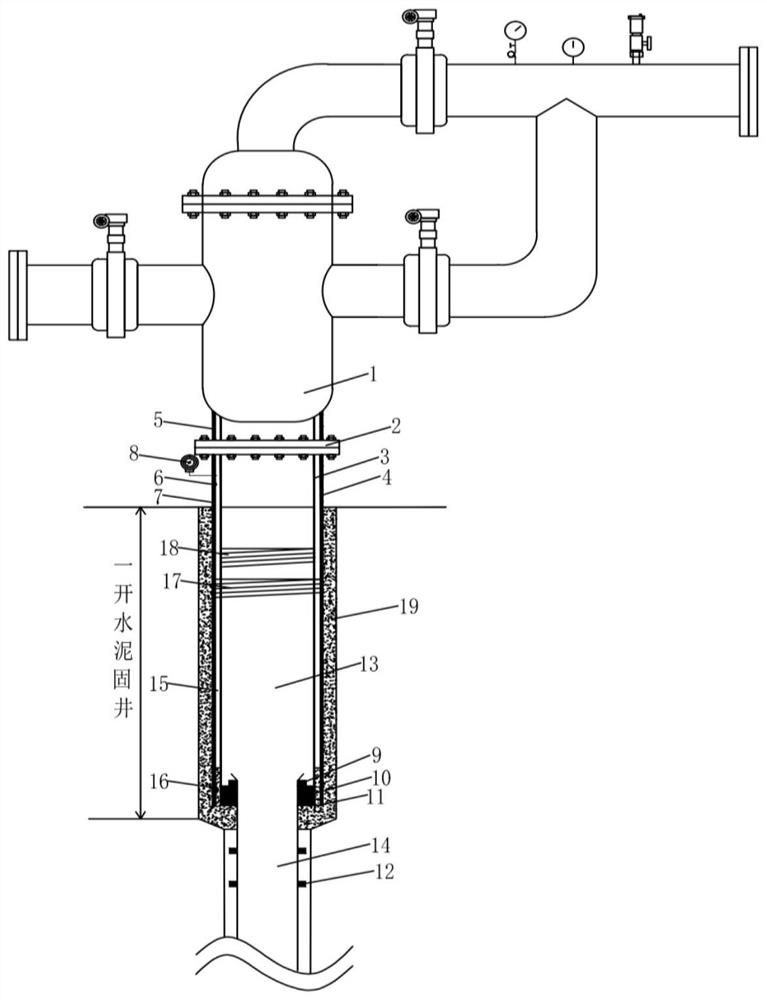

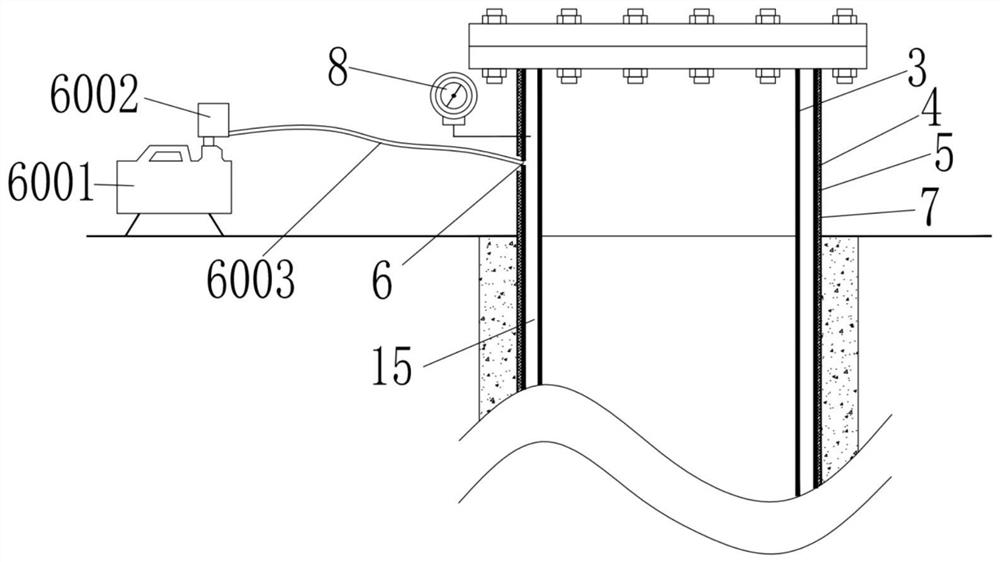

Multi-layer heat preservation structure of sleeve of one-opening shaft of hydrothermal type geothermal well and implementation process

The invention relates to the technical field of geothermal shaft heat preservation, and discloses a multi-layer heat preservation structure of a sleeve of a one-opening shaft of a hydrothermal type geothermal well. The multi-layer heat preservation structure comprises an inner-layer sleeve and an outer-layer sleeve, wherein the outer surface of the outer-layer sleeve is coated with a nano aerogel layer; an annular gap between the inner-layer sleeve and the outer-layer sleeve is a vacuum interlayer; a vacuum meter is arranged on the outer-layer sleeve; a vacuumizing reserved hole is formed in the outer-layer sleeve; and a flow guide groove is formed in the bottom end of the vacuum interlayer; and heat preservation cement enters the vacuum interlayer from the flow guide groove. The invention further discloses an implementation process of the heat preservation structure. According to the first-layer heat preservation structure of the sleeve of the multi-layer heat preservation structure, the interlayer of the well sleeve which is through inside and outside at the one-opening shaft of the geothermal well is vacuumized, so that vacuum heat insulation and insulation are realized; and according to the second-layer heat preservation structure, the outer surface of a vacuum pipe is coated with nano aerogel for heat insulation and heat preservation, and the outer-layer heat preservation structure adopts heat preservation cement mortar for well cementation, so that the full-size multi-layer long-acting heat insulation and heat preservation effects of the one-opening shaft are achieved, and comprehensive-grade efficient utilization of high-grade geothermal resources is guaranteed.

Owner:陕西省煤田地质集团有限公司 +1

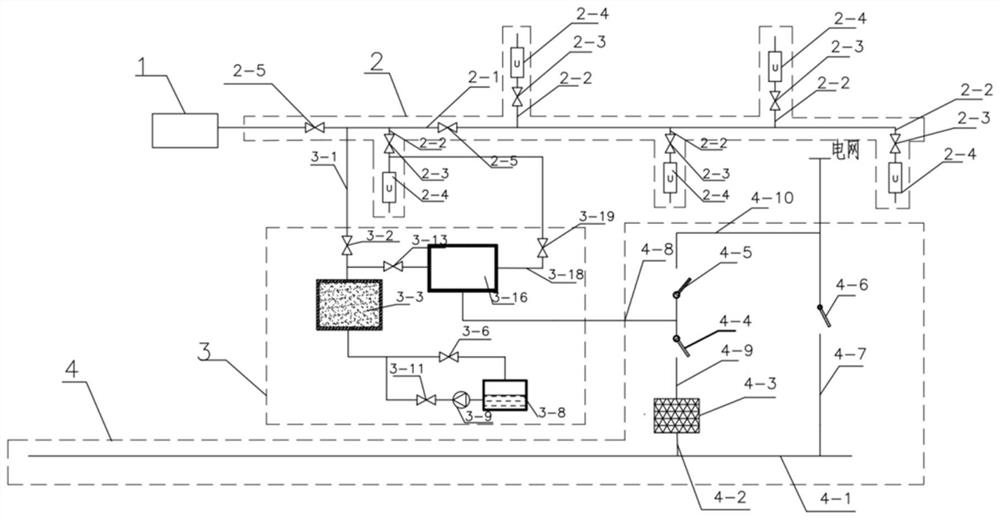

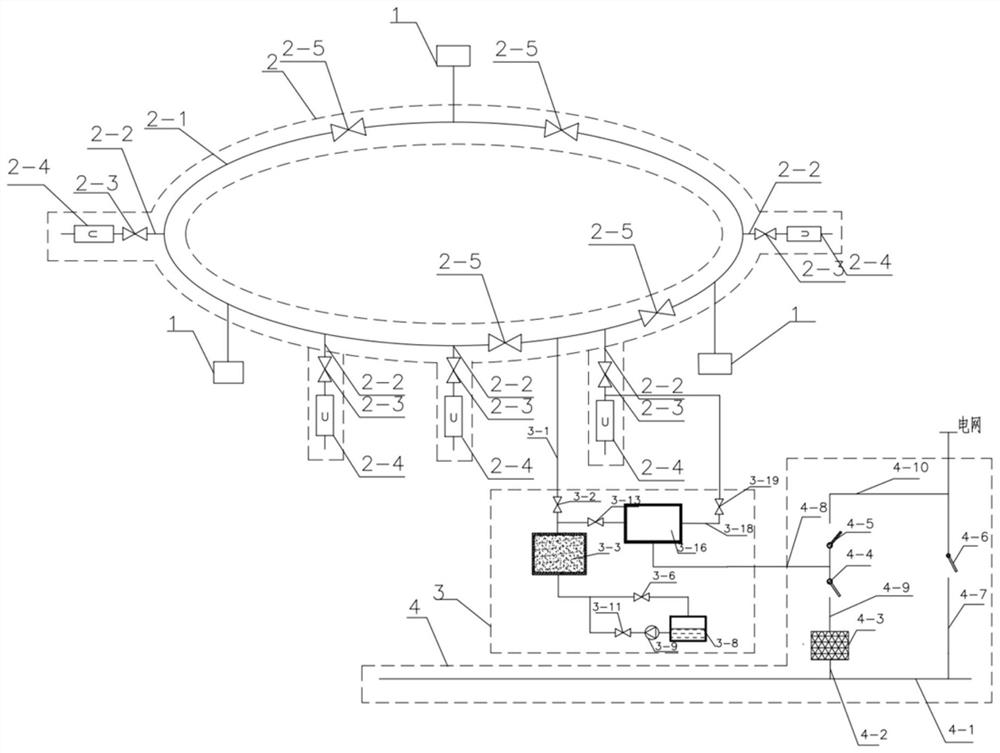

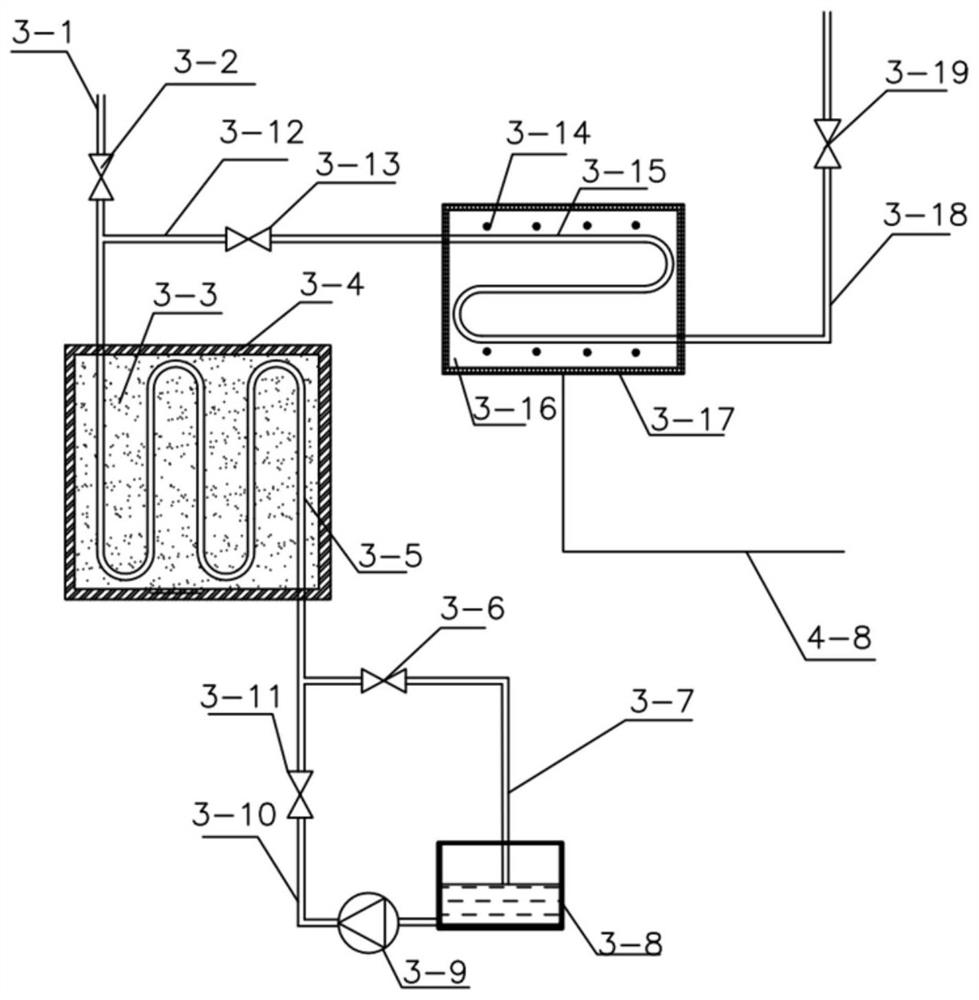

A regenerative steam heating network heating system and method with large load fluctuations

ActiveCN113028478BSolve the temperature dropEfficient use ofHeating fuelCentral heating with accumulated heatSuperheaterHeat energy

The invention discloses a heat storage type steam heat network heating system with large fluctuations in load, which comprises a heat supply heat source, a steam heat supply pipe network module, a heat storage heat supply system module, and an electric heating system module. On the one hand, the present invention proposes to use the high-temperature heat storage energy storage system to realize the storage and release of surplus heat network steam, realize the efficient utilization of steam heat energy in the heat network, and use the electric heat storage superheater as the secondary heat source to solve the problem of heat storage and storage. The problem that the steam temperature decreases during the release process ensures the grade of the heating steam. On the other hand, a method of using heat storage technology to realize local heating is proposed, which solves the problem of poor economy of the steam heating network under low load conditions, and avoids local water hammer due to excessive condensed water caused by excessive heat loss. The problem of safety risk improves the economy and safety of steam heating network operation. At the same time, the heat storage system supplements and increases the heating capacity of the heating network during peak load, and the load capacity of the heating network.

Owner:ZHEJIANG UNIV

A membrane concentrate liquid treatment system and its production process

ActiveCN112979046BSolve the temperature dropImprove processing efficiencyMultistage water/sewage treatmentTreatment involving sedimentationInorganic saltsPhysical chemistry

The invention discloses a membrane concentrate liquid treatment system, which comprises a mixing tank and a stirring shaft, a lifting device is fixed inside the stirring shaft, both ends of the lifting device are arranged outside the stirring shaft, and the upper end of the lifting device is connected with A feeding device, the outlet of the feeding device is connected to the mixing device, and the other side of the mixing device is connected to a liquid storage tank; the lower end of the lifting device is placed at the bottom of the mixing tank for extracting metal impurities in the mixing tank. The mixing device is used for mixing and reacting metal impurities and dilute sulfuric acid to generate inorganic salts and injecting the inorganic salts into the mixing pool. The device can greatly save resources and improve the treatment efficiency of the concentrated solution.

Owner:ZHEJIANG HONGDIAN ENVIRONMENTAL PROTECTION & TECH CO LTD

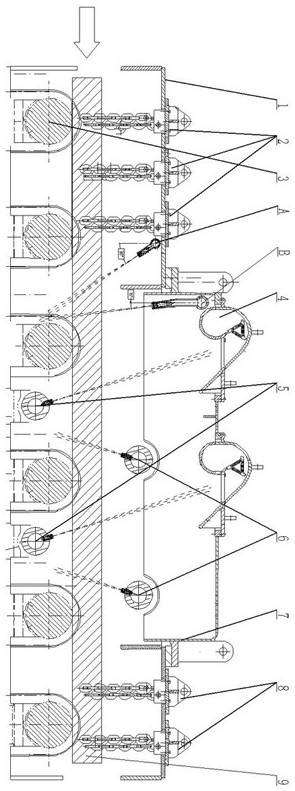

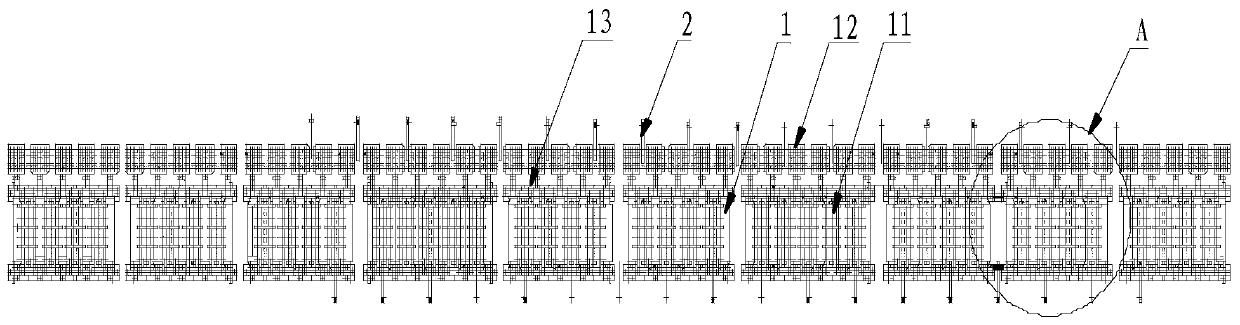

Heating device for intermediate blank

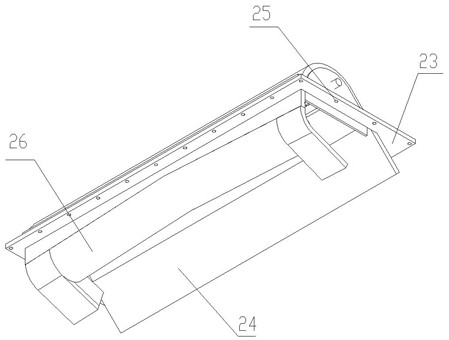

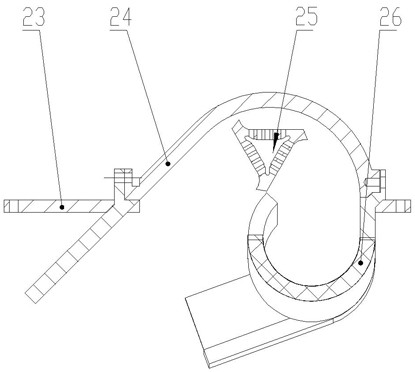

PendingCN110560493ASolve the temperature dropQuality improvementWork heating devicesMetal rolling arrangementsArchitectural engineeringDrive motor

The invention relates to the field of heating and particularly relates to a heating device for an intermediate blank. The device comprises an intermediate roller table and burner assemblies, wherein the intermediate roller table is provided with more than two transmission rollers arranged in the same direction and parallel to each other and a driving motor connected to one end of each transmissionroller in a one-to-one correspondence mode; the two sides of the intermediate roller table are each provided with protective plates, through holes are formed in the positions, at the rear section part of the intermediate roller table, of the protective plates, and the through holes are capable of accommodating the burner assemblies to extend from the outside of the intermediate roller table to the inside of the intermediate roller table; and the burner assemblies are configured to heat a steel billet placed on the intermediate roller table. The heating device for the intermediate blank solvesthe problem of temperature drop at the edge of the steel billet at the rear section of the intermediate roller table in a conveying process, and further improves the quality and the yield of black steel coils.

Owner:FUJIAN DINGXIN TECH

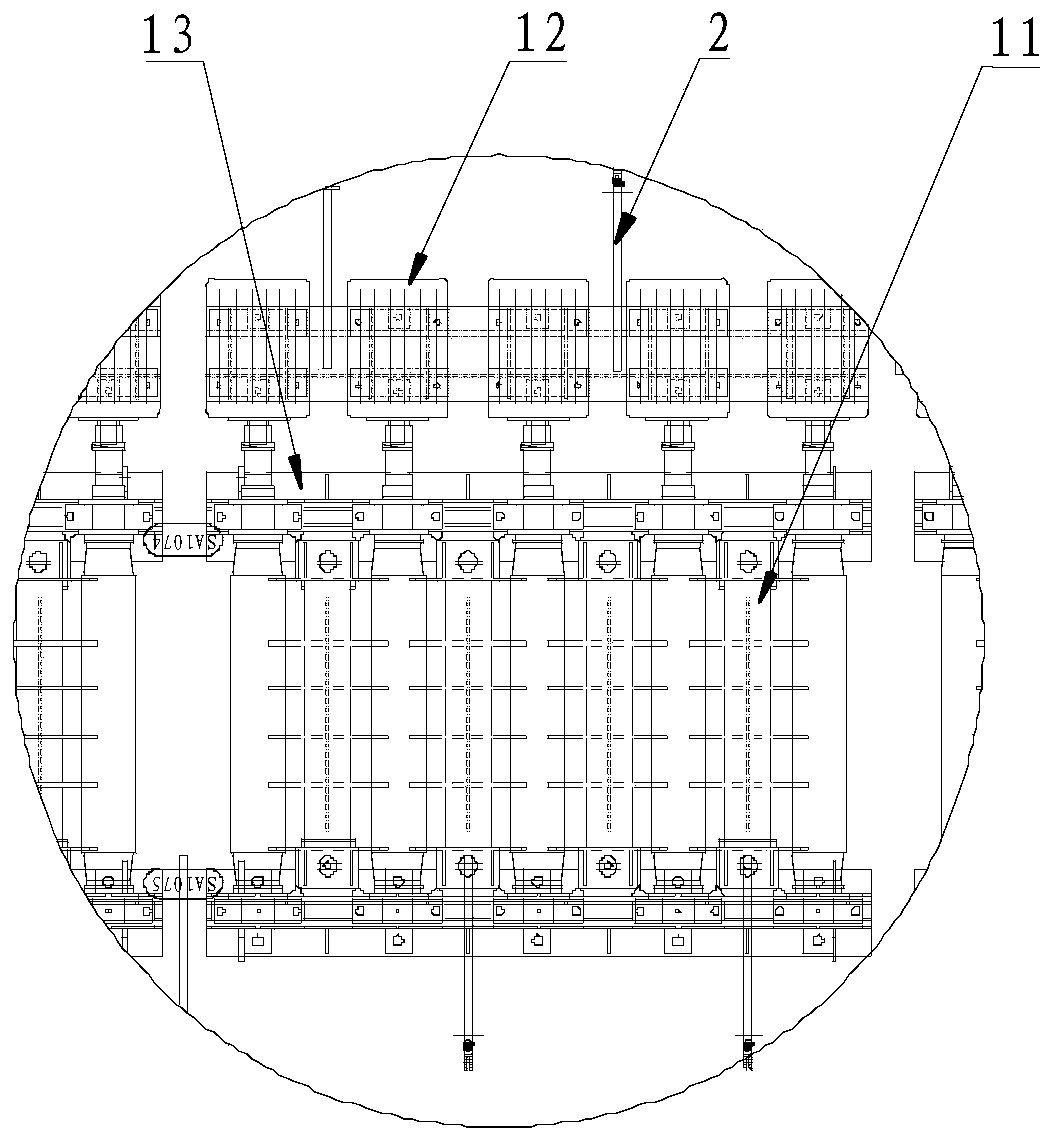

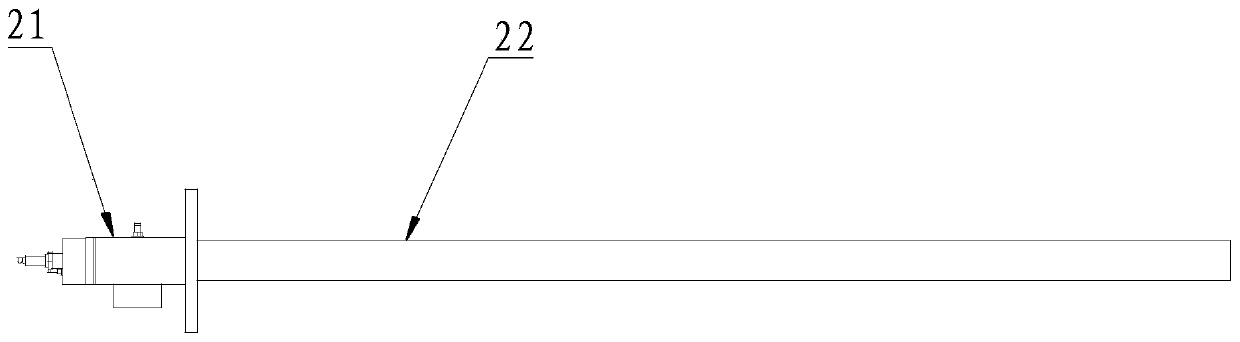

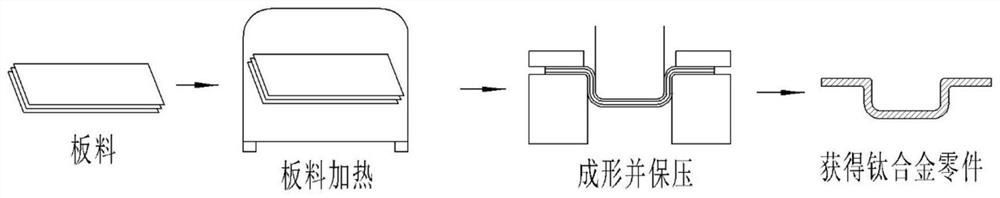

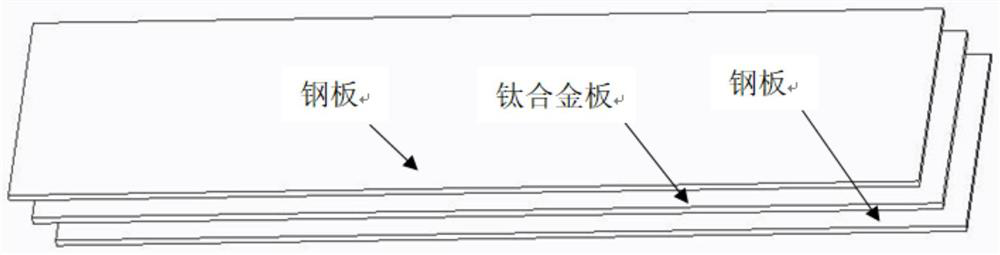

A hot stamping forming process of titanium alloy multilayer plate

The invention relates to the technical field of aviation plate processing, and provides a hot stamping forming process for titanium alloy multilayer plates. The forming process makes steel plates and titanium alloy plates into blanks of required shapes; The clamping method of alloy-steel is placed in a heating furnace for heating, without adding any adhesive between the three-layer boards, heated to 700-900°C, and then kept warm for 5-7min after reaching the specified temperature; the heated three-layer The sheets are transferred to the cold mold together for stamping and forming; the stamped and formed parts are subjected to die pressure holding for 30-180s, and finally titanium alloy parts are obtained. The invention reduces the heat loss of the sheet metal during the transfer process, increases the stamping formability of the titanium alloy sheet material, and the deformation force required for the hot stamping forming process is small, and the formed parts have high strength, high hardness, and a springback angle Small size ensures product accuracy and quality; simple process, high efficiency, and broad application prospects.

Owner:UNIV OF SCI & TECH BEIJING

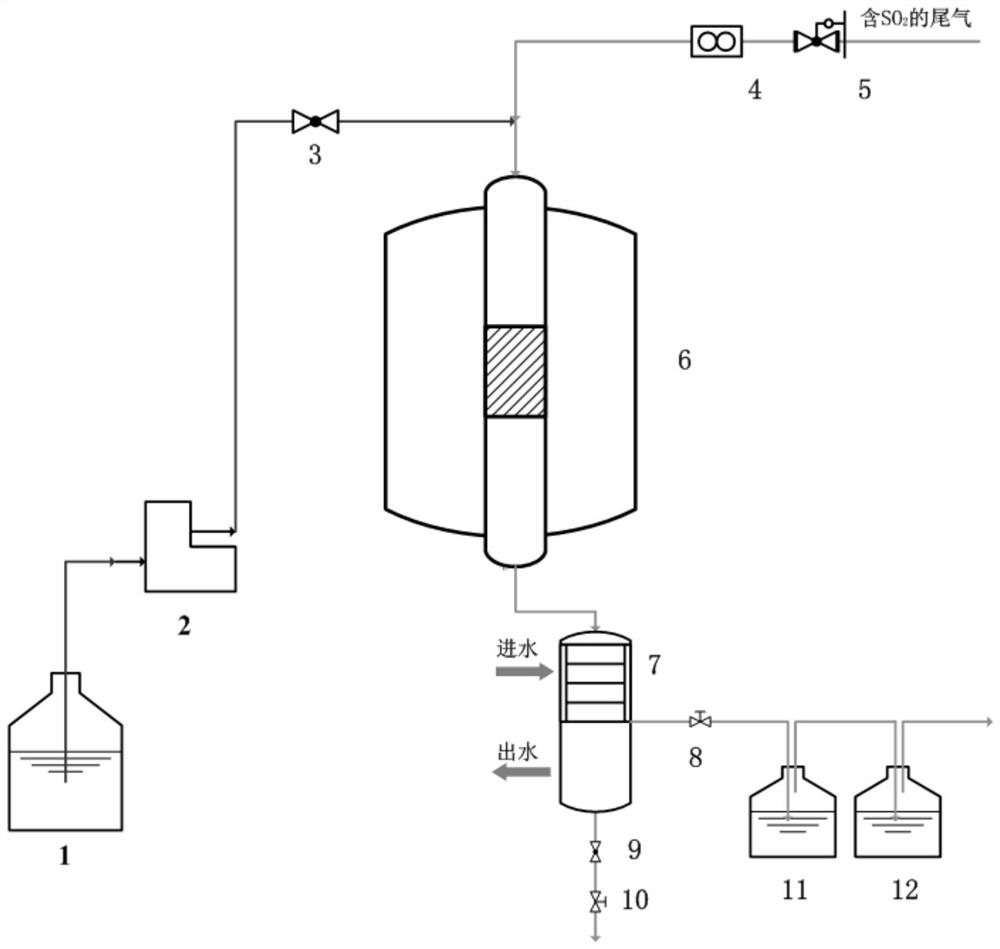

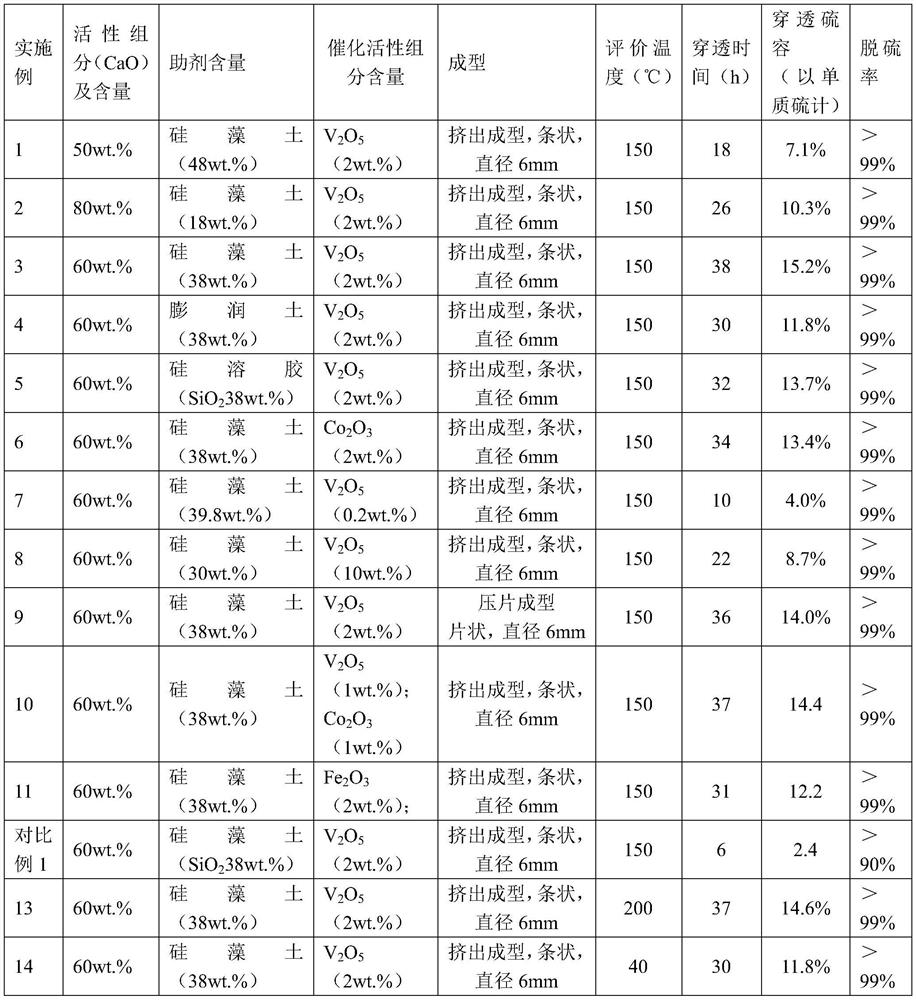

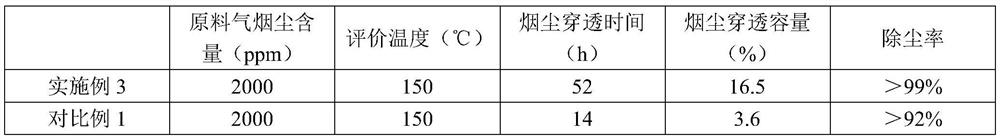

A kind of low-temperature dry flue gas desulfurizer and its preparation method and application

ActiveCN109603459BLow costHigh porosityGas treatmentDispersed particle separationChemical industryFlue gas

The invention discloses a low-temperature dry flue gas desulfurizer and a preparation method and application thereof, which are used for removing SO2 and SO3 components in the low-temperature (40-200DEG C) flue gas, and relates to the field of the flue gas desulfurization purification in coal-fired power plants, heat supply boilers, metallurgy and chemical industries. The desulfurizer comprises an active component CaO, a reaction auxiliary agent silicon source and a catalytic active component V, Fe or Co, wherein cheap quicklime is selected as the raw material of the active component, the silicon source as the auxiliary agent, comprising diatomite, bentonite, silica sol and other silicon sources, and V2O5, Fe2O3, Co2O3 or a combination thereof as the catalytic component. The desulfurizerhas the advantages of low raw material cost, good desulfurization effect, high sulfur capacity, low use temperature to normal temperature, and great breakthrough on low-temperature flue gas dry desulfurization. The desulfurizer matched with a dry moving bed desulfurization process or a fixed bed dry desulfurization process has both desulfurization and dust removal effects in the application process.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

A high-efficiency production process for high-standard bearing steel

ActiveCN111793772BSolve the temperature dropPrevent slaggingManufacturing convertersSteelmakingAluminate

The invention belongs to the technical field of steelmaking technology, and relates to a high-efficiency production technology of high-standard bearing steel, which adopts the "BOF-RH-CC" process route. The alloy is melted by the alloy melting furnace, which cleverly solves the problem of large temperature drop of the molten steel due to the addition of a large amount of alloys such as ferrochrome during the tapping process. After tapping, the molten steel can be directly vacuumed at the RH station. By canceling the LF refining furnace, the improvement of production efficiency, avoiding the problem of slag entrainment in refining slag, and at the same time avoiding the reaction of slag steel caused by the submerged arc heating process of LF slag making, making Al 2 o 3 The inclusions are transformed into calcium aluminates that are not conducive to subsequent control, and the inclusions can be controlled throughout the process to be solid Al with high removal efficiency 2 o 3 , after RH vacuum, Al 2 o 3 The inclusions are efficiently removed, and the total oxygen in the molten steel is controlled to 3.0-4.5ppm. At the same time, because the Al in the steel 2 o 3 Inclusion control, the excessive ratio of B-type and Ds-type calcium-aluminate inclusions in steel is greatly reduced.

Owner:ZENITH STEEL GROUP CORP +1

Surrounding rock detection device

PendingCN114200000ASolve the temperature dropWith ultrasonic wave velocity test functionAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationEngineeringMechanical engineering

The invention provides a surrounding rock detection device, comprising: a container for placing surrounding rock to be detected; the heating assembly is arranged in the container; the ultrasonic component comprises an emitter for emitting ultrasonic waves and a receiver for receiving the ultrasonic waves; the emitter and the receiver are both arranged on the outer side of the container, and ultrasonic waves emitted by the emitter penetrate through the container; the beating assembly comprises a driving part and a beating body arranged at the top of the container; the striking body is movably arranged in the vertical direction, and the striking body is driven by the driving part to strike the surrounding rock to be detected in the container. The experimental device has the functions of high-temperature heating test, durability striking test and ultrasonic wave velocity test, during experiments, the three functions can be separately carried out, two of the three functions can be randomly selected for coupling, or three experiments can be simultaneously carried out, and the problem that a plurality of experimental devices need to be used in traditional surrounding rock tests can be solved.

Owner:SHANGHAI TUNNEL ENG CO LTD +2

Technique of maufacturing electrocast refractories through bubbling method

A technology for preparing the electrosmelting refractory material by bubbling method includes proportionally mixing its raw materials and flux, loading the mixture in electric smelting furnace which has an air tube communicated with compressed air tank, and smelting while introducing compressed air to the furnace. Its advantages are no need of turning off power supply on blowing oxygen, high uniformity and density of refractory.

Owner:侯松发

Double-layer efficient energy-saving drying cylinder

InactiveCN103673579AReduce gas consumptionSolve the cylinder temperature dropDrying chambers/containersCoalElectricity

The invention relates to drying equipment, in particular to a double-layer efficient energy-saving drying cylinder. The double-layer efficient energy-saving drying cylinder comprises a cylinder barrel, a cylinder inner container, an air inlet pipe, an operation-side cylinder cover and a transmission-side cylinder cover. The operation-side cylinder cover and the transmission-side cylinder cover are installed at the two ends of the cylinder barrel respectively. The cylinder inner container is arranged in the cylinder barrel, and the two ends of the cylinder inner container are connected with the operation-side cylinder cover and the transmission-side cylinder cover respectively. An air inlet is formed in the operating-side cylinder cover, a ventilating hole is formed in the cylinder inner container, the air inlet pipe is arranged in the cylinder inner container, and the two ends of the air inlet pipe are communicated with the air inlet and the ventilating hole in the cylinder inner container respectively. The double-layer efficient energy-saving drying cylinder reduces air consumption, saves coal and electricity and reduces production cost.

Owner:东港市合金烘缸厂

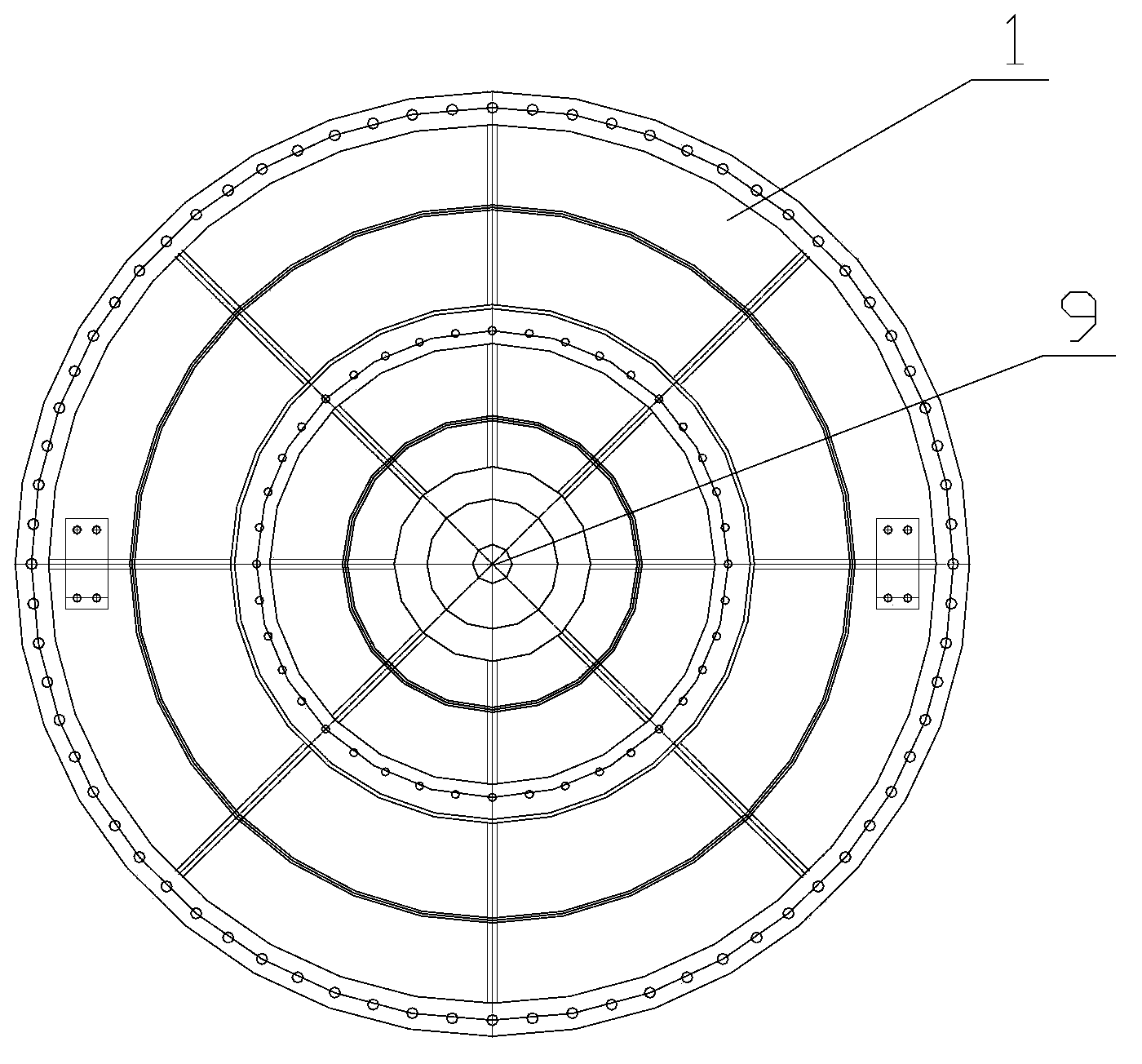

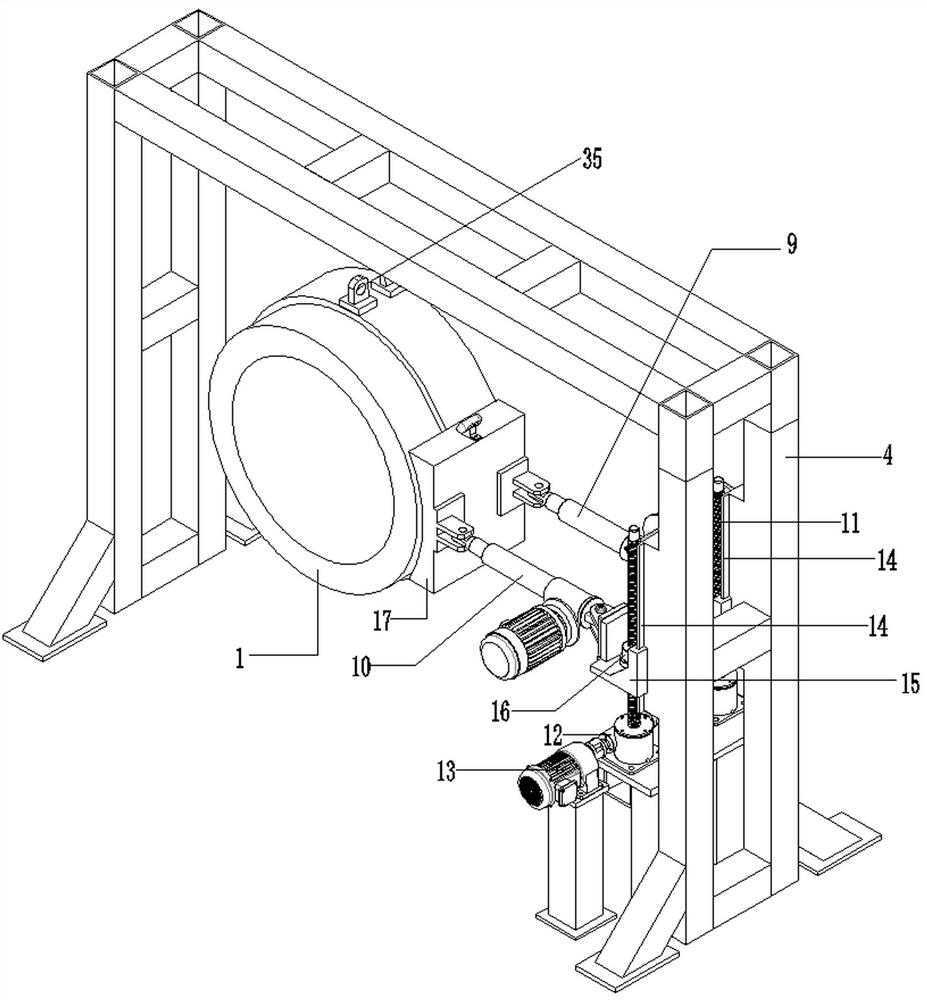

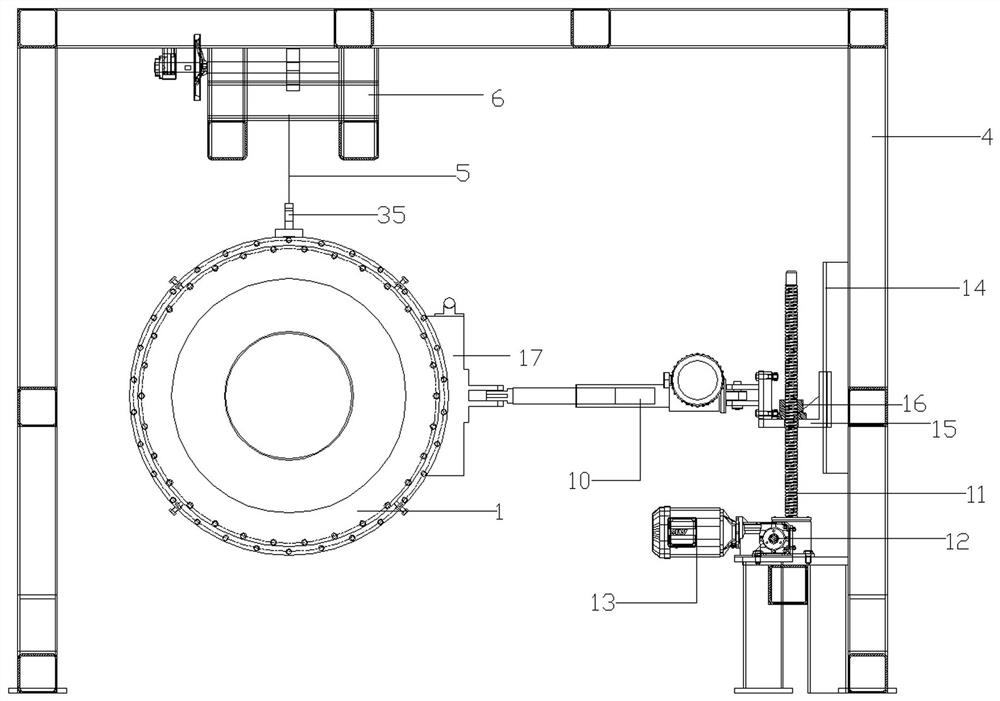

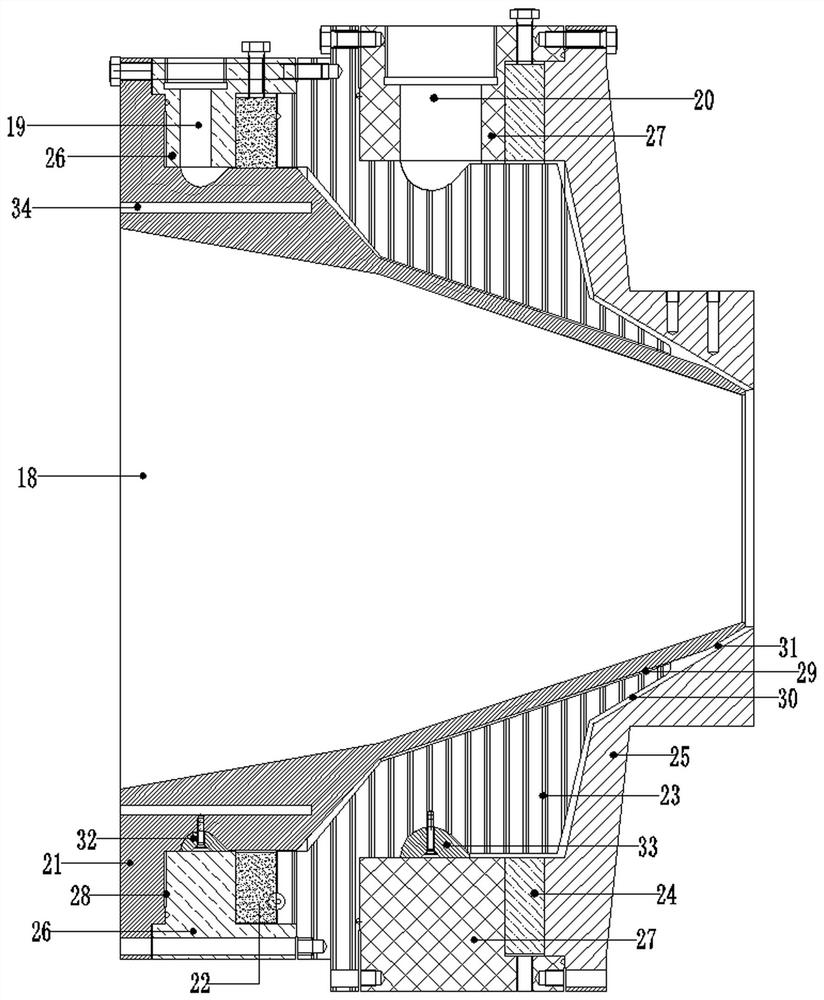

A kind of 3lpe coating equipment for hot-simmering bent pipe coating

ActiveCN112519173BGuaranteed clearance positionUniform thicknessCoatingsEngineeringMechanical engineering

The present invention relates to the technical field of 3LPE coated production technology of hot-simmered bent pipe, in particular to a hot-simmered bent pipe-coated 3LPE coating equipment, which includes a mold body and a driving device for driving the angle adjustment of the mold body; The mold body encloses and forms an annular trumpet-shaped cavity; the mold body is provided with an annular AD flow channel, an annular PE flow channel, a discharge cavity, an adjustment ring A and an adjustment ring B; the adjustment There are several bolts in the radial direction of the ring A and the adjusting ring B, and the bolts are used to make the outer width of the AD flow channel and the PE flow channel larger than the corresponding inner width; the driving device includes a controller, which is used to support the mold body The supporting part, the first driving part that drives the mold body to move up and down, the second driving part that drives the mold body to adjust left and right, and the third driving part that drives the second driving part to move up and down. The coating equipment can effectively solve the problem of uneven thickness of the anti-corrosion layer coated on the inner and outer sides of the hot bending pipe.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

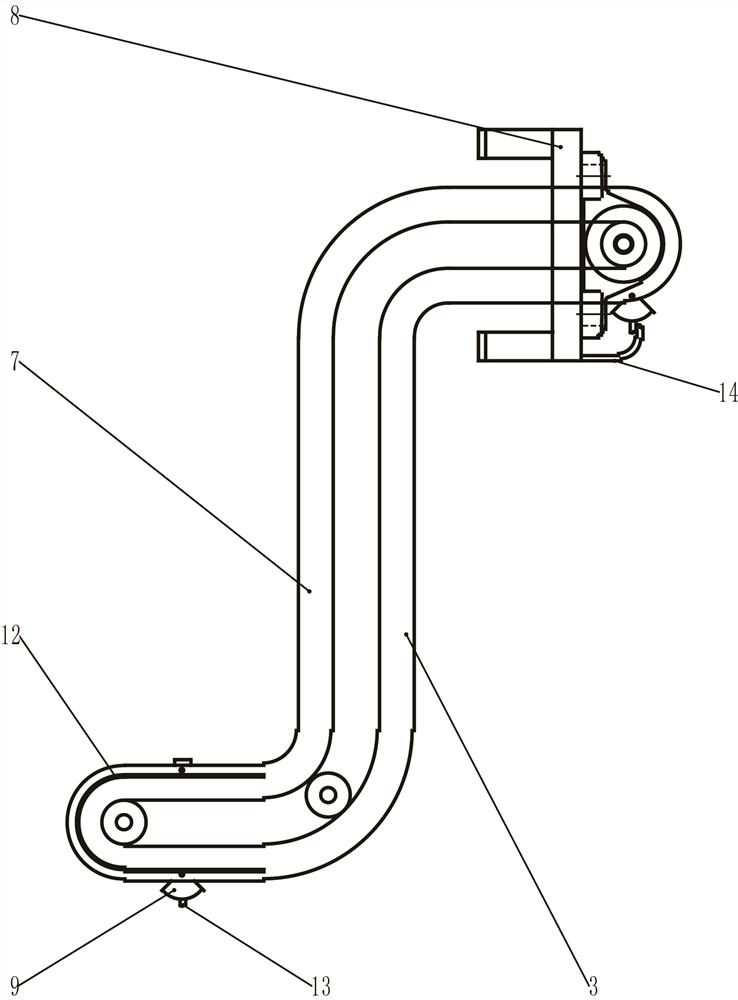

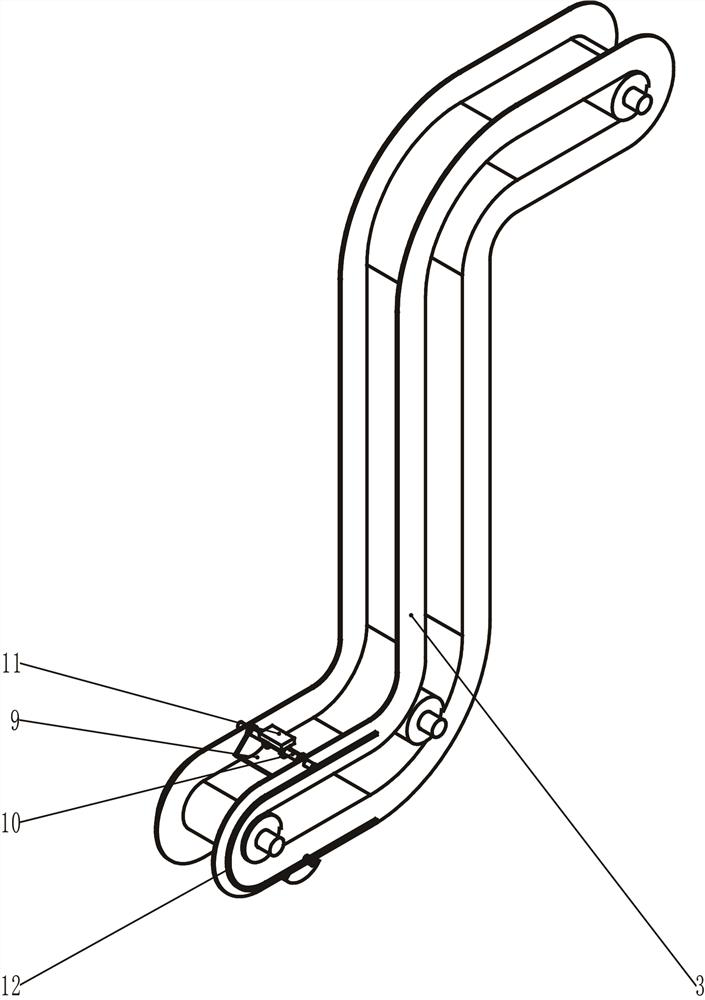

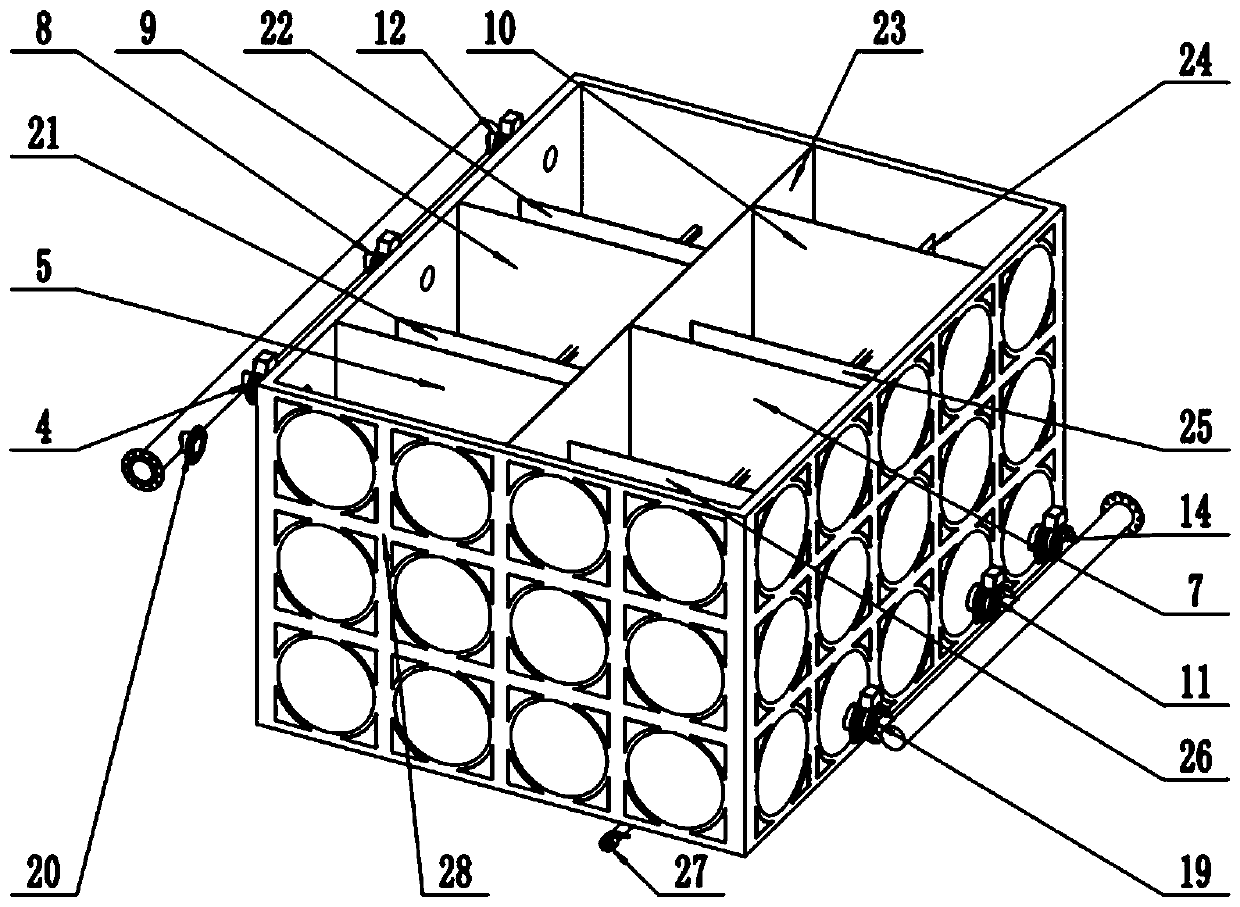

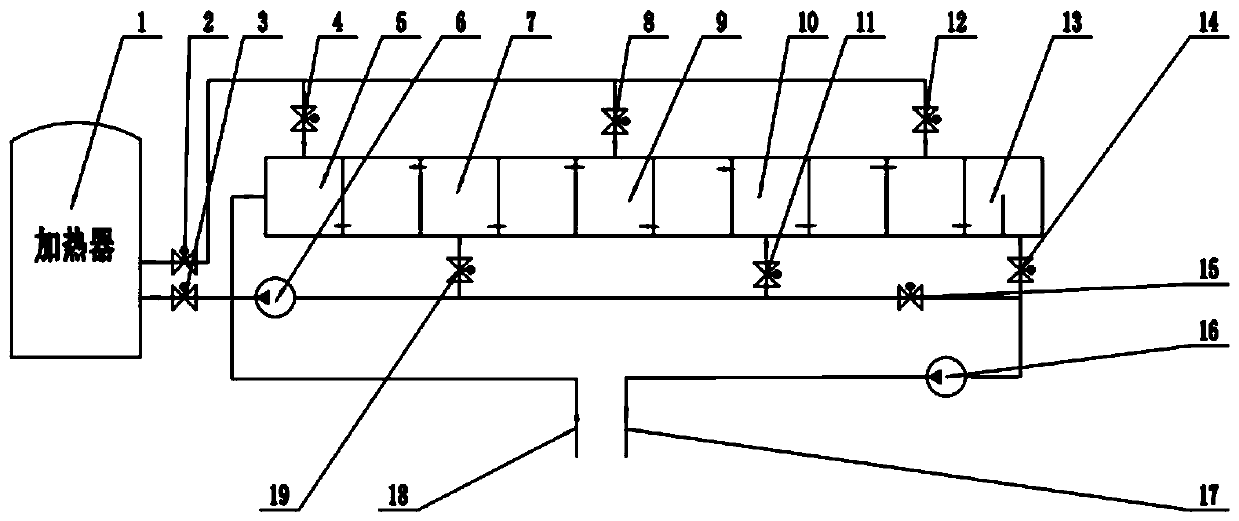

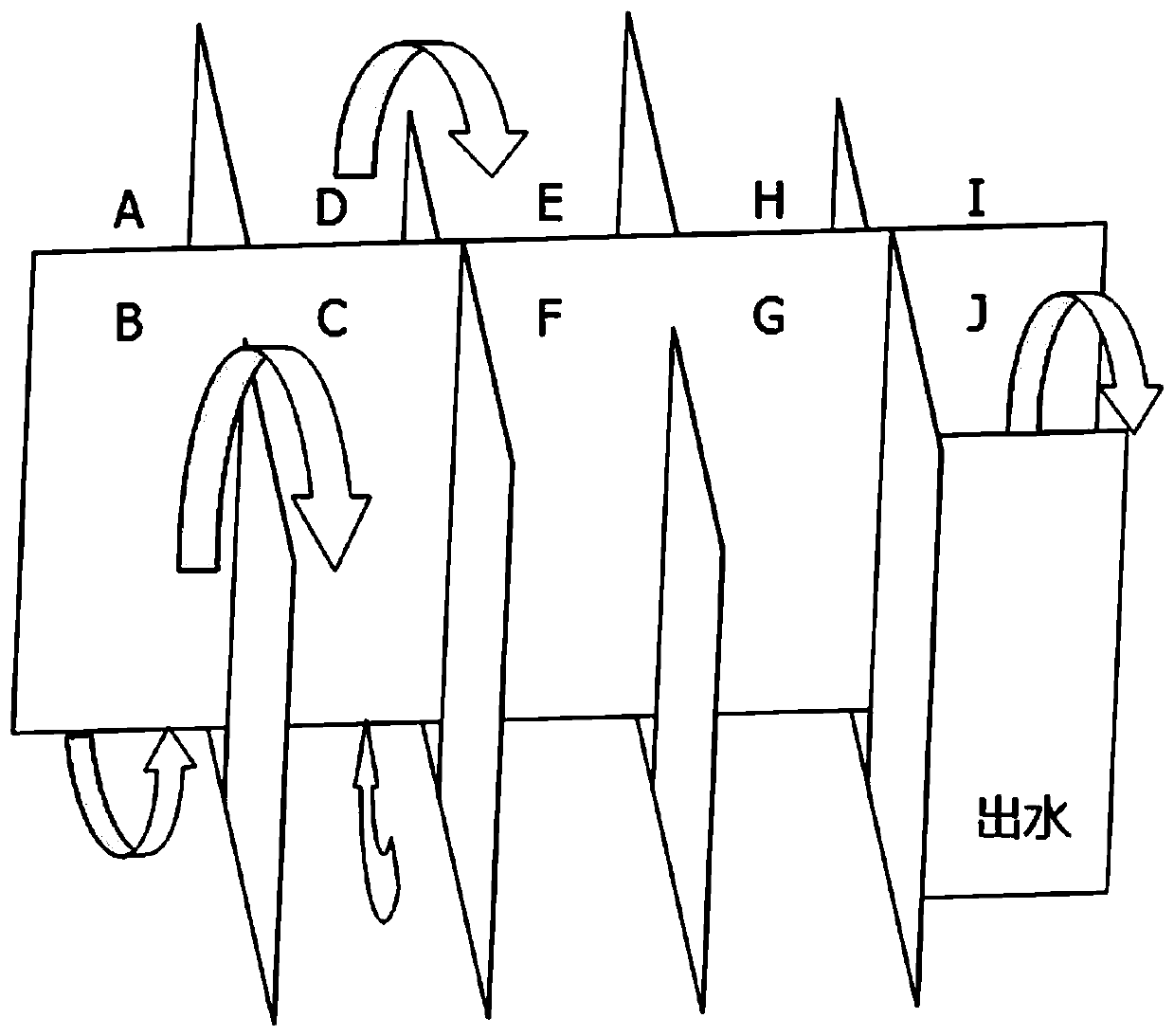

Intelligent control three-dimensional bending channel type heat preservation water tank

ActiveCN108253627BRealize intelligent controlSolve the temperature dropStorage heatersWater storageSolenoid valve

The present invention is an intelligently controlled three-dimensional bending channel type thermal insulation water tank, comprising a box body, the inside of which is divided into several water storage cavities by a plurality of heat-insulating flow guide plates, and several pieces of heat-insulating flow guide plates are composed of a middle heat-insulating flow guide plate Composed of heat-insulating deflectors on both sides, the middle heat-insulating deflector and both sides of the heat-insulating deflector divide the interior of the box into several connected water storage chambers; the box is equipped with a hot water inlet and a hot water outlet , the hot water inlets are set at the upper end of the water storage cavity on one side of the middle heat-insulating deflector, and the hot water outlets are respectively set at the lower end of the water storage cavity on the other side of the middle heat-insulation deflector; Solenoid valves are respectively installed between the water inlet main pipes, between the hot water outlet and the hot water outlet main pipe, and the hot water inlet and the hot water outlet are intelligently controlled by the solenoid valves respectively. The invention solves the problem that the temperature of the water tank decreases as a whole caused by the direct mixing of cold and hot water during the thermal circulation process of the existing thermal insulation water tank, and realizes the effects of flexible control of water consumption and energy saving.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com