Multi-layer heat preservation structure of sleeve of one-opening shaft of hydrothermal type geothermal well and implementation process

A multi-layer thermal insulation, geothermal well technology, applied in casings, wellbore/well components, drilling pipes, etc., can solve the problems of temperature reduction and dissipation, and achieve the effect of ensuring efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

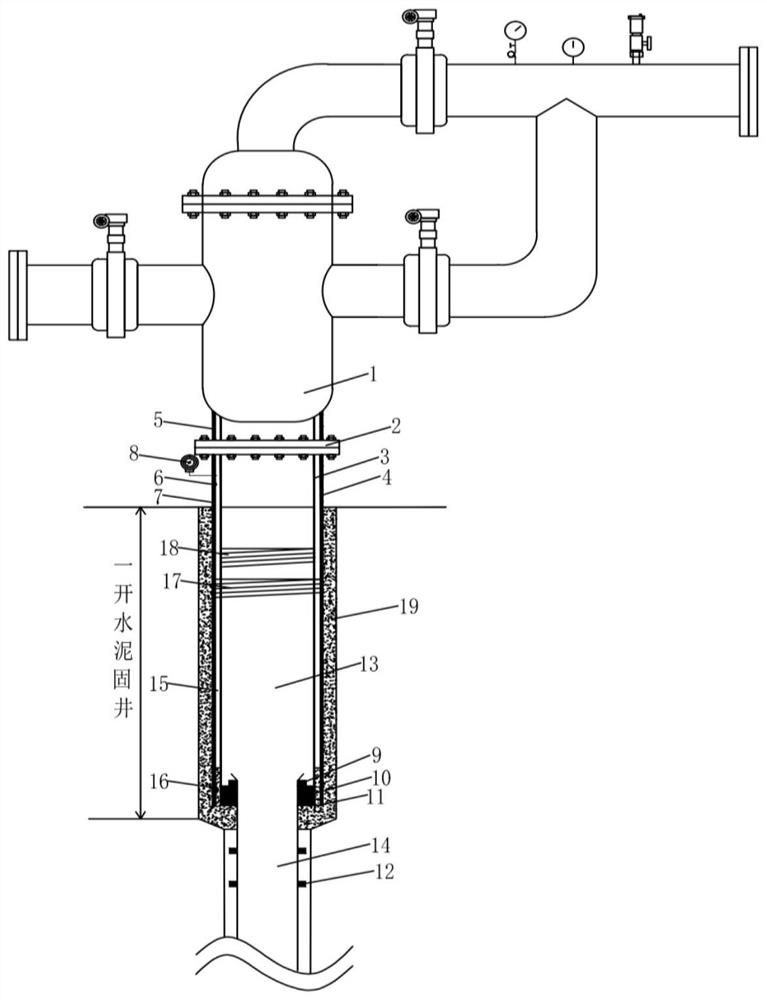

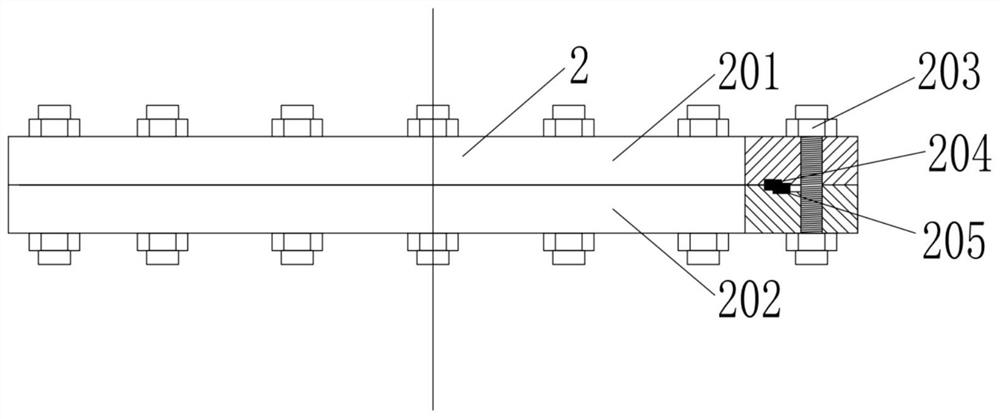

[0049] Such as figure 1 Shown, a kind of hydrothermal type geothermal well-wellbore casing multi-layer thermal insulation structure, comprises inner layer casing 3 and the outer layer casing 4 that is coated with nano airgel layer 5 outside, and described inner layer casing 3 The annular gap between the outer casing 4 and the outer casing 4 is a vacuum interlayer 15, and the outer casing 4 is provided with a vacuum gauge 8 for detecting the vacuum degree of the vacuum interlayer, and the outer casing 4 is provided with a vacuum pumping The hole 6 is reserved for injecting hydrogen absorbing agent into the vacuum interlayer 15, the bottom of the vacuum interlayer 15 is provided with a diversion groove 11, and the heat preservation cement 19 enters the inner and outer casing vacuum interlayer 15 from the diversion groove. The heat-retaining cement 19 enters the vacuum interlayer 15 and returns to a height of 70m to seal the bottom of the inner casing 3 and the outer casing 4 to ...

Embodiment 2

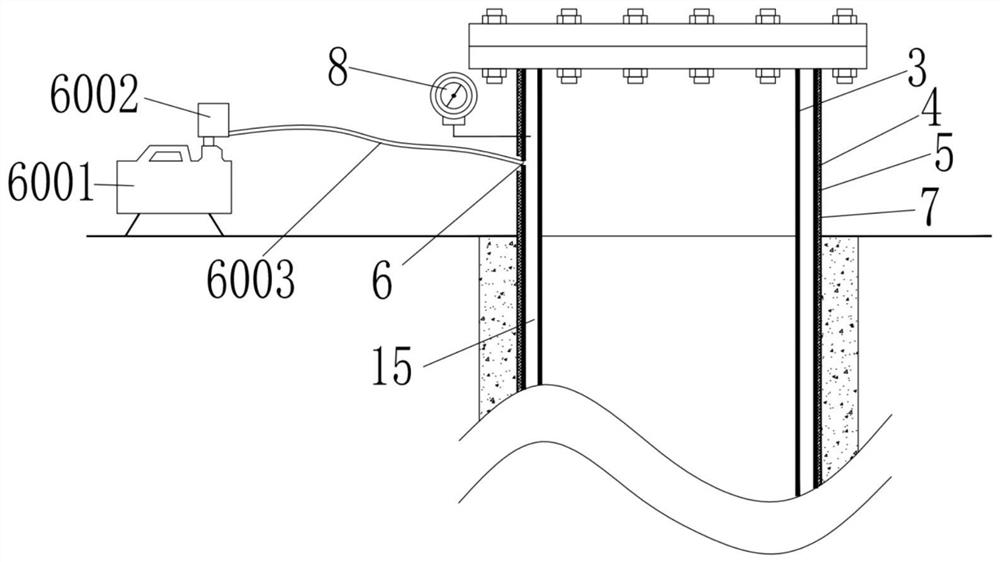

[0060] Such as Figure 4 Shown, a kind of hydrothermal type geothermal well-open wellbore casing multi-layer thermal insulation structure implementation process, comprises the following steps:

[0061] Step 100, as soon as the geothermal well is started and drilled, the inner casing and the outer casing with the nano-airgel layer pre-coated on the outer layer and the suspension device are sequentially lowered in sections according to the pipe arrangement sequence;

[0062] Step 200, after opening the inner and outer casings and running them down, cement the well with insulating cement, and control the annular space of the inner and outer casings to return to the height of the insulating cement;

[0063] Step 300, put hydrogen absorbing agent in the vacuum interlayer between the inner casing and the outer casing in the first well opening section, vacuumize to reach the standard, and seal the reserved hole;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com