Double-layer efficient energy-saving drying cylinder

A high-efficiency, energy-saving, drying cylinder technology, used in dryers, drying chambers/containers, etc., can solve the problems of uncompetitive products, energy waste, and increased costs for production enterprises, to solve the temperature drop of the cylinder block and reduce production costs. , The effect of saving gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

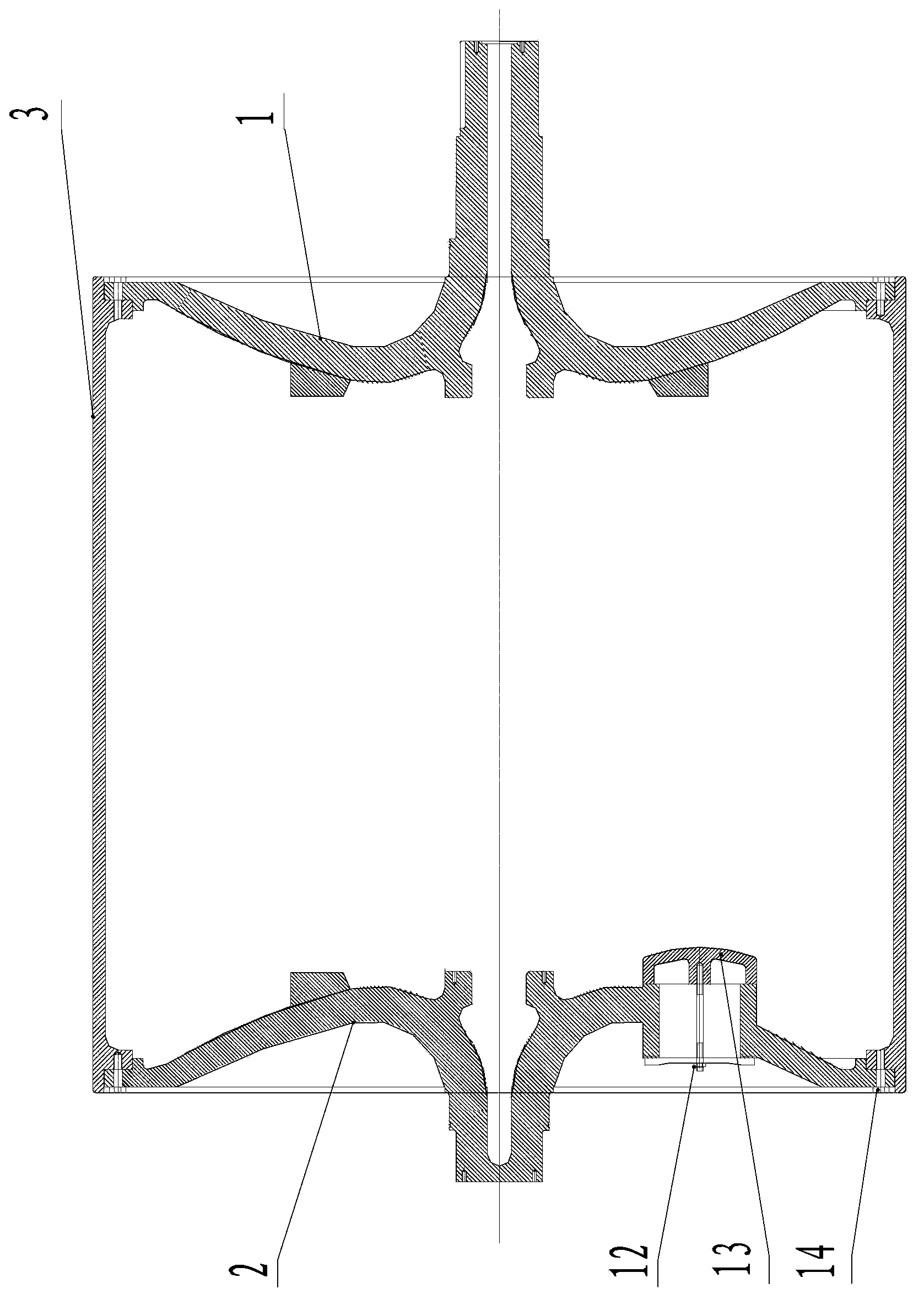

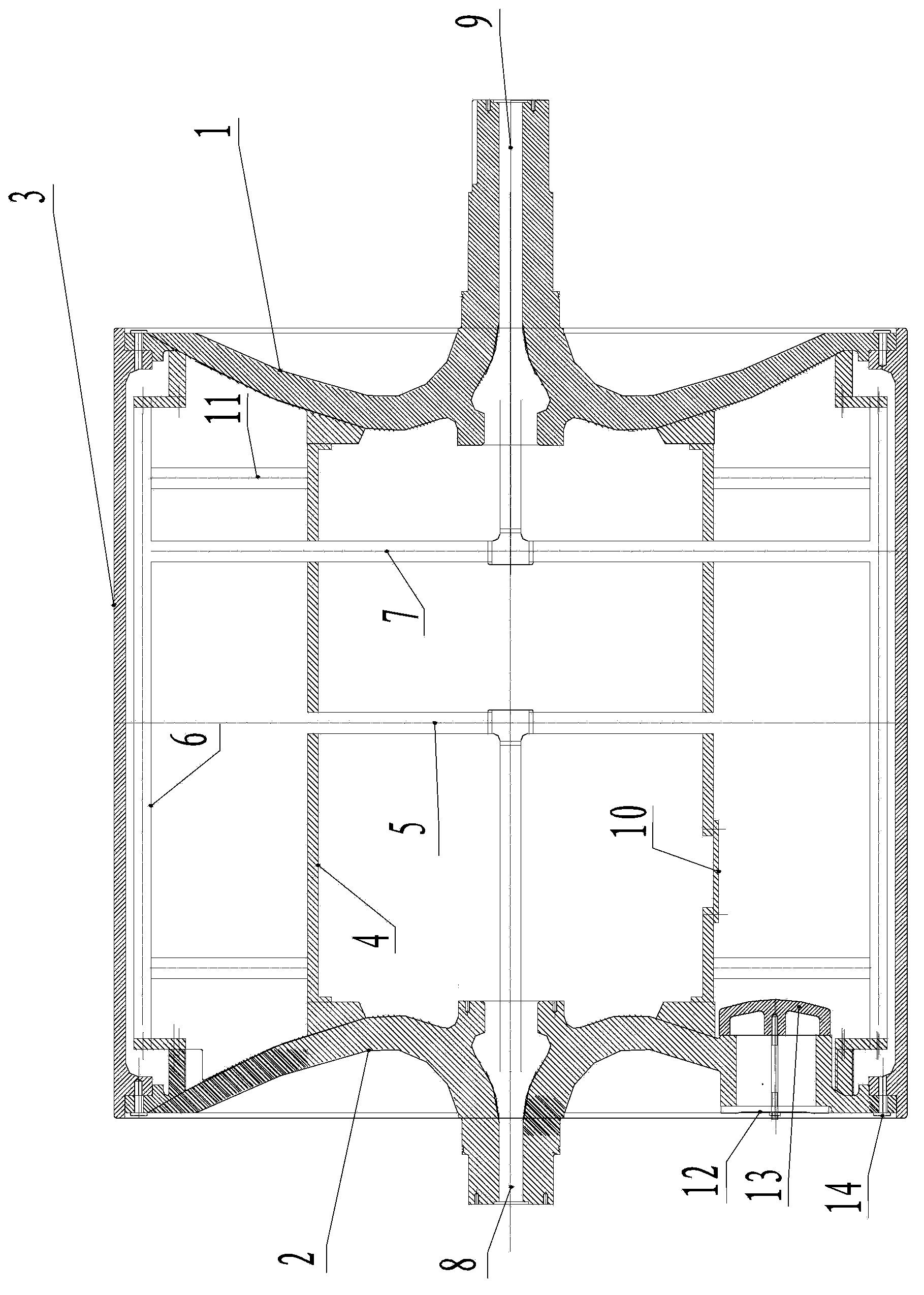

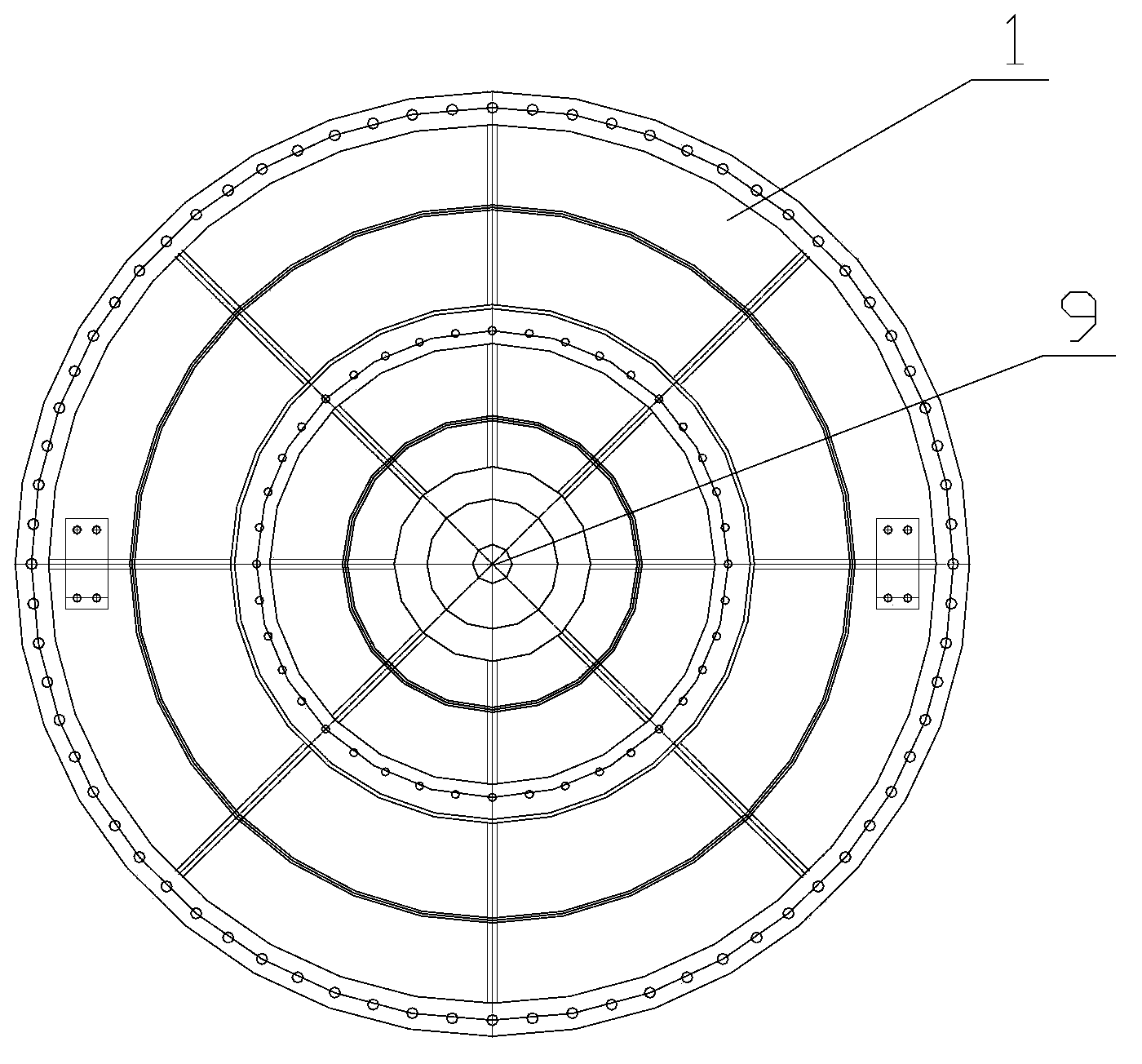

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as Figure 2-10 As shown, the present invention comprises a cylinder barrel 3, a cylinder liner 4, an intake pipe 5, an operation side cylinder cover 2, a transmission side cylinder cover 1, a water suction connecting pipe 7 and a water absorption device 6, wherein the operation side cylinder cover 2 and the transmission side cylinder cover 1 are respectively installed at both ends of the cylinder 3, the cylinder 4 is set inside the cylinder 3 and is coaxial with the cylinder 3, and the two ends of the cylinder 4 are respectively connected to the operating side cylinder cover 2 and the transmission side cylinder cover through the flange The inner wall of 1 is fixedly connected, and the cylinder gall 4 is provided with a cylinder manhole 10, and the cylinder manhole 10 is provided with a cylinder manhole cover for sealing. The operation side cylinder cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com