Rapid switching method for coke oven gas blower

A coke oven gas and blower technology, which is applied to machines/engines, mechanical equipment, non-variable capacity pumps, etc., can solve the problems of negative environmental impact, waste of gas energy, smoke from coke ovens, etc., so as to reduce environmental pollution and reduce The effect of gas loss and fast shutdown speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

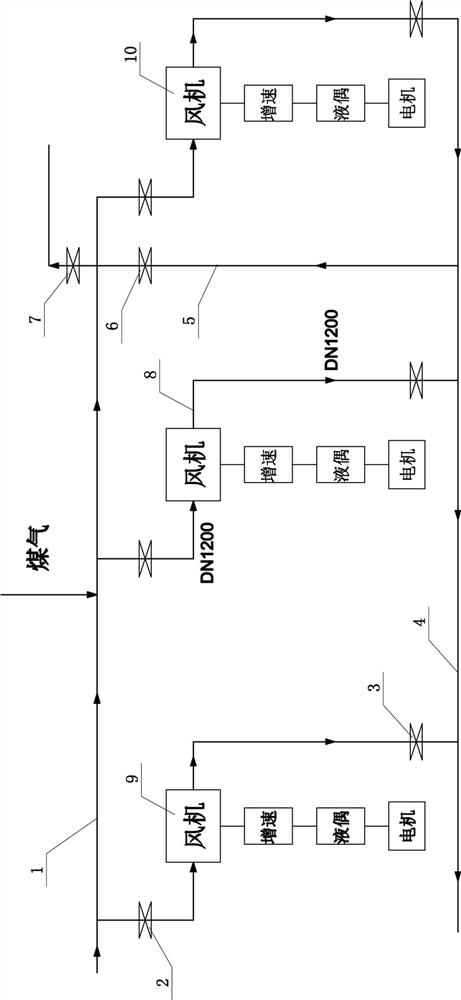

[0019] The present embodiment includes a gas inlet main pipe 1, three branch pipes 8 are arranged in parallel on the gas inlet main pipe 1, and a blower fan is installed on each branch pipe 8, and all fans are D700-211 model gas blowers, whose critical speed is 3520r / min, the air inlet valve 2 is installed at the air inlet of the fan on the branch pipe 8, and the air outlet valve 3 is installed at the air outlet. The outlets of all the branch pipes 8 are connected to a main air outlet pipe 4. The machine method includes the following steps:

[0020] 1) In order to avoid the excessive suction force during the reversing process and oxygen entering the gas main pipe, stop the operation of the electric tar catcher and close the valve of the fan drain pipe before the reversing starts;

[0021] 2) Start one of the spare fans 10, and open its air inlet valve 100mm at the same time to prevent the equipment from being damaged due to atmospheric pressure due to excessive suction. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com