Gas control system for stripping machine

A technology of control system and strip machine, which is applied in the control of combustion, combustion method, combustion equipment, etc., can solve the problems of difficulty in labor, difficulty in controlling the heating temperature of charcoal fire, pollution of smoke and dust, etc., and achieve the effect of reducing gas consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

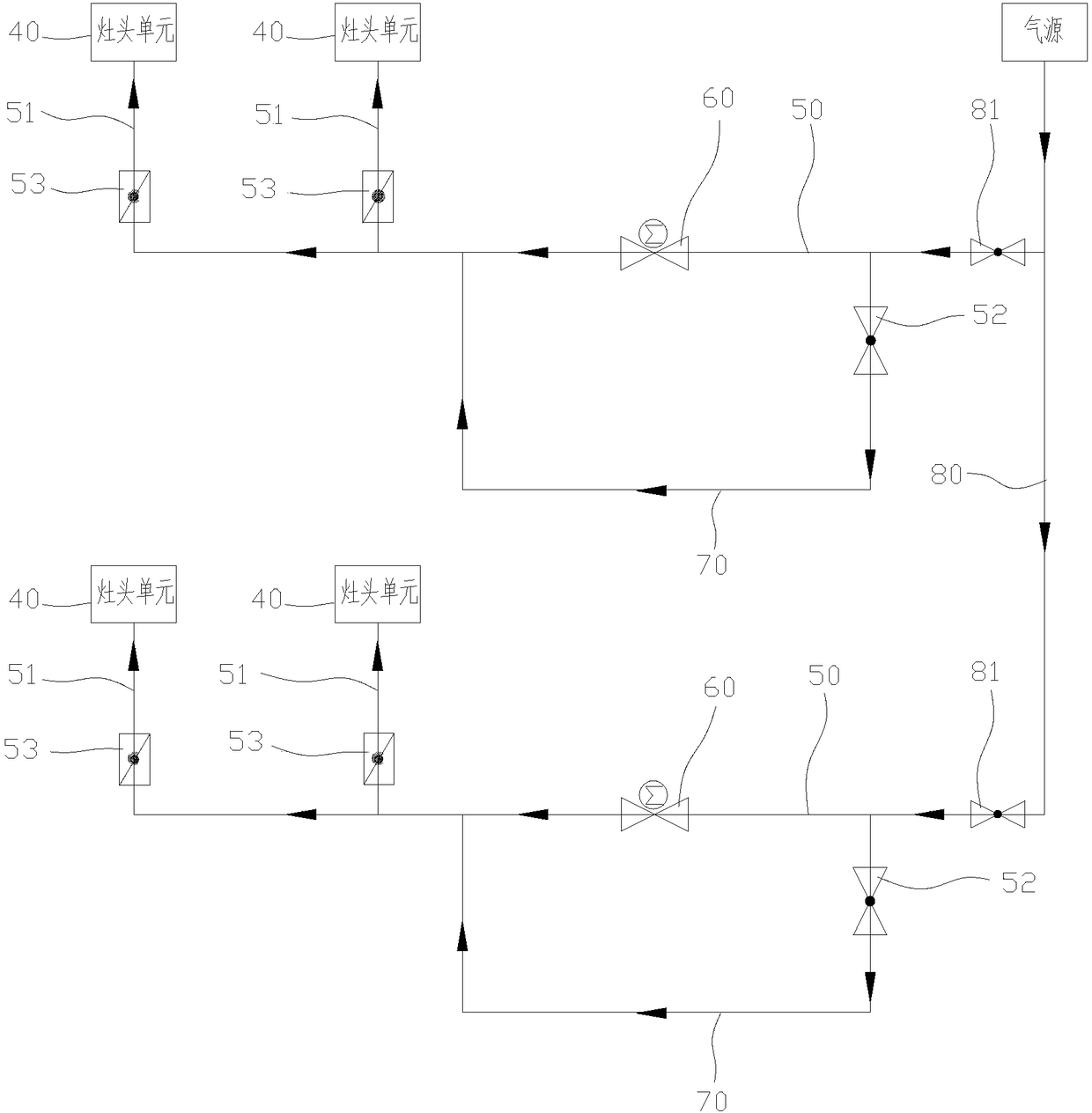

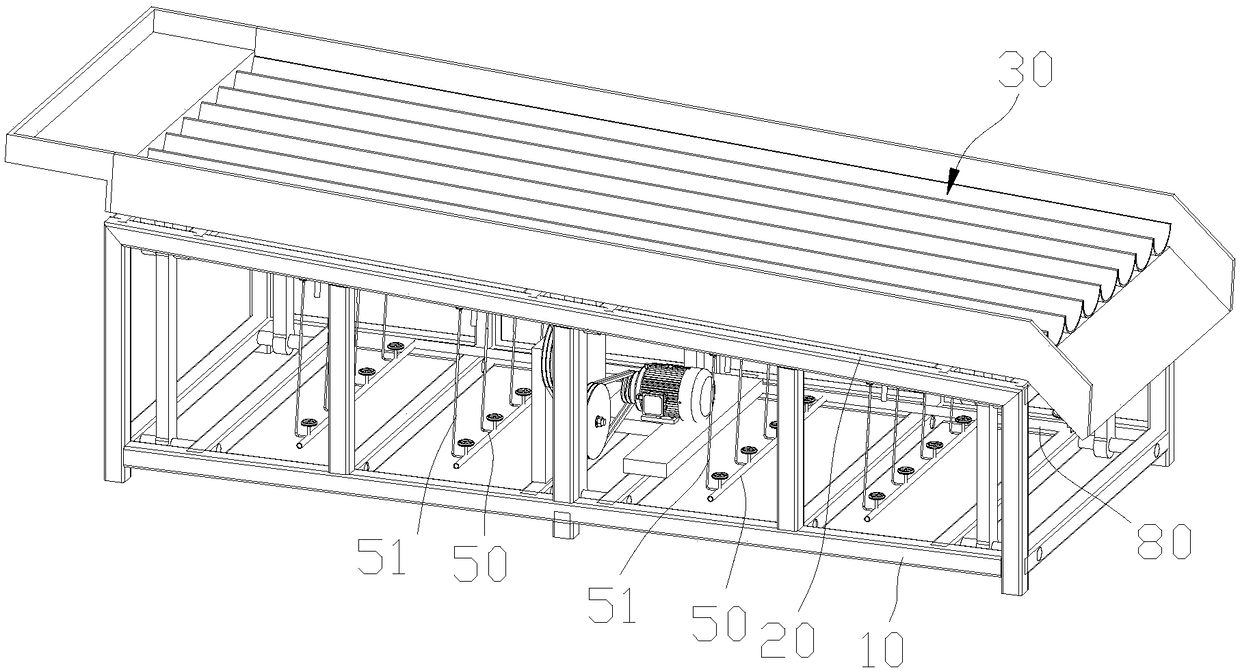

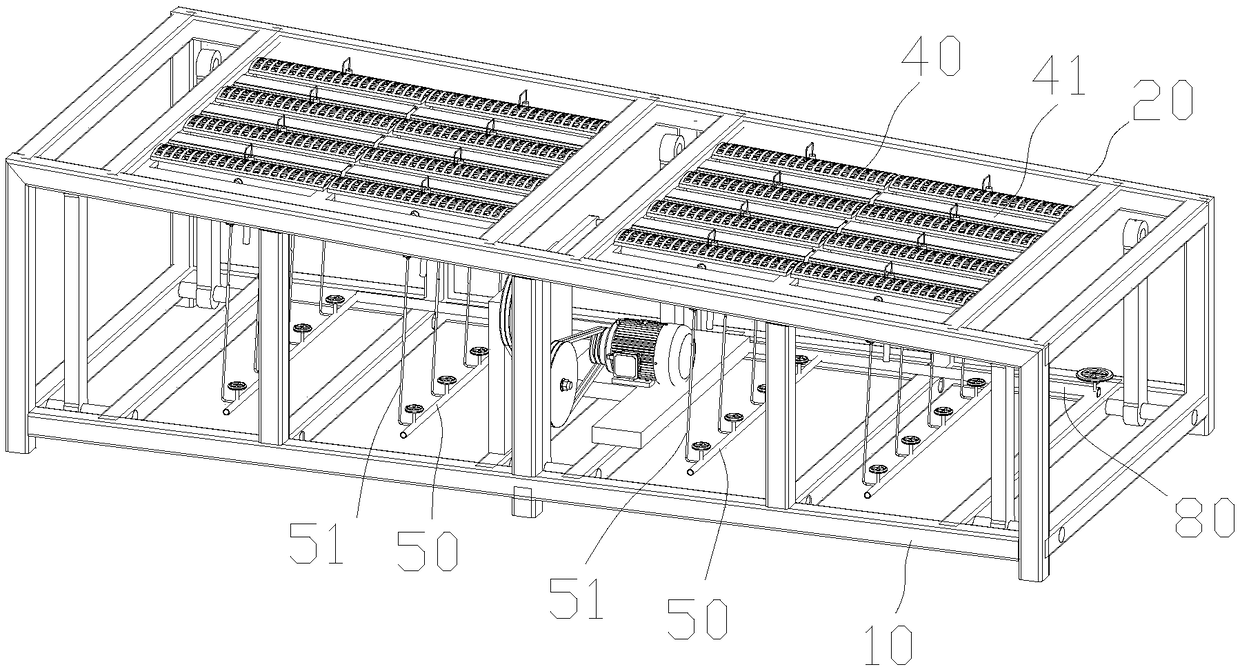

[0010] A kind of gas control system of a rationalizer, comprising a frame 10, a tank support 20 is arranged on the frame 10, a tank 30 is arranged on the tank support 20, a driving mechanism arranged on the frame 10 drives the tank support 20 and The tank 30 on it reciprocates vertically to the direction of the tank length, the cooker unit 40 is evenly arranged under the bottom of the tank 30, the gas collection box 41 of the cooker unit 40 is connected with the gas pipe 51 arranged from bottom to top, The lower end of the gas pipe 51 is connected to the gas branch pipe 50, and the gas branch pipe 50 at the upstream position where the gas pipe 51 is connected to the gas branch pipe 50 is provided with a valve 60. Between the bypass air pipe 70 and the communicating position of the gas branch pipe 50 .

[0011] The above scheme adopts the heating method of gas as the heat source. After the gas enters the gas branch pipe 50, the gas is supplied to the stove unit 40 through the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com