Molten aluminum distribution device and molten aluminum distribution system

A technology for matching soup and soup spoon, which is applied in the field of soup mixing device and soup mixing system, and can solve the problems of loss of molten aluminum, easy splashing around, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

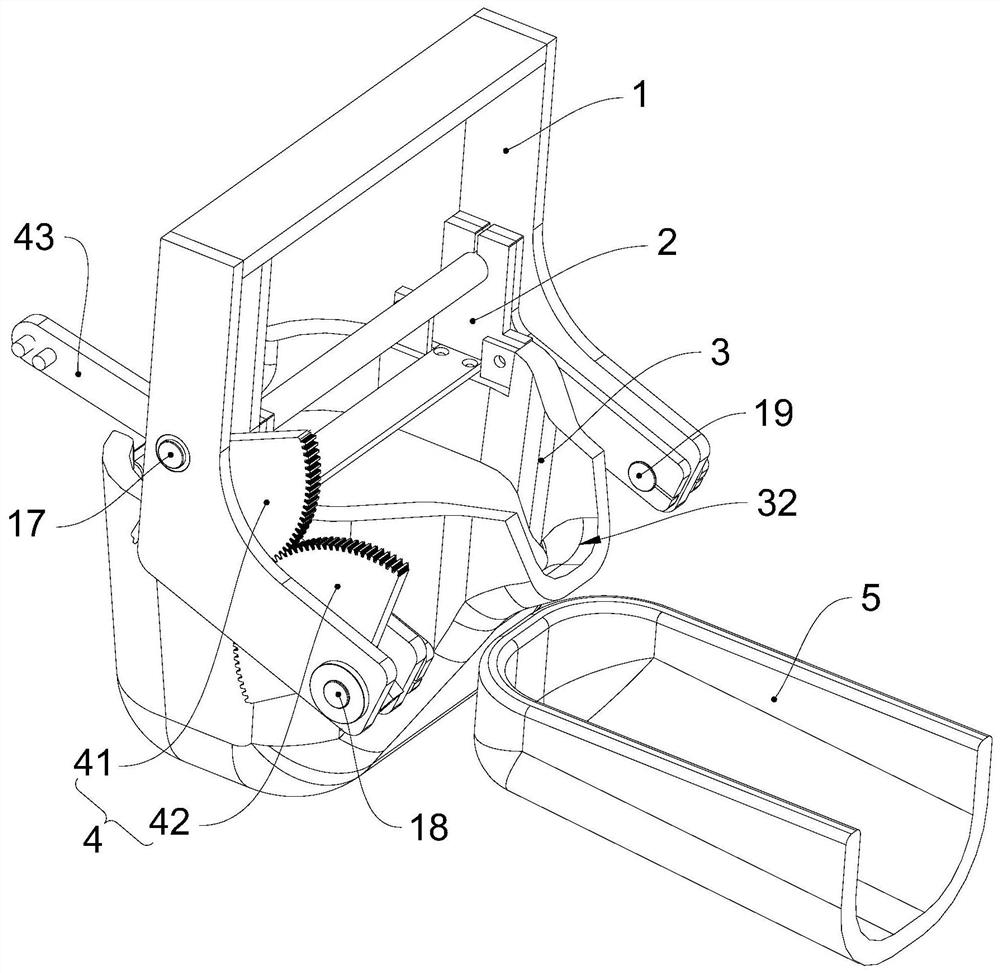

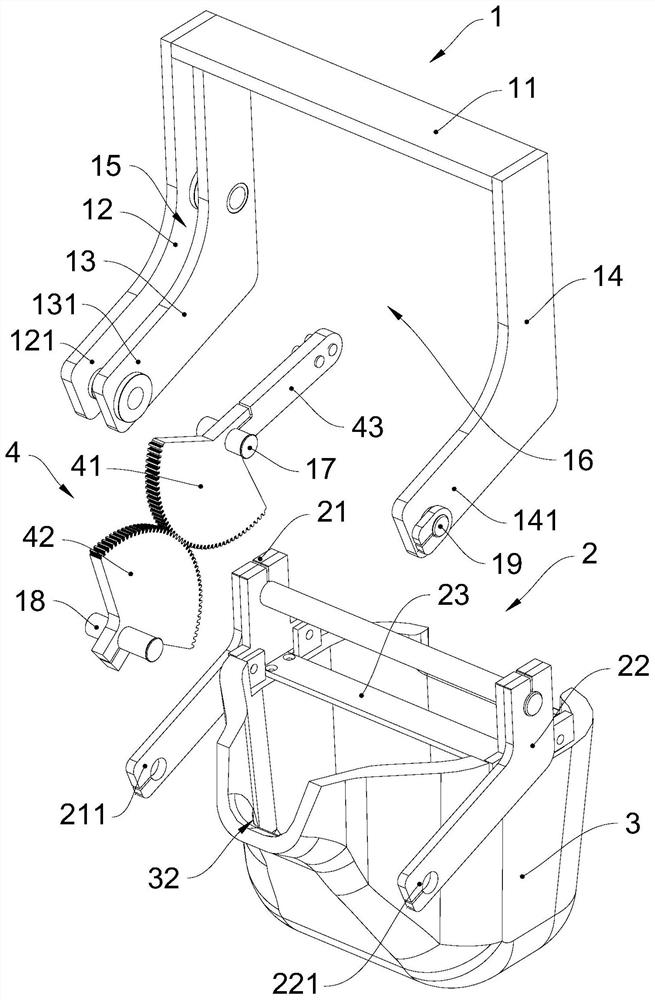

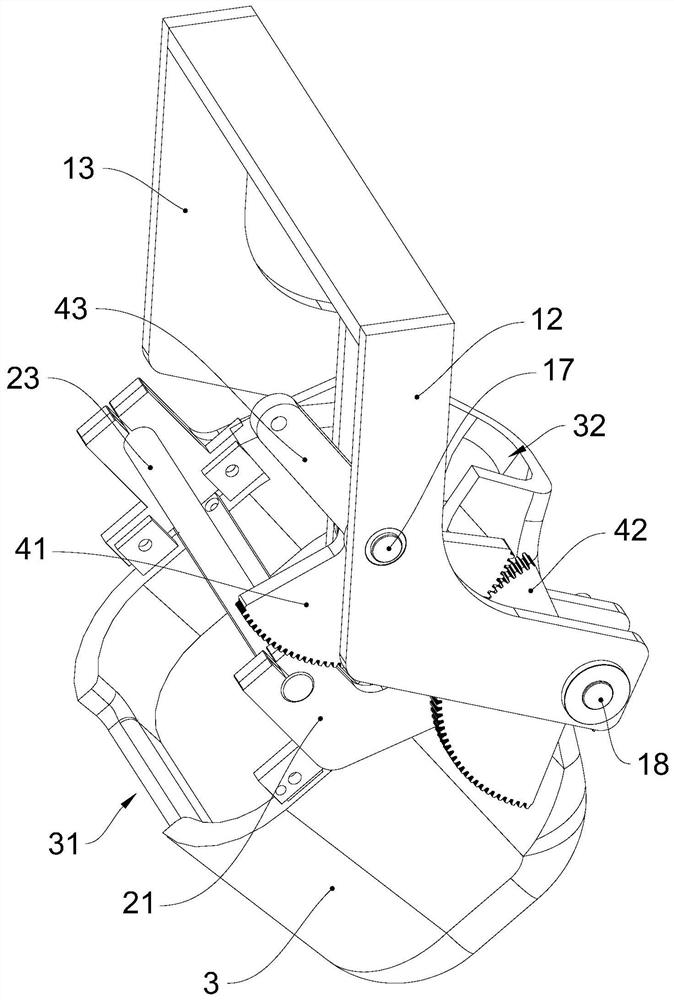

[0030] Embodiment of soup making device

[0031] see figure 1 with figure 2 , The soup preparation device provided in this embodiment is mainly used to transport the molten aluminum in the holding furnace and pour it into the receiving tank 5 connected with the die-casting machine. The soup dispensing device comprises a mounting frame 1, a turret 2, a soup ladle 3 and a rotating drive assembly 4, the turret 2 is rotatably arranged on the mounting frame 1, the middle part of the soup ladle 3 is fixedly connected with the turret 2, and rotates The driving assembly 4 is arranged on the mounting frame 1 and is located on one side of the turret 2 , and the rotating driving assembly 4 drives the turret 2 and the soup spoon 3 to rotate forward and reverse relative to the mounting frame 1 together. exist figure 1 In the middle, the forward rotation means that the spoon 3 rotates clockwise, and the spoon 3 pours the material at this time; the reverse rotation means that the spoon 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com