Spiral blade unimpeded type vertical-axis wind turbine wind wheel

A helical, generator technology, applied in wind turbines, wind turbines at right angles to the wind direction, wind turbine combinations, etc. High utilization rate, small rotation space, and no noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

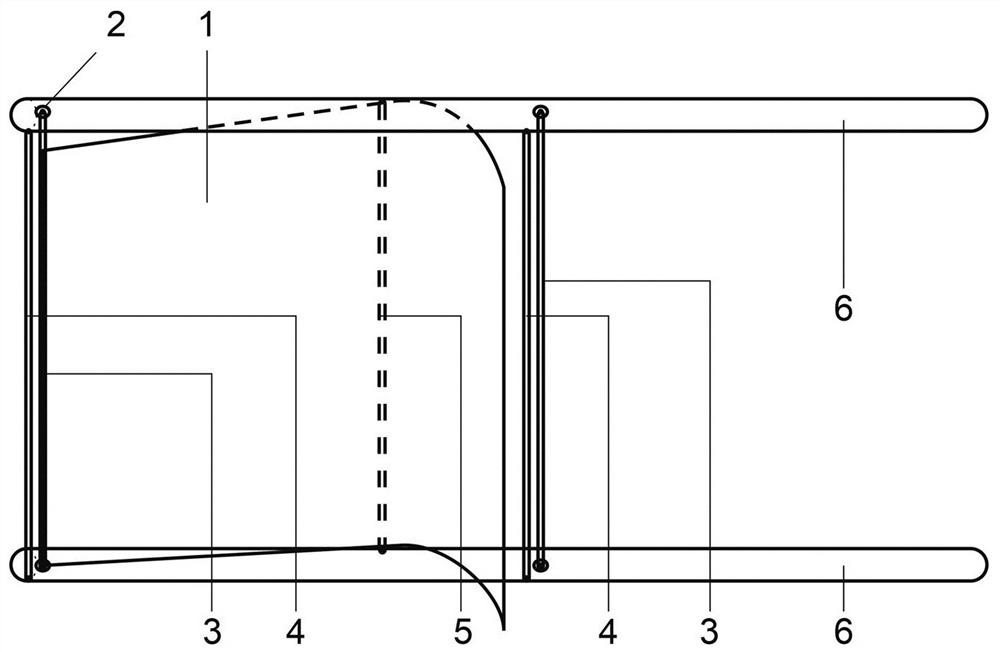

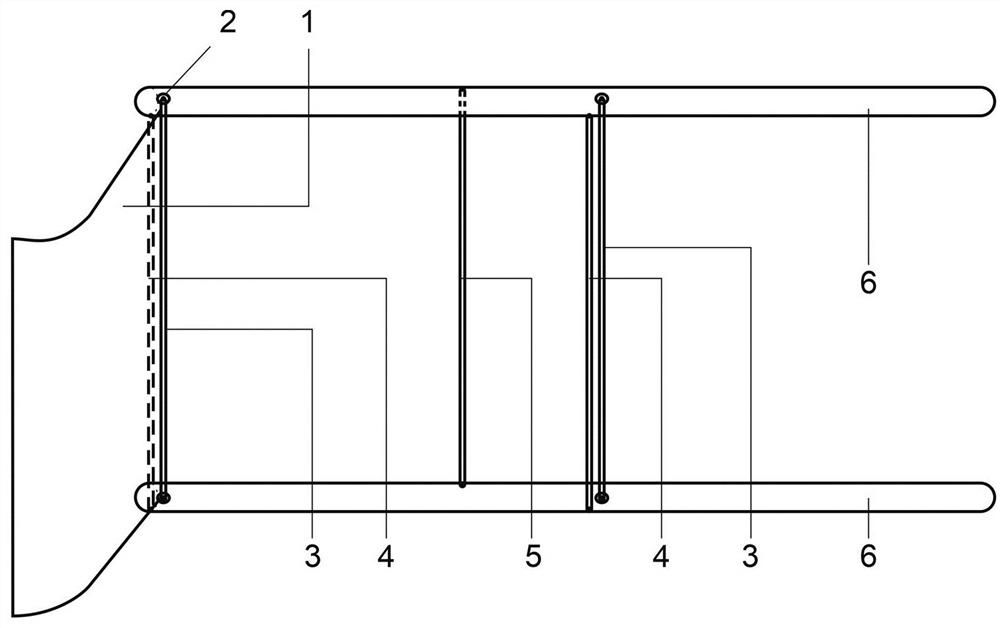

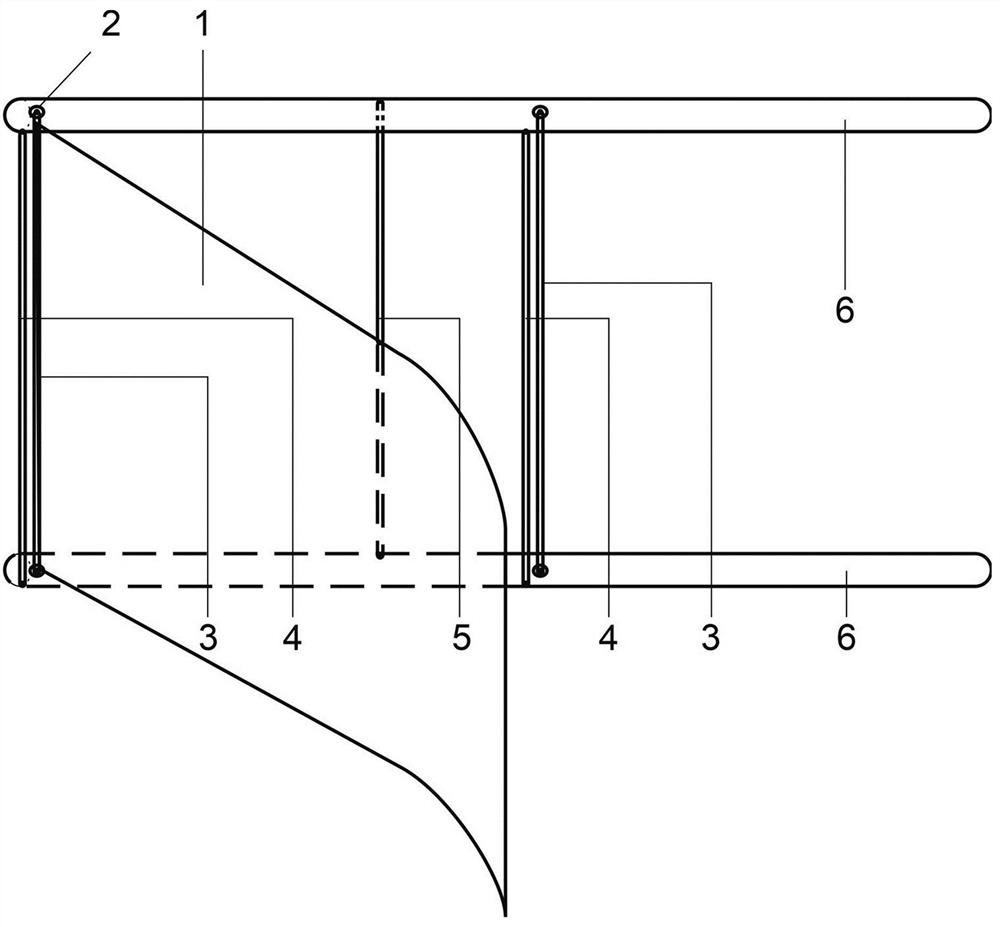

[0018] The leaf door 1 has three states under the impact of the external wind: when the external wind starts to impact the inner arc surface of the leaf door 1, the leaf door 1 is subjected to the impact force and rotates relative to the cantilever support frame until it is blocked by the outer bar. 5 Blocking no longer rotates to its leeward direction, forming the leaf door in an outwardly tilted closed state ( figure 1 ); when the leaf door 1 rotates with the cantilever support frame to the outer arc surface to face the wind, the outside wind blows the leaf door 1 open until it is blocked by the inner stop rod 4 and forms the fully open state of the leaf door 1 ( figure 2 ), so that the blade door does not form resistance to the rotation of the main shaft of the wind turbine; when the downwind and headwind are switched, the blade door 1 presents ( image 3 )state. The leaf door 1 can be opened and closed relative to the plane where the cantilever support frame 6 and the ge...

Embodiment 2

[0029] The number of blade door shafts 3 of the combined fan blades 7 is the same as that of the blade doors 1, and one blade door 1 corresponds to one blade door shaft 3. The number of blade doors 1 of the type fan blade 7 can be set as two to five, and the blade door shafts are arranged sequentially along the extension direction of the cantilever support frame to the generator main shaft 8 from the free end of the cantilever support frame (6); The vane door 1 is in the shape of an "integrated semi-arc rectangle", one end is set in a flat plate shape, and the other end is set in an arc-shaped plate shape. One end of the shape is fixed on the blade door shaft, the inner arc surface of the arc plate end is set against the wind, and the central angle of the inner arc surface of the arc plate end does not exceed 90°; the blade door 1 is impacted by the external wind Next, there are three states: when the external wind starts to impact the inner arc surface of the leaf door 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com