A kind of 3lpe coating equipment for hot-simmering bent pipe coating

A kind of hot simmering bending and wrapping technology, applied in the direction of coating, etc., to achieve the effect of wide range of motion, avoiding interference and large inner diameter of cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1

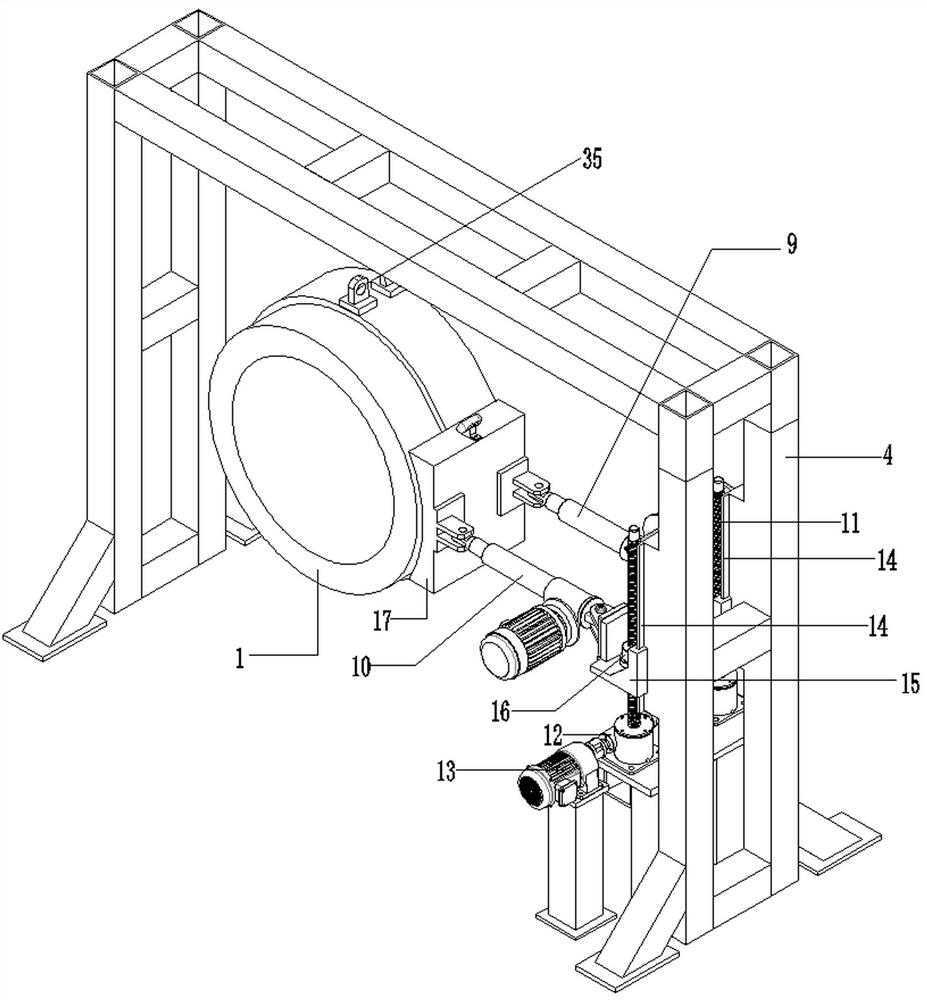

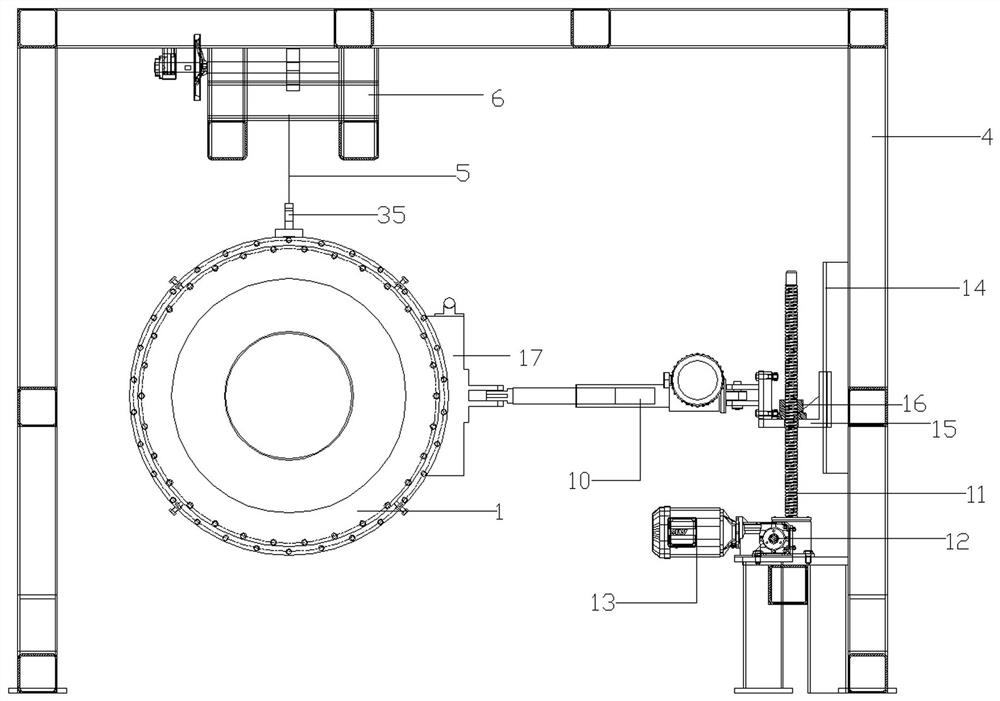

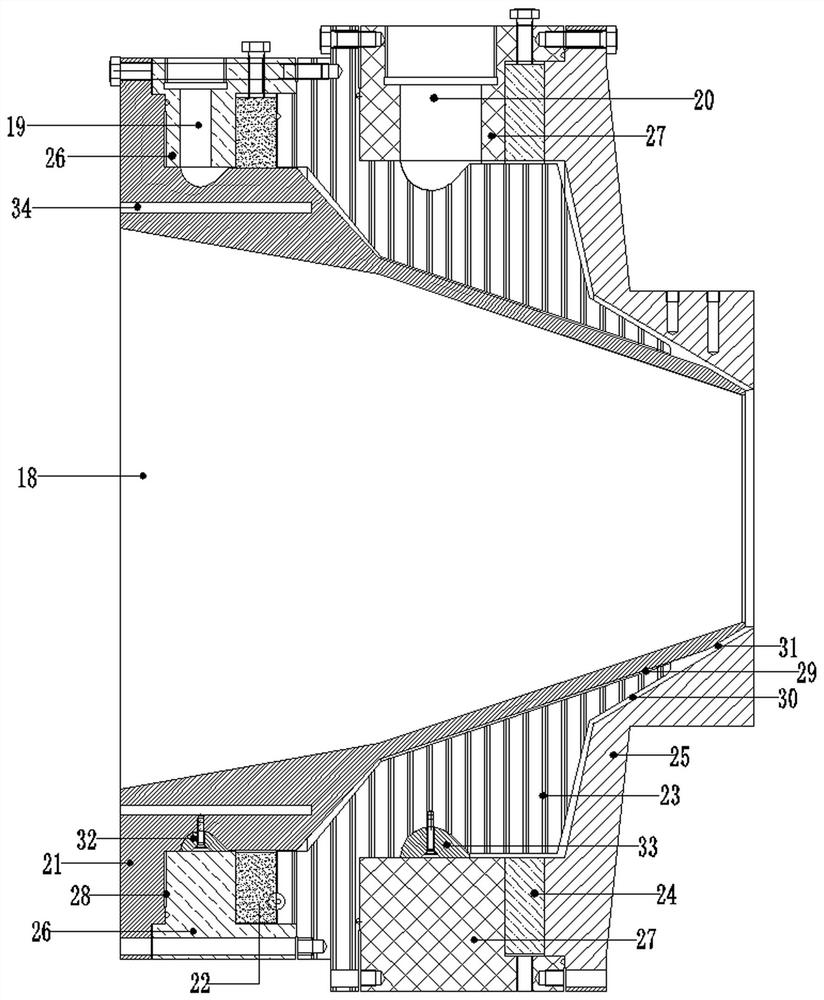

[0041] As the basic embodiment of the present invention, the present invention includes a hot-simmering elbow-coated 3LPE coating equipment, which includes a mold body 1 and a driving device for driving the angle adjustment of the mold body 1 . The mold body 1 encloses and forms an annular trumpet-shaped cavity 18 , and the inner diameter of the cavity 18 at the head of the mold body 1 is smaller than the inner diameter of the cavity 18 at the tail. The mold body 1 is provided with an annular AD flow channel 29, an annular PE flow channel 30, a discharge chamber 31 for merging the PE flow channel 30 and the AD flow channel 29, and a valve for adjusting the width of the AD flow channel 29. An adjustment ring A 22 and an adjustment ring B 24 for adjusting the width of the PE channel 30 . Both the adjustment ring A 22 and the adjustment ring B 24 are provided with several bolts in the radial direction, through the adjustment of the bolts, the outer widths of t...

Embodiment 2

[0043] Example 2

[0044] As a preferred embodiment of the present invention, the present invention includes a 3LPE coating equipment for hot-simmering bent pipe, which includes a mold body 1 and a driving device for driving the angle adjustment of the mold body 1 . The mold body 1 encloses and forms an annular trumpet-shaped cavity 18 , and the inner diameter of the cavity 18 at the head of the mold body 1 is smaller than the inner diameter of the cavity 18 at the tail. The mold body 1 is provided with an annular AD flow channel 29, an annular PE flow channel 30, a discharge chamber 31 for merging the PE flow channel 30 and the AD flow channel 29, and a valve for adjusting the width of the AD flow channel 29. An adjustment ring A 22 and an adjustment ring B 24 for adjusting the width of the PE channel 30 . The other ends of the AD flow channel 29 and the PE flow channel 30 are respectively connected with the external AD extruder and the PE extruder through heating hoses.

...

Embodiment 3

[0049] Example 3

[0050] As another preferred embodiment of the present invention, the present invention includes a 3LPE coating equipment for hot-simmering bent pipe, which includes a mold body 1 and a driving device for driving the angle adjustment of the mold body 1 . The mold body 1 encloses and forms an annular trumpet-shaped cavity 18 , and the inner diameter of the cavity 18 at the head of the mold body 1 is smaller than the inner diameter of the cavity 18 at the tail. Die body 1 is provided with AD feed inlet 19 and PE feed inlet 20, mandrel A 21, adjustment ring A 22, mandrel B 23, adjustment ring B 24 and die 25, described mandrel A 21 and core An annular AD flow channel 29 is formed between the dies B 23 , an annular PE flow channel 30 is formed between the core die B 23 and the die 25 , and a discharge chamber 31 is formed between the core die A 21 and the die 25 . The AD flow channel 29 is located inside the PE flow channel 30, the AD flow channel 29 communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com