Bottom-powder-spraying molten steel refining device with heating function

A heating device and powder spraying technology, applied in the field of iron and steel refining, can solve the problems of low production efficiency of the molten steel temperature drop and ladle furnace refining technology, and achieve the effects of promoting the development of automation, reducing the labor of workers and increasing the production output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

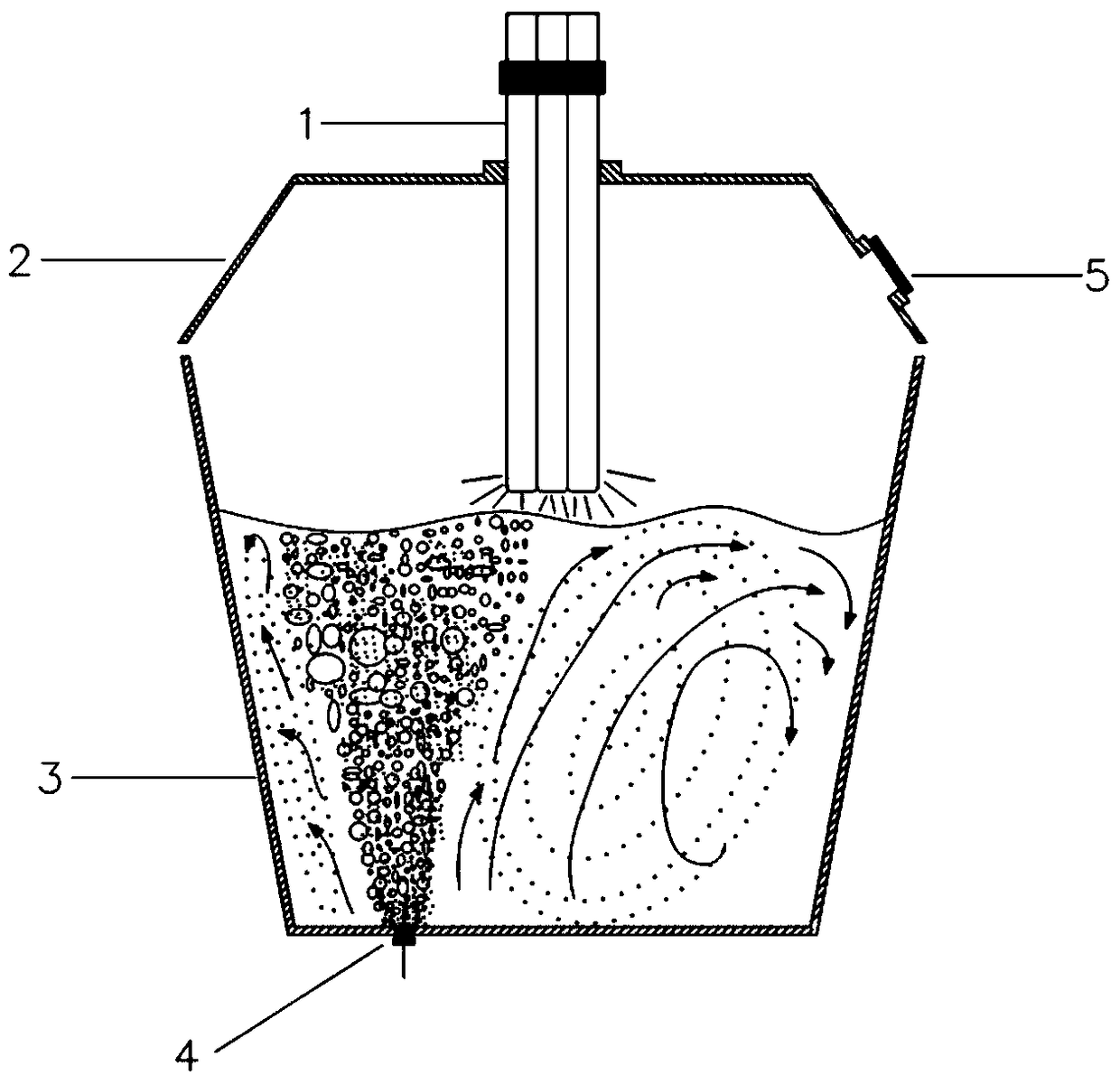

[0032] Such as figure 1 Shown is a bottom spray powder refining molten steel device with heating function of the present invention, including: a ladle for refining molten steel, a heating device for heating the ladle, and a gas and powder for passing into the ladle The powder spraying device 4; the heating device is set inside the ladle, the upper part of the molten steel, and the powder spraying device 4 is set at the bottom of the ladle. The heating device in this embodiment includes three heating electrodes 1, and the heating electrodes 1 pass through the water-cooled furnace cover 2 through the electrode holes on the water-cooled furnace cover 2 to enter the interior of the ladle.

[0033] The ladle includes a ladle body 3 and a water-cooled furnace cover 2. The radius of the bottom of the ladle body 3 is R; the water-cooled furnace cover 2 is arranged above the ladle body 3; the water-cooled furnace cover 2 is provided with an observation hole 5 for observing the inside of th...

Embodiment 2

[0041] When the device for refining molten steel of the present invention is used for refining molten steel, the specific process is as follows:

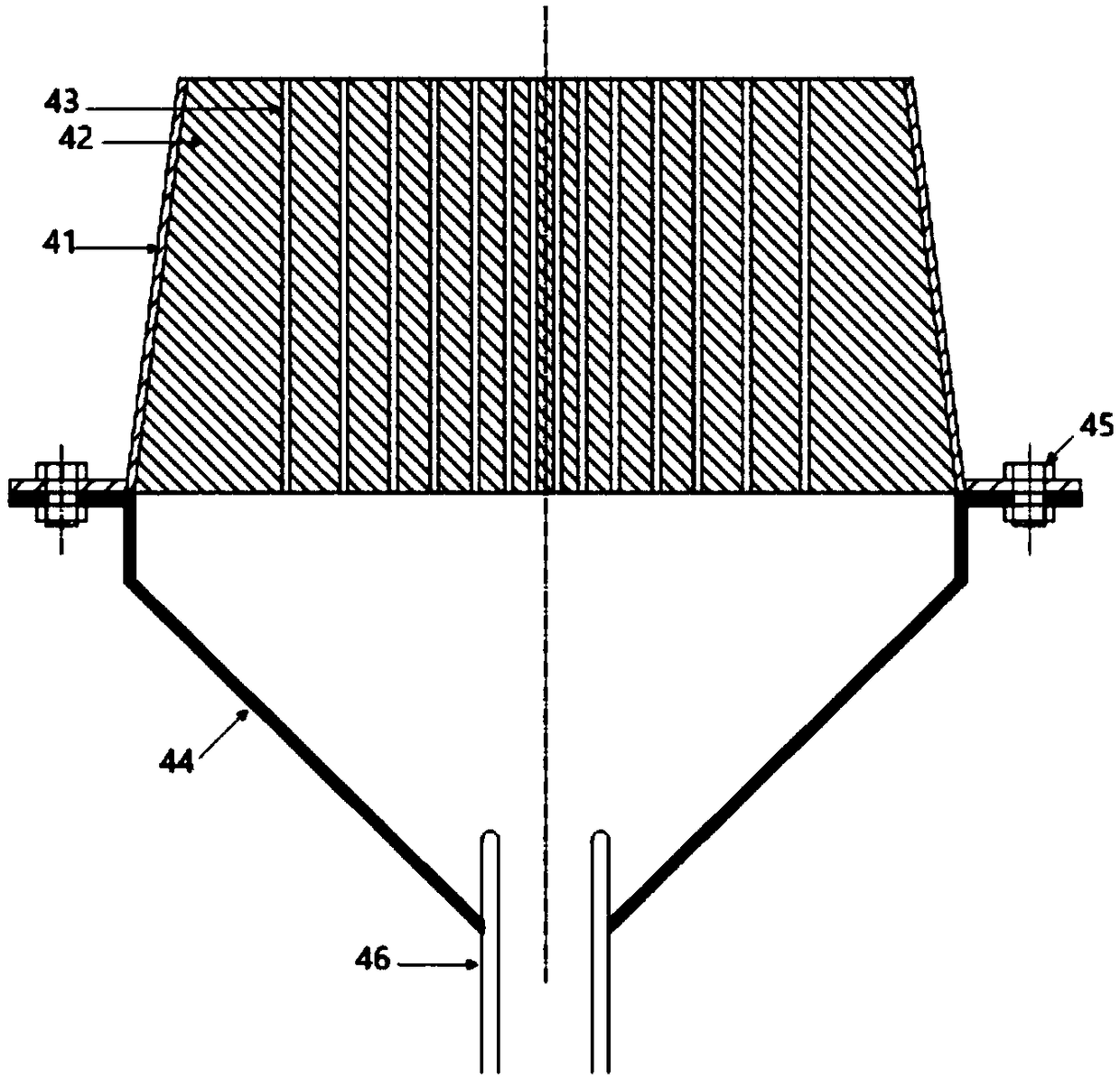

[0042] First, after installing the device for refining molten steel on the ladle car, connect the powder spraying system to the accumulator 44 through the quick plug 46. The powder spraying system adopts the powder spraying system of the traditional ladle furnace heating and refining process, and the powder spraying is turned on The gas valve of the system adjusts the argon flow into the ladle body 3, lowers the water-cooled furnace cover 2, and adjusts the input current and voltage according to the measured temperature and the requirements of the steel type to ensure that the heating electrode 1 passes through the water-cooled furnace cover 2. The hole of the electrode penetrates the water-cooled furnace cover 2 and is suspended on the molten steel surface by 100mm-120mm, and the heating electrode 1 is energized to heat the ladle body ...

Embodiment 3

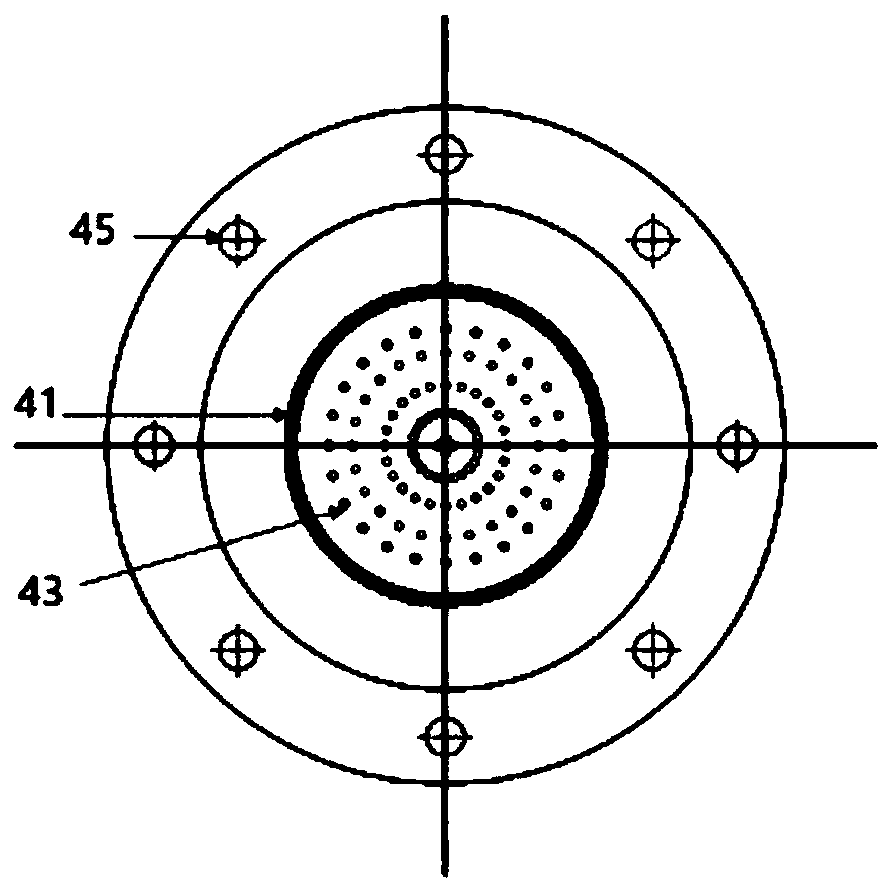

[0046] This embodiment adopts figure 1 The shown device for refining molten steel performs molten steel refining, the number of powder spraying devices 4 in this embodiment is one, such as Figure 4 Shown is a schematic diagram of the distribution of a powder spraying device according to an embodiment of the present invention. The powder spraying device 4 is arranged in an area with a radius of 0.5R at the bottom of the ladle body 3, and the center of this area is the center of the bottom of the ladle body 3.

[0047] In this embodiment, the powder spraying element body 42 is a truncated cone-shaped straight cylinder type air-permeable brick. The maximum diameter of the truncated cone-shaped straight cylinder ventilating brick is 120mm, the diameter of the holes 43 in the truncated cone-shaped straight cylinder ventilating brick is 0.2mm;

[0048] In this embodiment, passivated lime is used as the powder, the particle size of the powder is 200-600 mesh, the pressure of dry argon is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com