Patents

Literature

31results about How to "Reduce worker labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

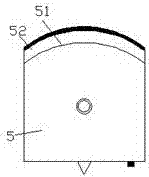

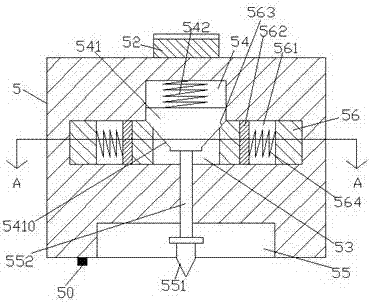

Peanut planting device

InactiveCN107750719AReduce worker laborReduce labor costsCultivating equipmentsReceptacle cultivationCropArchitectural engineering

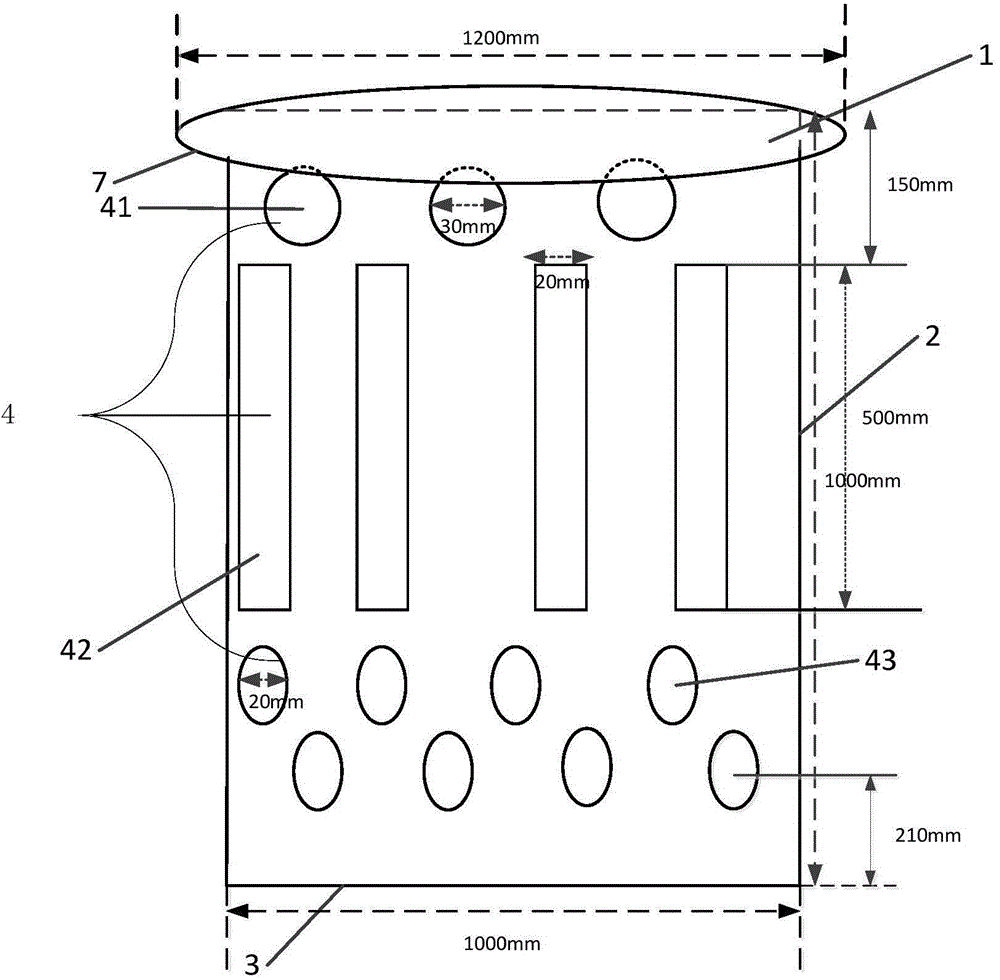

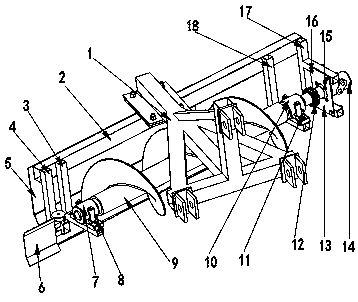

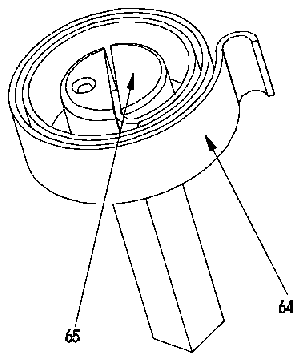

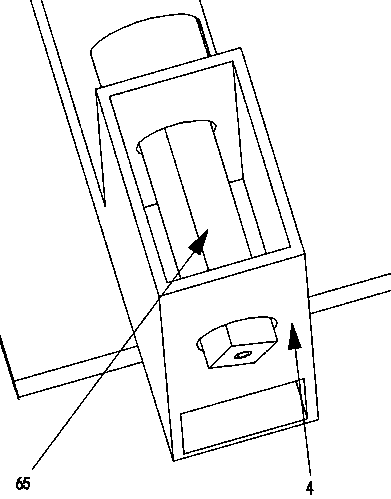

The invention relates to the field of crop planting, in particular to a peanut planting device. The peanut planting device comprises an inner cylinder and an outer cylinder, wherein the inner cylinderand the outer cylinder are provided with a plurality of through holes respectively; the top of the inner cylinder is provided with a first lifting handle; a stirring shaft is arranged in the inner cylinder; a plurality of stirring blades are arranged on the stirring shaft; a telescopic rod is arranged on the wall of the inner cylinder; a first spring is connected between one end of the stirring shaft and the wall of the inner cylinder; the other end of the stirring shaft is connected with one end of the telescopic rod; the telescopic rod penetrates through the inner cylinder and the other endof the telescopic rod is butted with a baffle; and a pull rope is connected between the baffle and the first lifting handle; an annular first chute and an annular second chute are arranged on the inner wall of the outer cylinder at intervals, the depth of the first chute is greater than that of the second chute; and a connecting groove is arranged on the inner wall of the outer cylinder and connects the first chute and the second chute to form a thread groove. The peanut planting device provided by the invention solves the problem that a planting basket cannot be easily pulled out of soil during harvesting.

Owner:NINGBO SHENYICAO BIO TECH

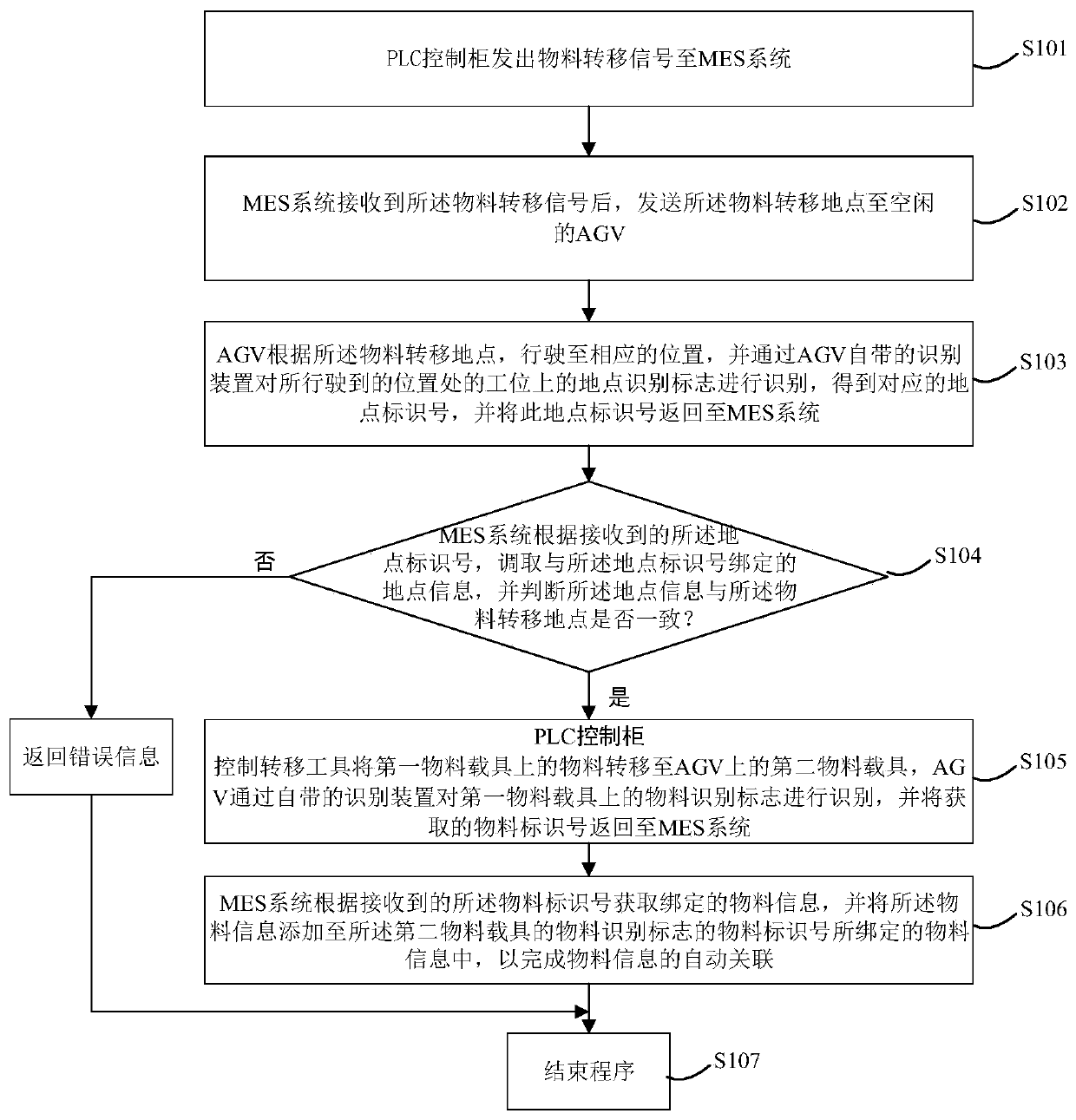

Method for automatically associating MES system with material information

ActiveCN110245731AReduce labor costsReduce worker laborCo-operative working arrangementsElectric/hybrid propulsionMaterial transferIdentification device

The invention provides a method for automatically associating an MES system with the material information, and the method comprises the steps of firstly, enabling a PLC control cabinet to send a material transfer signal to the MES system, enabling the MES system to control an AGV to drive to a corresponding station, and returning a corresponding place identification number to the MES system; then enabling the MES system to judge whether the location information is consistent with the material transfer location or not according to the received location identification number, if yes, using the PLC control cabinet to control the transfer tool to transfer the materials, and meanwhile, using the AGV to identify the material identification mark through the identification device and return the obtained material identification number to the MES; and finally, enabling the MES system to complete the automatic association of the material information according to the received material identification number. The invention has the beneficial effects that the technical scheme provided by the invention can reduce the labor cost, and is suitable for the unmanned factories needing multiple sections of automatic line bodies; the material information is automatically associated systematically in the whole process, the situation of manual error association is avoided, meanwhile, the labor intensity of the workers can be reduced, and the method is perfectly suitable for the high-beat production.

Owner:山东魔方新能源科技有限公司

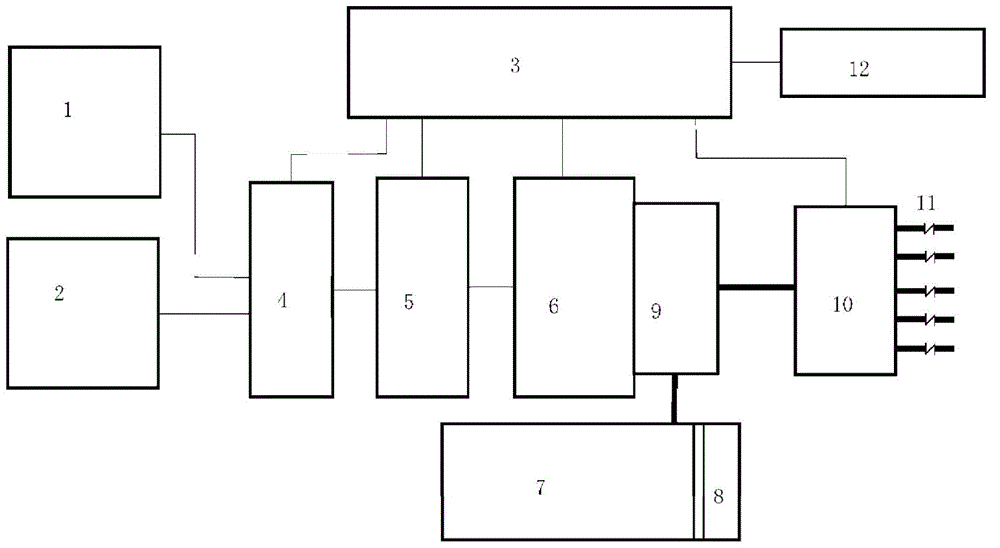

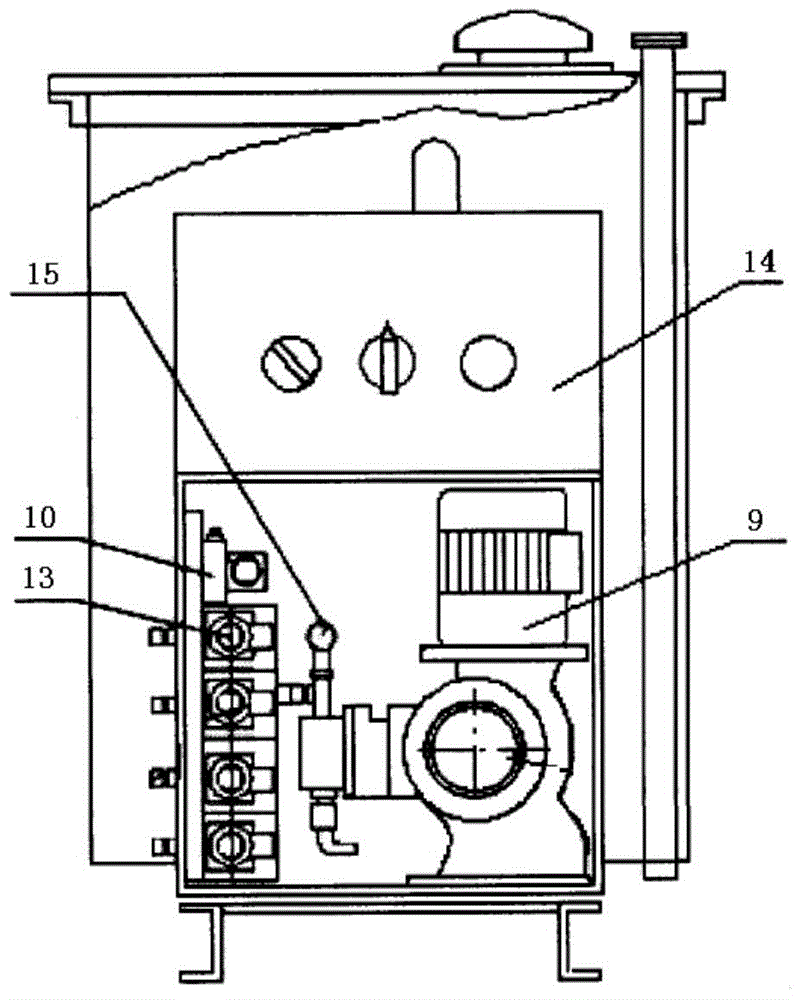

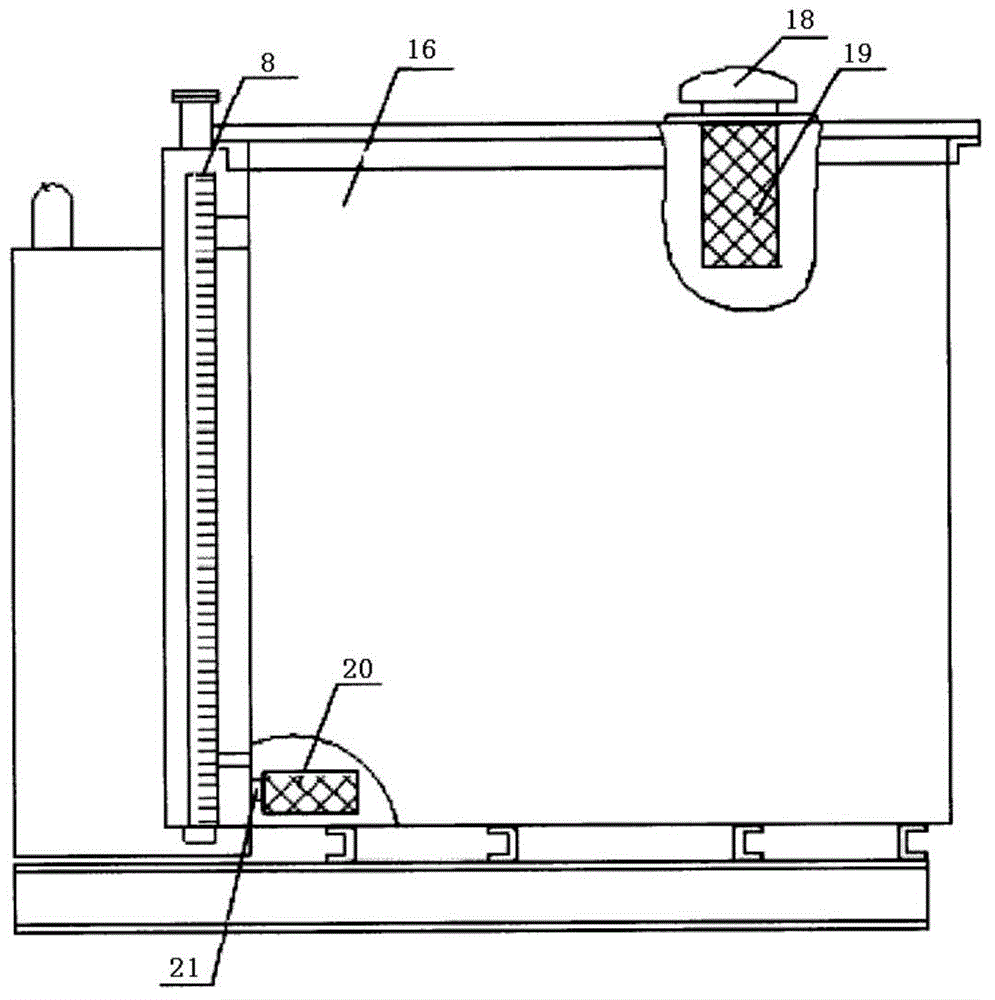

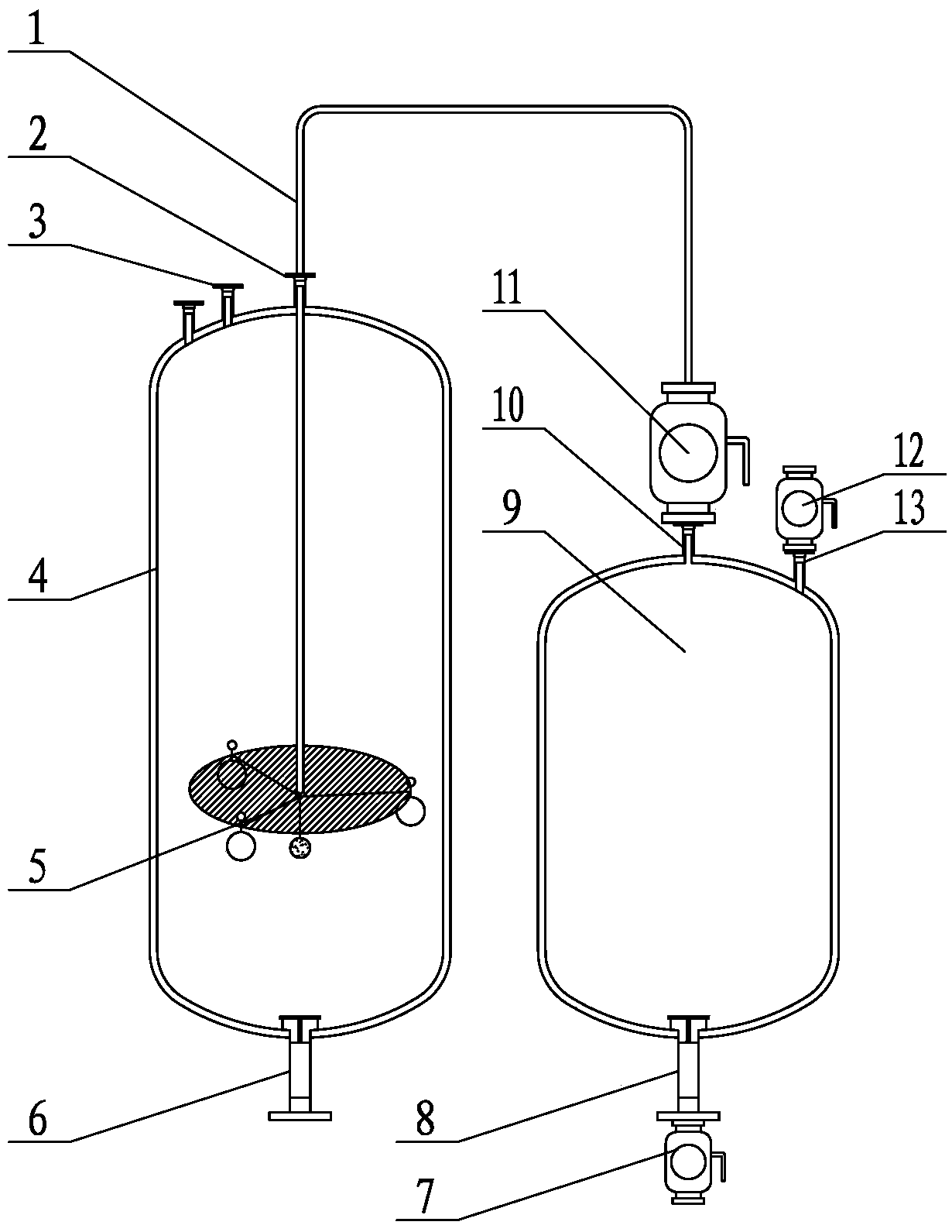

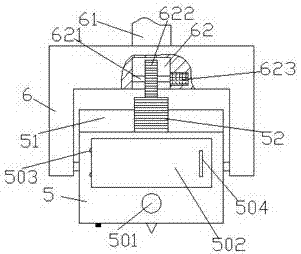

Cluster gas well dosing device and intelligent effusion-diagnosis and effusion quantity-calculation method

ActiveCN104632156AReduce worker laborDosing frequency and dosage are finely controllableSurveyFluid removalCharge controllerPlunger pump

The invention provides a cluster gas well dosing device and an intelligent effusion-diagnosis and effusion quantity-calculation method, and belongs to the technical field of control over dosing and filling capacity. The cluster gas well dosing device is mainly composed of a solar cell, a wind generator, a charge controller, a storage battery pack, a dose storage box, a level meter, a direct current gear motor, a high pressure plunger pump, an intelligent dosing controller, a multi-well gate valve terminal and a wireless communication unit; the dose storage box and the high pressure plunger pump, and the high pressure plunger pump and the wireless communication unit are connected by pipelines; outlets in the back of the multi-well gate valve terminal are connected with check valves; the rest devices are connected by a control circuit, transmission of power and instructions is maintained, the outlet pipeline of the high pressure plunger pump is in parallel connection with the multi-well gate valve terminal, eight solenoid valves are arranged on the multi-well gate valve terminal, and the outlet of each solenoid valve is connected with a dosing opening of each gas well through a pipeline; check valves are connected to the pipelines from the outlets of the solenoid valves to the dosing openings of the gas wells respectively. By adopting the cluster gas well dosing device and the intelligent effusion-diagnosis and effusion quantity-calculation method, the intelligent control and remote operation of dosing on the well site, and automatic collection of dosing data are realized.

Owner:PETROCHINA CO LTD

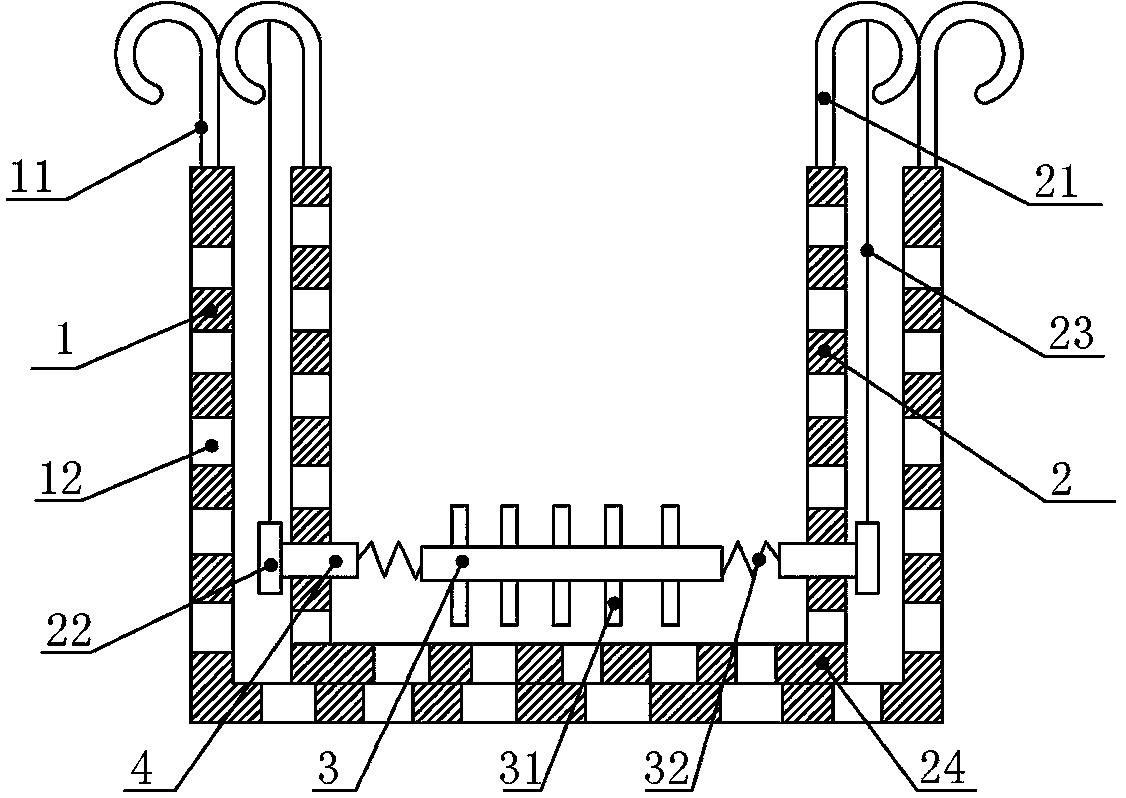

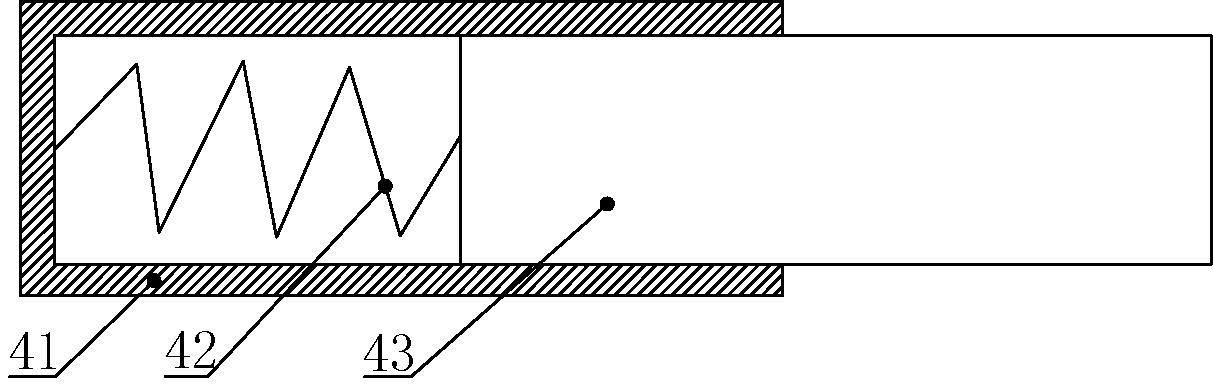

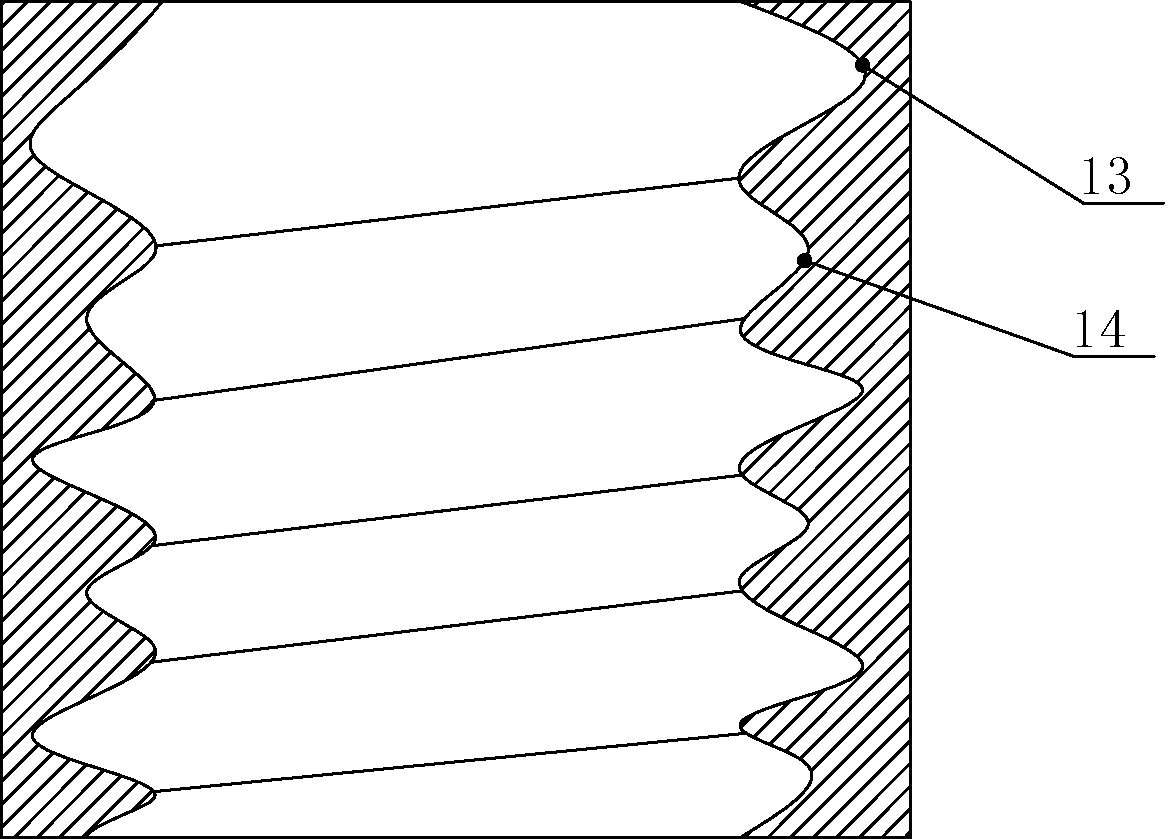

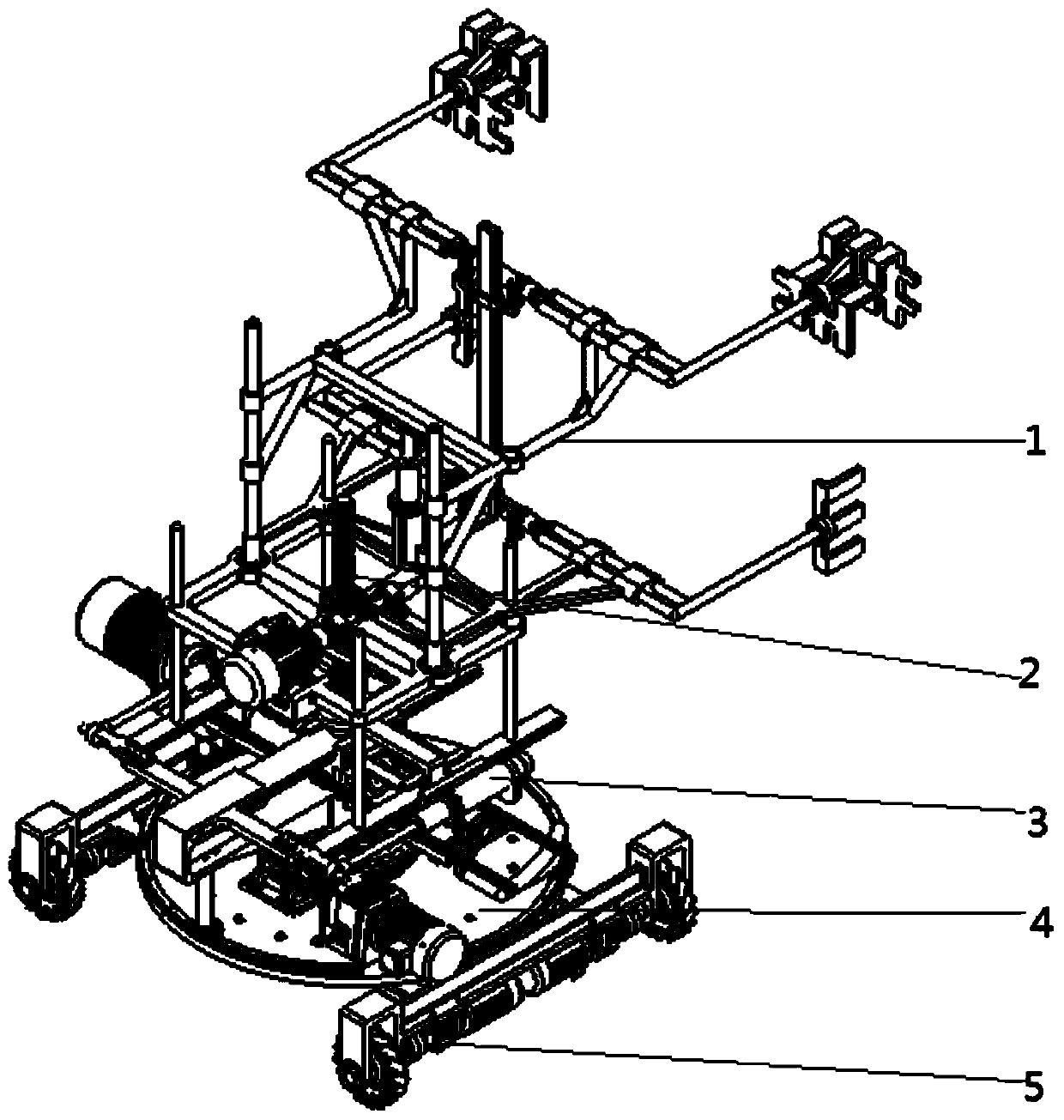

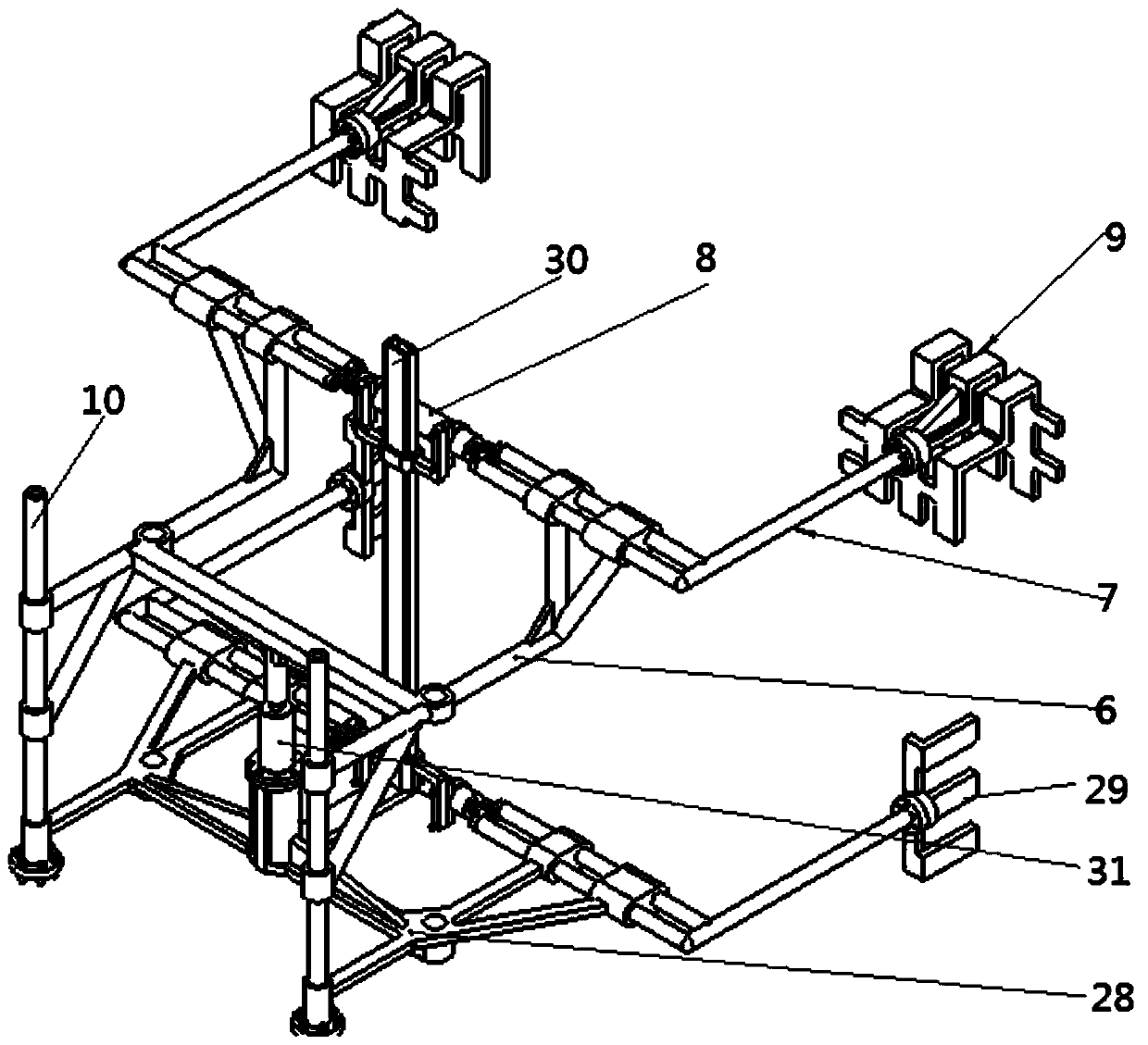

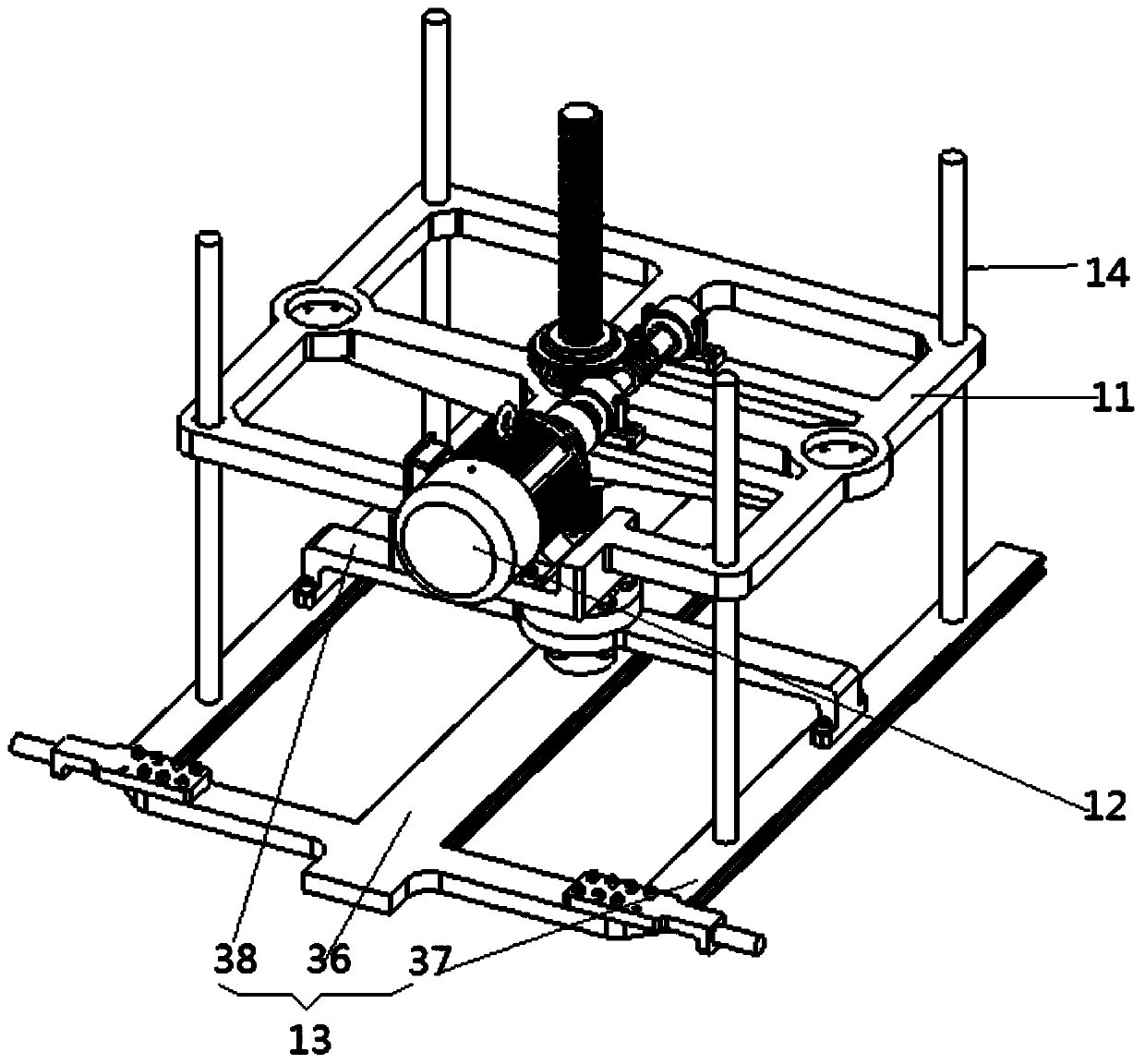

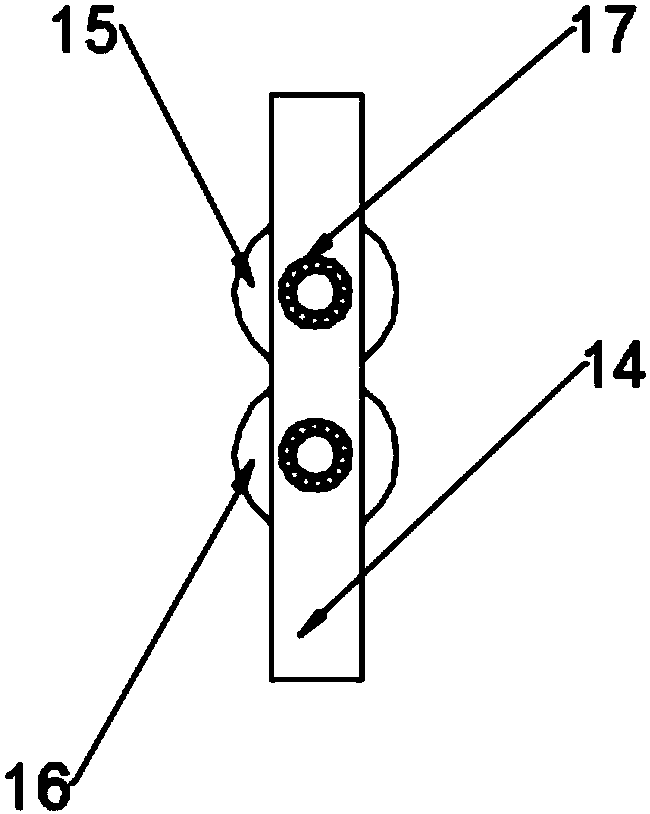

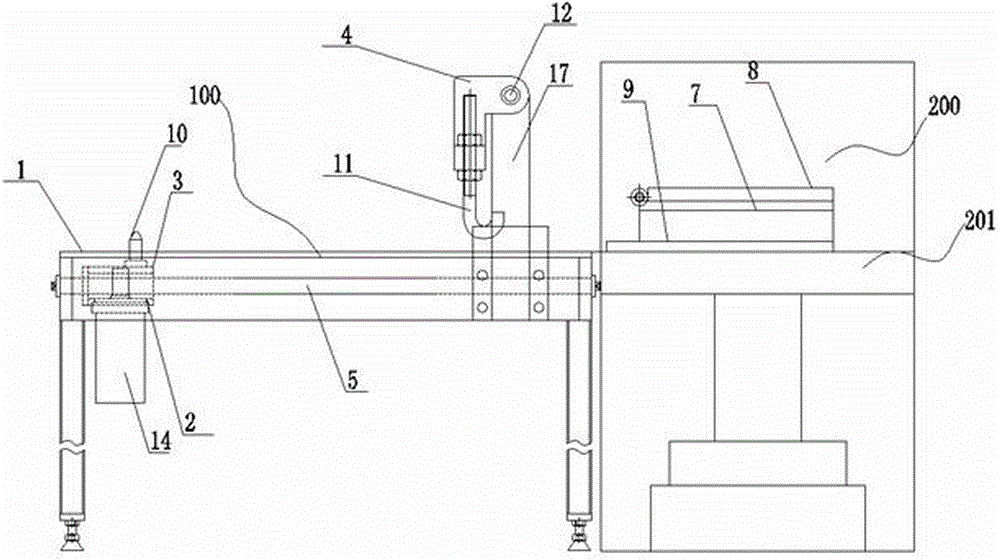

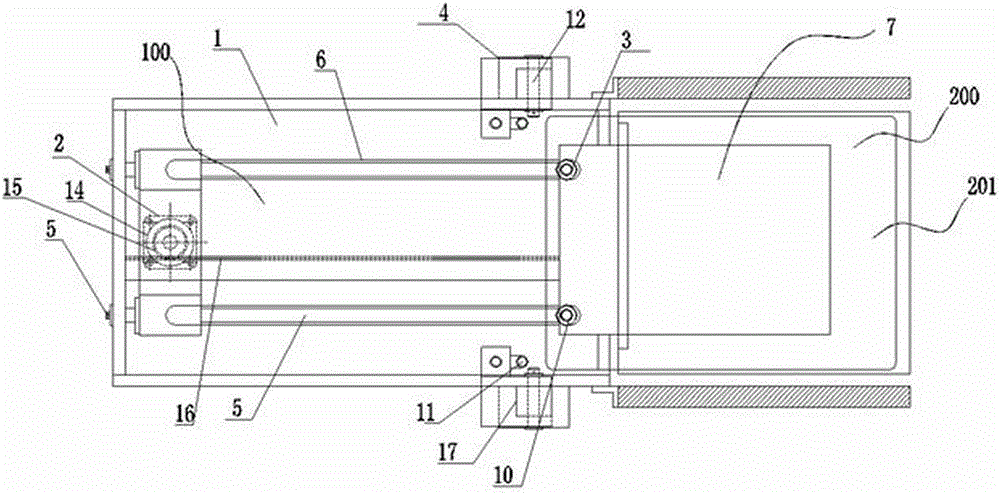

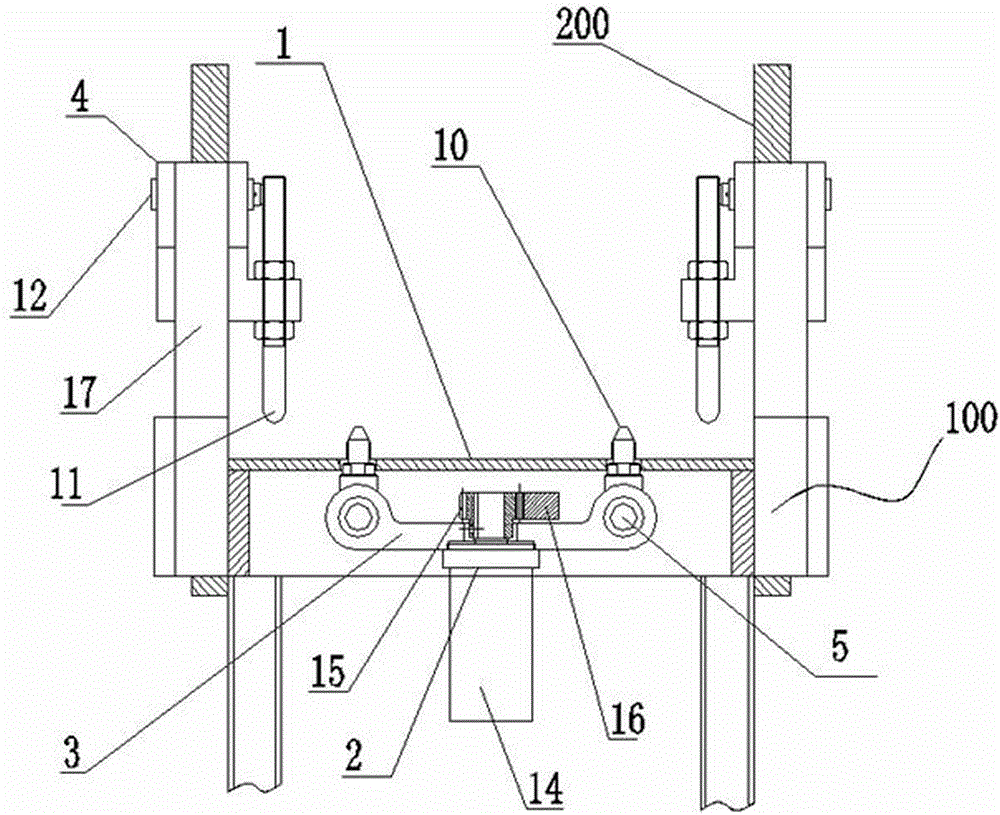

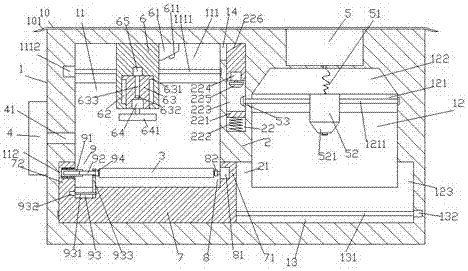

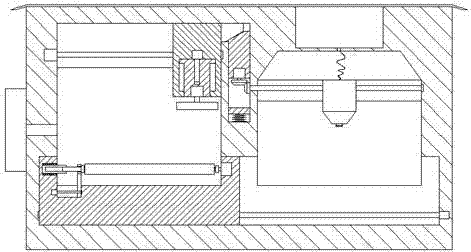

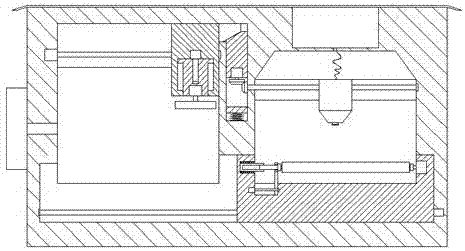

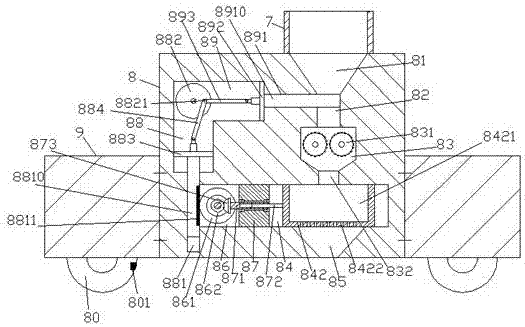

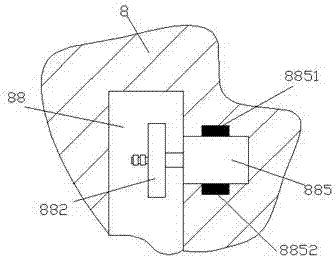

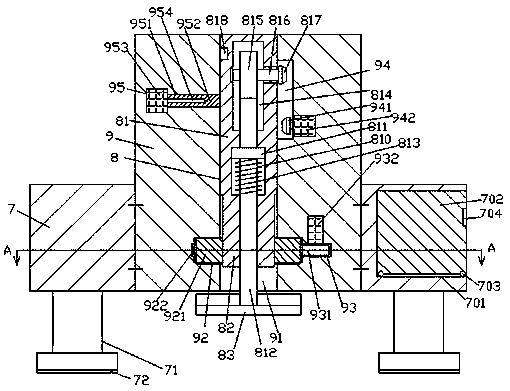

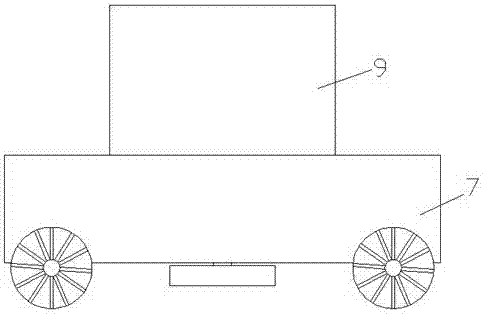

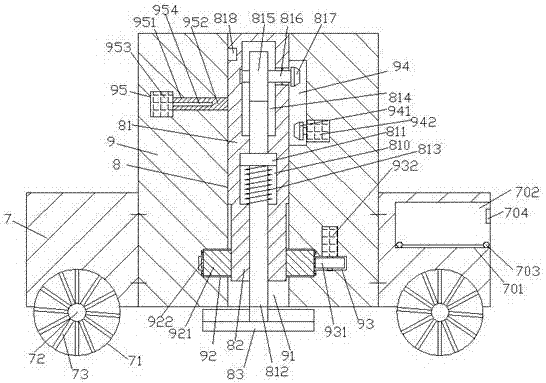

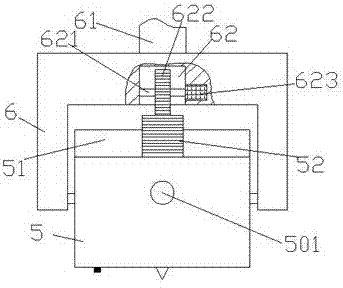

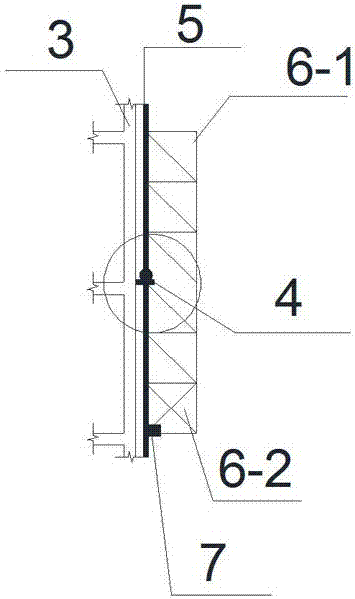

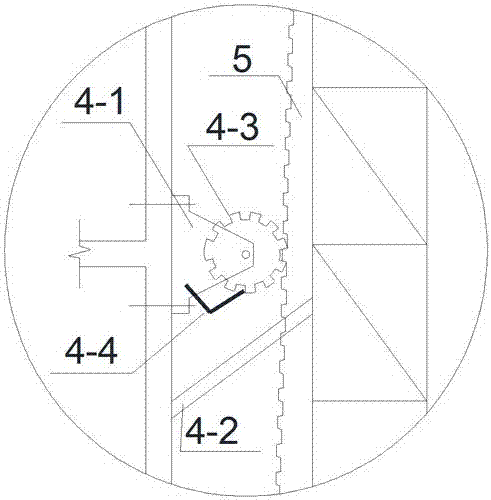

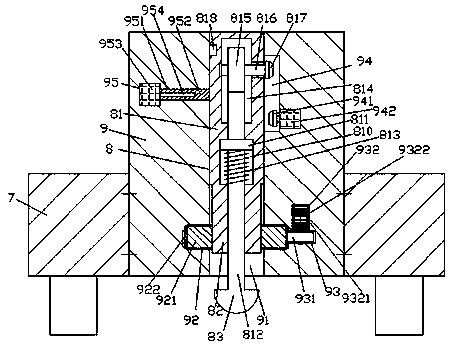

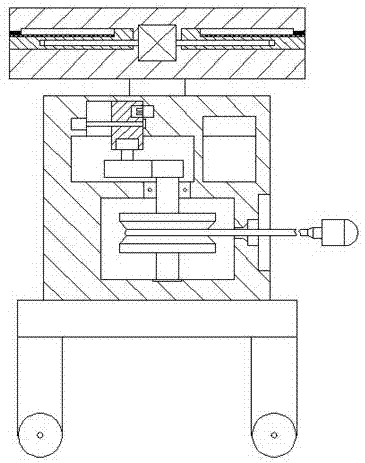

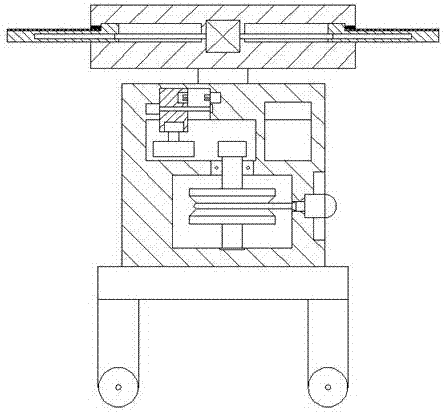

Fabricated building field mounted wall panel butt joint device

PendingCN110512879AReduce worker laborImprove construction safetyBuilding material handlingGear transmissionWall plate

The invention belongs to the technical field of constructional engineering, and particularly relates to a fabricated building field mounted wall panel butt joint device. The fabricatedbuildingfield mounted wall panel butt joint device comprises an execution mechanism, a lifting mechanism, a displacement mechanism, a rotation mechanism, and a traveling mechanism, wherein the execution mechanism comprises an upper part connecting frame, a mechanical arm, a bidirectional hydraulic cylinder, a first manipulator, and a smooth rod, the lifting mechanism comprises a lifting plate, a screw transmission part, a moving sliding plate, and a polished rod, the displacement mechanism comprises a sliding platform, a ball nut, a motor, a leadscrew, and a hydraulic cylinder, the rotating mechanism comprises a rotating support, a slewing bearing, a gear transmission component, a base, and an arc guide rail, the traveling mechanism comprises a chassis and wheels, the base of the rotating mechanism is mounted above the chassis, and the wheels are mounted below the chassis. The provided fabricated building field mounted wall panel butt joint device is high in fabrication operation accuracy, high in construction safety coefficient, and high in mechanical automation degree.

Owner:TIANJIN CHENGJIAN UNIV

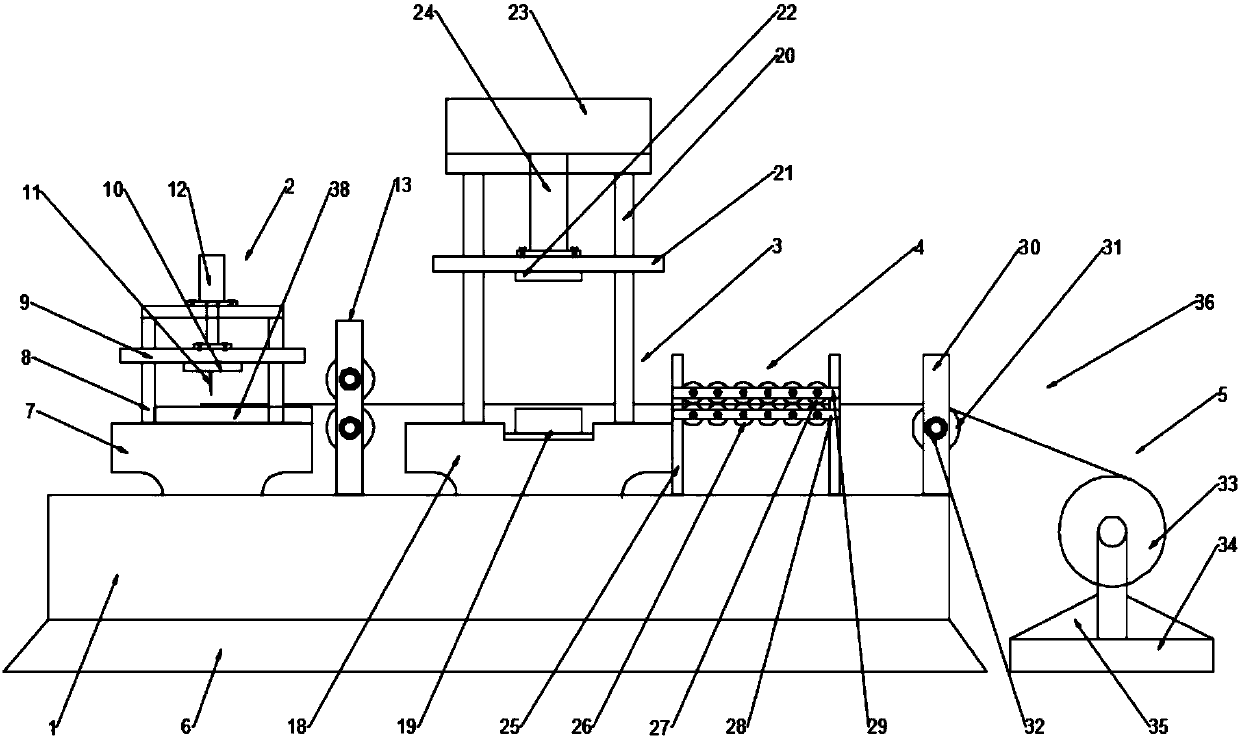

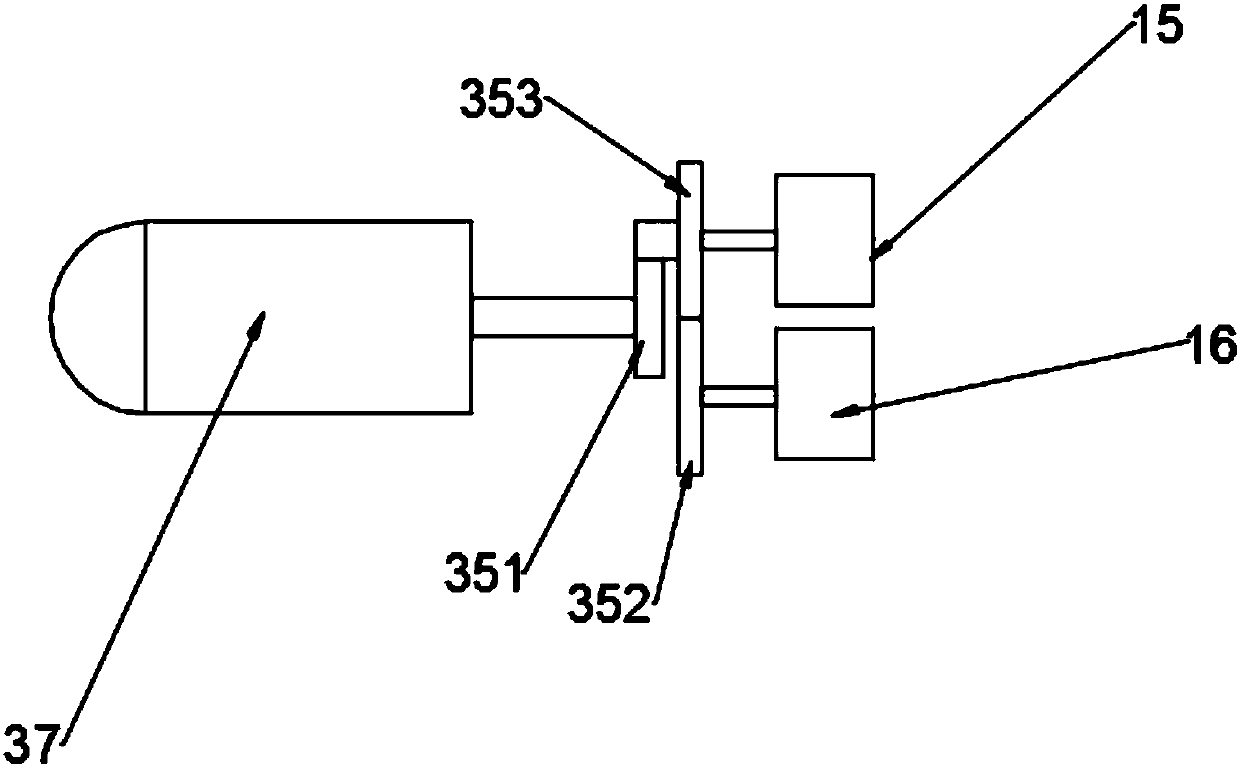

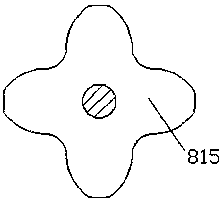

Automatic plastic product forming production machine

InactiveCN107856279AReduce worker laborIncrease productivityDomestic articlesMetal working apparatusHydraulic ramPlastic molding

The invention discloses an automatic production machine for molding plastic products, comprising: a base, a shearing device, a stamping device, a pressing plate fixing device, a plate guiding device, a plate driving device and a plastic product raw material rack, the plate guiding device is guided by a plate It is composed of pillars, guide rollers and bearings. The platen fixing device is composed of platen pillars, lower beams, upper beams, lower rollers and upper rollers. The plate driving device is composed of symmetrically arranged drive pillars, lower drive cylinders, upper drive cylinders, Bearing 2, motor, driving wheel, driven wheel 1 and driven wheel 2. The shearing device is composed of a shearing base, a shearing pillar, a shearing mobile table, a cutting knife, a cutting pad and a hydraulic push rod. The stamping device consists of It consists of stamping base, stamping pillar, stamping mobile table, hydraulic cylinder, hydraulic push rod 2, upper mold and lower mold. The present invention realizes automatic production of products, requires less manpower, has low labor load of workers, has high production efficiency, facilitates raw material transportation, and reduces production costs.

Owner:WUXI WEI KELAI TECH CO LTD

Sole manufacturing equipment with automatic die taking and die sinking capability

InactiveCN106273159AReduce labor intensityReduce worker laborDomestic articlesManufacturing engineering

Owner:SICHUAN YUANXING RUBBER

Preparation method of IMT decorative part

The invention relates to a preparation method of an IMT decorative part. The preparation method comprises the following steps: preparing a film, and forming an enhancer layer and a release-type coating layer on the surface of the film of a first coiling roll from top to bottom; carrying out UV transfer printing process, and forming a UV transfer printing layer on the enhancer layer of the film of the first coiling roller; carrying out primary vacuum electroplating processing, and forming a first vacuum plating film layer on the UV transfer printing layer of the film of a second coiling roll; carrying out the secondary vacuum electroplating processing, and forming a second vacuum plating film layer on the first vacuum plating film layer of the film of a third coiling roll; printing a pattern layer, and forming a pattern layer on the second vacuum plating film layer of the film of a fourth coiling roll; and injection molding, and forming an injection molding layer on the pattern layer of the film of a fifth coiling roll. Compared with the prior art, by adopting integrally-coiling operation, only the coiling rolls need to be transported in the entire process, the labor intensity is small, the working efficiency is high, the flatness is good, the injection molded decorative part can be well matched with an electronic product and is easy to assemble, and no gap is formed.

Owner:通达(石狮)科技有限公司

Wet food canning device for pet cat food production

ActiveCN112572908AReduce worker laborEasy for canning workSolid materialEngineeringEnvironmental geology

Owner:滨州殿歌生物科技有限公司

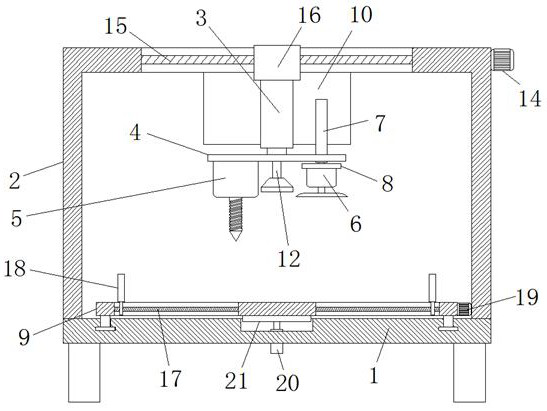

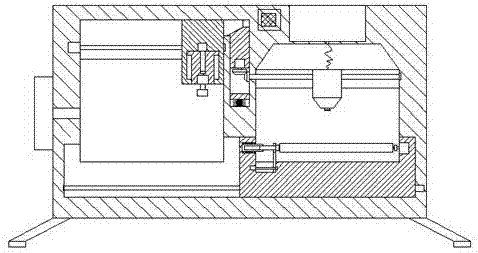

Polishing and drilling integrated equipment for machine parts

InactiveCN112372375AReduce worker laborImprove processing efficiencyAutomatic control devicesFeeding apparatusPhysicsDrill hole

The invention relates to the technical field of mechanical accessory machining, and discloses polishing and drilling integrated equipment for machine parts. The polishing and drilling integrated equipment comprises a machining table; a U-shaped plate is fixedly connected to the upper end of the machining table; a hydraulic cylinder is arranged on the upper portion of the interior of the U-shaped plate; a fixing plate is fixedly connected to the output end of the hydraulic cylinder; a drilling assembly is fixedly connected to the left side of the lower end of the fixing plate; a polishing assembly is arranged on the right side below the fixing plate; a first cylinder is fixedly connected to the right side of the upper end of the fixing plate; a mounting plate is fixedly connected to the output end of the first cylinder; and the lower end of the mounting plate is fixedly connected with the upper end of the polishing assembly. By means of the polishing and drilling integrated equipment, the labor amount of workers can be effectively reduce; the overall machining efficiency is improved; meanwhile, sweeps and dust generated during machining can be adsorbed and collected, and the influence of the sweeps and dust on the workers is reduced; the cleaning convenience is improved; adjustment is convenient; and the application range is large.

Owner:西安汇龙中鼎机械设备有限公司

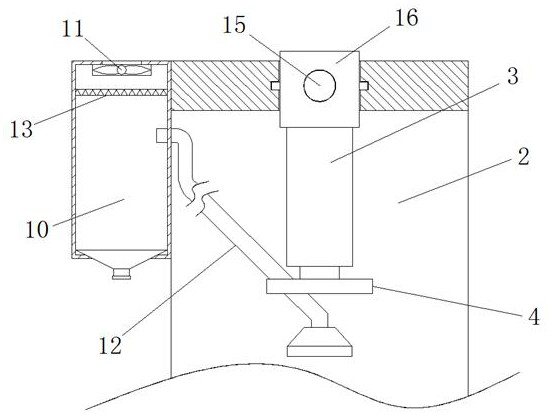

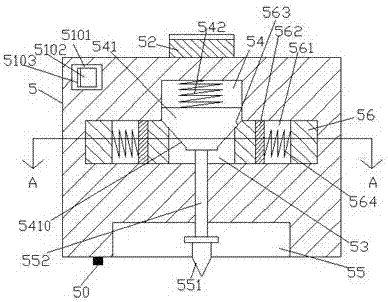

Power cable erecting device

InactiveCN107724766AReduce worker laborImprove the efficiency of knocking and the quality of knockingSoil-shifting machines/dredgersTowersEngineeringMechanical engineering

The invention discloses a device for power cable erection, which comprises a base body and a knocker fixed in the base body. A chamber is arranged in the knocker, and a guide extending to the left is arranged in the inner wall of the left top of the chamber. There is a guide cavity extending up and down in the extension section on the left side of the guide groove, and the bottom wall of the guide cavity is connected with a guide hole extending downward and penetrating the bottom surface of the base body. The sliding in the guide cavity is connected with a lifting slide block. There is a recessed groove in the front side of the take-off and landing sliding block, and the recessed groove is connected with the guide groove, and the guide block is slidingly connected in the guide groove, and the guide block is connected with the recessed groove. The top surface of the guide block is provided with a tooth shape There is a convex wheel in the recessed groove above the toothed bar; the invention improves the working efficiency and quality of knocking, speeds up the progress of cable erection, and reduces the cost of cable erection.

Owner:杜勉

Bridge device

InactiveCN107042181AReduce worker laborImprove work efficiencyRevolution surface grinding machinesSpraying apparatusEngineering

The invention discloses a bridge device. The device comprises a rack with a first empty bin and a second empty bin in the left side and the right side, a top cover is fixedly mounted on the top of the rack, the outer side of a top rod is provided with a slope in a deviation manner, a partition board is arranged between the first empty bin and the second empty bin, a guide moving groove extending towards the left side and the right side is formed in the bottom in the first empty bin, the bottom of the partition board is provided with a first through bin with the bottom communicated with the guide moving groove, a first concave bin is arranged at the position, opposite to the left side of the first through bin, in the left side of the first empty bin, a second concave bin is arranged at the position, opposite to the right side of the first through bin, in the right side of the second empty bin, a first screw rod extending in a left-and-right manner is arranged in the first through bin, and a grinding table is arranged on the first screw rod in a matched connection manner. The bridge device is simple in structure, convenient to operate, high in work efficiency and high in environment-friendly function.

Owner:孙美娟

Liquid phase separation device and using method thereof

InactiveCN108939617AReduce worker laborImprove work efficiencyLiquid separationSeparation processLiquid layer

The invention discloses a liquid phase separation device and a using method thereof, and belongs to the technical field of liquid phase separation. The liquid phase separation device is characterizedby comprising a main tank, an auxiliary tank and a liquid separating and extracting device, wherein a main tank feeding hole and a main tank discharging hole are formed in the upper part of the main tank; a main tank discharging hole is formed in the lower part of the main tank; an auxiliary tank feeding hole and a vacuum-pumping nozzle are arranged at the upper part of the auxiliary tank; an auxiliary tank discharging hole is formed in the lower part of the auxiliary tank; the liquid separating and extracting device comprises a liquid absorbing pipe and a suspension device; the lower end of the liquid absorbing pipe is arranged in the main tank through the suspension device; the upper end of the liquid absorbing pipe upwards penetrates out of the main tank discharging hole, and then is connected to the auxiliary tank feeding hole through an auxiliary tank feeding valve; and a vacuum valve is arranged on the vacuum-pumping nozzle. The liquid phase separation device solves the problemsthat as the position of a liquid separation layer is invisible in the liquid phase separation process of liquid which does not dissolve each other, a worker needs to repeatedly confirm the position ofthe liquid separation layer, the amount of labor is great, and the work efficiency is low, and the automatic separation without manual operation is realized.

Owner:SHANDONG HUAAN NEW MATERIAL

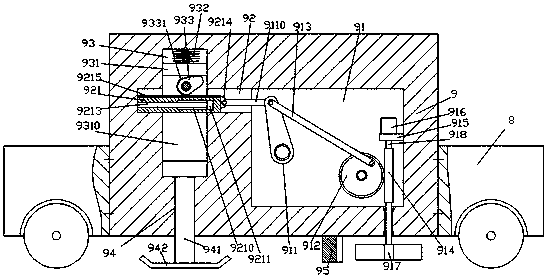

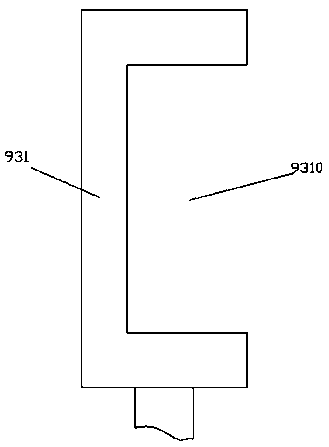

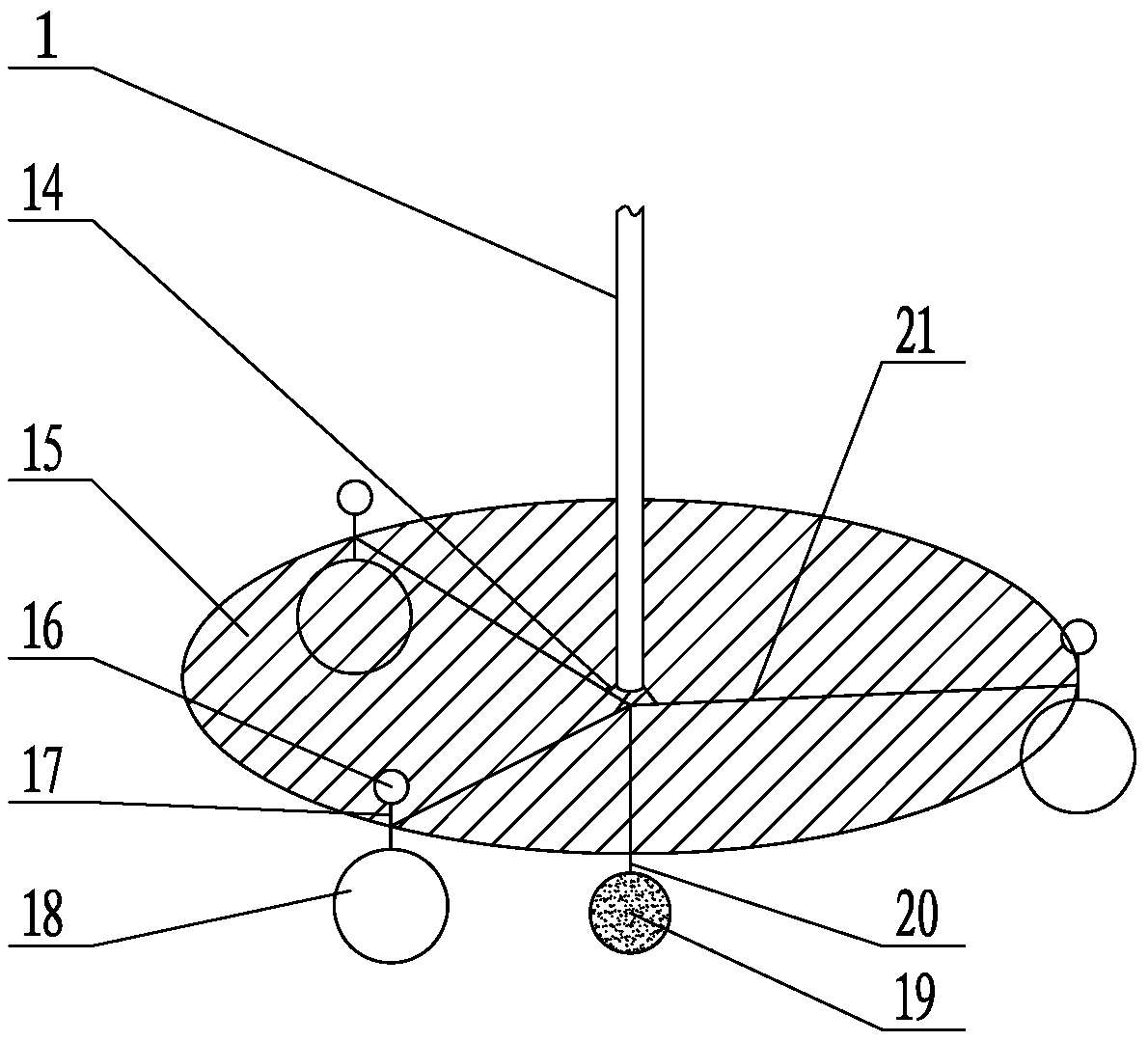

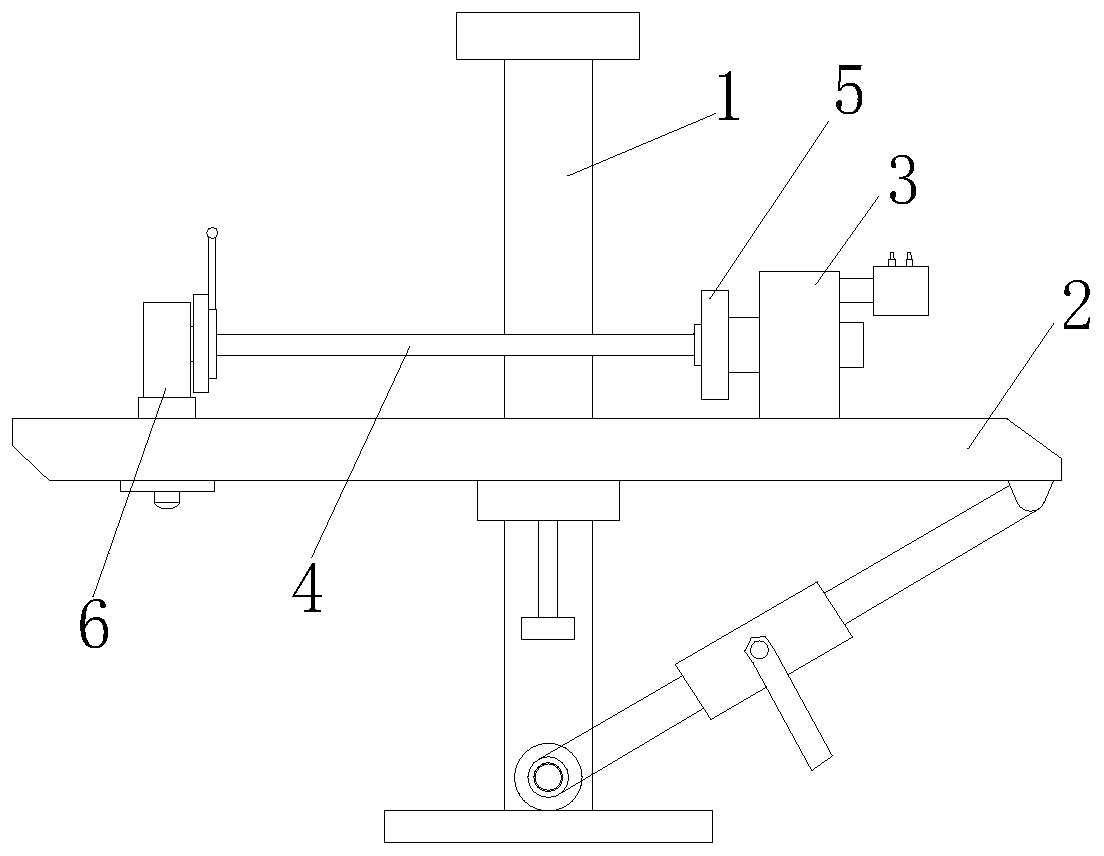

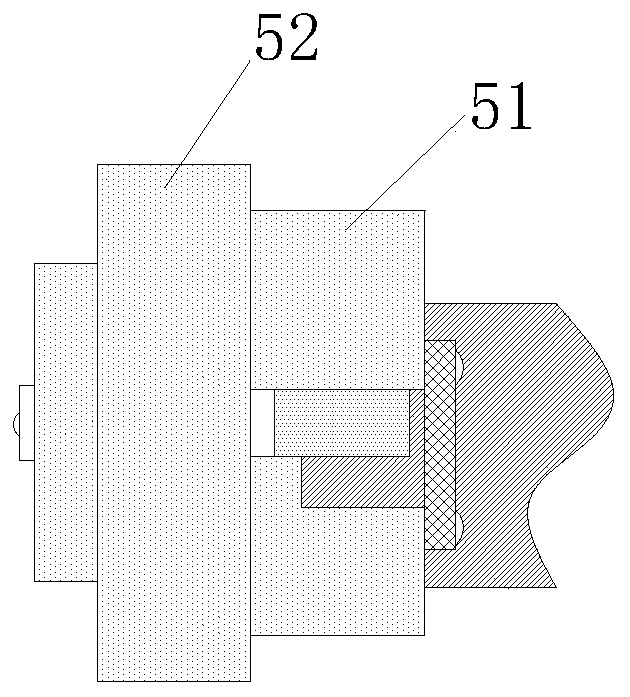

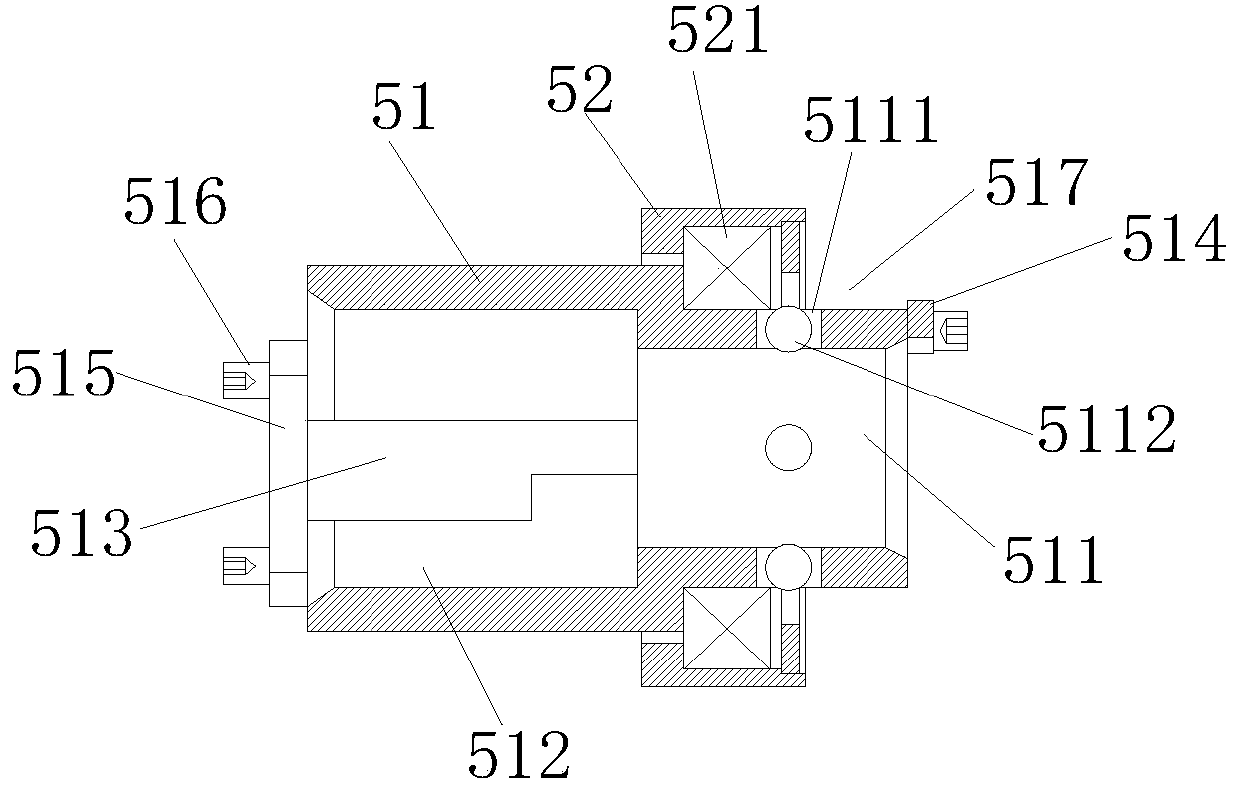

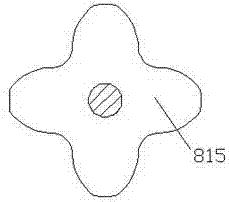

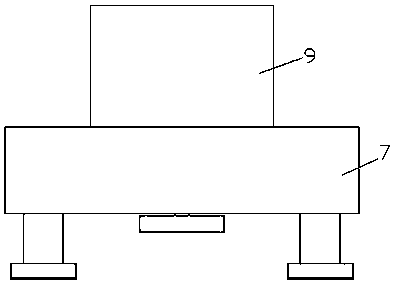

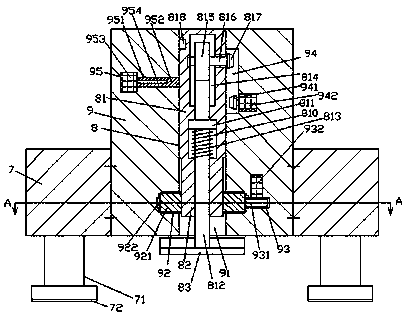

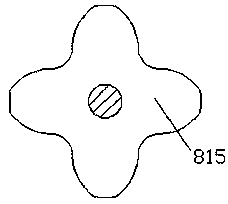

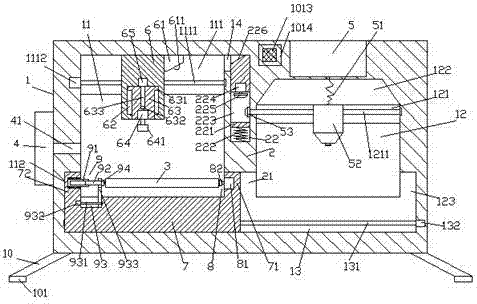

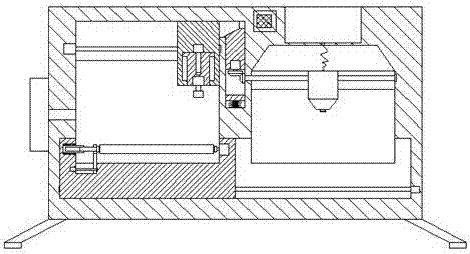

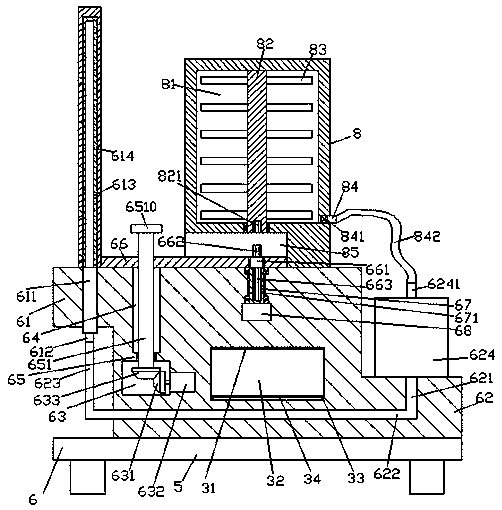

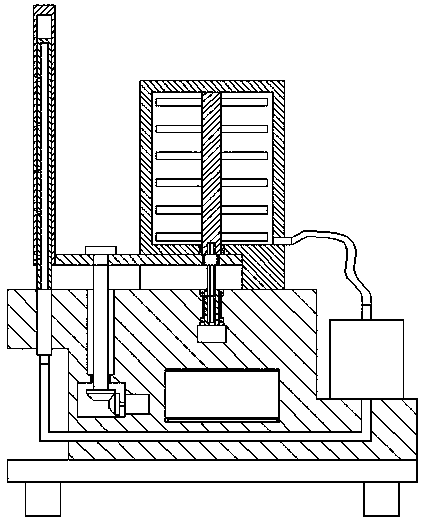

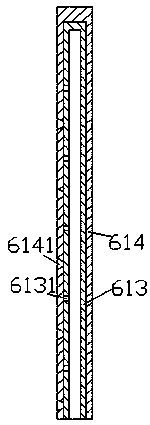

Multi-stage gear rod detaching and clamping integrated frame-column emulsion drilling machine

ActiveCN111101852AEffortless disassemblyReduce worker laborDrilling rodsConstructionsProcess engineeringDrill pipe

The invention discloses a multi-stage gear rod detaching and clamping integrated frame-column emulsion drilling machine. The multi-stage gear rod detaching and clamping integrated frame-column emulsion drilling machine comprises a column, a cross frame and a motor, the cross frame is installed on the column, the motor is slidably installed on the cross frame, the multi-stage gear rod detaching andclamping integrated frame-column emulsion drilling machine further comprises a rod unloader fixed on a motor power head and used for connecting the motor power head with a drill pipe and a clamping device fixed on the cross frame and used for limiting the rotation of the drill pipe. According to the multi-stage gear rod detaching and clamping integrated frame-column emulsion drilling machine, traditional manual detaching is replaced with a multi-stage drill pipe detaching device, the detaching operation of the multi-stage drill pipe can be completed through the cooperation of the rod unloaderand the clamping device, detaching of the drill pipe is labor-saving and convenient, the labor amount of a worker is greatly reduced, the detaching time is saved, the structure is simple, and the normal use of the equipment cannot be influenced.

Owner:安徽恒立通液压气动技术有限公司

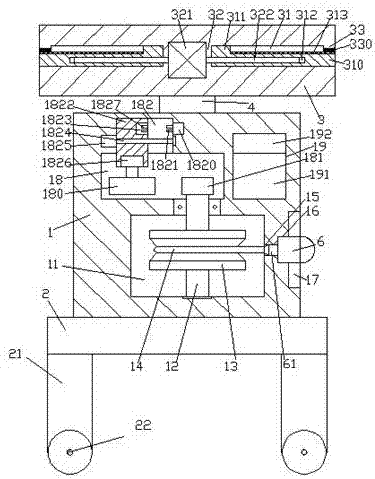

Rapid operation equipment based on big data information

The invention discloses rapid operation equipment based on big data information. The rapid operation equipment based on big data information comprises a pedestal, and a sowing device arranged in the pedestal; the top surface of the sowing device is provided with a conical chamber; the bottom of the conical chamber is provided with a seed outlet; the conical chamber is communicated with the seed outlet; the bottom of the seed outlet is provided with a stirring chamber; the seed outlet is communicated with the stirring chamber; the bottom of the stirring chamber is provided with a seed dischargeport; the stirring chamber is communicated with the seed discharge port; the bottom of the seed discharge port is provided with a slide convey chamber designed to stretch to the left and the right; the seed discharge port is communicated with the slide convey chamber; the bottom of the slide convey chamber is provided with a conical sowing groove; the slide convey chamber is communicated with theconical sowing groove; the bottom of the sowing device is penetrated by the conical sowing groove; a first accommodation chamber is arranged in the sowing device on the left side of the slide conveychamber; a blocking plate is arranged between the first accommodation chamber and the slide convey chamber; a first slide convey groove designed to stretch upward and downward is arranged in the sowing device on the left side of the first accommodation chamber; the top of the first slide convey groove is provided with a second accommodation chamber designed to stretch upward; the first slide convey groove is communicated with the second accommodation chamber; the top stretching tail end of the second accommodation chamber is provided with a third accommodation chamber designed to stretch to the right side; and the top stretching tail end of the second accommodation chamber is communicated with the third accommodation chamber. The rapid operation equipment is simple in structure; operationis convenient; stirring efficiency is increased; sowing quality is increased; sowing working efficiency is increased; and scientific plantation is realized.

Owner:姚瑞波

Environment-friendly garbage compressing device

InactiveCN108215275AImprove work efficiencyReduce worker laborSolid waste disposalPressesCircular discEngineering

Owner:郑姗姗

Efficient power cable device

InactiveCN107465149AImprove work efficiencyReduce worker laborApparatus for laying cablesEngineeringPower cable

The invention discloses a high-efficiency power cable device, which comprises a base body and a beating part fixedly installed in the base body, a square sliding groove is arranged up and down in the beating part, and a first cavity is arranged in the lower side wall of the sliding groove in a circular direction. , the first cavity is rotatably connected with an inner texture disc, the beating part on the right side of the first cavity is provided with a first conduction cavity, the first conduction cavity is rotatably connected with a toothed wheel, and the top of the toothed wheel is connected to the second A motor is mated and connected, the outer surface of the first motor is set in the inner wall of the top of the first conduction cavity and fixedly connected, the outer surface of the inner grain disc is fixedly provided with a toothed ring, and the right side of the toothed ring extends into the first conduction cavity and It is coincidently connected with the left side of the toothed wheel; the present invention is simple in structure and easy to operate, and realizes the reciprocating beating work by driving the beating hammer at the bottom of the combination device through the transmission device, which improves the work efficiency of beating.

Owner:俞灿

Garbage compressing device

ActiveCN107672981AImprove work efficiencyReduce worker laborRefuse receptaclesRefuse transferringEngineeringCircular disc

Owner:南京浦口科创投资集团有限公司

Efficient punching machine for packaging bag

The invention discloses an efficient punching machine for a packaging bag. The punching machine comprises a support and a punching machine body which is rotationally installed in the support in a matched mode; a transition section is arranged at the top part of the punching machine body, and a tooth arc strip is fixedly arranged on the transition section; an angle adjusting device which is connected with the tooth arc strip in a matched mode is arranged in the support on the upper side of the tooth arc strip; a first containing groove is formed in the bottom surface of the hole opening machinebody, wherein a first sliding cavity extending leftwards and rightwards is formed in the part, on the upper side of the first containing groove, of the punching machine, and a second sliding cavity is formed in the middle part of the top wall in the first sliding cavity in a penetrating mode; a pushing block is connected in the second sliding cavity in a sliding fit mode, and a first pressing spring is arranged in the position, at the top part of the pushing block, of the second sliding cavity; the bottom part of the pushing block is fixedly provided with a protruding block which extends intothe first sliding cavity; and a push column extending leftwards and rightwards is slidably connected to the position, between the bottom part of the first sliding cavity and the top part of the firstcontaining groove, of the interior of the punching machine. The punching machine has the advantages of being simple in structure, convenient to operate and capable of improving the working efficiencyand quality of punching.

Owner:重庆帅业电力机械有限公司

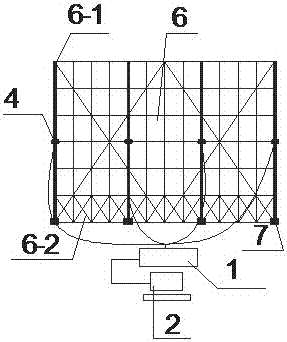

Quick installation scaffold for ultra-high buildings and implementation method

PendingCN106917500AReduce worker laborImprove work efficiencyBuilding material handlingScaffold accessoriesEngineeringSignal acquisition

The invention discloses a quick installation scaffold for ultra-high buildings and an implementation method. The scaffold comprises a signal acquisition and transmission device, a control device which is connected with the signal acquisition and transmission device in a communication mode, a wall-attaching supporting device which is installed on the wall body of a high-rise building, a guide rail which is connected with the wall-attaching supporting device, a lifting scaffold body which is connected with the guide rail and a lifting device which is connected with the signal acquisition and transmission device in a communication mode; the lifting scaffold body is installed on the guide rail and is adaptive to the lifting device; the lifting scaffold body and the guide rail vertically move on the wall surface of the high-rise building along with the lifting device; the communication connection comprises Bluetooth connection, data wired connection and wireless signal network connection; the lifting scaffold body comprises a main framework structure and a frame body horizontal truss which is connected with the main framework structure. By means of the quick installation scaffold for ultra-high buildings and the implementation method of the invention, scaffolds for ultra-high buildings can be safely and rapidly installed and uninstalled; engineering cost is reduced through reducing labor intensity and increasing working efficiency.

Owner:江苏省第一建筑安装集团股份有限公司

Quick welding equipment

InactiveCN107984120AReduce worker laborImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringWelding

The invention discloses quick welding equipment. The welding equipment comprises a frame body; a first cavity and a second cavity are formed inside the left side and the right side of the frame body correspondingly; foot rods are fixedly mounted around the bottom of the frame body; foot pads are fixedly arranged at the bottoms of the foot rods; the foot rods are inclined outwards; a separating plate is arranged between the first cavity and the second cavity; a guide groove extending towards the left side and the right side is formed in the inner bottom of the first cavity; a first through holewith the bottom communicating with the guide groove is formed in the bottom of the separating plate; a first concave hole is formed in the left side of the first cavity opposite to the left side of the first through hole; a second concave hole is formed in the right side of the second cavity opposite to the right side of the first through hole; a first spiral rod extending leftwards and rightwards is arranged in the first through hole; and a welding platform connected in a matched manner is arranged on the first spiral rod. The welding equipment is simple in structure, convenient to operate,high in working efficiency and strong in environmental protection function.

Owner:黄东卫

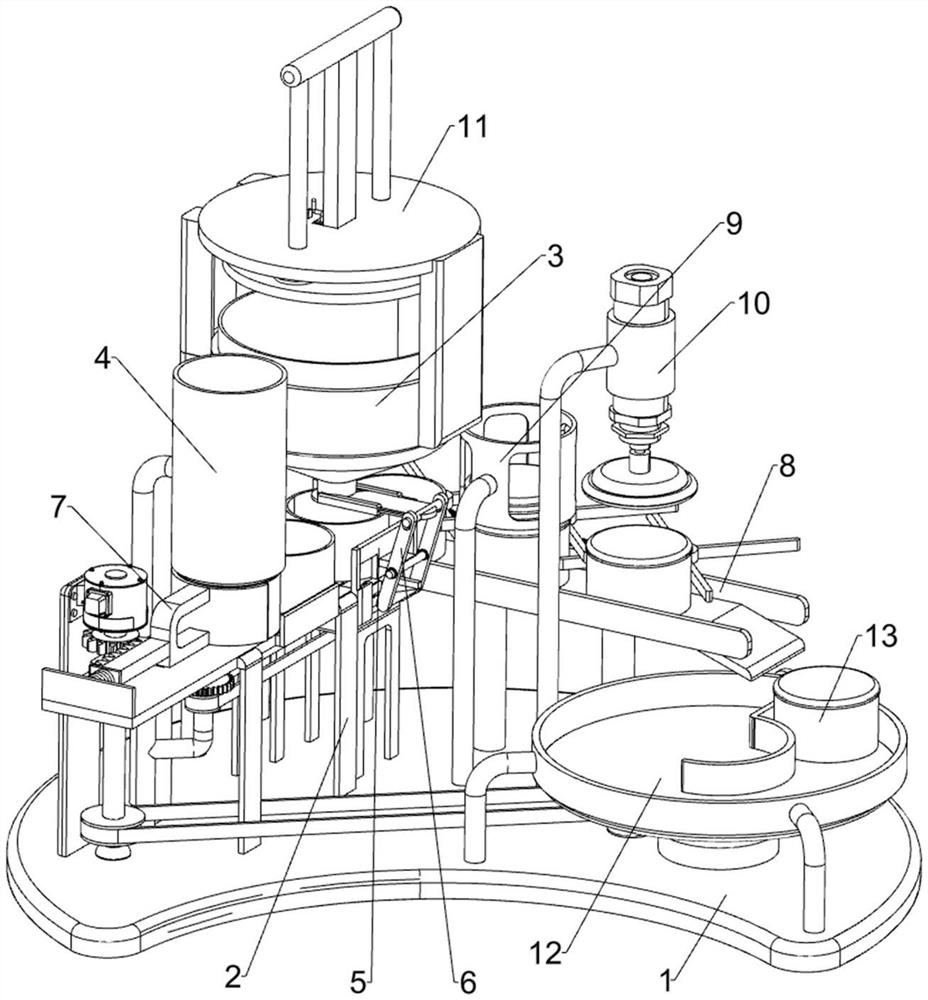

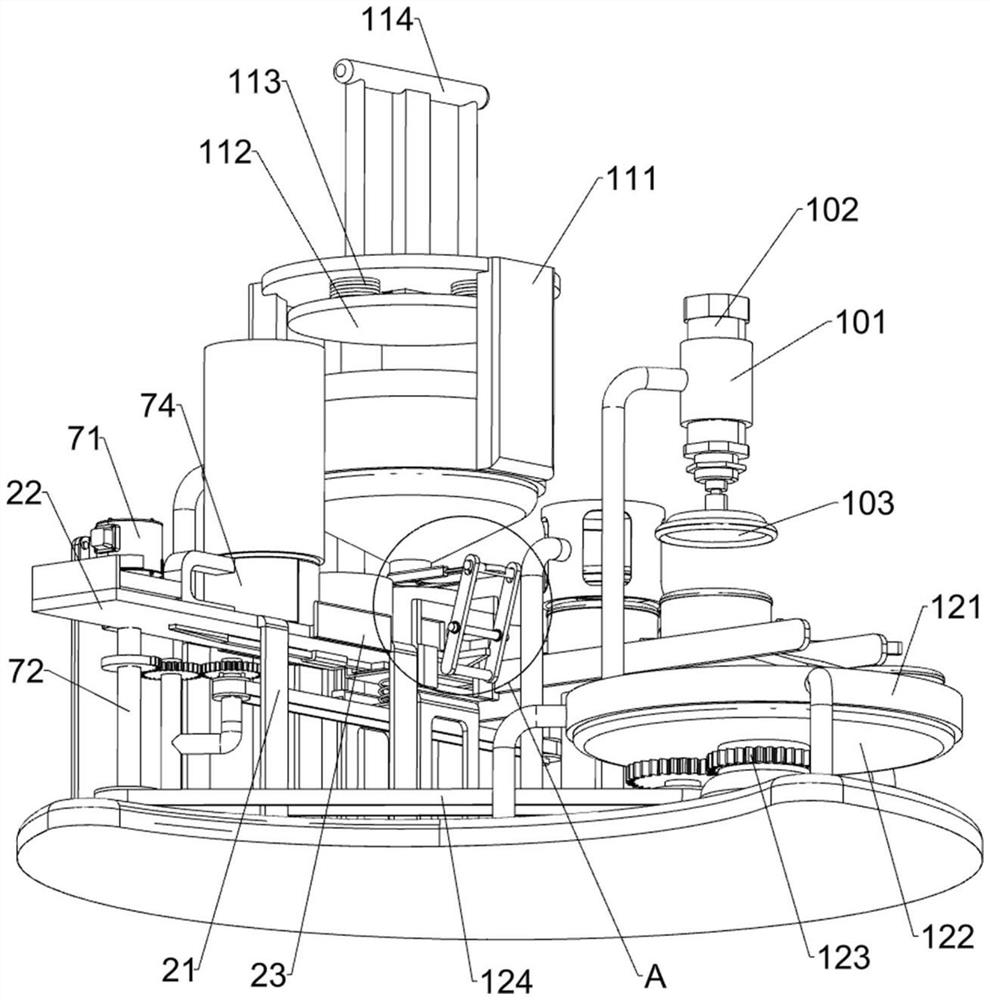

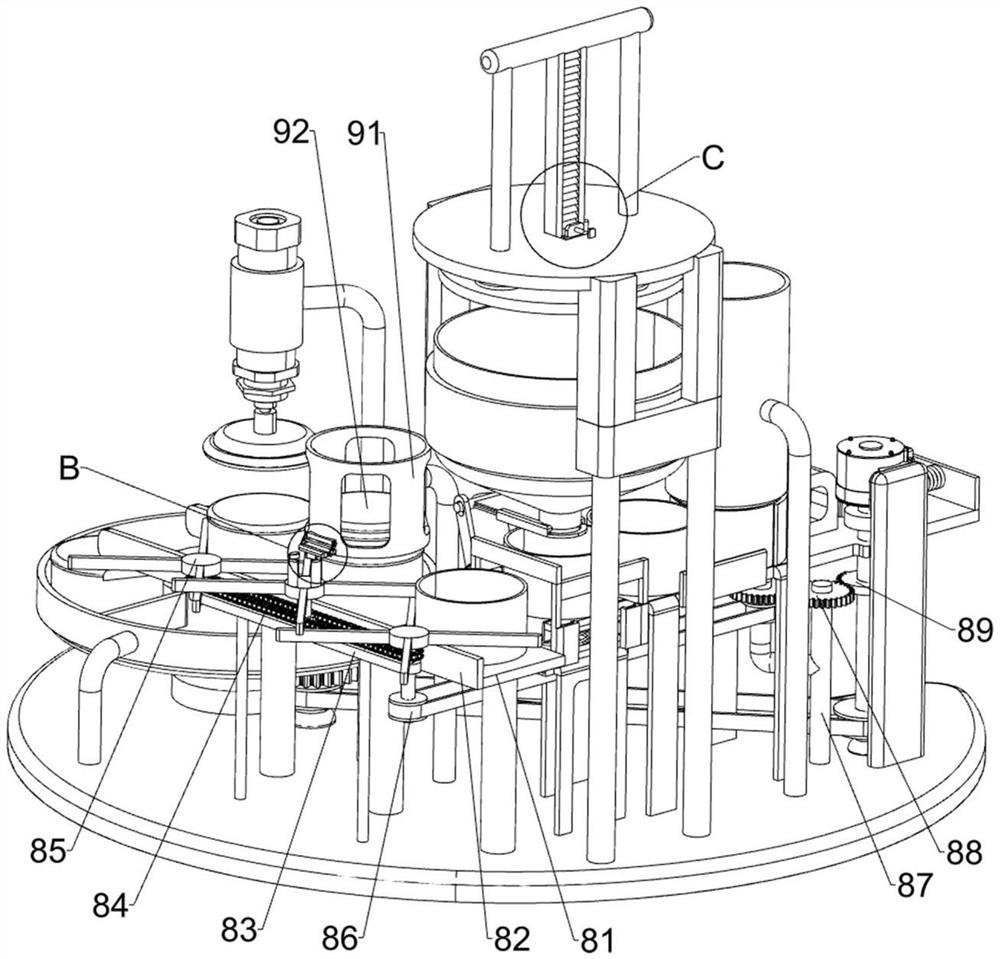

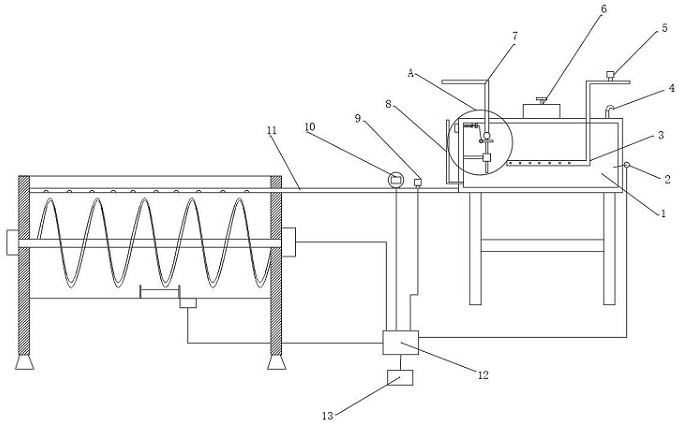

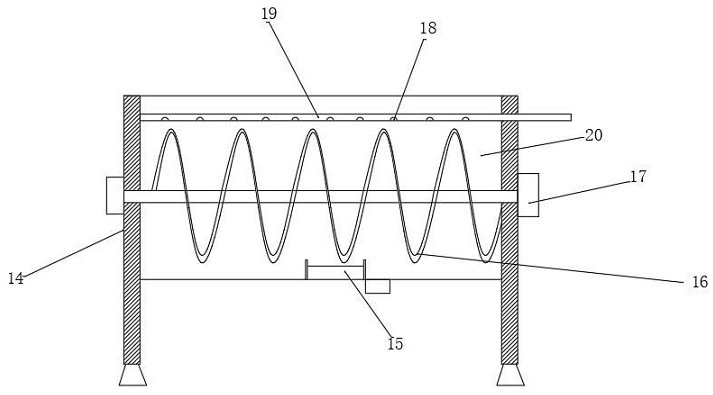

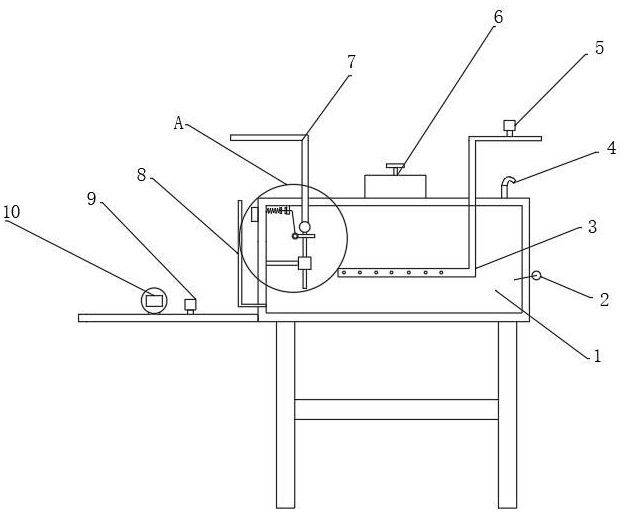

Intelligent temperature and water control yeast mixing device

PendingCN114644967AReduce worker laborIncrease productivityRotary stirring mixersTransportation and packagingProcess engineeringWater pipe

The invention belongs to the technical field of wine brewing, and particularly relates to an intelligent temperature and water control yeast mixing device which comprises a cylindrical tank body, a temperature sensor, a steam pipe, a steam outlet pipe, a steam electromagnetic valve, an observation hole, a water inlet pipe, a liquid level meter, a water outlet electromagnetic valve, a flow meter, a water outlet pipe, a parallel water pipe and a yeast mixing chamber. The yeast mixing machine completely replaces manual turning and mixing operation of workers, the labor amount of the workers is greatly reduced, the production efficiency is improved, clean production, perfect combination of the water storage tank and the controller and quantitative control and standardized operation of the yeast mixing procedure are achieved, and the production efficiency is improved. A solid foundation is laid for subsequent stacking and heating, fermentation in a pool, generation of aroma-producing and taste-producing substances in a wine body and formation of a sesame aroma style, mechanical and automatic operation is achieved, manual operation is perfectly replaced, and standardized operation and clean production are achieved while the labor amount of workers is reduced and the production efficiency is improved.

Owner:山东景芝白酒有限公司

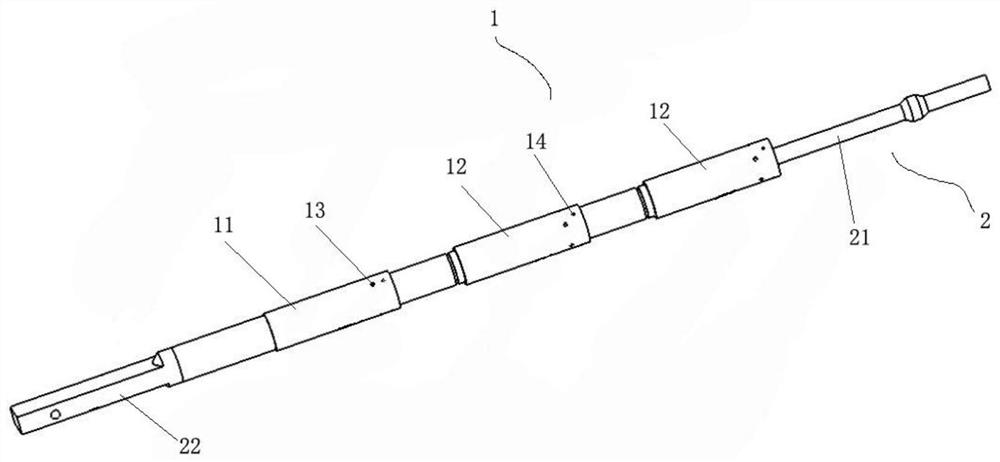

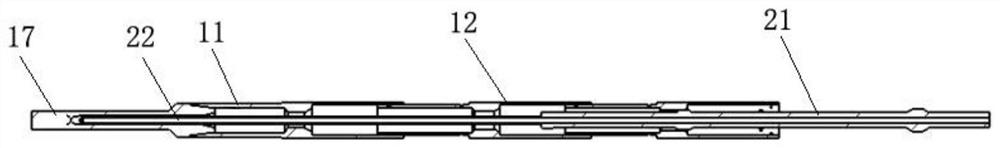

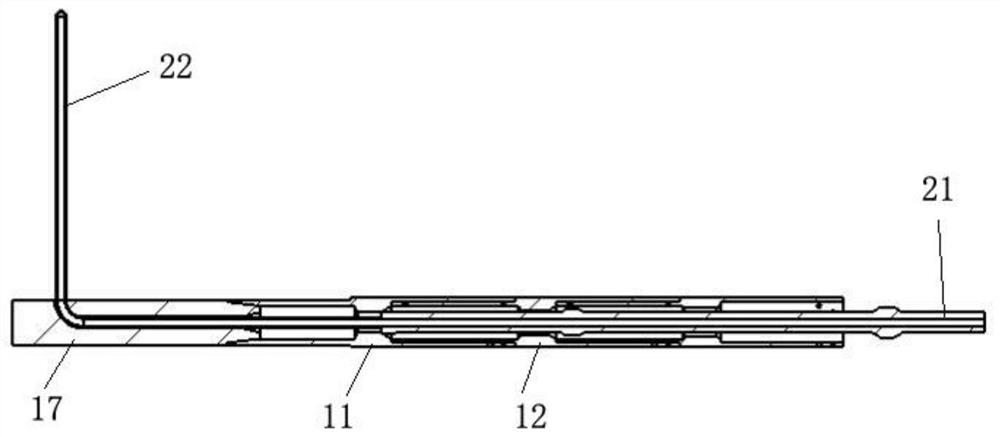

Spring pin type radial well guider layer changing device

PendingCN114763733AShorten the timeReduce worker laborLiquid/gas jet drillingDirectional drillingPressure - actionClassical mechanics

The spring pin type radial well guider layer changing device comprises a guiding outer pipe, and the guiding outer pipe comprises an oil pipe, a multi-stage layer changing device connected to the lower portion of the oil pipe and a guider connected to the lower end of the multi-stage layer changing device; the tool string penetrates through the guide outer pipe and extends out of the guide outer pipe in the radial direction to crush rocks; wherein the multi-stage layer changing device is constructed to be capable of extending stage by stage under the pressure action of the tool string, so that the guider is moved to different positions, and layer changing is completed. Reversing of one-time drilling of the radial well can be achieved, time is saved, labor of workers is relieved, and construction cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-precision product packaging bag hole forming machine

ActiveCN108000617AImprove efficiencyReduce worker laborMetal working apparatusMechanical engineering

The invention discloses a high-precision product packaging bag hole forming machine. The high-precision product packaging bag hole forming machine comprises a support and a hole forming machine installed in the support in a rotary fit manner. The top of the hole forming machine is provided with a transition section. A toothed arc strip is fixedly arranged on the transition section. An angle adjusting device which is connected with the toothed arc strip in a matched manner is arranged in the support and located on the upper side of the toothed arc strip. A first containing groove is formed in the bottom face of the hole forming machine. The portion, on the upper side of the first containing groove, of the hole forming machine is provided with a first sliding cavity extending leftwards and rightwards. A second sliding cavity is arranged in the middle of the inner top wall of the first sliding cavity in a penetrating manner. A pushing block is connected into the second sliding cavity in sliding and matched manners. A first compression spring is arranged in the second sliding cavity and on the top of the pushing block. The bottom of the pushing block is fixedly provided with a convex block extending into the first sliding cavity. The portion, between the bottom of the first sliding cavity and the top of the first containing groove, of the hole forming machine is connected with a pushing column extending upwards and downwards in sliding and matched manners. The high-precision product packaging bag hole forming machine is simple in structure and convenient to operate and improvesthe work efficiency and quality of hole formation.

Owner:重庆帅业电力机械有限公司

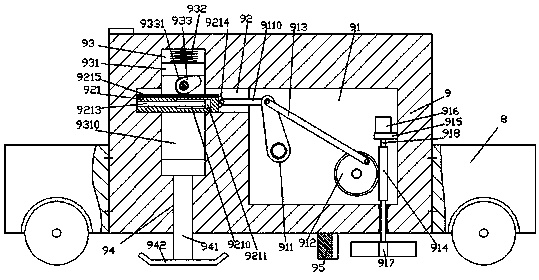

High-efficiency agriculture pesticide spraying vehicle

InactiveCN108207875AImprove work efficiencyReduce worker laborInsect catchers and killersAutomatic controlEngineering

The invention discloses a high-efficiency agricultural pesticide spraying vehicle, which comprises a moving trolley and a pesticide spraying mechanism arranged on the top of the moving trolley. The top of the left end of the pesticide spraying mechanism is provided with a first bump. The bottom of the right end of the pesticide spraying mechanism is provided with a second bump. The first bump is fixedly provided with a first pesticide transmission tube with upper and lower extension arrangement. The top end face of the first bump is provided with a pesticide spraying pipe fixedly connected with the extension end of the top extension end of the first conveying pipe. The outer surface of the pesticide spraying pipe is provided with a protecting sleeve. The top of the spraying mechanism is provided with a storage tank. A medicine storage cavity is arranged in the storage tank. A guide groove which extends to the left side is arranged in the water storage cavity below the bottom of the medicine storage cavity. A stirring shaft which extends up and down is arranged in the medicine storage cavity. The extension end of the top extension of the stirring shaft is rotationally matched and connected with the top wall of the medicine storage cavity; the invention has the advantages of simple structure, convenient operation, automatic control of the opening and closing operation of the medicine spraying pipe and the protective sleeve. The service life is prolonged. The stirring work can be realized by the automatic matching connection, and the control effect is improved.

Owner:广州菀倾科技有限公司

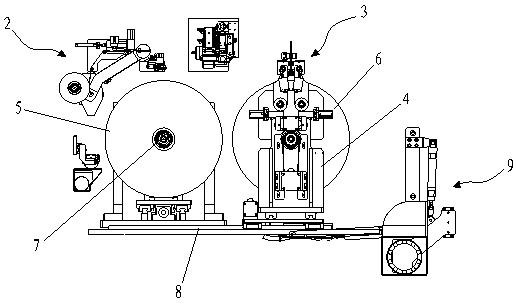

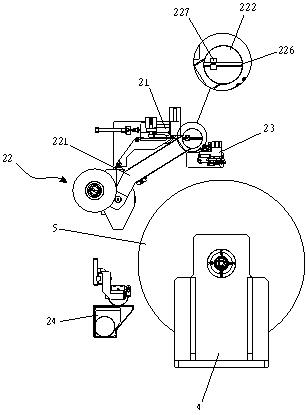

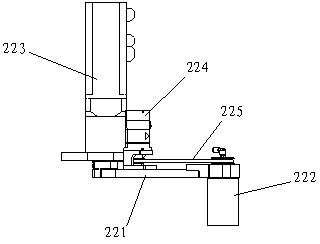

Multi-material-roll pole piece unwinding device

PendingCN114056981AReduce worker laborImprove processing efficiencyWebs handlingControl modeMachine control

The invention discloses a multi-material-roll pole piece unwinding device which comprises a roll preparing position, an unwinding position, a pole roll automatic bar code tearing device, a pole roll automatic roll exchanging device and a pole roll carrying mechanism, the roll preparing position and the unwinding position are close to each other, and hanging shafts used for hanging pole rolls extend out of the middle of the roll preparing position and the middle of the unwinding position. The automatic pole roll bar code tearing device is used for tearing bar codes of roll material heads of new pole rolls on the roll preparing position, and the automatic pole roll exchanging device is used for splicing the roll material heads of the new pole rolls with the bar codes torn and the roll material heads of old pole rolls above the roll unwinding position. The pole roll carrying mechanism is movably arranged between the roll preparing position and the roll unwinding position, and a conveying track for the pole roll carrying mechanism to move is arranged below the roll preparing position and the roll unwinding position. By means of the multi-material-roll pole piece unwinding device, the labor amount of workers can be greatly reduced, the machining efficiency is improved, and the one-person multi-machine control mode becomes possible.

Owner:DONGGUAN ARECONN PRECISION MACHINERY

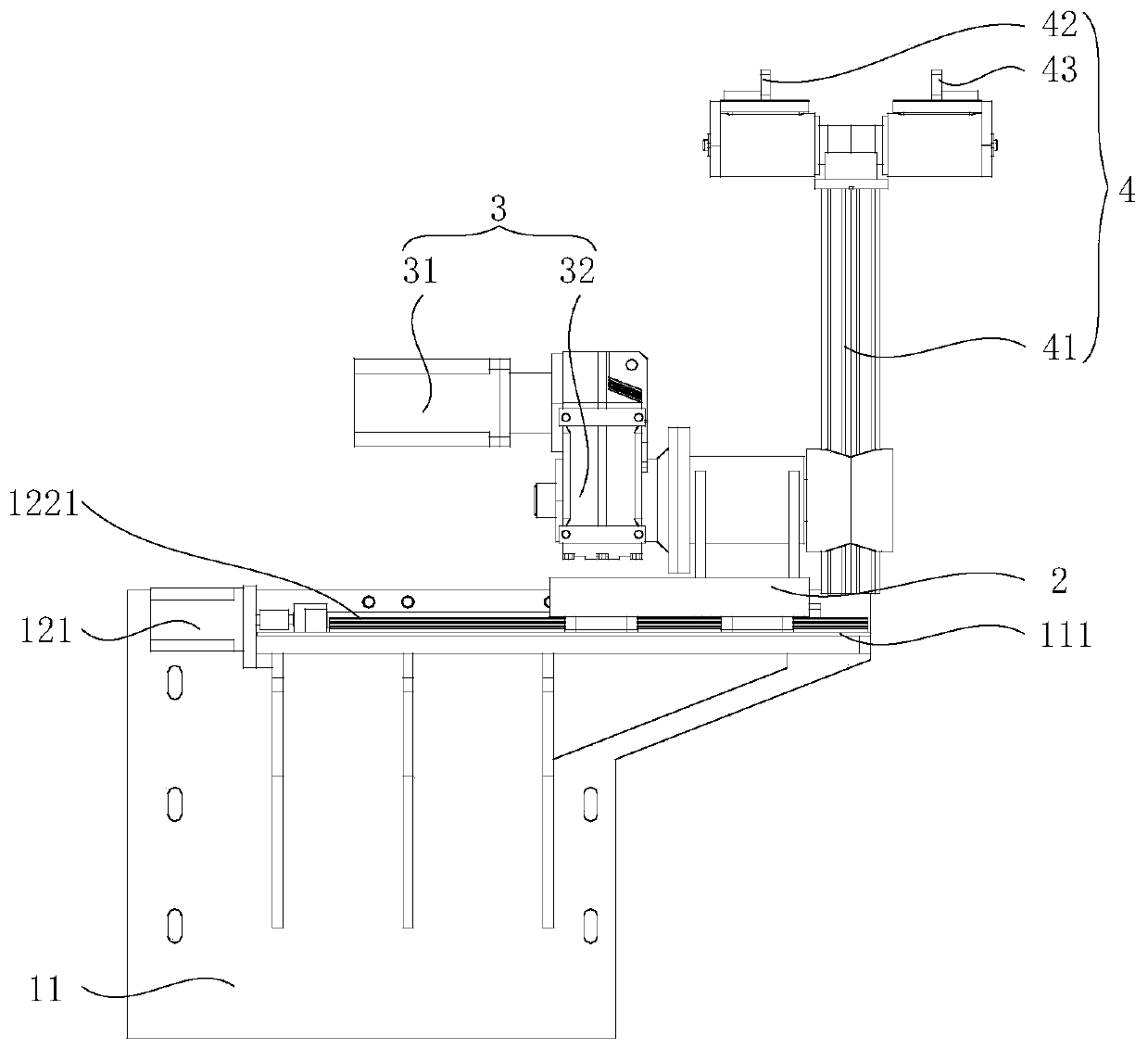

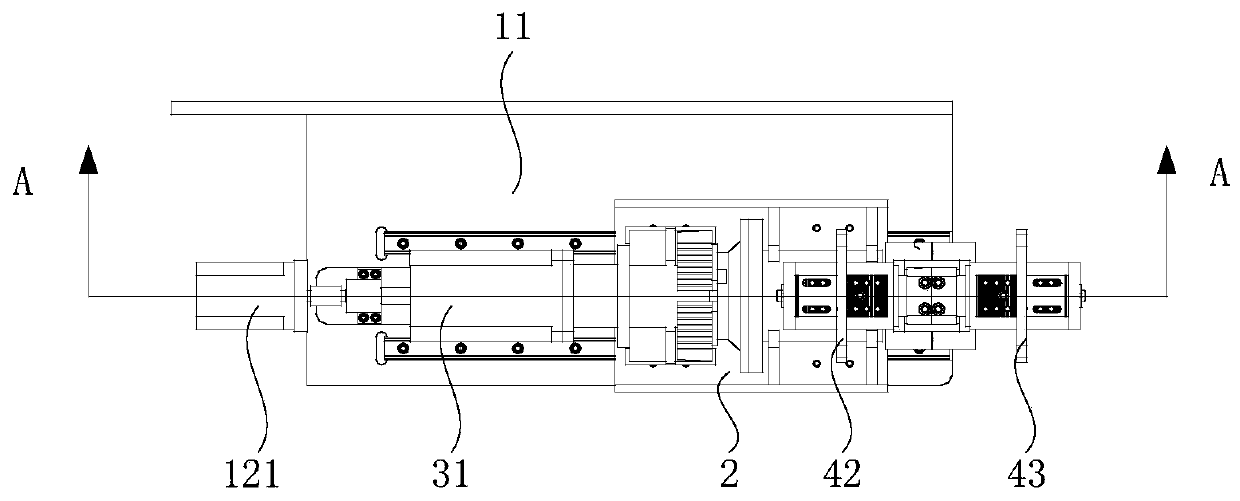

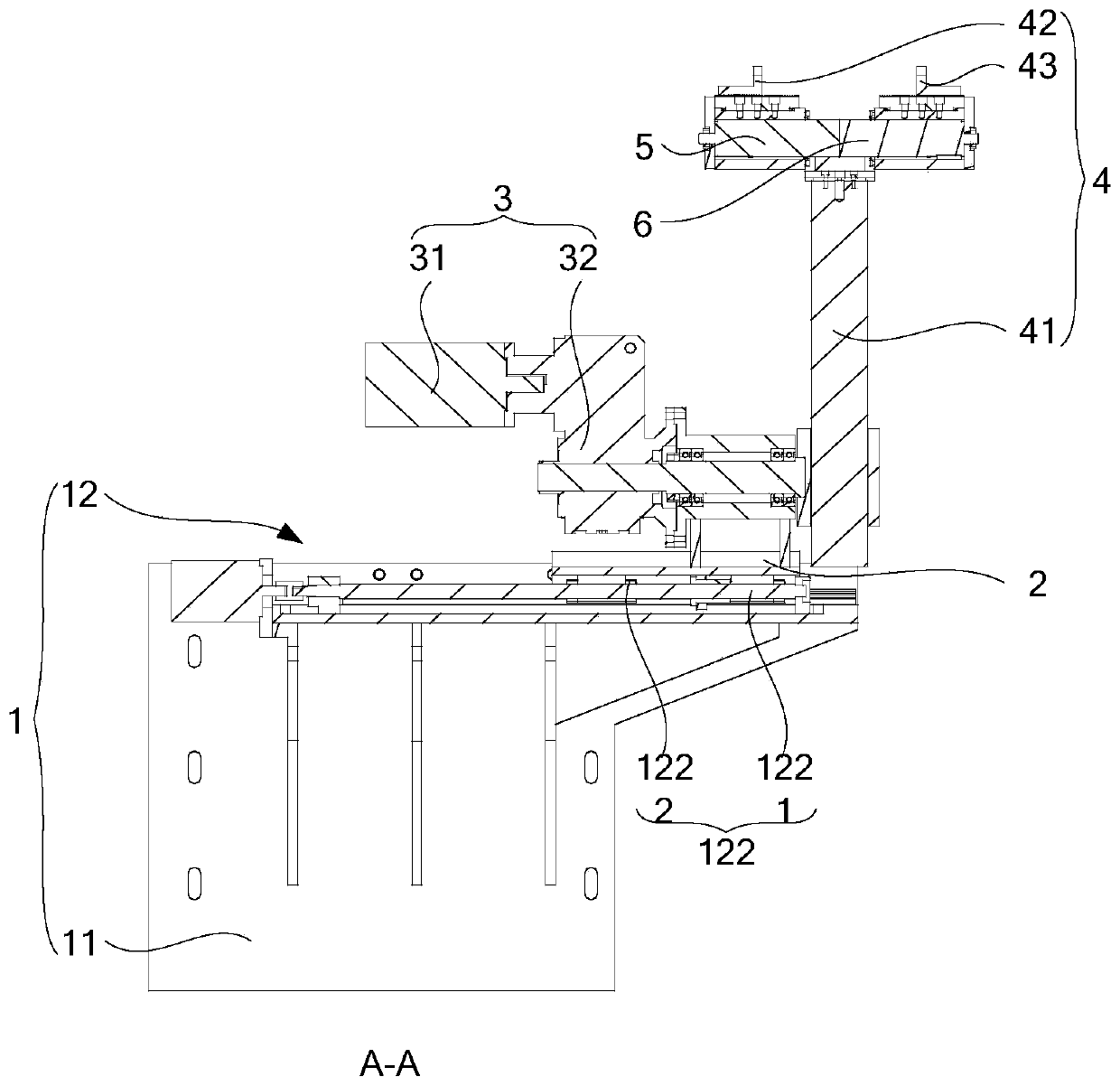

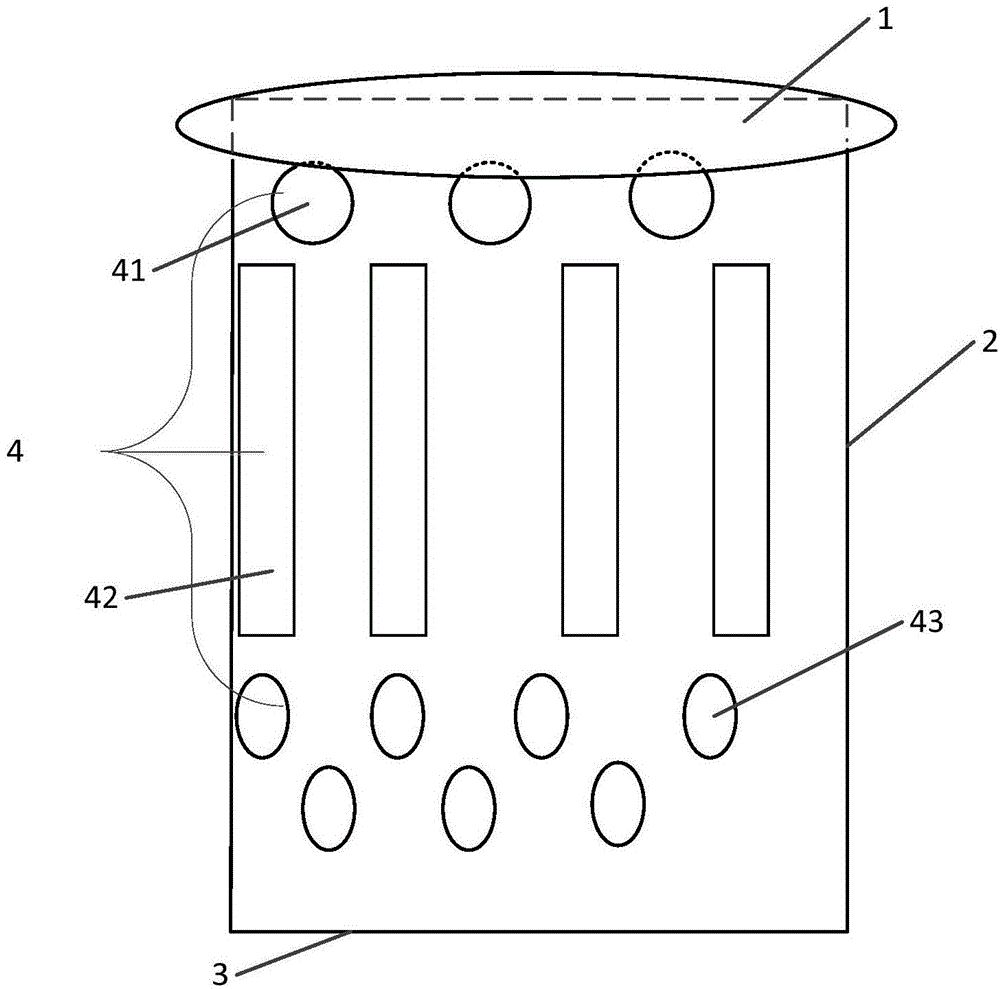

Manipulator and rim feeding and discharging device

PendingCN109746937AReduce worker laborImprove processing efficiencyProgramme-controlled manipulatorGripping headsManipulatorMaterial transfer

The invention provides a manipulator and a rim feeding and discharging device, and relates to the technical field of material transfer. The manipulator comprises a first driving device, a moving seat,a second driving device and a clamping arm for clamping materials, wherein the first driving device is connected with the moving seat, and the first driving device is used for driving the moving seatto approach or depart from the materials; and the second driving device is correspondingly connected with the moving seat and the clamping arm, and the second driving device is used for driving the clamping arm to rotate relative to the moving seat. The manipulator provided can effectively reduce the labor amount of workers, the material processing efficiency is improved, and the personal safetyof the workers is ensured.

Owner:SHANDONG XIAOYA PRECISE MACHINERY

FRP inspection shaft safety filter element

InactiveCN104929233ALow costReduce worker laborFatty/oily/floating substances removal devicesBilgeSewage

The present invention provides an FRP inspection shaft safety filter element. The filter element comprises a top end, a bottom end and a side wall positioned between the top end and the bottom end; the top end is of an opening structure; the bottom end is of a sealed structure; the side wall is provided with filtering holes; sewage flows in from the opening structure and flows out from the filtering holes; the side wall is divided into an upper layer side wall, an intermediate layer side wall and a lower layer side wall from top to bottom; the upper layer side wall is provided with first filtering holes; the intermediate layer side wall is provided with second filtering holes; the lower layer side wall is provided with third filtering holes; and the first filtering holes and the second filtering holes are distributed in a staggered manner. According to the FRP inspection shaft safety filter element, the problems that bilge wells and sewers are easily blocked and difficult to clean, and cost is high are solved; and after the filter element is filled with sewage, municipal workers can clean and recycle the sewage as clean a dustbin, and municipal pipeline dredging cost and worker labor are reduced.

Owner:朱建强

Poultry house ground cleaner

The invention discloses a poultry house ground cleaner and belongs to the technical field of stockbreeding machinery. The poultry house ground cleaner comprises an upper rack, a lower rack, a supporting pipe, an auxiliary scraping plate, an elastic scraping plate component, a spiral conveying mechanism, a coupler and a hydraulic motor; an elastic scraping plate can rotate around the supporting pipe, so that the cleaner can effectively avoid poultry house obstacles and clean poultry-livestock excrement at corners; the spiral conveying mechanism conveys excrement in front of the scraping plate to one side away from the scraping plate, so that impact on operation efficiency due to excessive accumulation of the excrement is avoided. The poultry house ground cleaner is suitable for cleaning poultry house ground excrement, the current problem that excrement at corners of a poultry house is difficult to clean can be solved effectively, worker's labor is relieved, and working efficiency is improved.

Owner:NORTHWEST A & F UNIV

Novel robot

InactiveCN108041664AImprove work efficiencyReduce worker laborFood shapingMechanical engineeringRobot

The invention discloses a novel robot which comprises a base and a hammering machine installed in the base; the hammering machine is internally provided with a rectangular slippage groove in an up anddown penetrating manner; a first cavity is arranged in the lower side wall of the slippage groove in a manner of mutually communicating and surrounding; a turning disc is connected to the interior ofthe first cavity in a matching and rotation manner; a first transfer cavity is arranged in the hammering machine on the right side of the first cavity; a toothed wheel is connected to the interior ofthe first transfer cavity in the matching and rotation manner; the top of the toothed wheel is connected with a first electromotion rotation machine in the matching manner; the outer surface of the first electromotion rotation machine is arranged in the inner wall of the top of the first transfer cavity and is fixedly connected with the interior of the inner wall of the top of the first transfercavity; a toothed ring is fixedly arranged surrounding the outer surface of the turning disc; and the right side of the toothed ring extends into the first transfer cavity and is in wedged connectionwith the left side of the toothed wheel. The novel robot provided by the invention is simple in structure and convenient to operate, realizes reciprocating hammering work by driving a hammer at the bottom of an associated device by a transfer device and improves the working efficiency of hammering.

Owner:吴康康

LED lamp

ActiveCN106895356AReduce worker laborPrevent accidental electric shock accidentsElectric circuit arrangementsWith built-in powerEngineeringMechanical engineering

The invention discloses an LED lamp. The LED lamp comprises a shell fixed to the top of a machine seat and a ceiling arranged above the shell. A cavity is formed in the shell. A first transverse cavity and a second transverse cavity are formed in the portion, on the top of the cavity, in the shell. A sliding groove is formed in the top wall in the first transverse cavity. A taking and placing groove is formed in the portion, on the right side of the cavity, on the outer wall of the shell. A penetrating groove and a clamping groove are formed between the taking and placing groove and the cavity. A rotary pin shaft is arranged in the cavity in a vertically-extending manner. The extending section of the top of the rotary pin shaft penetrates the inner wall of the shell and enters the first transverse cavity. A first tooth-shaped wheel is fixedly arranged at the tail end of the rotary pin shaft in the first transverse cavity. A rolling disc is fixedly arranged on the portion, in the cavity, of the rotary pin shaft. A power line is wound around the inner portion of the rolling disc. A sliding block is arranged in the sliding groove. The bottom of the sliding block enters the first transverse cavity. A first electromotor is arranged in the end face of the bottom of the sliding block. The LED lamp is simple in structure, convenient to operate, capable of conducting the take-up work and high in safety.

Owner:ZHEJIANG MINGCHUANG OPTO ELECTRONICS TECHNOLOGH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com