High-precision product packaging bag hole forming machine

A technology of hole punching machine and packaging bag, which is applied in metal processing and other directions, and can solve the problems of not being able to make holes in packages with special shapes, the accuracy of hole opening positions is not high, and can only be operated on a plane, so as to improve the efficiency of punching work and reduce The effect of worker labor and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

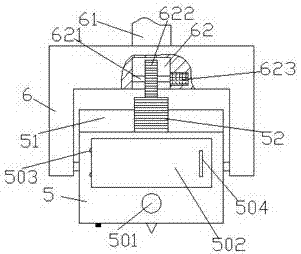

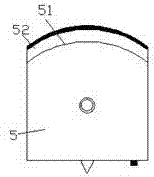

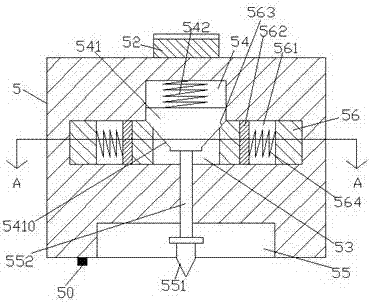

[0020] Such as Figure 1-Figure 5 As shown, a high-precision product packaging bag punching machine of the present invention includes a bracket 6 and a punching machine 5 that is rotatably mounted in the bracket 6. The top of the punching machine 5 is provided with a transition section 51. The transition section 51 is fixed with a toothed arc bar 52, and the bracket 6 on the upper side of the toothed arc bar 52 is provided with an angle adjustment device that is connected with the toothed arc bar 52. The bottom surface of the hole opening machine 5 There is a first accommodation groove 55 inside, and the inside of the drilling machine 5 on the upper side of the first accommodation groove 55 is provided with a first slide chamber 53 extending left and right, and the middle part of the inner top wall of the first slide chamber 53 is opposite to each other. A second slide chamber 54 is connected through it, and a pushing block 541 is slidingly fitted in the second slide chamber 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com