Liquid phase separation device and using method thereof

A liquid phase separation and suspension device technology, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of large labor load of workers, and achieve the effect of improving work efficiency and reducing labor load of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

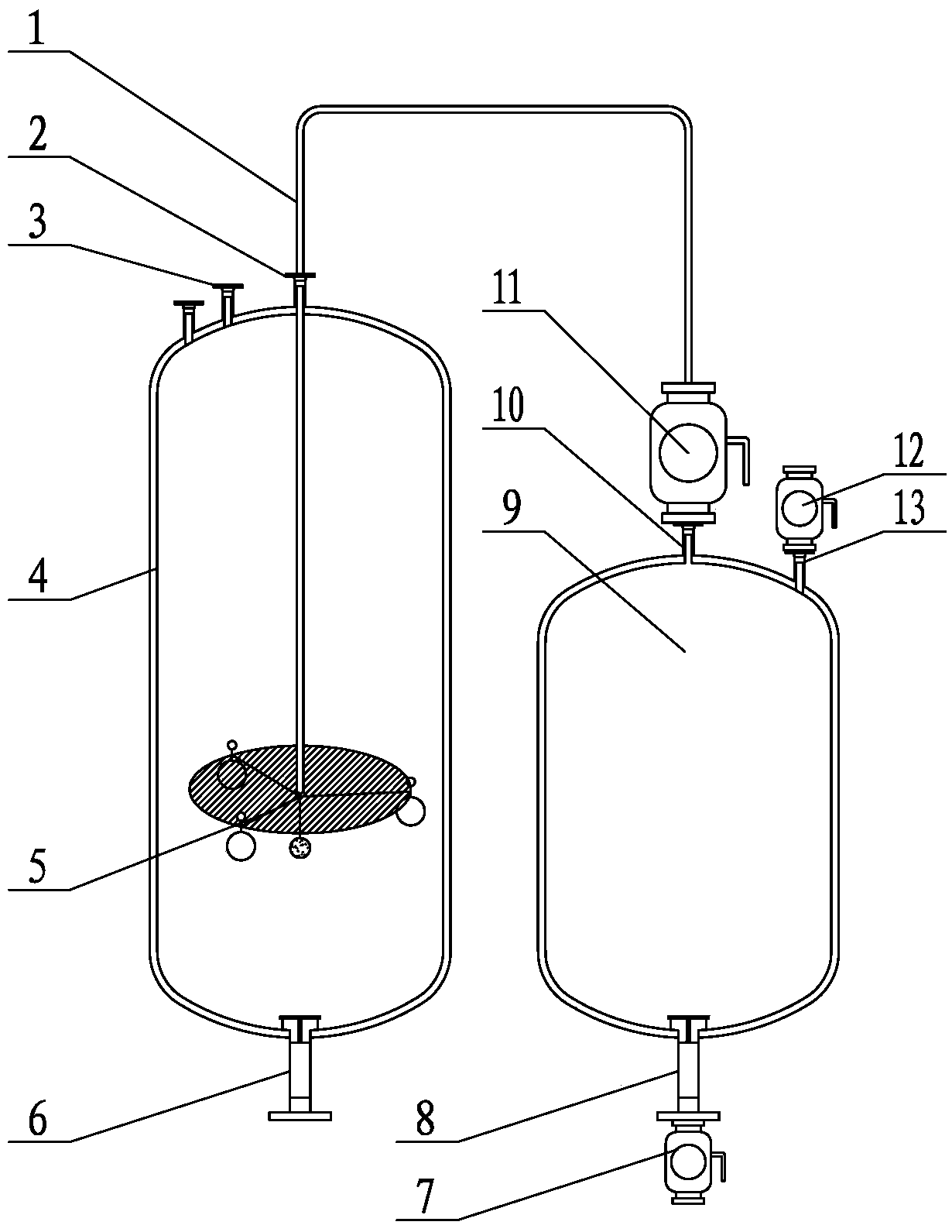

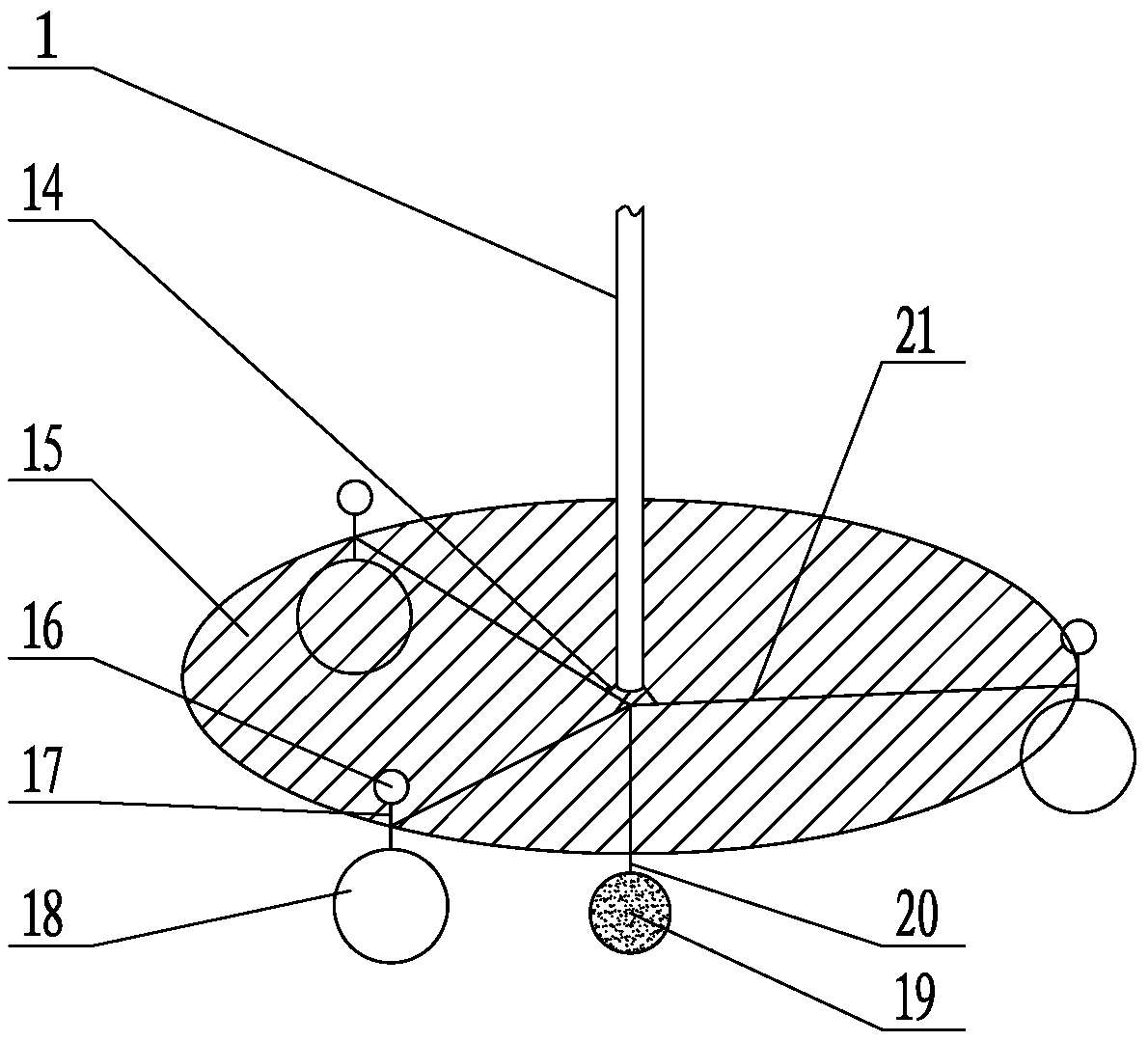

[0038] In this example, the two liquid phases that need to be separated are difluorochloroethane (R142b) and water. The outer diameter of the lower float is 15 cm, and the outer diameter of the upper float is 10 cm. The float is made of stainless steel with a thickness of 1 mm. The discharge pipe Using translucent silicone tube, size 20.0*23.0, wall thickness 1.5mm, density 1.18g / cm 3 , the distance between the upper and lower floats is 1cm, the connecting shaft is located in the middle of the upper and lower floats, and the height of the discharge pipe inlet is level with the bottom of the upper float. The liquid separation tank has a diameter of 1.6m and a height of 4m.

[0039] According to the calculation, the maximum buoyancy force that can be generated by the three lower floats in R142b is 57.15N, so the total weight of the separation device is designed to be 5.83kg.

[0040] In addition, it can be known through calculation that the maximum buoyancy force that can be ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com