Patents

Literature

36results about How to "Accurate nesting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

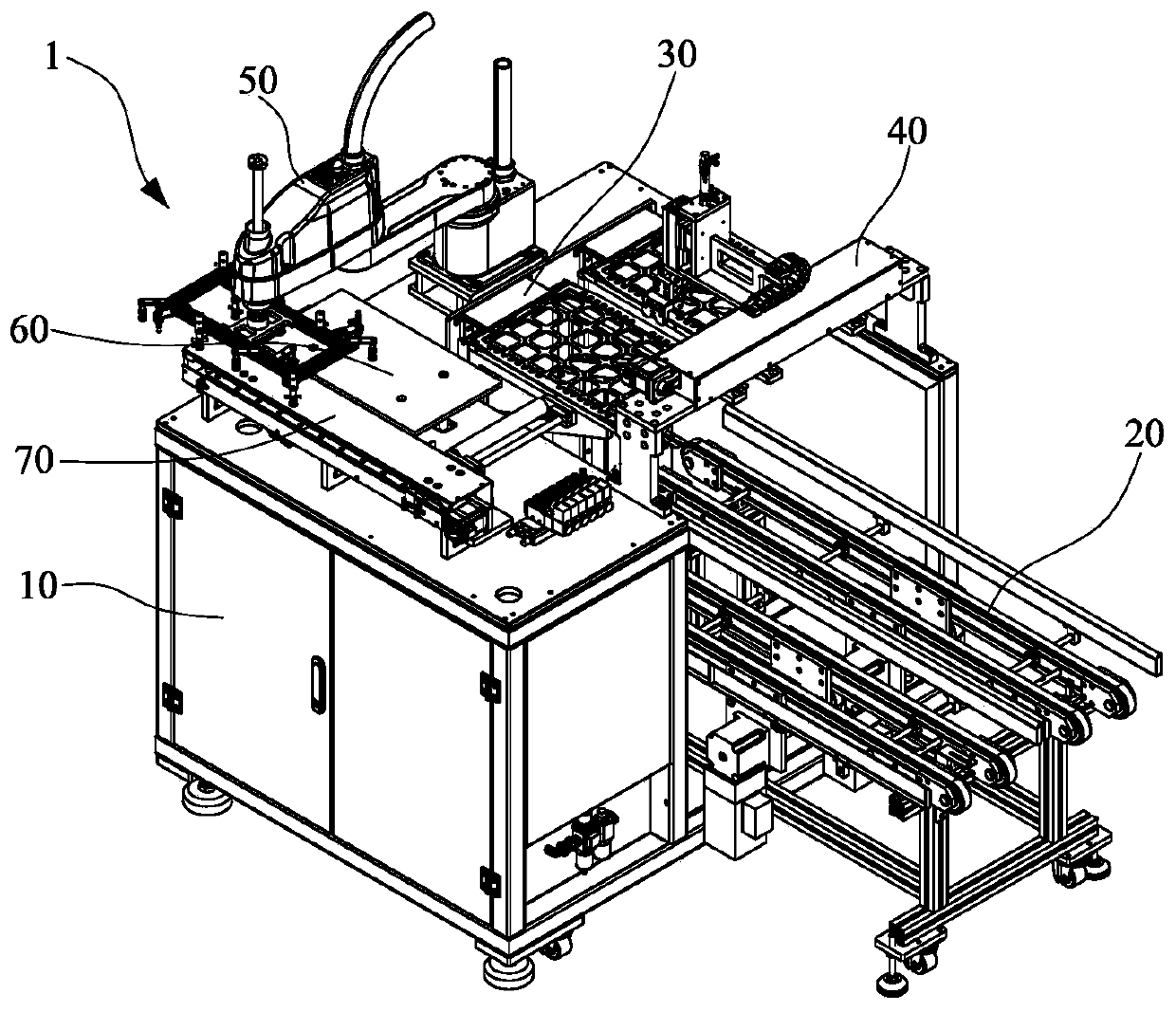

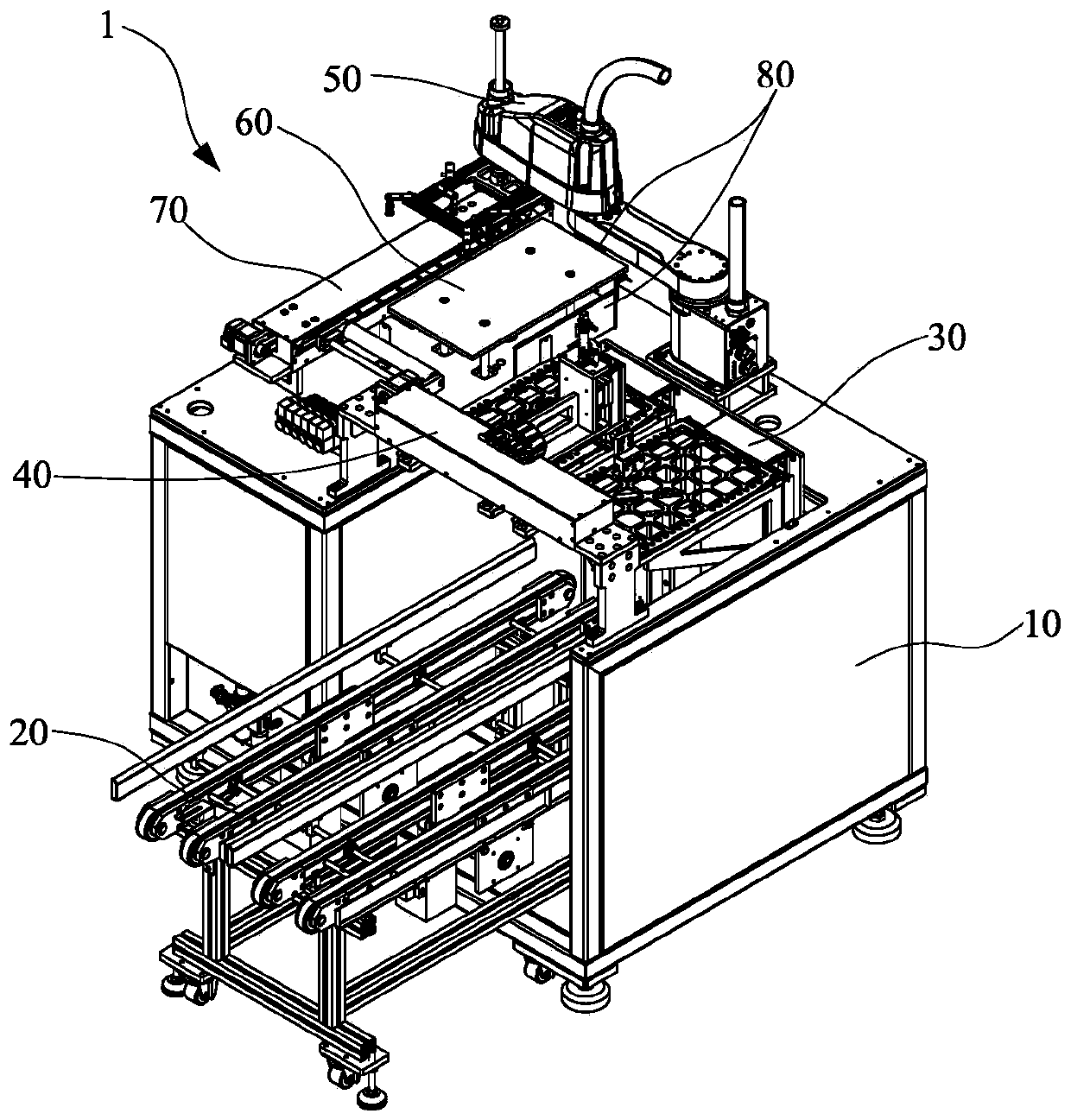

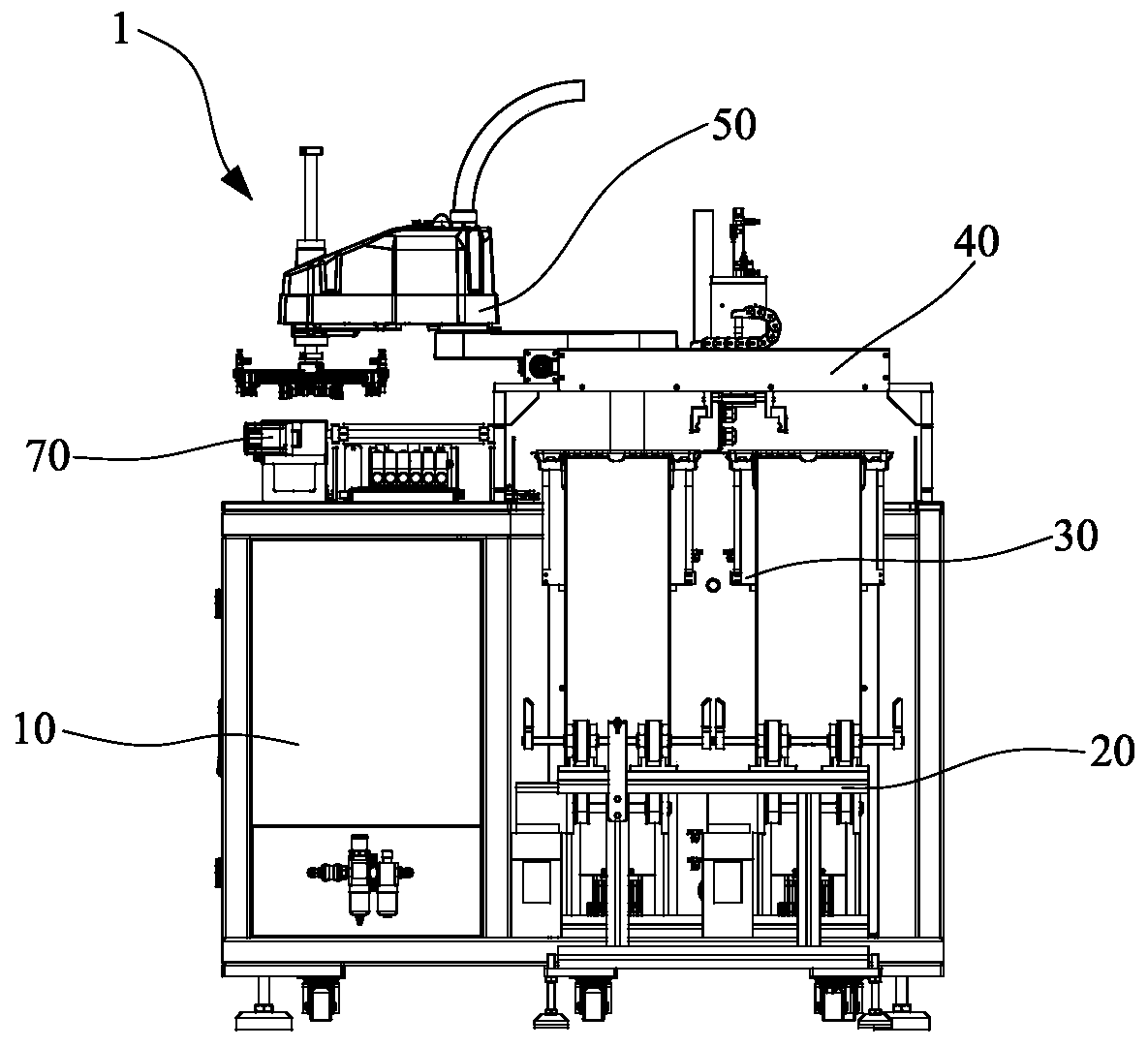

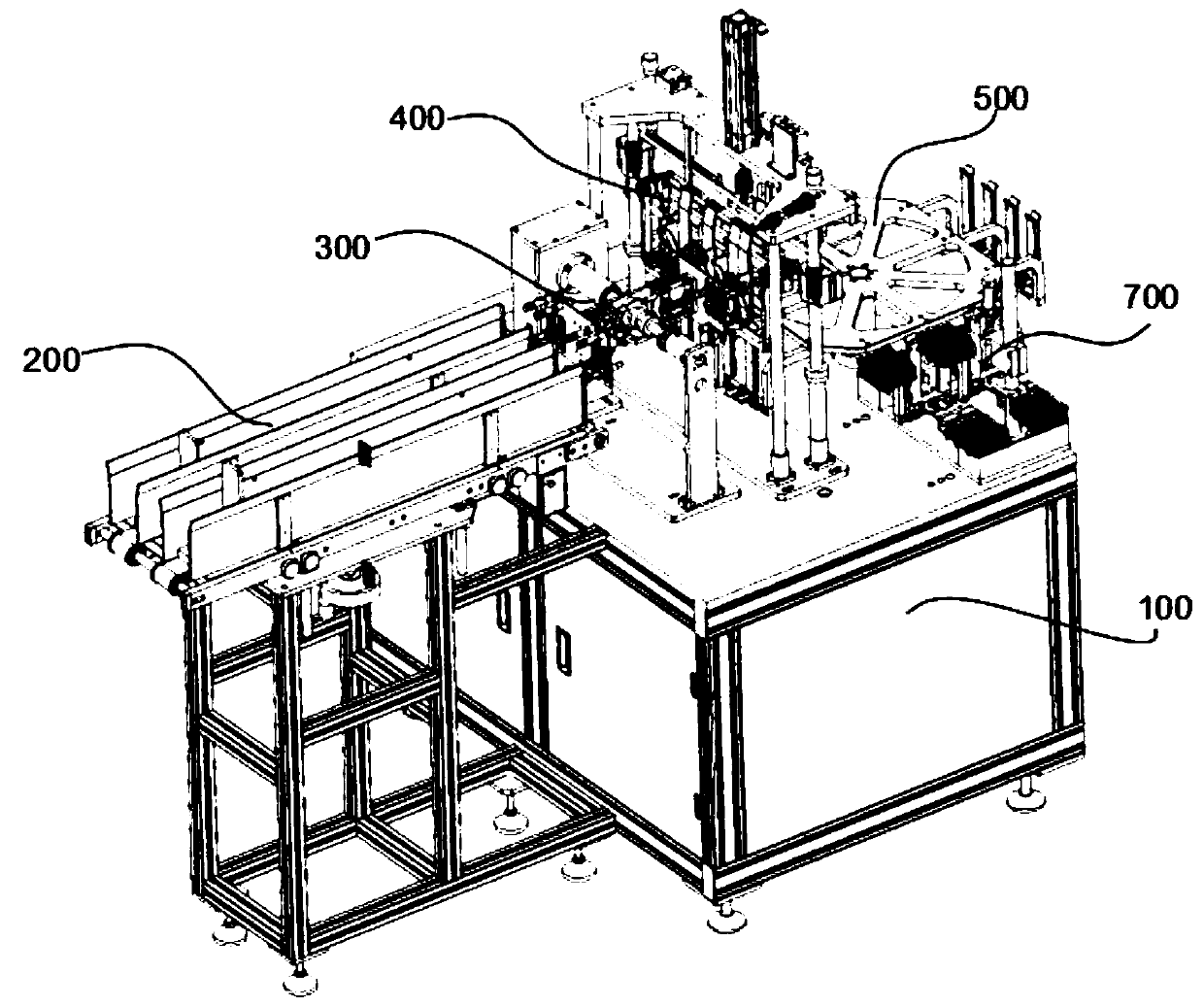

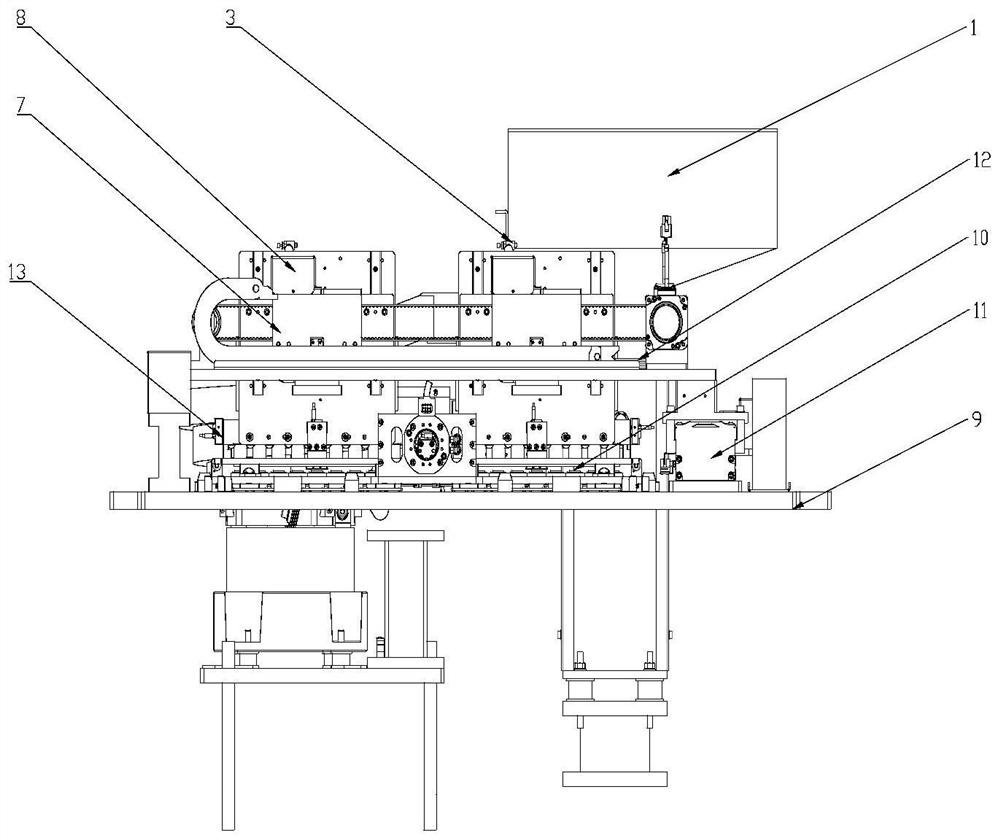

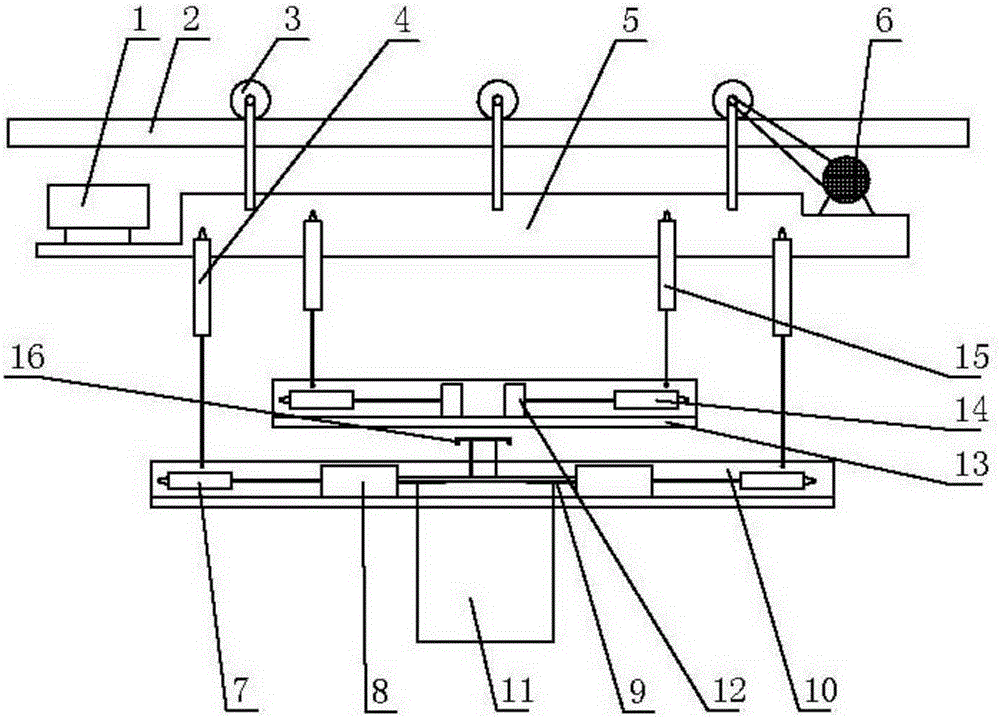

Silk-screen feeding and discharging device

PendingCN111252491ARealize handoverReduce waiting timeControl devices for conveyorsStacking articlesScreen printingEngineering

The invention discloses a silk-screen feeding and discharging device. The silk-screen feeding and discharging device comprises a rack, a tray conveying and buffering mechanism, a tray feeding and discharging mechanism, a tray carrying mechanism, a material moving manipulator and a feeding platform mechanism, wherein a workbench and a tray feeding and discharging space are arranged on the rack; thetray conveying and buffering mechanism penetrates through the tray feeding and discharging space of the rack; the tray feeding and discharging mechanism can move up and down relative to the tray conveying and buffering mechanism; the tray carrying mechanism is transversely erected on the portion, above the corresponding tray conveying and buffering mechanism, of the rack and moves in the space above the tray feeding and discharging mechanism; the material moving manipulator is arranged on the portion, on one side of the tray feeding and discharging mechanism, of the rack and rotates and movesin the space above the rack at multiple stations; and the feeding platform mechanism is arranged on the workbench of the rack and is close to the side, close to the tray feeding and discharging mechanism, of the material moving manipulator. The silk-screen feeding and discharging device can be matched with an existing semi-automatic silk-screen printing machine and transformed into a full-automatic silk-screen printing machine, existing equipment resources are fully utilized, and automation of silk-screen printing of products is achieved.

Owner:XIAMEN HONGXIN ELECTRON TECH +1

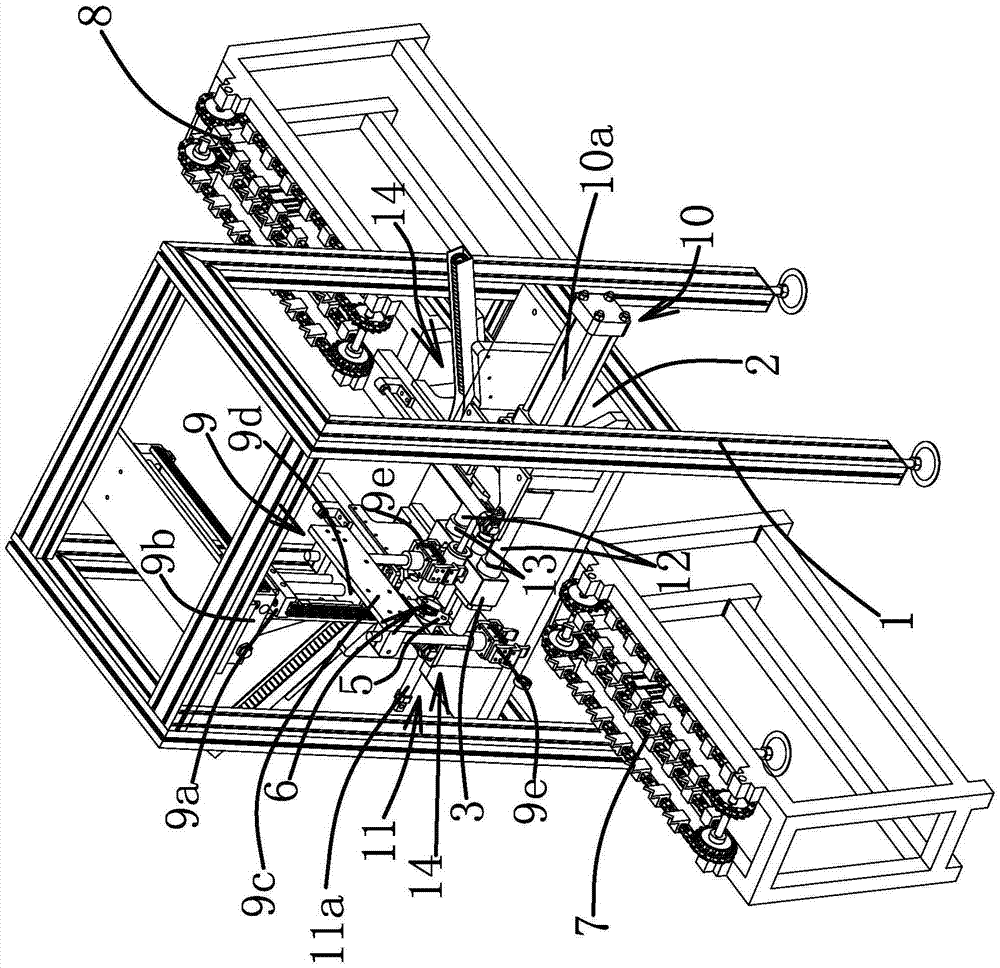

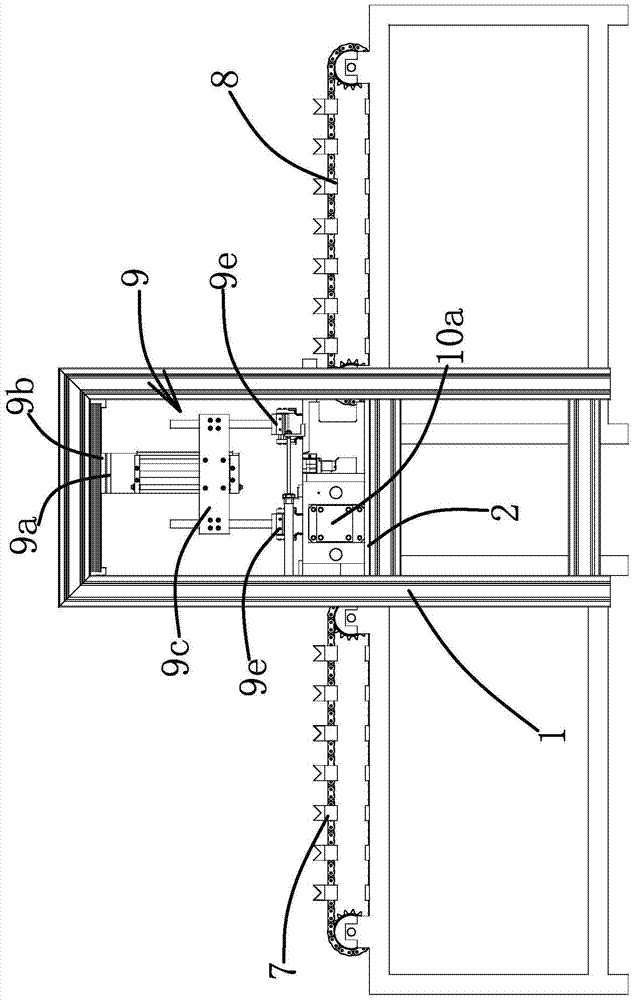

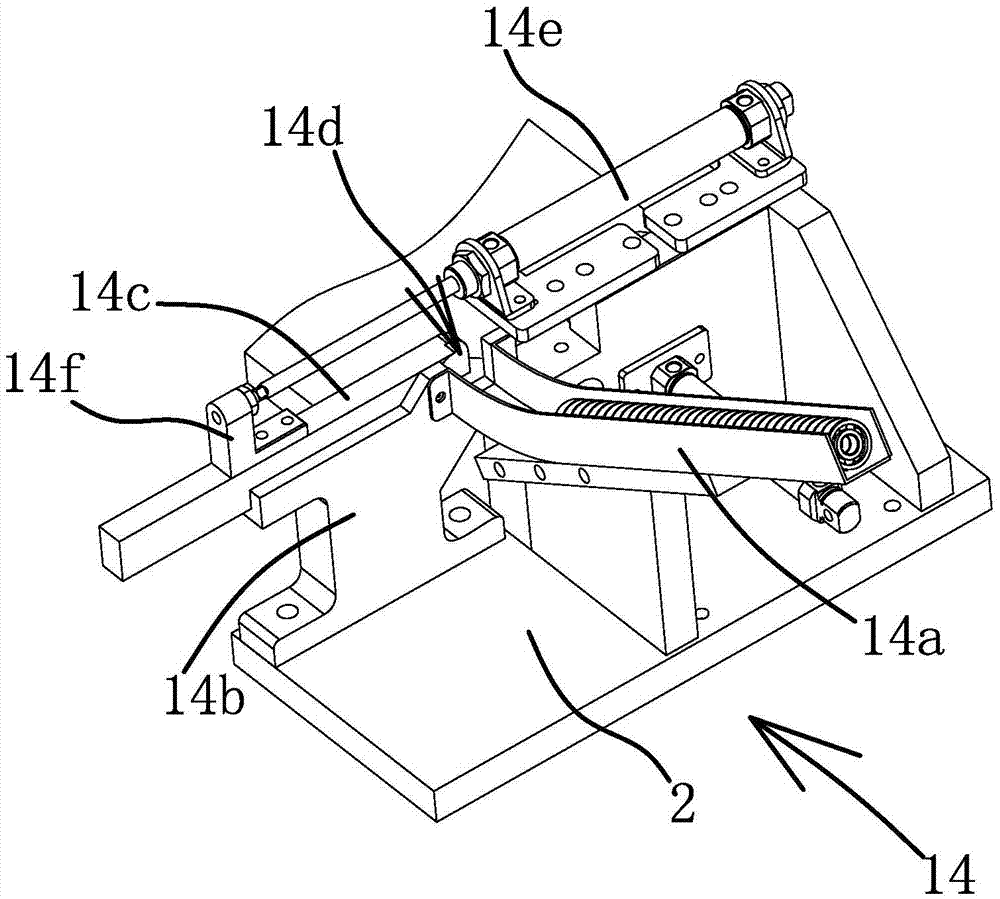

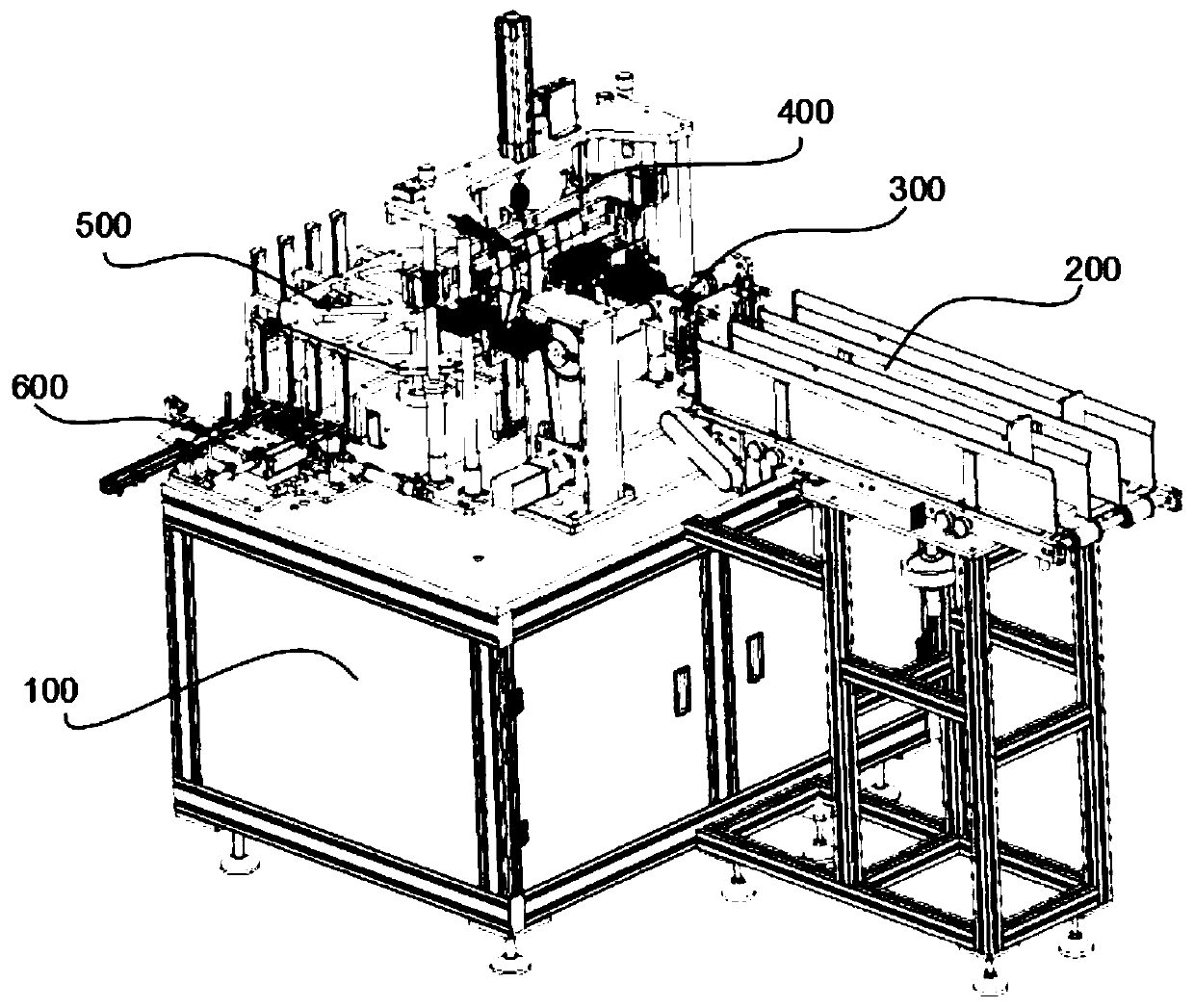

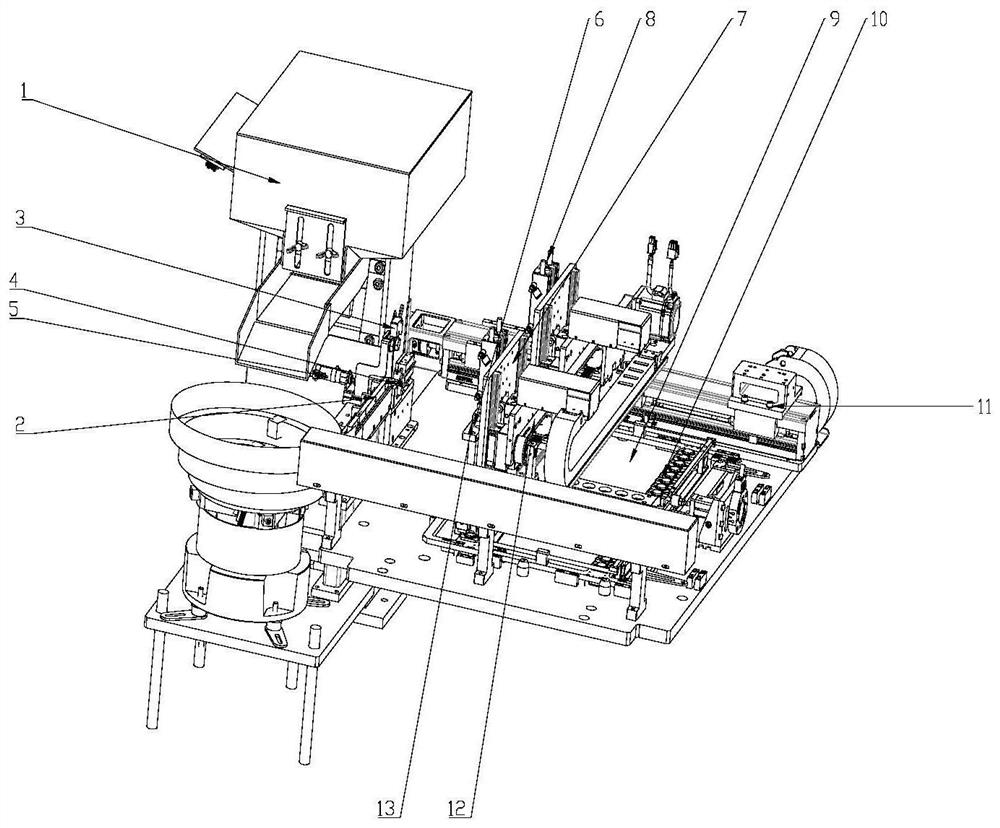

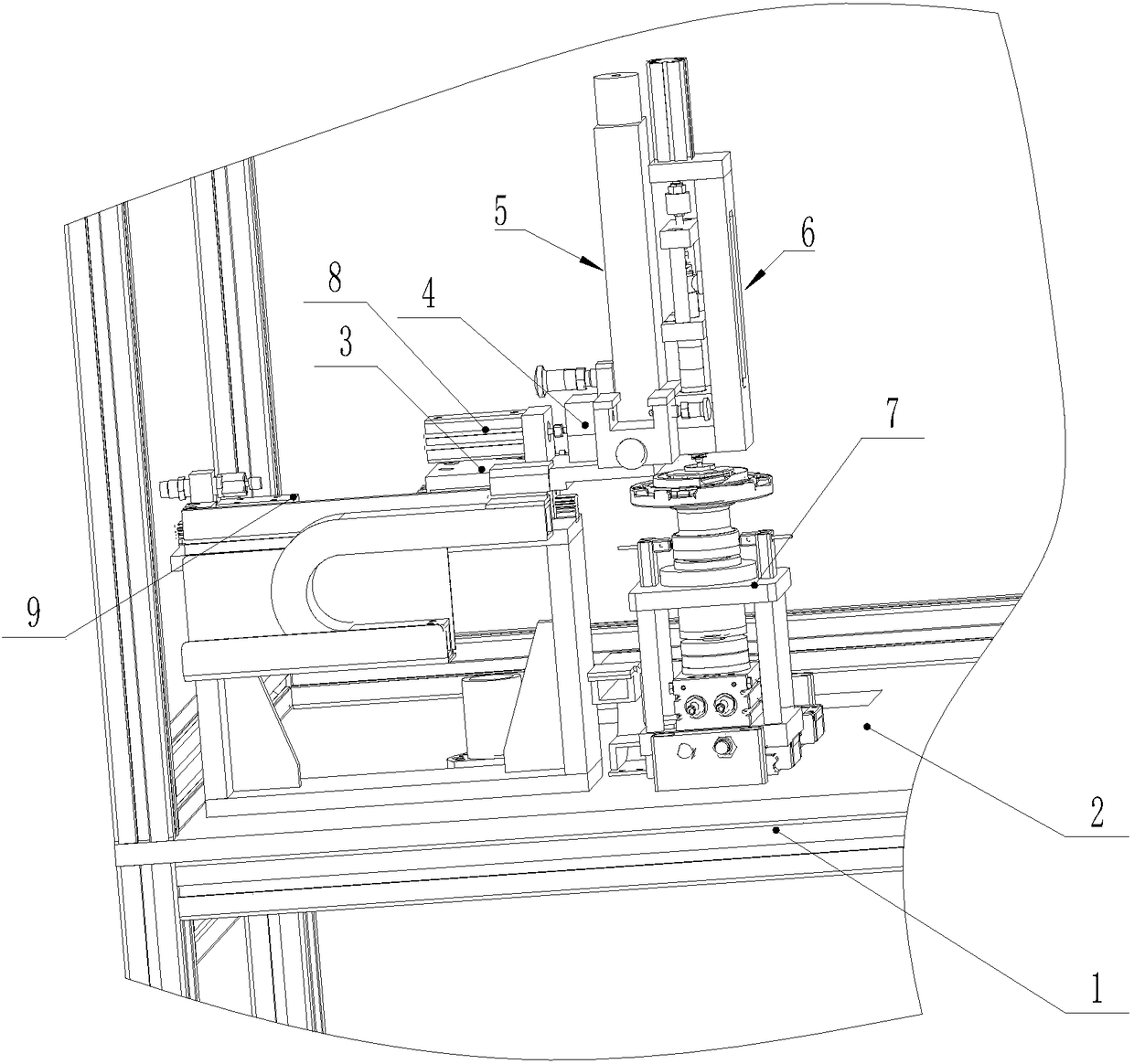

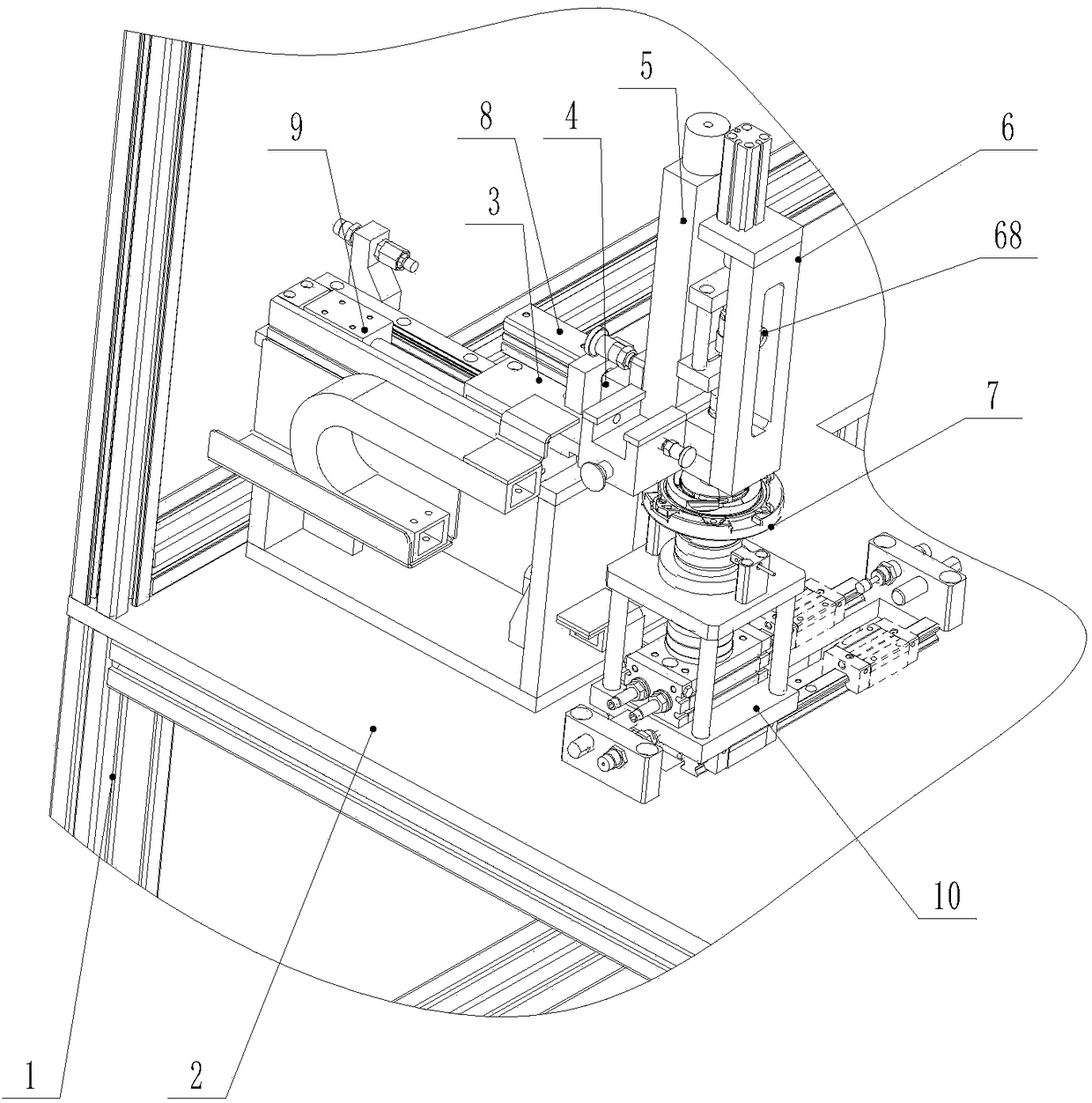

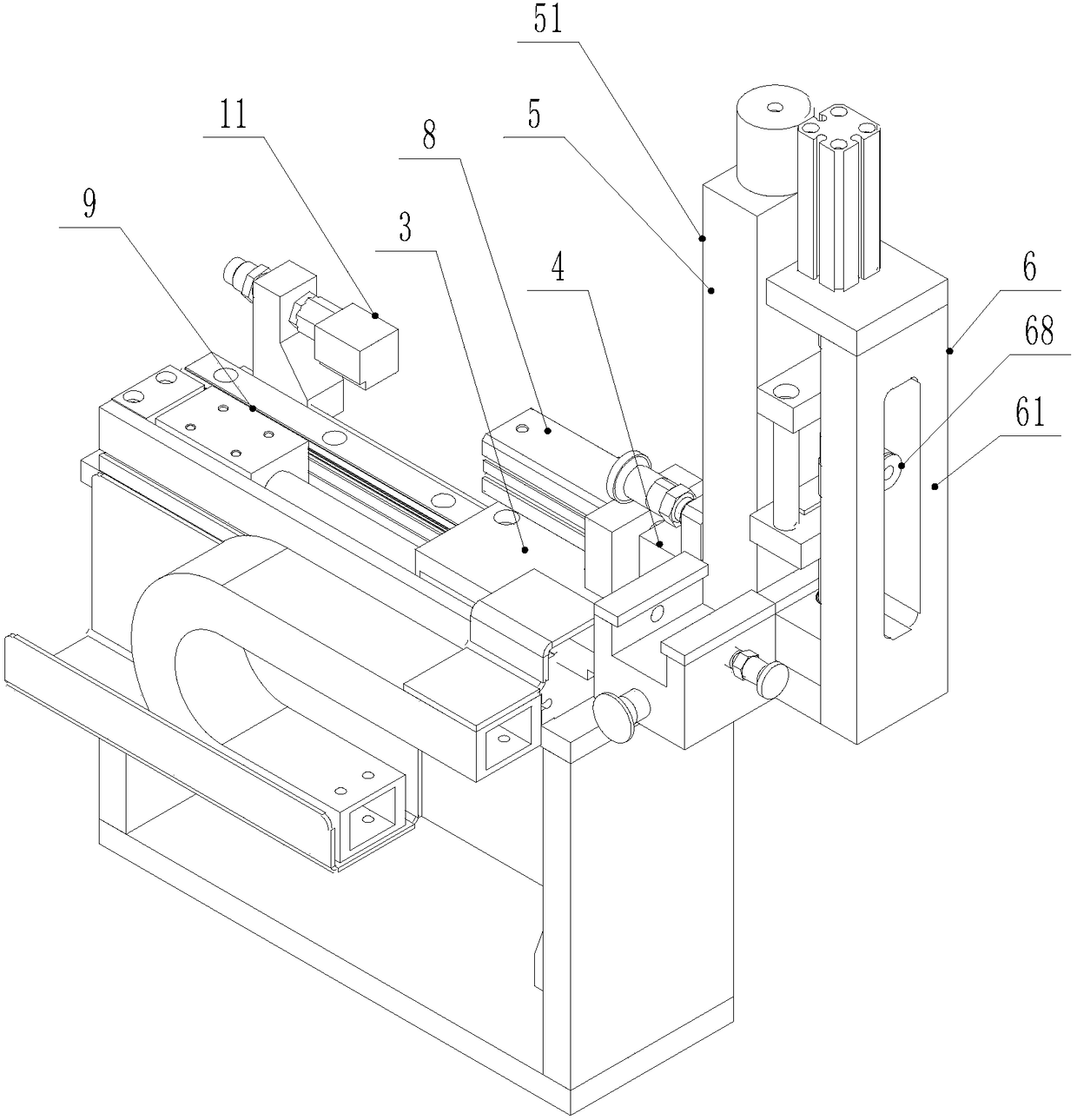

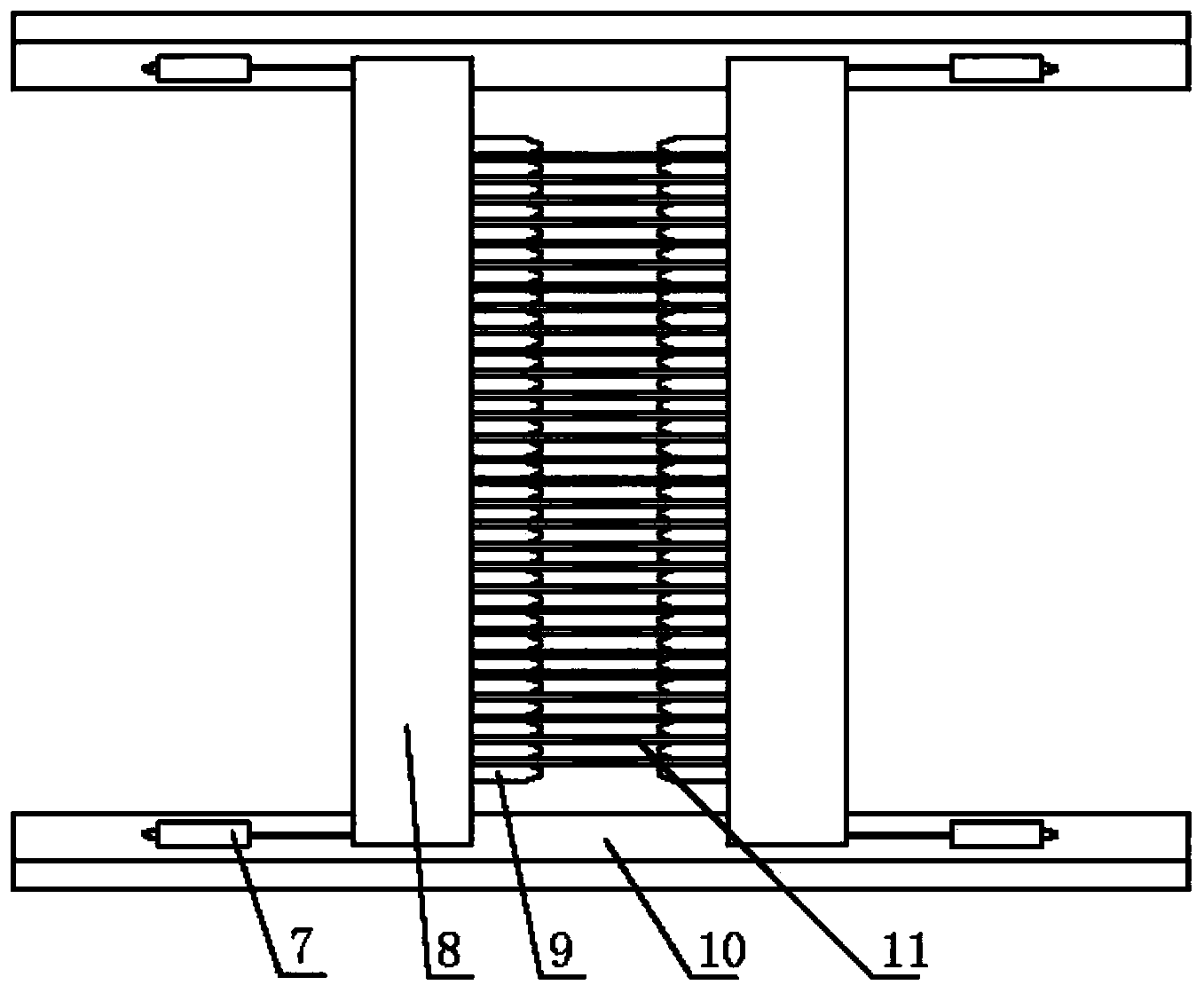

Automatic assembling machine of rotors and bearings of motors

PendingCN105436870ARealize the assemblyGuaranteed smooth assemblyMetal working apparatusMechanical equipmentEngineering

The invention provides an automatic assembling machine of rotors and bearings of motors, belongs to the technical field of mechanical equipment and solves the problem that the rotors and the bearings cannot be assembled smoothly by the existing automatic assembling machine of the rotors and the bearings of the motors. The automatic assembling machine of the rotors and the bearings of the motors comprises a frame and a workbench, wherein a positioning seat is arranged on the workbench; a material receiving block I and a material receiving block II are arranged on two longitudinal sides of the positioning seat; storage slots are formed in the material receiving block I and the material receiving block II; a conveying chain I and a conveying chain II are respectively arranged on two transverse sides of the positioning seat; a mechanical arm assembly is arranged on the workbench; a translation mechanism I capable of driving the material receiving block I to be subjected to longitudinal translation is arranged on the workbench; a resetting mechanism is arranged between the workbench and the positioning seat. The automatic assembling machine of the rotors and the bearings of the motors has the advantage that the rotors and the bearings are smoothly assembled.

Owner:LEO GRP ZHEJIANG PUMP CO LTD

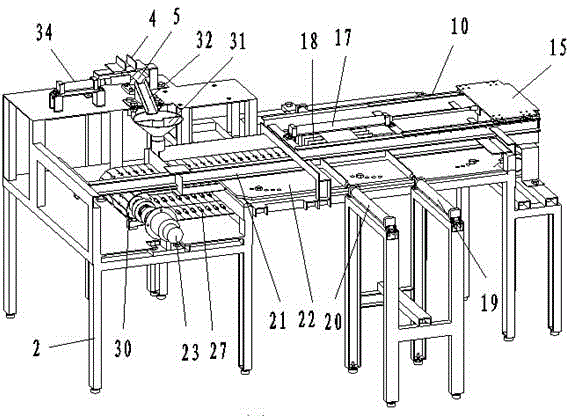

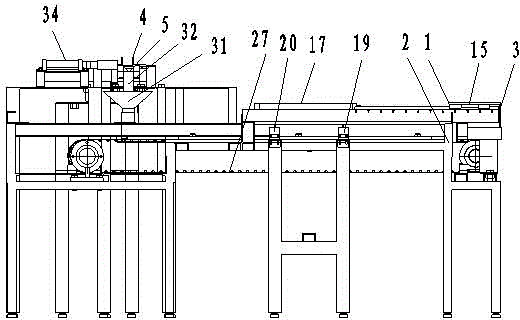

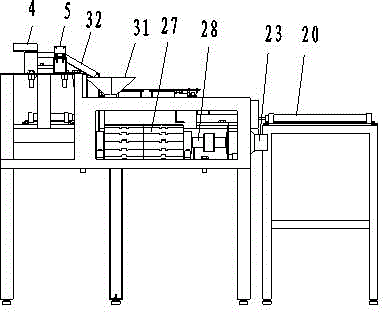

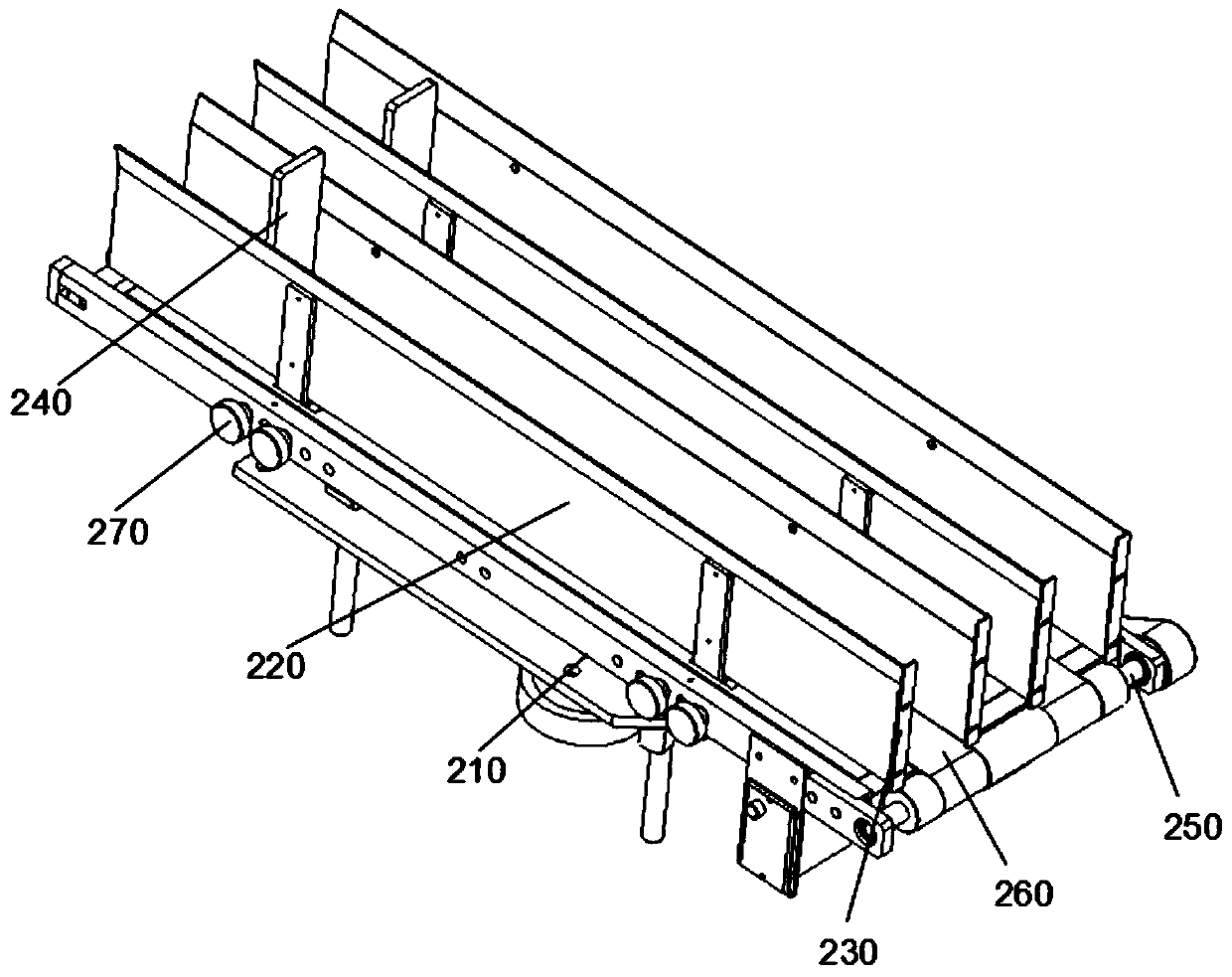

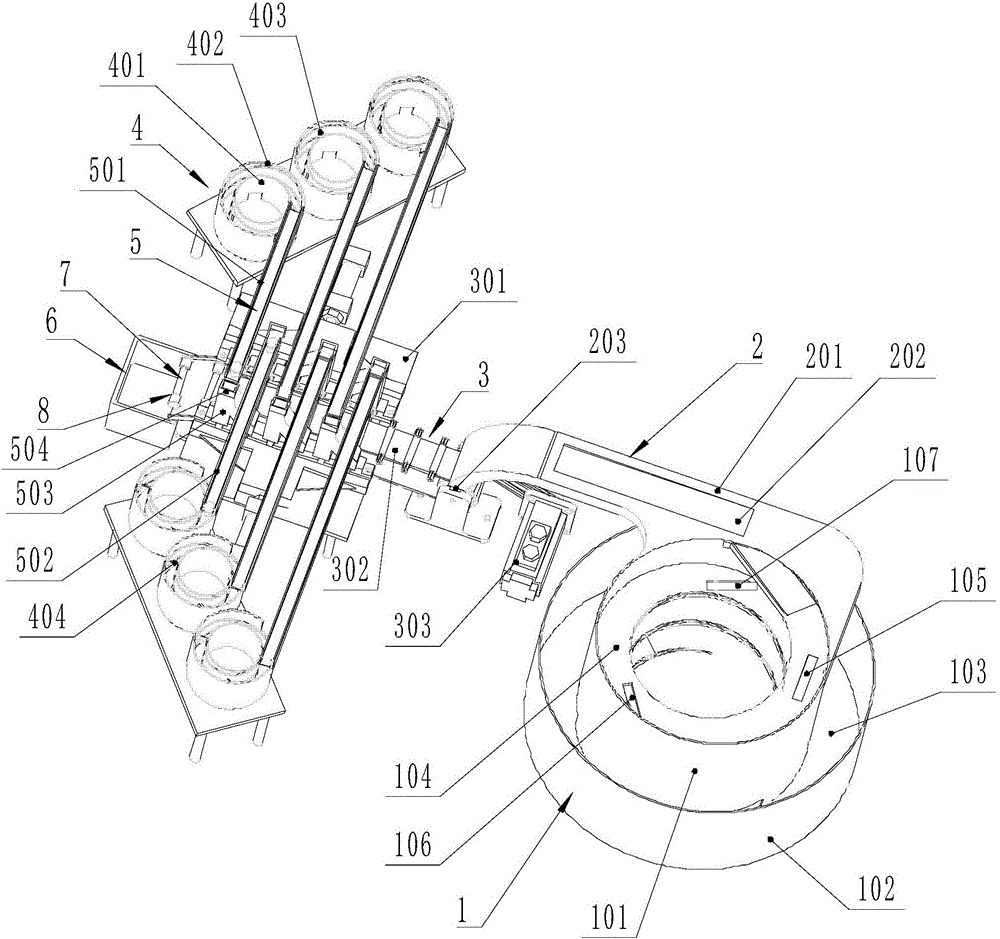

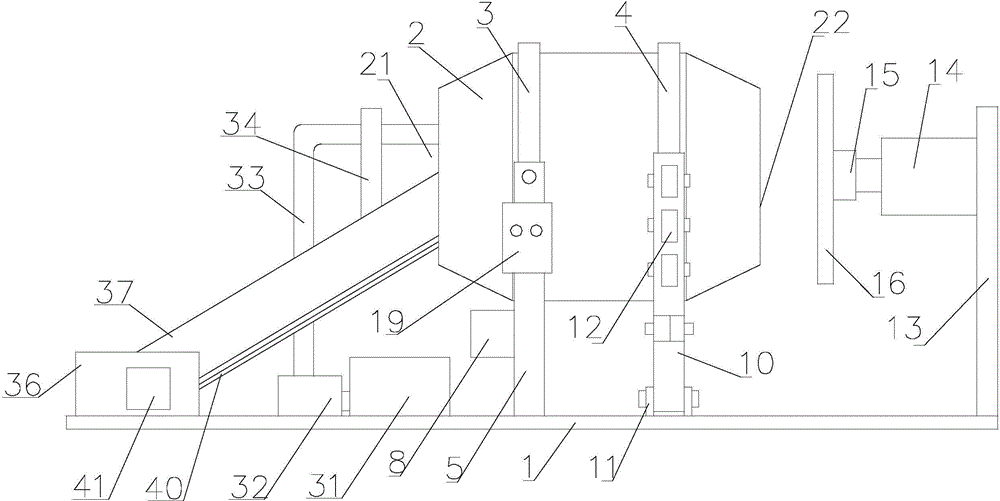

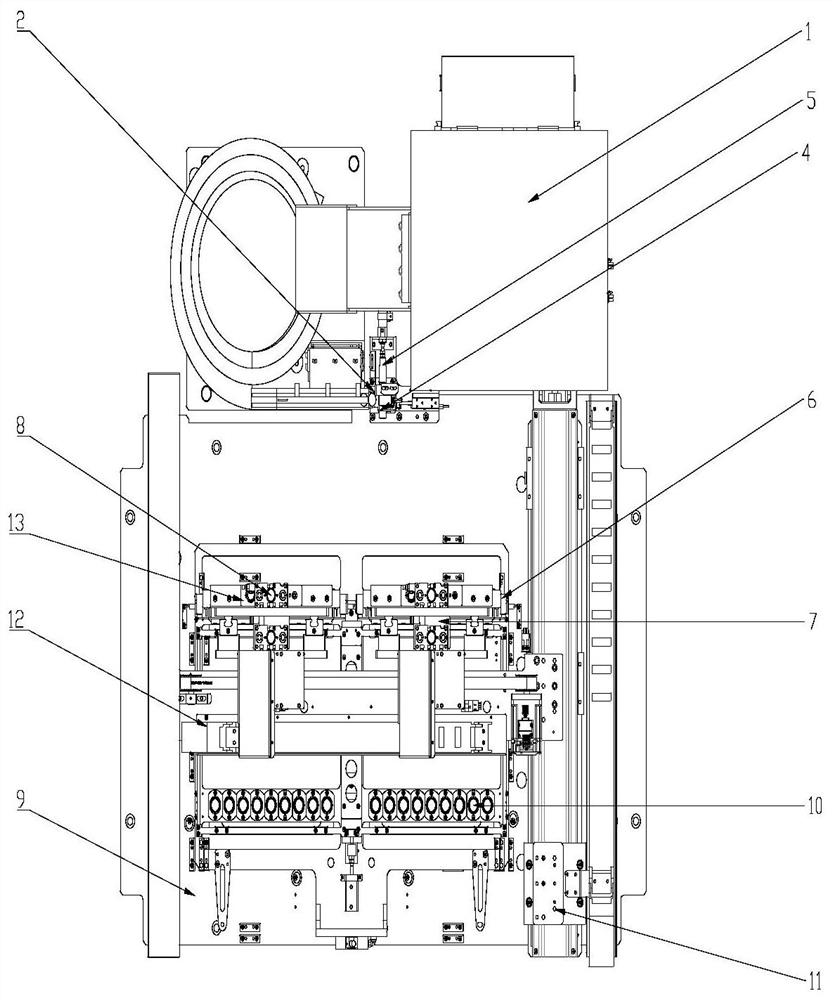

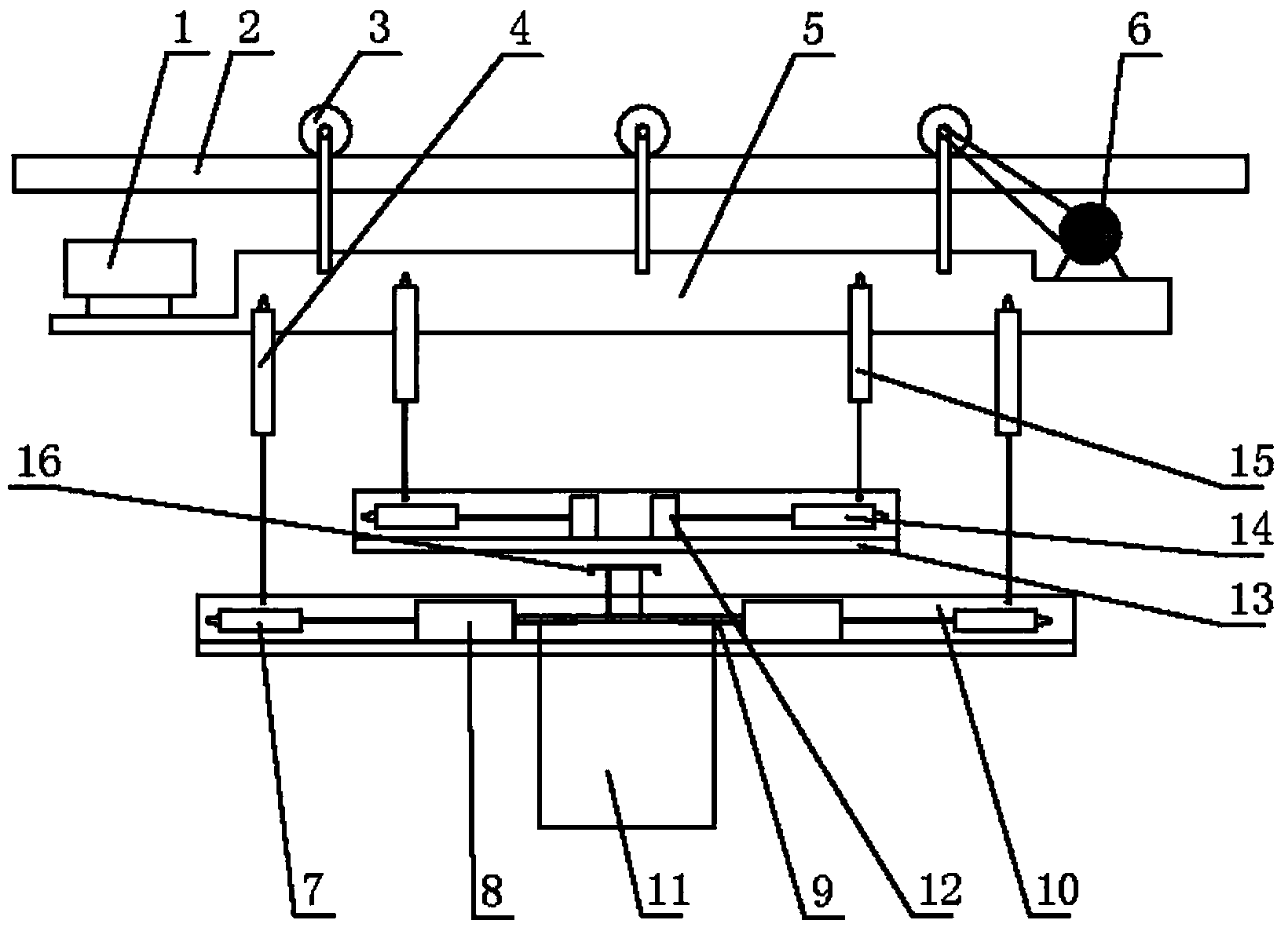

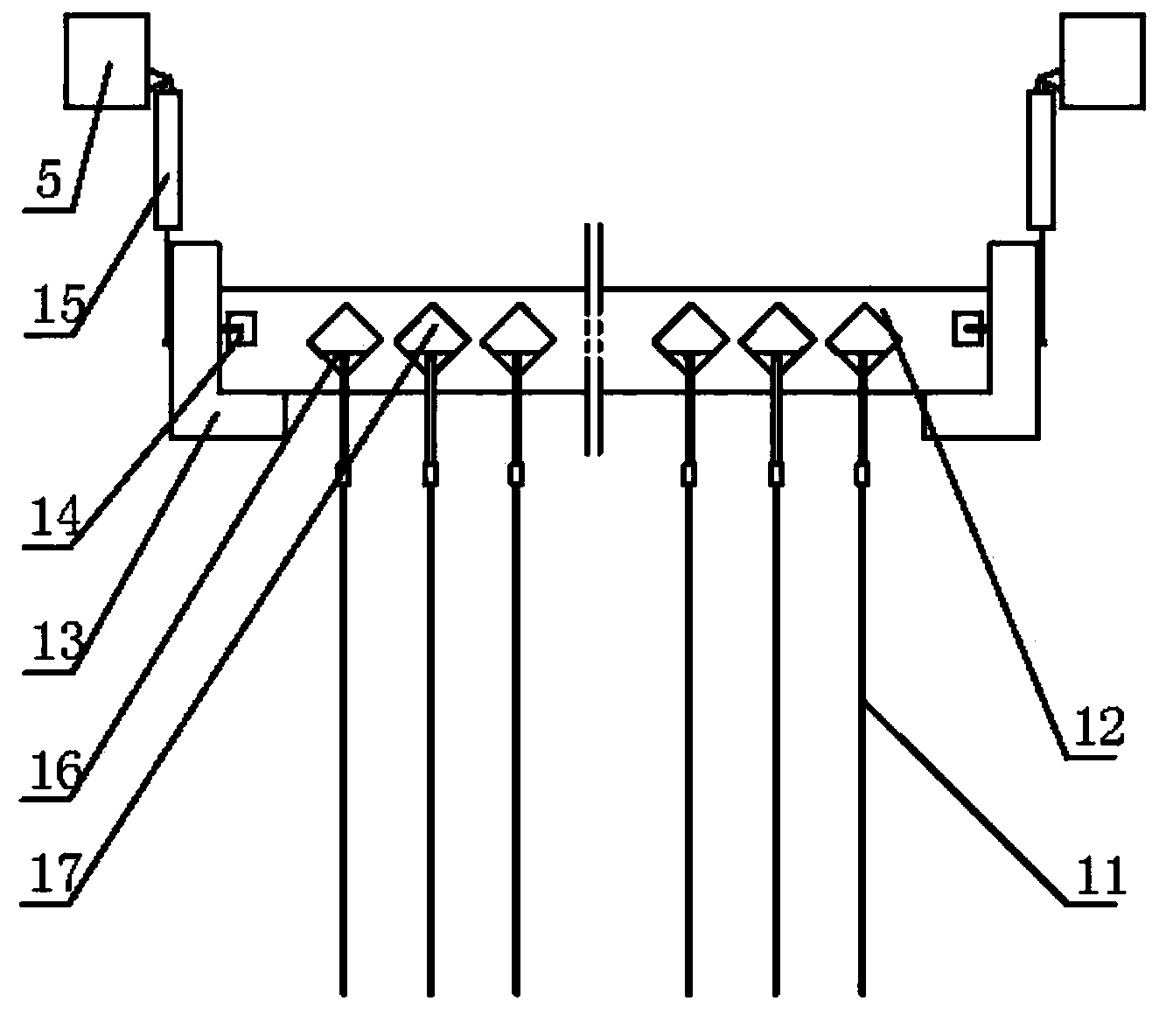

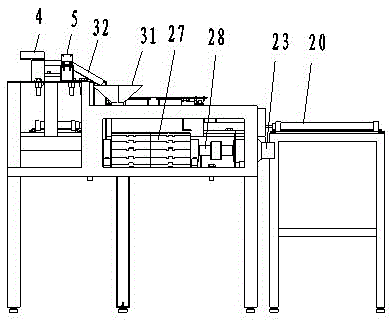

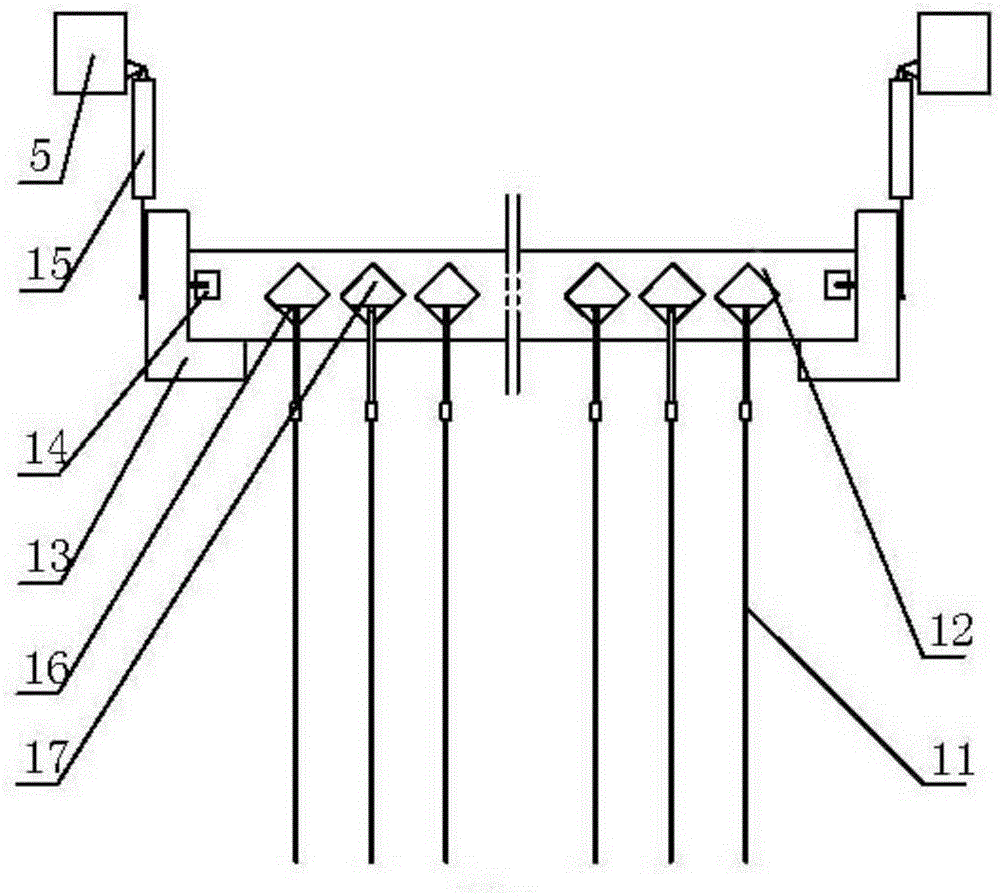

Rebar connecting sleeve conveying and arranging device

ActiveCN104097803AHigh degree of mechanization and automationReasonable layoutPackagingEngineeringWorkstation

The invention belongs to the technical field of rebar connecting sleeve packaging equipment and discloses a rebar connecting sleeve conveying and arranging device which is used for directionally arranging connecting sleeves. The technical scheme includes that a printing, feeding and conveying mechanism can print and convey the connecting sleeves individually, a connecting sleeve conveying and turning mechanism changes the connecting sleeves from horizontal direction to vertical direction and conveys the same onto chain plates, a chain plate conveying mechanism realizes material transmission in the process of array arrangement of the connecting sleeves, an array arranging mechanism performs array rule sequencing on the connecting sleeves on the chain plates, an array sleeve pushing mechanism conveys the connecting sleeves which are arranged well to a next workstation, and an adjusting mechanism can perform array adjusting of the connecting sleeves. The rebar connecting sleeve conveying and arranging device fills a gap in automatic packager arranging equipment for the connecting sleeves, is reasonable in layout, perfect in connection, accurate in discharging and reliable in running, and is suitable for being used as an arranging device of an automatic connecting sleeve packager, and mechanized and automated degree of the automatic connecting sleeve packager is increased greatly.

Owner:HEBEI YIDA REINFORCING BAR CONNECTING TECH

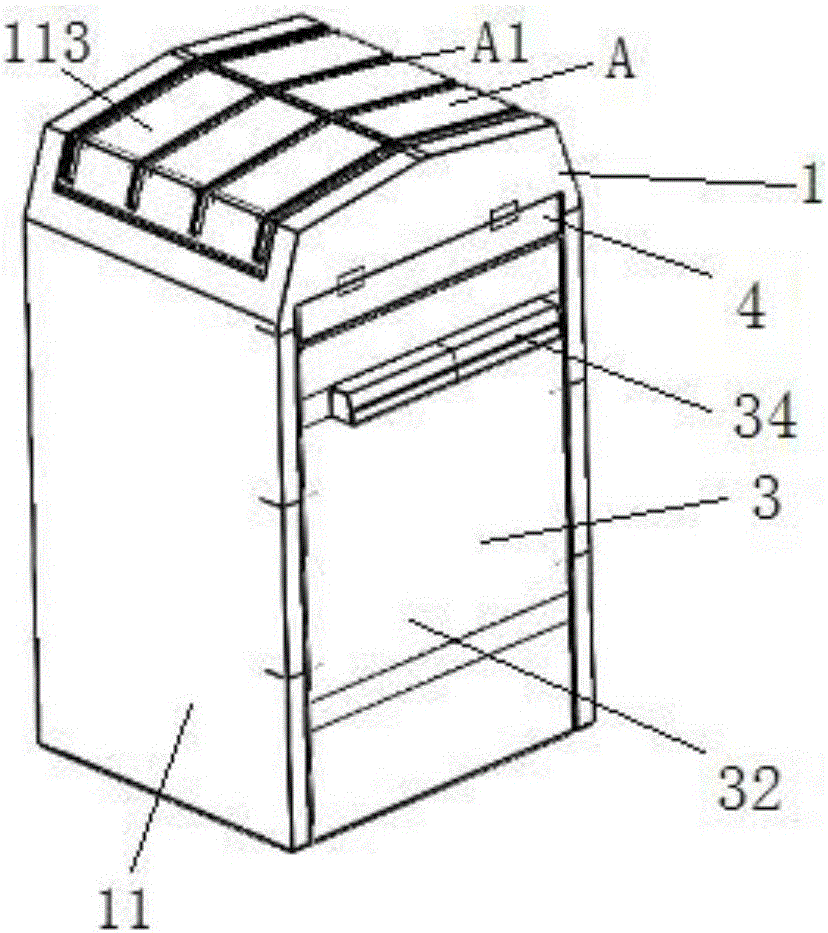

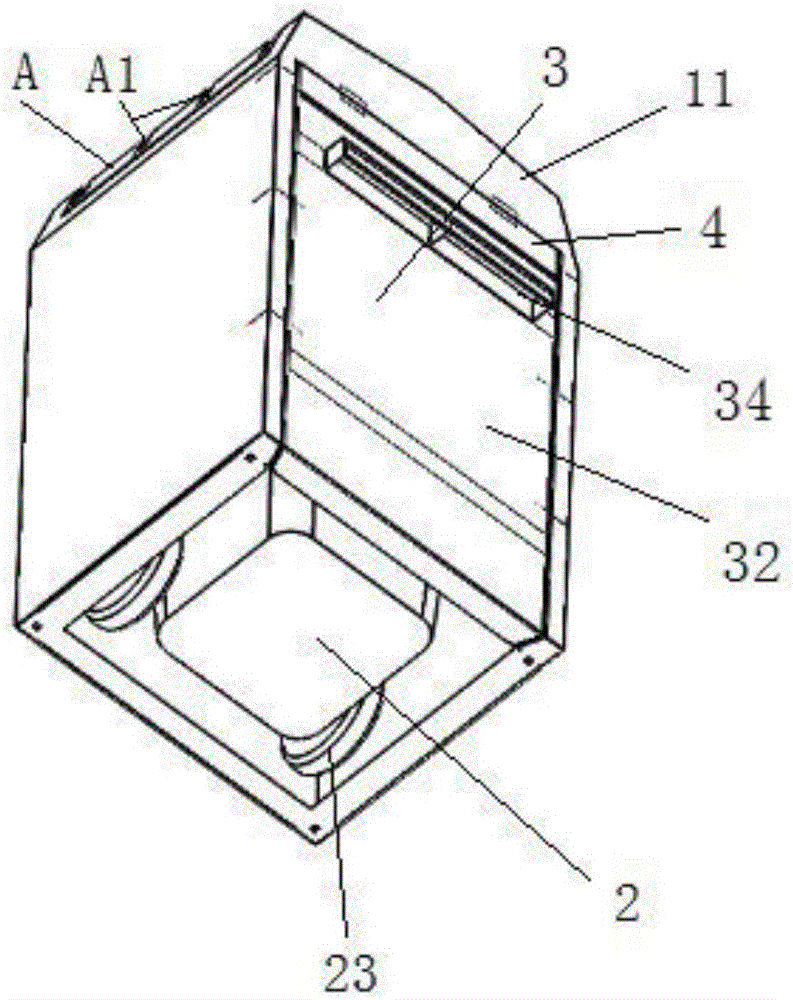

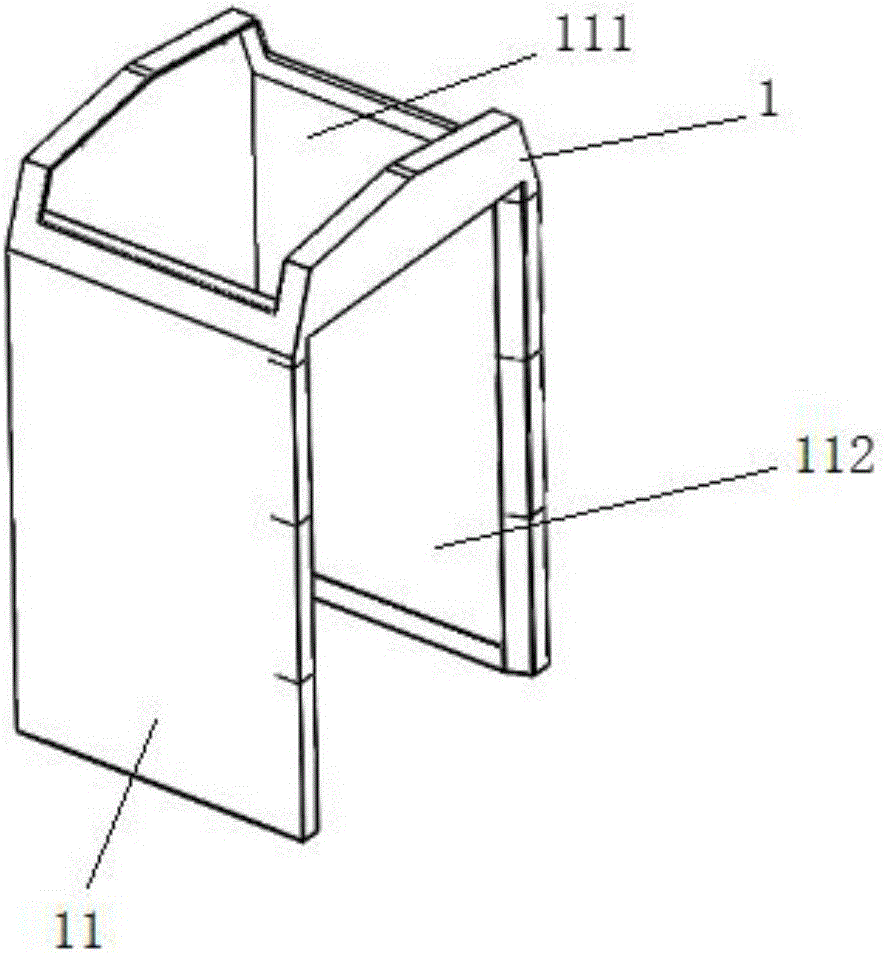

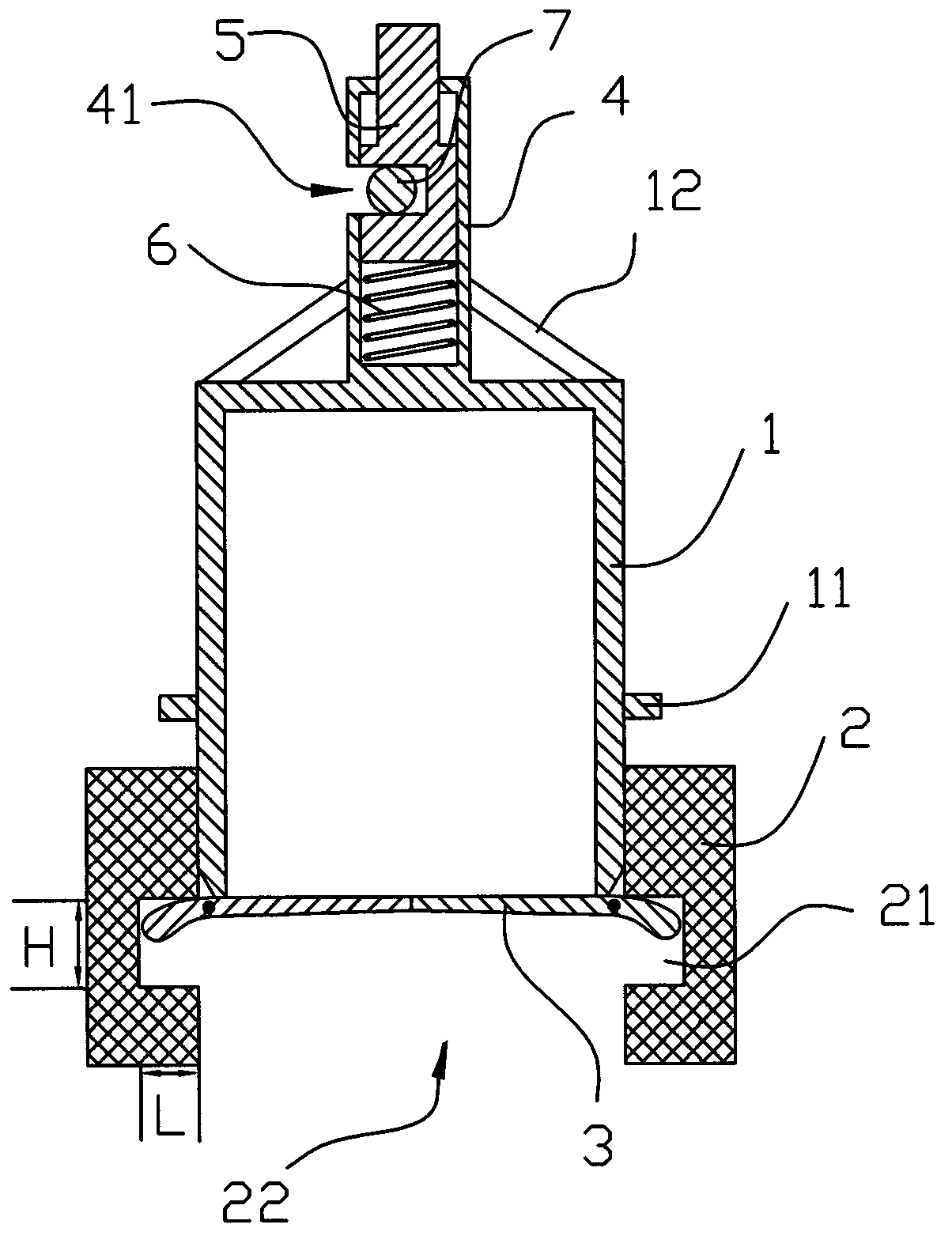

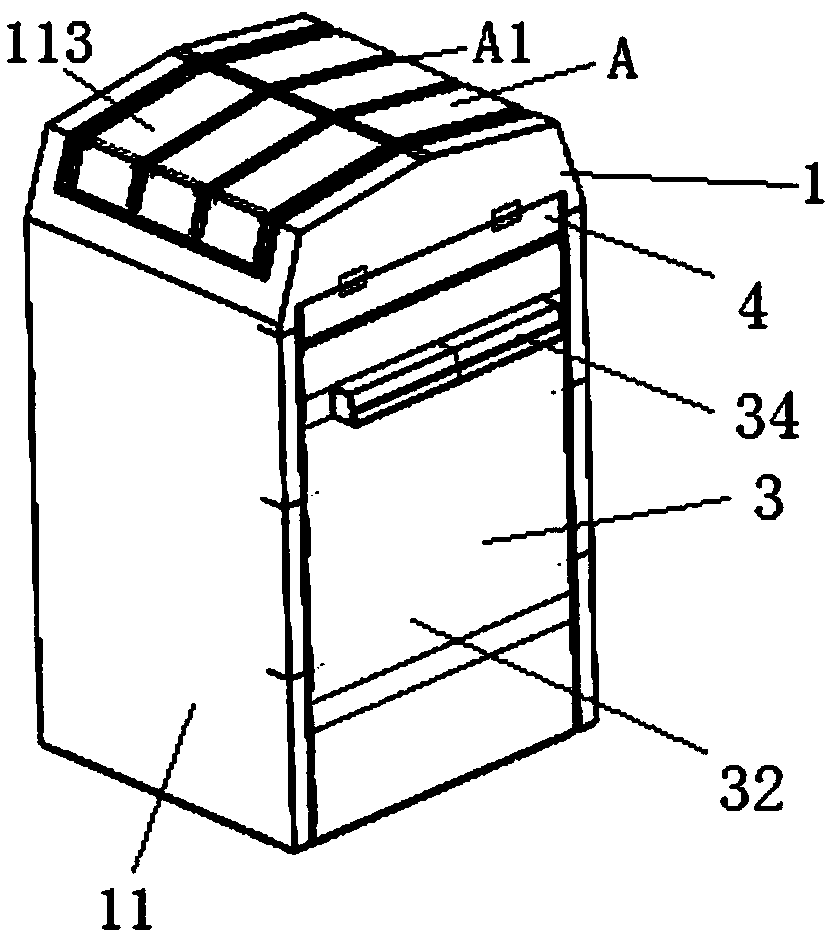

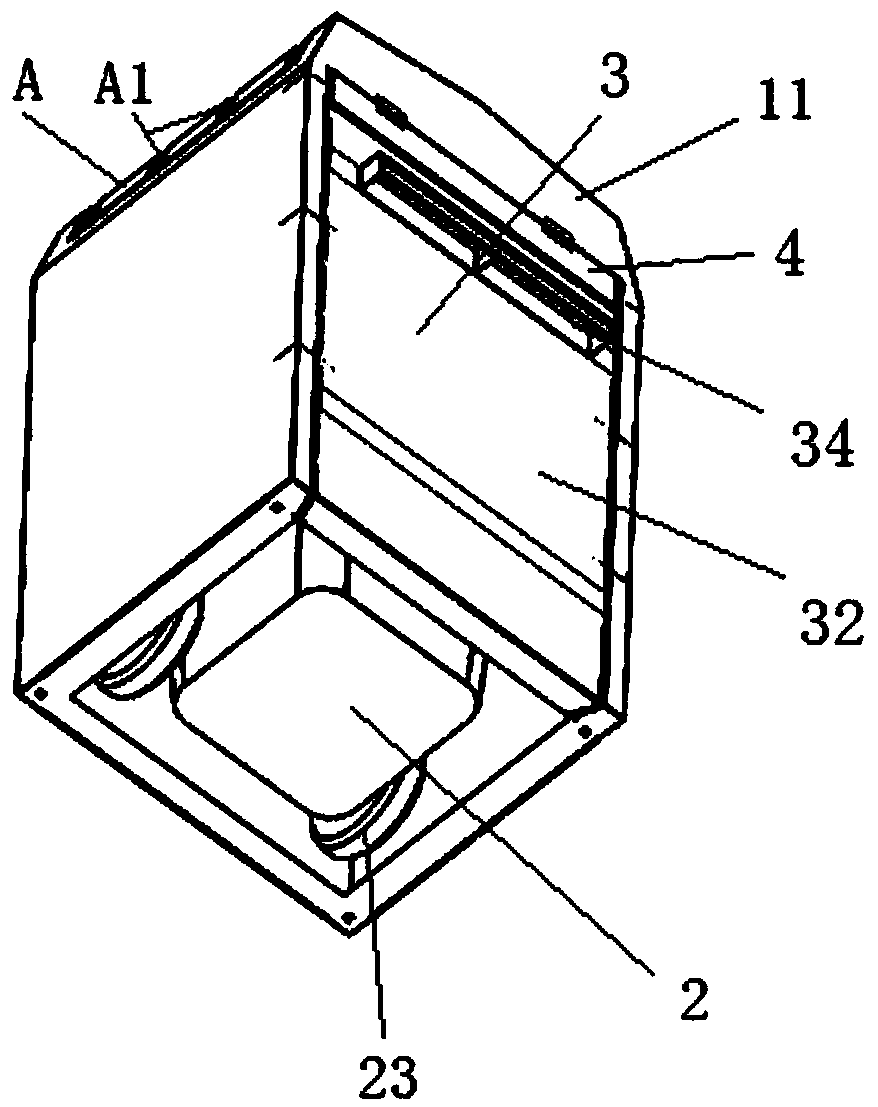

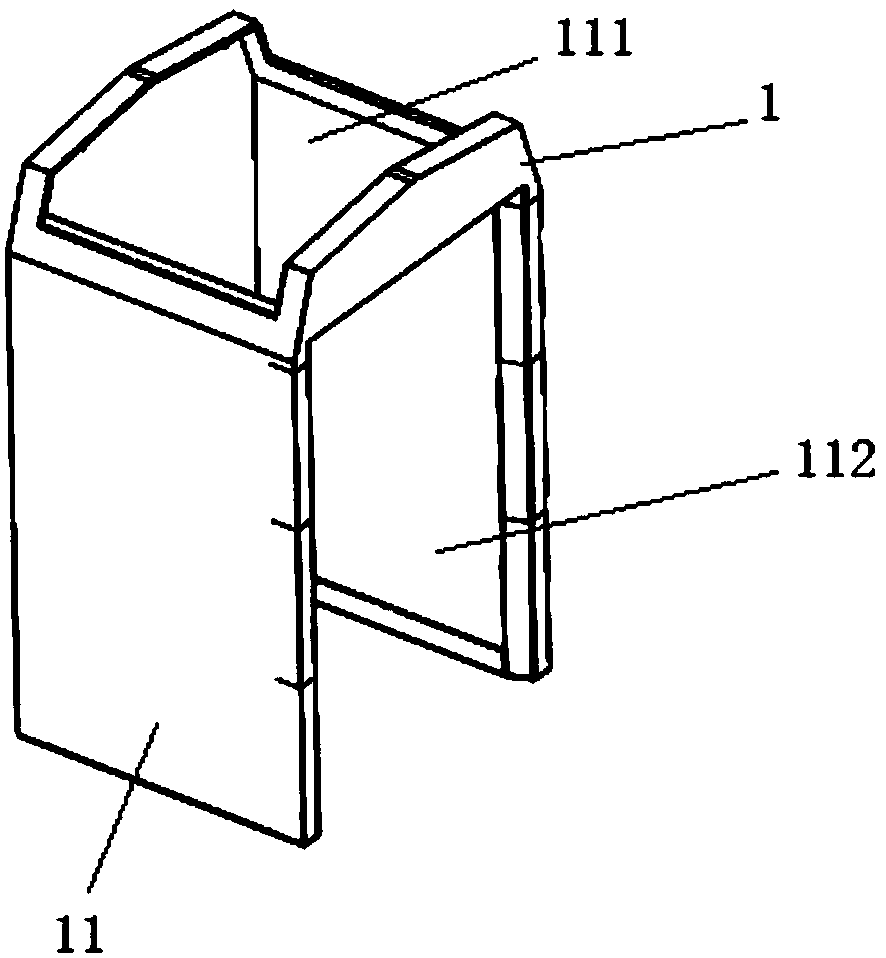

Combination type garbage can

The invention provides a combination type garbage can. The combination type garbage can comprises a garbage can shell, a garbage can inner barrel and a cover plate, wherein the garbage can shell comprises a shell body, a garbage feeding opening and a first opening are formed in the shell body, and a herringbone cover plate group is arranged at the part of the garbage feeding opening; the size of the cover plate is matched with that of the first opening, and a boss and a clamping part are arranged on the cover plate; and a second opening and a U-shaped clamp are arranged on the garbage can inner barrel. By applying the technical scheme, the integral structure is simple. By adopting the combination design of the garbage can shell and the garbage can inner barrel, the garbage can shell is always kept clean and tidy, and the garbage can inner barrel can meet garbage storing requirements, so that the practicability is strong. The design objective of the cover plate is to seal the first opening, and the clamping part arranged on the cover plate is clamped by a manipulator to take the garbage can inner barrel out of the garbage can shell and restore the garbage can inner barrel in the original position. The operation is convenient, and fixed-point placing requirements are met.

Owner:HUNAN UNIV

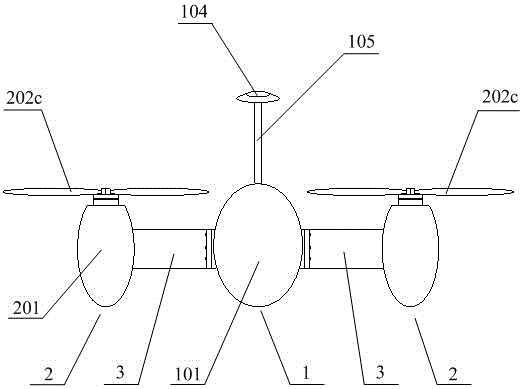

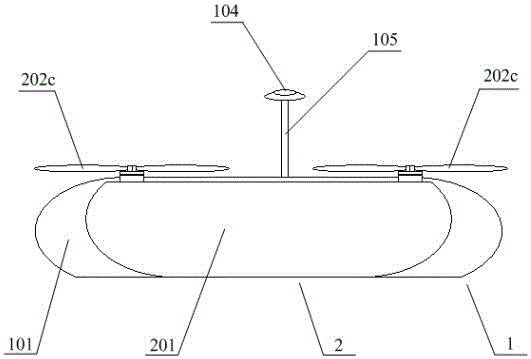

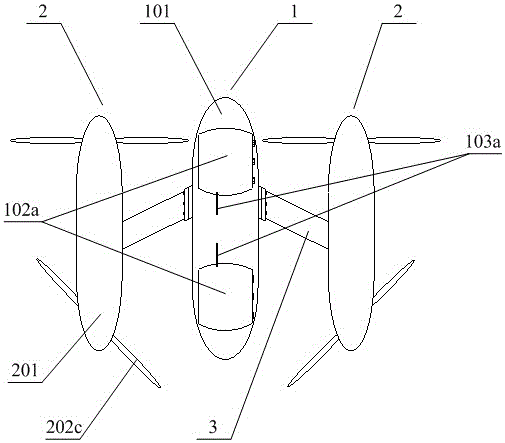

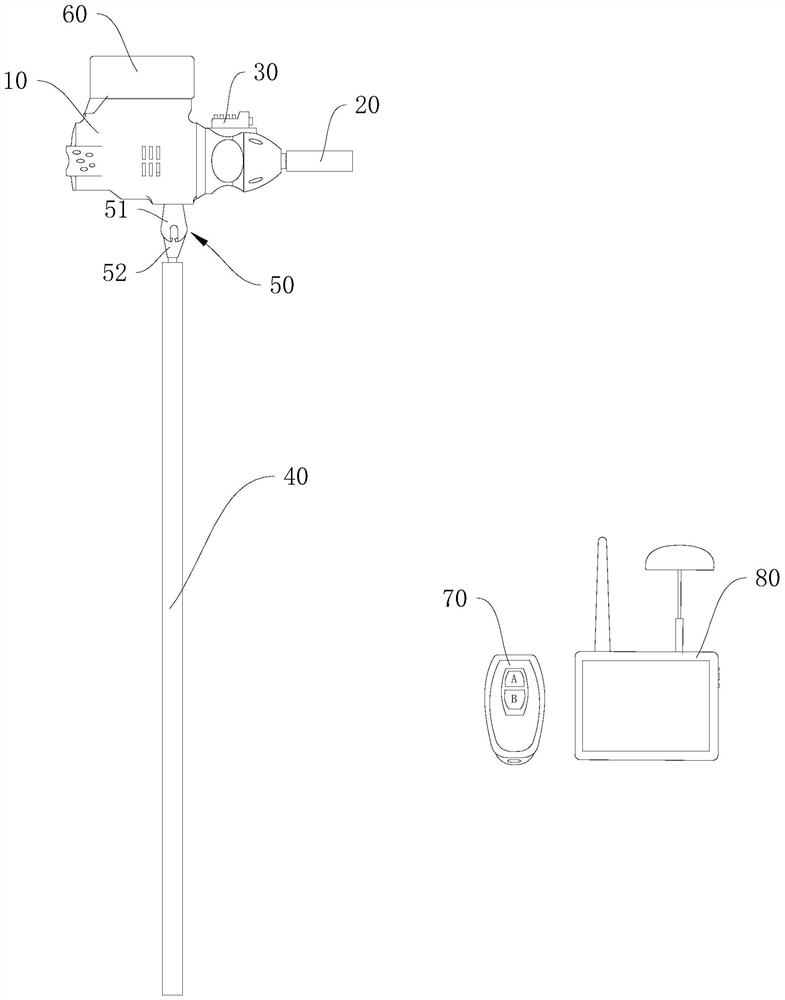

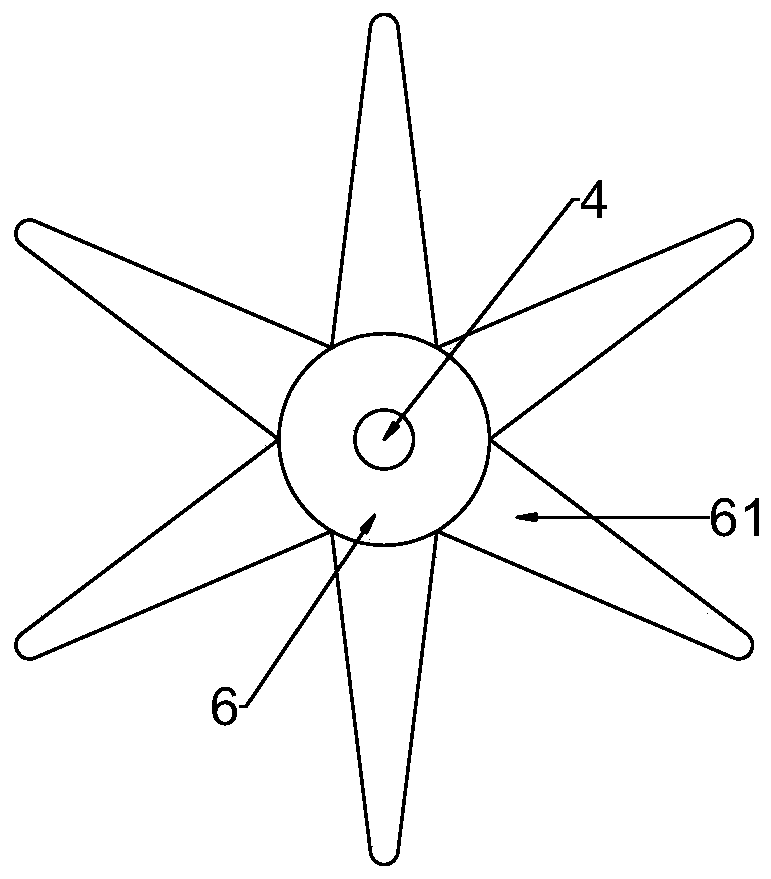

Rotor unmanned plane used for nest building, working method thereof, and flight remote control system

InactiveCN105974937AAvoid lossSmall sizeOther angling devicesPosition/course control in three dimensionsRemote controlArchitectural engineering

The invention relates to the fishing nest building device field, and discloses a rotor unmanned plane used for nest building, a working method thereof, and a flight remote control system. The rotor unmanned plane is combined with a nest building device, and therefore long-distance inflight nest building is realized by adopting a remote control way or a map positioning way, a use process is more convenient and safer, and at the same time, nest building efficiency and nest building precision are higher, and then user experience is greatly improved. The rotor unmanned plane is advantageous in that the overall size is small, the weight is light, the bait carrying capacity is high, the wind-resistant capability is strong, the inflight balance capability is good, and the maintenance is easy, and therefore the actual popularization and the actual application are facilitated.

Owner:NANCHONG YUYUN INNOVATIVE TECH CO LTD

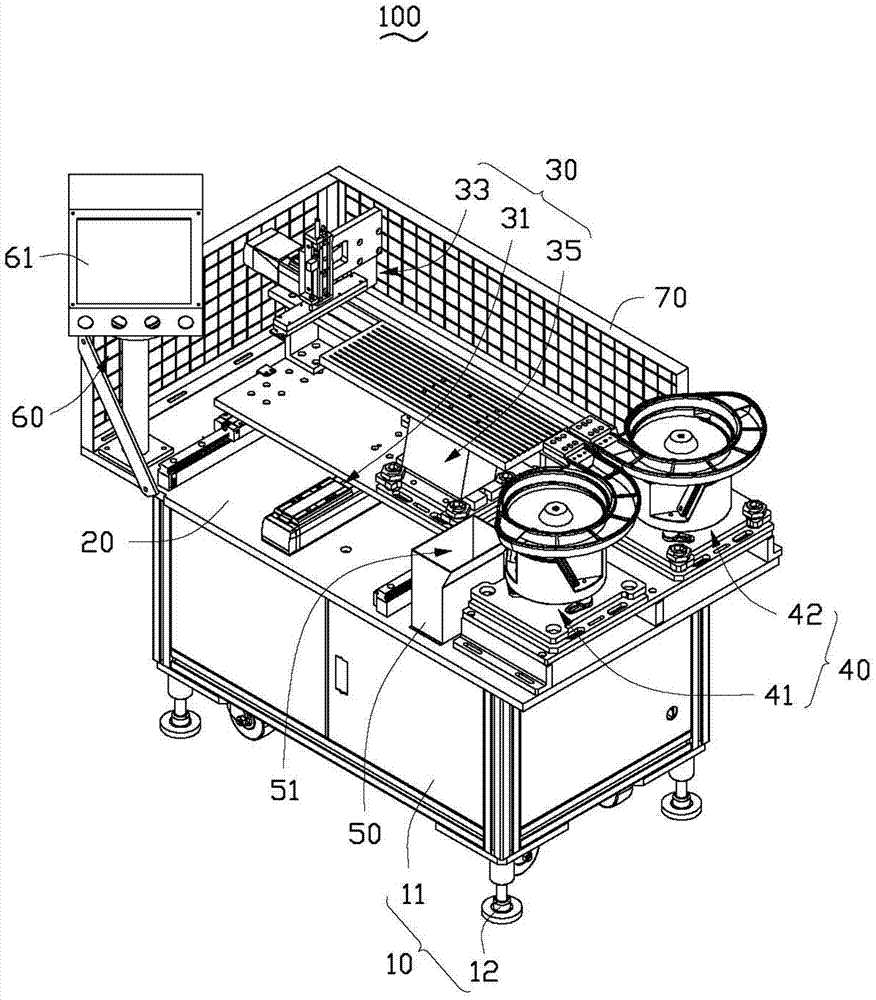

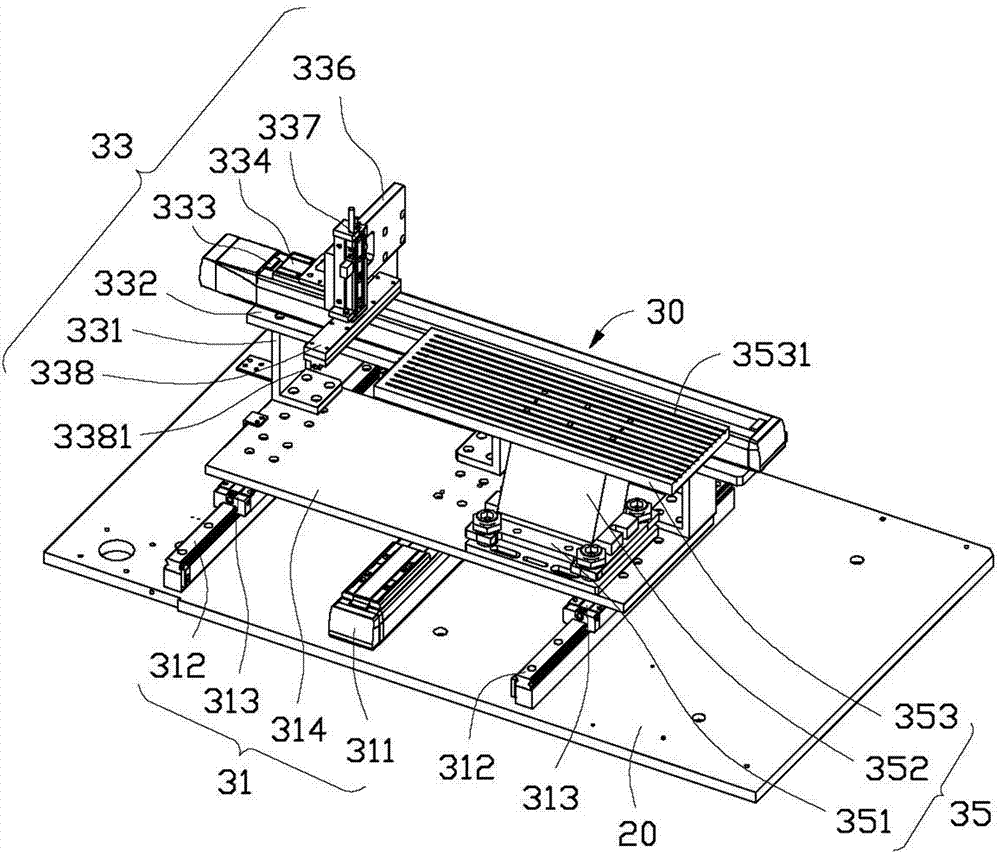

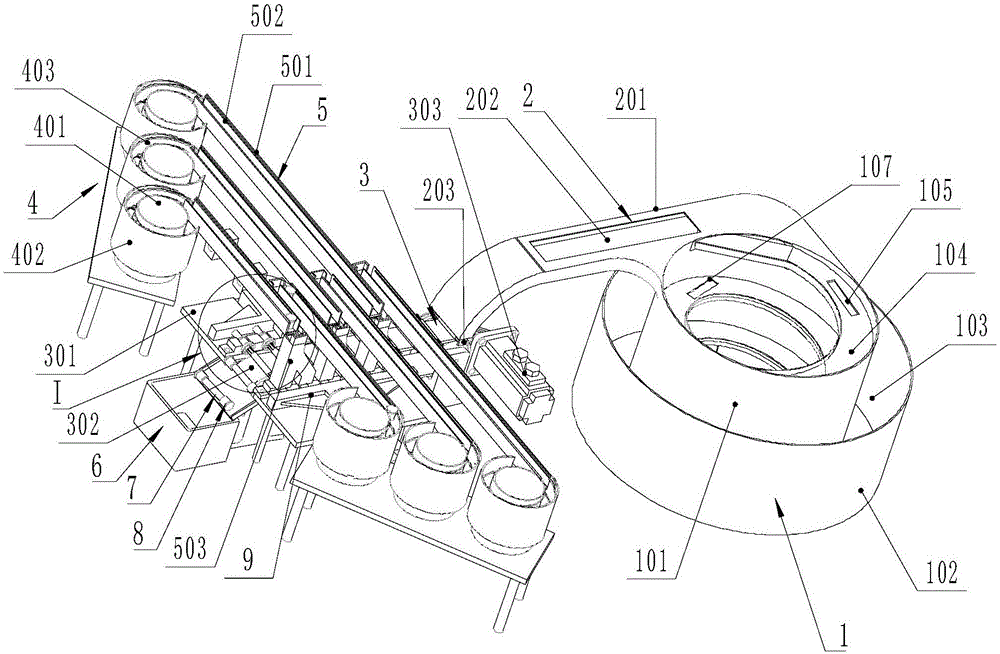

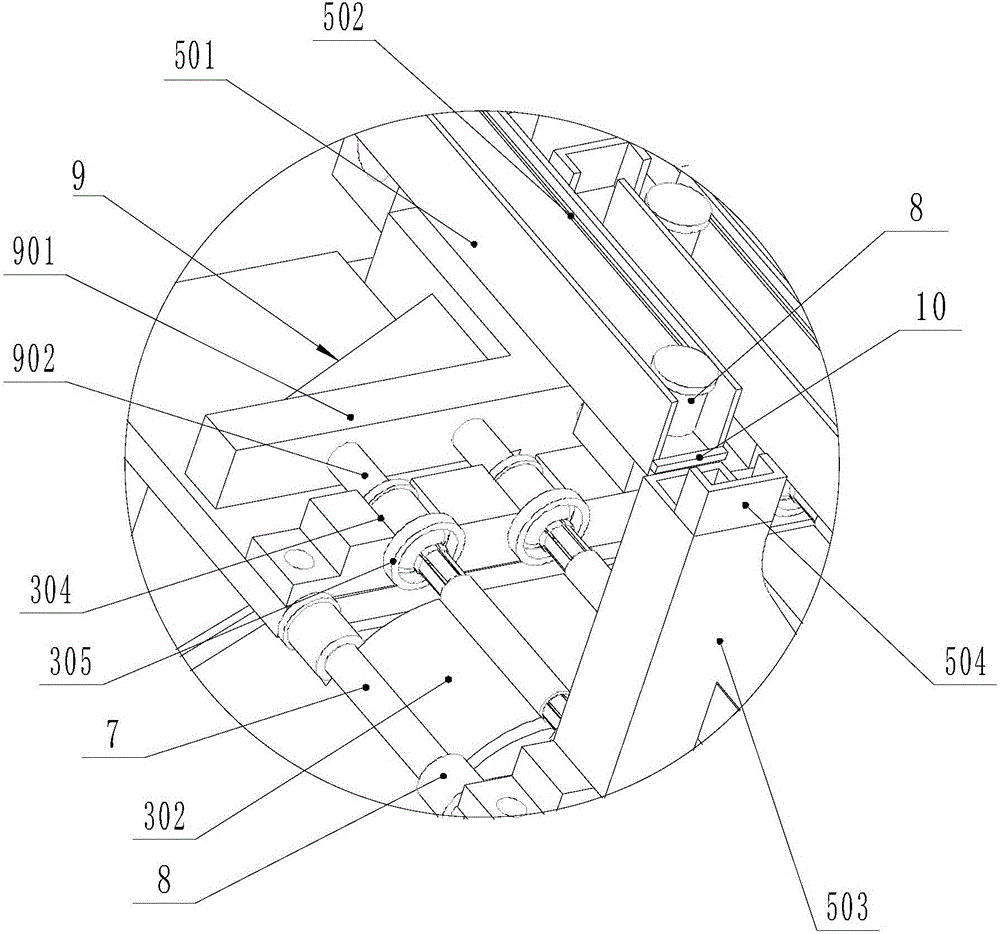

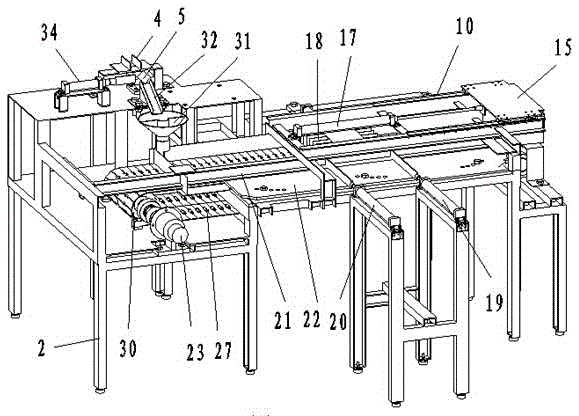

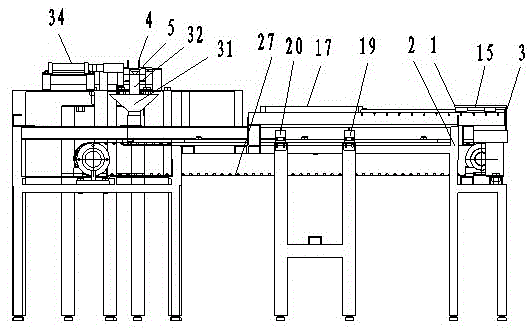

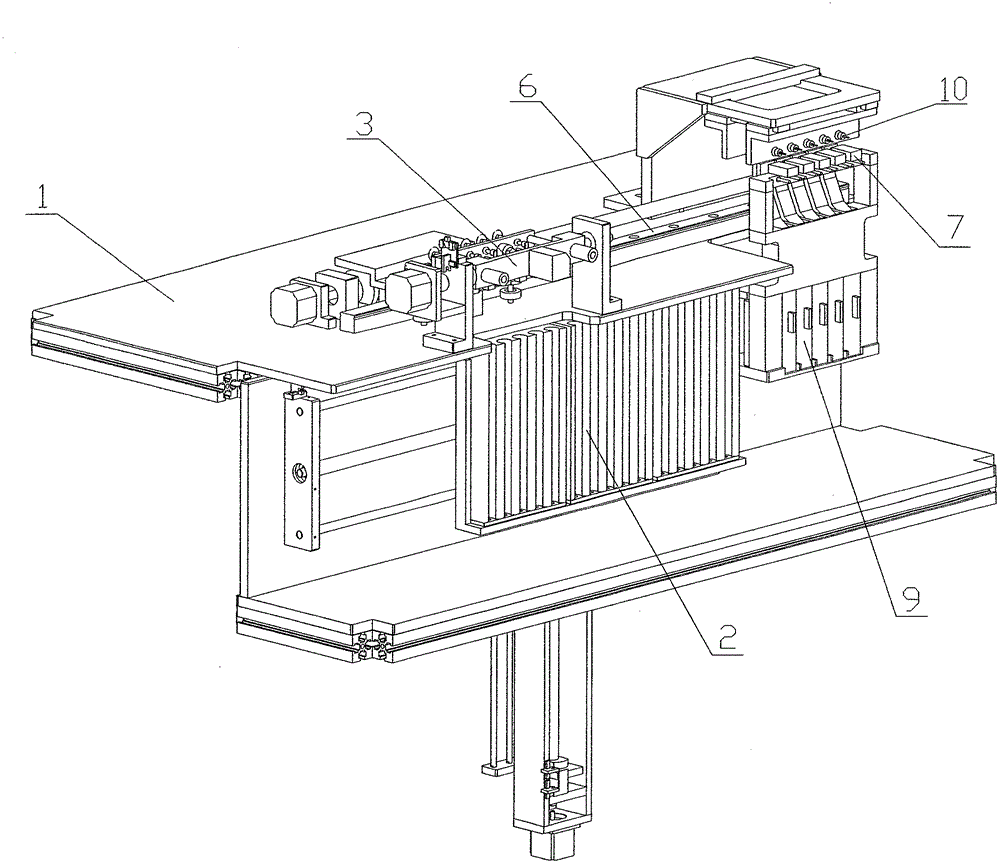

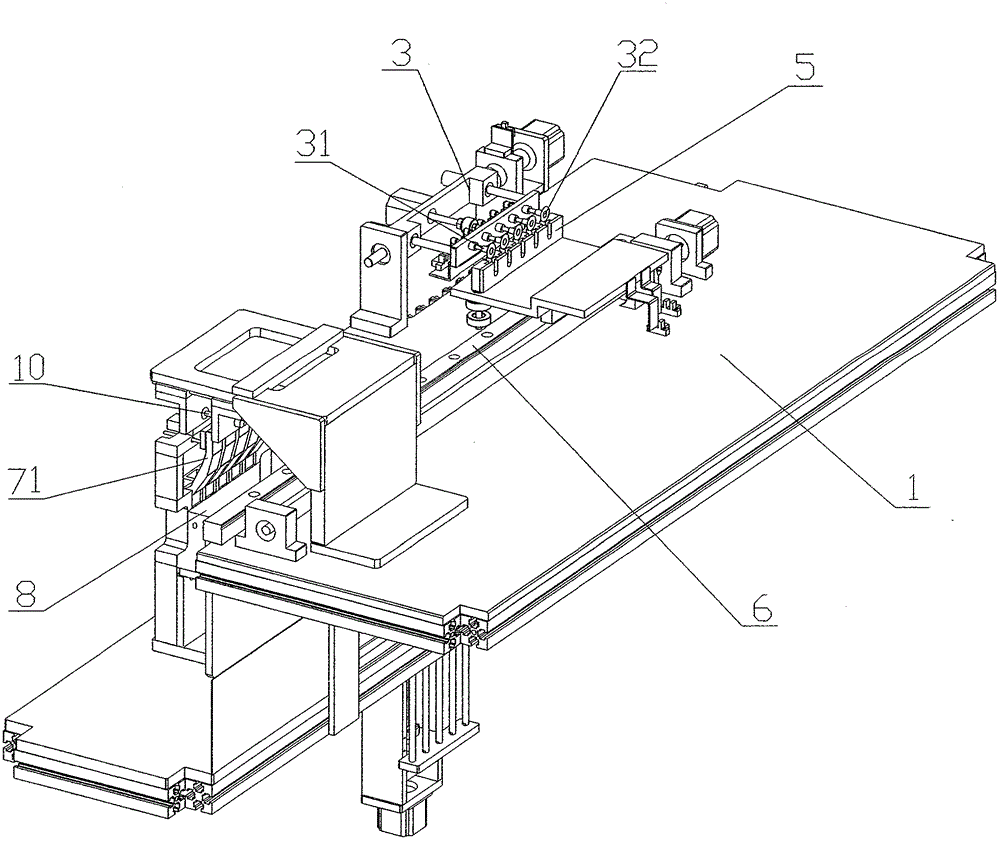

Automatic arranging machine

InactiveCN104760833AAccurate nestingEnsure equidistant settingsStacking articlesConveyor partsMechanical engineering

The invention provides an automatic arranging machine for arranging multiple workpieces. The automatic arranging machine comprises a moving component and a vibrating component, wherein the multiple workpieces are placed in the vibrating component. The moving component comprises a first moving component, a second moving component and a tool; the tool comprises a tool plate; and a guide groove is formed in the tool plate. The first moving component drives the tool plate to move so as to align the guide groove to the vibrating component; and the vibrating component vibrates to enable the multiple workpieces to enter the guide groove one by one. The second moving component comprises a poking block; the poking block is pressed against the workpieces positioned on the tool plate; and the second moving component drives the poking block to move so as to arrange the adjacent workpieces at equal intervals. The automatic arranging machine is accurate in arrangement and automatic in arranging process.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

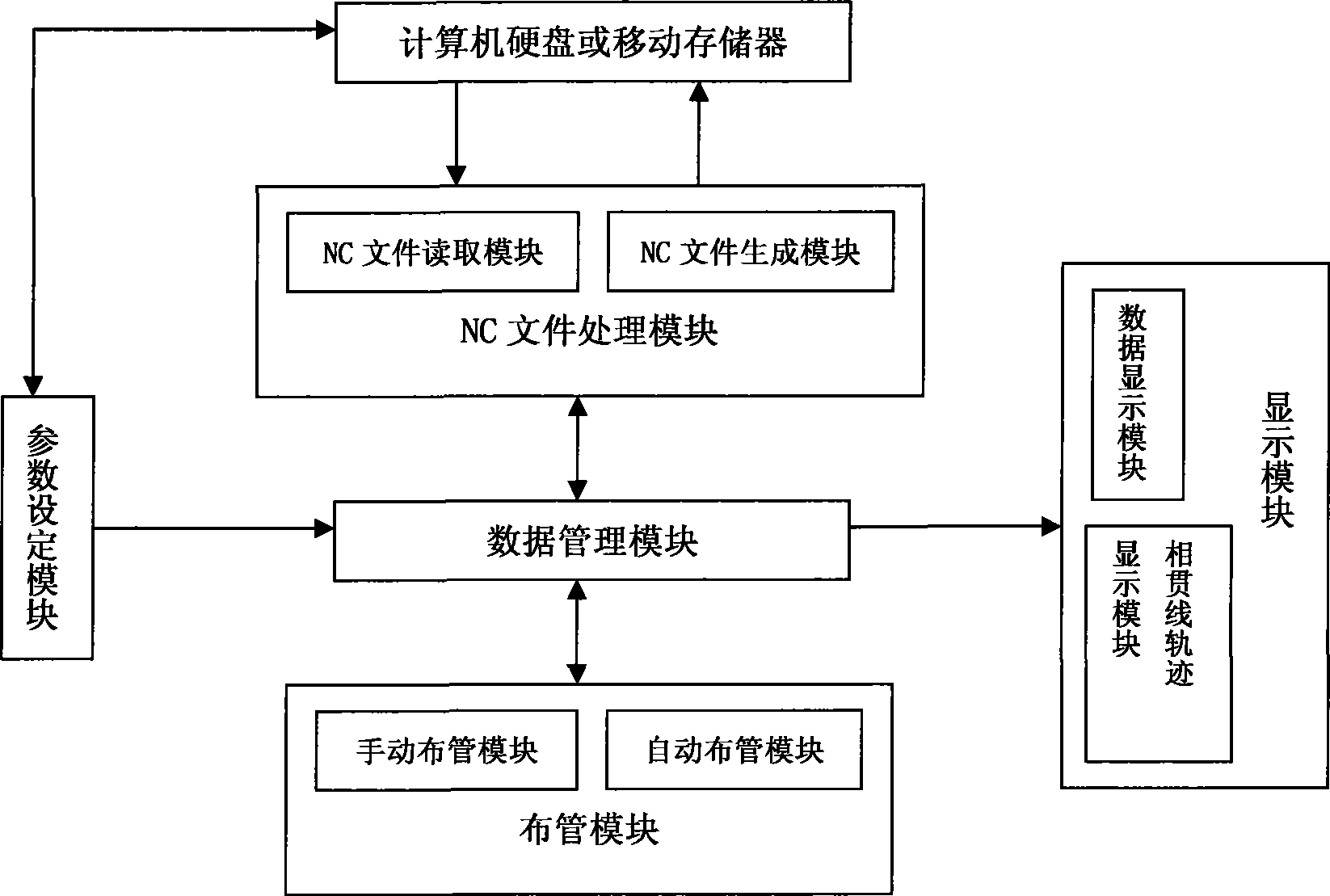

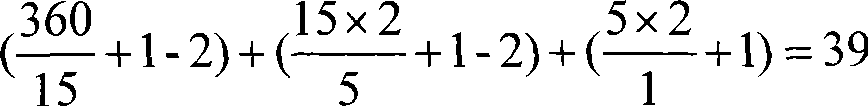

Numerical control plasma cutting machine trepanning modular system

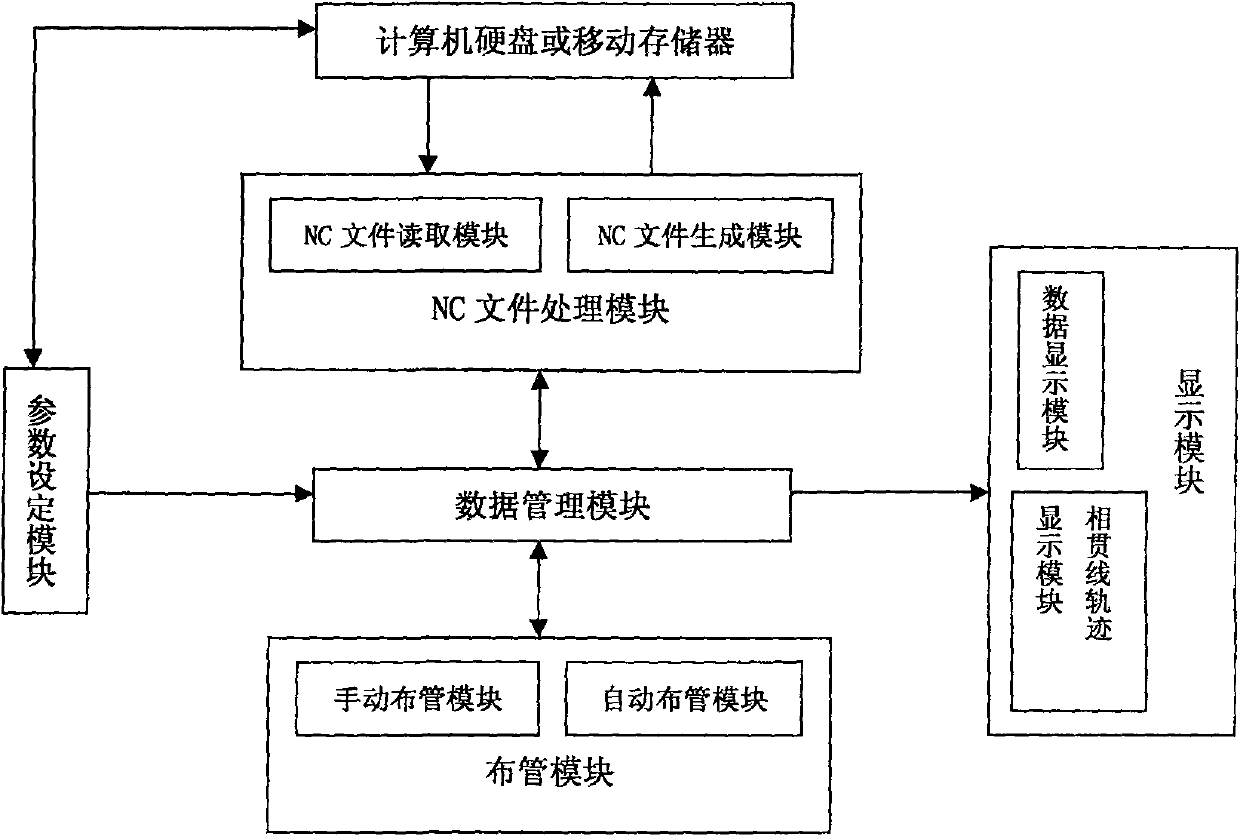

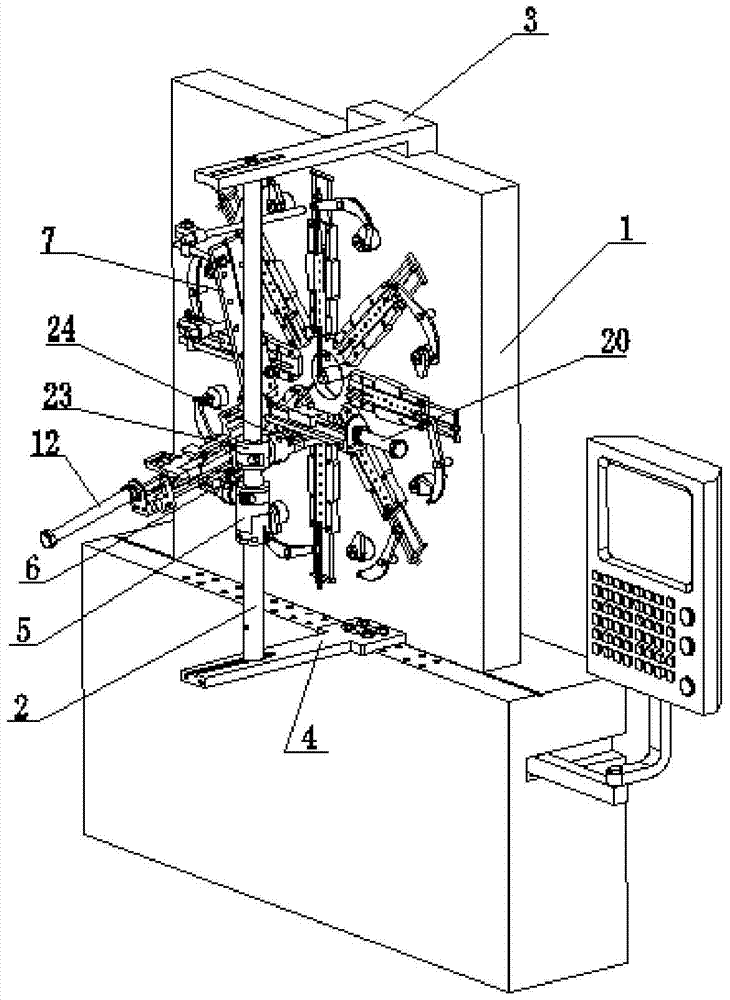

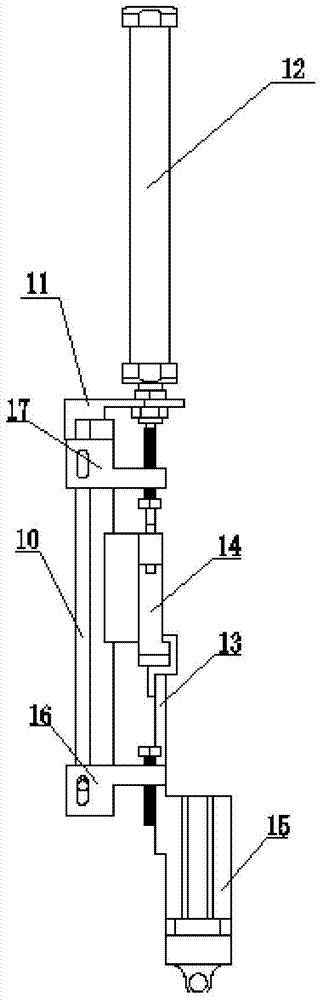

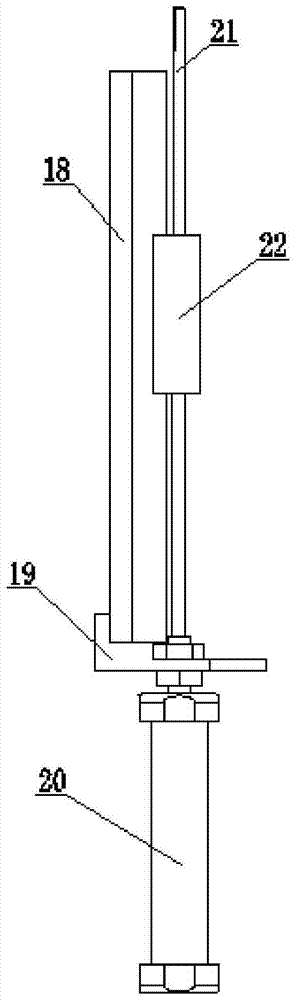

InactiveCN101364101ARetain the function of manual nestingAccurate nestingNumerical controlNumerical controlProcess module

The invention relates to a numerically-controlled (NC) intersection-line cutting machine nest system used in the field of NC cutting. The system comprises a NC file processing module, a parameter-setting module, a tube-laying module, a data management module and a display module. The NC file processing module reads a NC file to be processed from a computer hard disk or a mobile memory and generates a new NC file that is stored in the computer hard disk or a mobile memory. The parameter-setting module lists the tube-laying parameters which are required for the tube-laying operation and need to be reset or modified to allow a user to reset or modify. The data management module transmits the data to other modules. The tube-laying module receives the tube-laying parameters and the original steel tube processing data of the tubes and performs the tube-laying, and optimizes the arrangement of the tube nest by adjusting the position of the intersection-line track of each tube. The display module displays the data that are required to be viewed by the user during the tube-laying process. The NC intersection-line cutting machine nest system can not only maximize the utilization rate of the blank material but also greatly increase the time efficiency of the user.

Owner:SHANGHAI JIAO TONG UNIV

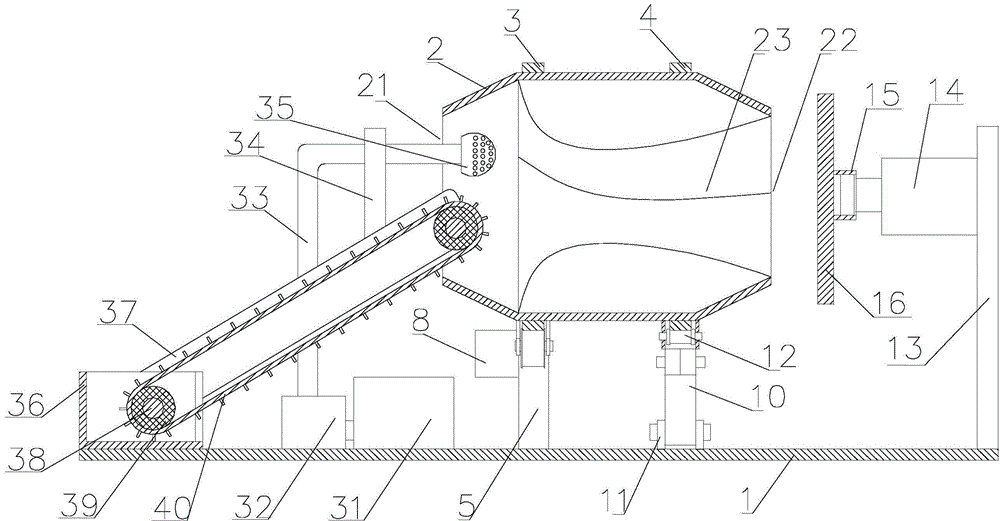

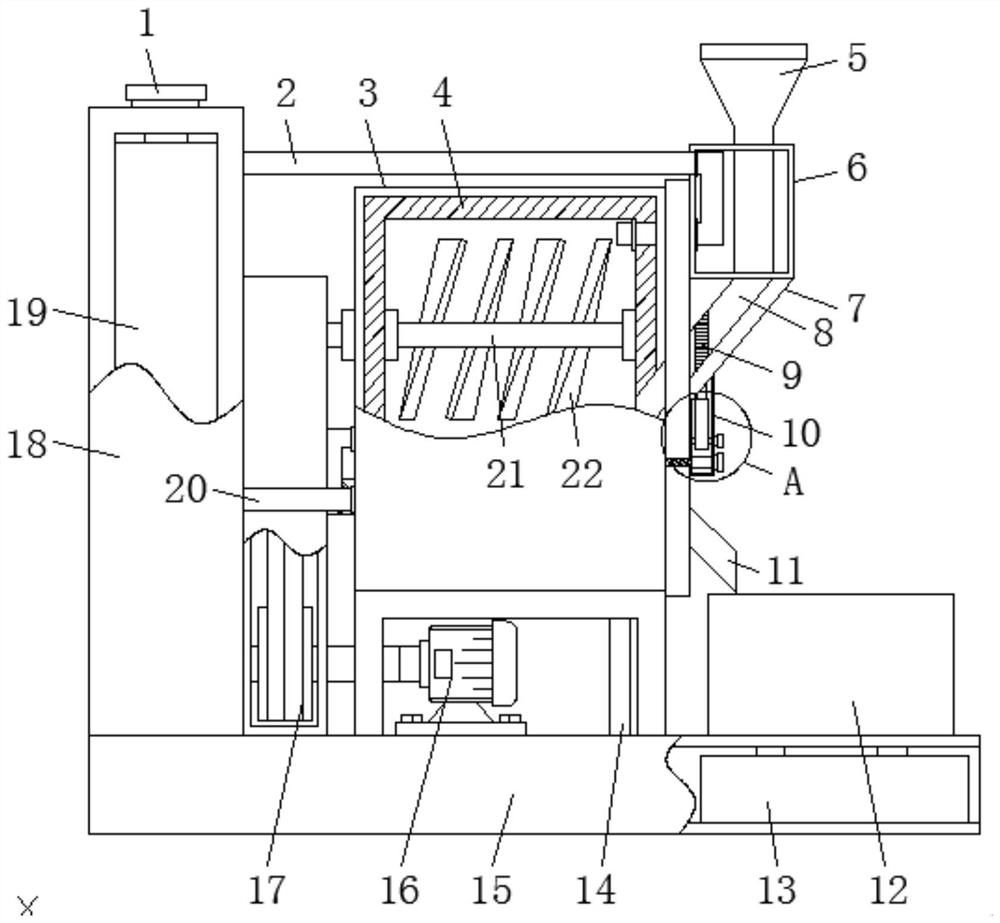

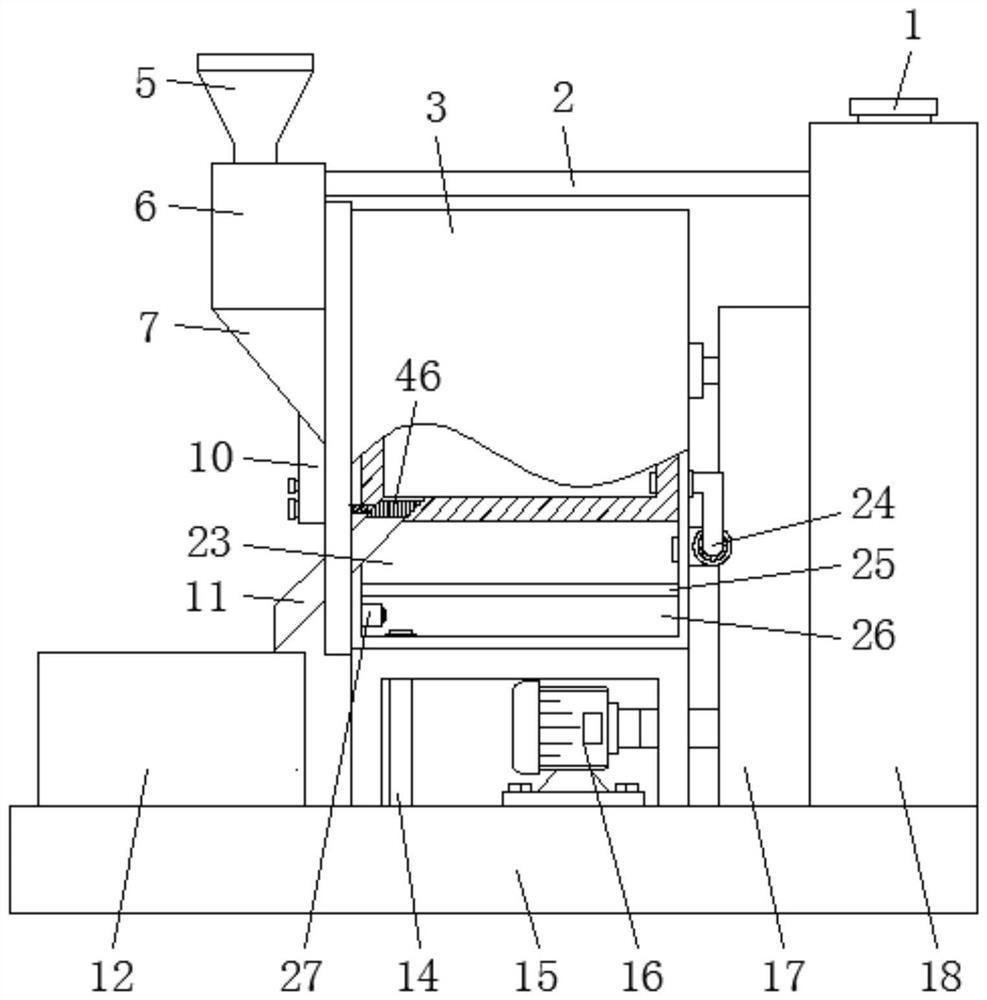

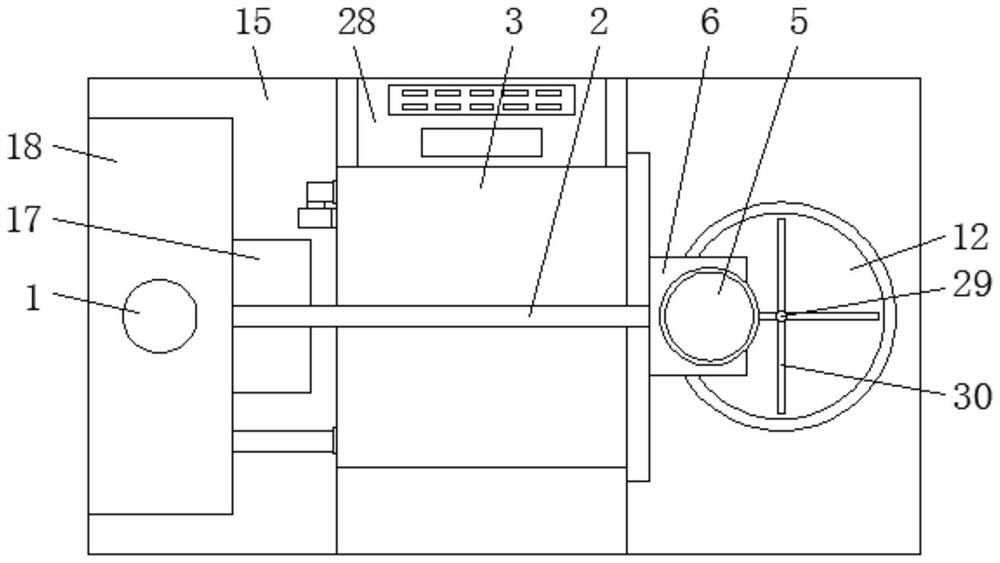

Energy-saving high-efficiency coffee bean baking machine

ActiveCN108606344AReduce consumptionImprove baking efficiencyFood treatmentCombustorProcess engineering

The invention discloses an energy-saving high-efficiency coffee bean baking machine. The energy-saving high-efficiency coffee bean baking machine comprises a base, wherein a baking machine body, a cooling disk and a tail gas box are mounted at the top end of the base; the baking machine body is located between the cooling disk and the tail gas box; an inner cylinder and a gas filtering plate are mounted in the baking machine body; the gas filtering plate is located below the inner cylinder; a thermal mixing cavity and a combustion cavity are separately formed in two sides of the gas filteringplate; a combustor is mounted in the combustion cavity; and a fuel gas pipe is connected between the combustion cavity and the base. According to the energy-saving high-efficiency coffee bean baking machine disclosed by the invention, an exhaust pipe, the tail gas box, a gas return pipe, the thermal mixing cavity, a fan, the gas filtering plate and the combustion cavity are arranged, when the baking machine operates, and fuel gas enters the baking machine body, the fuel gas is combusted through ignition of the combustor, so that expansion combustion is realized in the combustion cavity, and the temperature is quickly raised; after combustion, generated high-temperature gas penetrates through the gas filtering plate to enter the thermal mixing cavity, and then the high-temperature gas is guided to the inner cylinder through the fan to heat and bake coffee beans.

Owner:扬州市生态科技新城杭集中小企业服务中心有限公司

Flexible packaging bag feeding and sealing device

PendingCN109795161AImprove processing efficiencyHigh degree of automationBag making operationsPaper-makingEngineeringAutomation

The invention provides a flexible packaging bag feeding and sealing device. The flexible packaging bag feeding and sealing device comprises a rack, a bag feeding mechanism mounted on the rack, an overturning bag taking mechanism mounted behind the bag feeding mechanism, a leading-in mechanism mounted behind the overturning bag taking mechanism, a rotary conveying mechanism mounted behind the leading-in mechanism, a suction nozzle feeding mechanism mounted on one side of the rotary conveying mechanism, and a bag sealing mechanism mounted on one side of the rotary conveying mechanism and opposite to the suction nozzle feeding mechanism. The flexible packaging bag feeding and sealing device is high in automation degree and high in production continuity, can automatically achieve automatic pressing discharging of flexible packaging bag bodies, continuous overturning taking, automatic leading-in and front-back separation of the bag bodies, automatic sleeving of suction nozzles and the bag bodies, and automatic heating solder sealing of the suction nozzles and the bag bodies, and can greatly improve the processing efficiency of flexible packaging bags.

Owner:ZHONGSHAN NCA

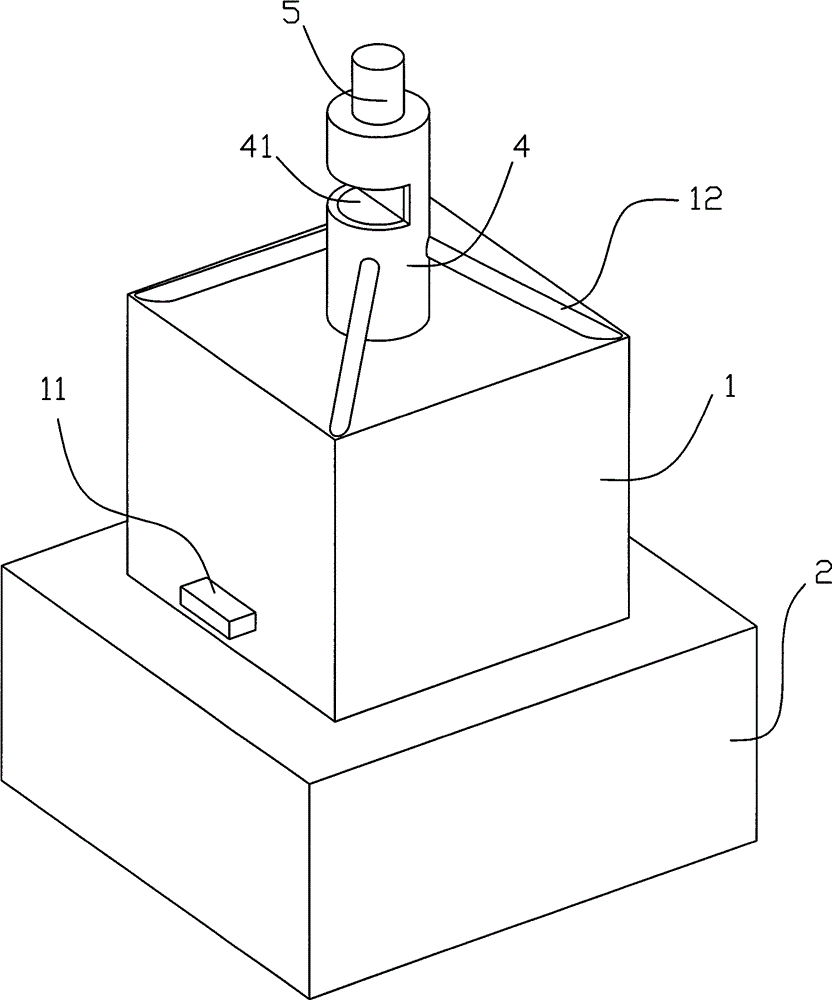

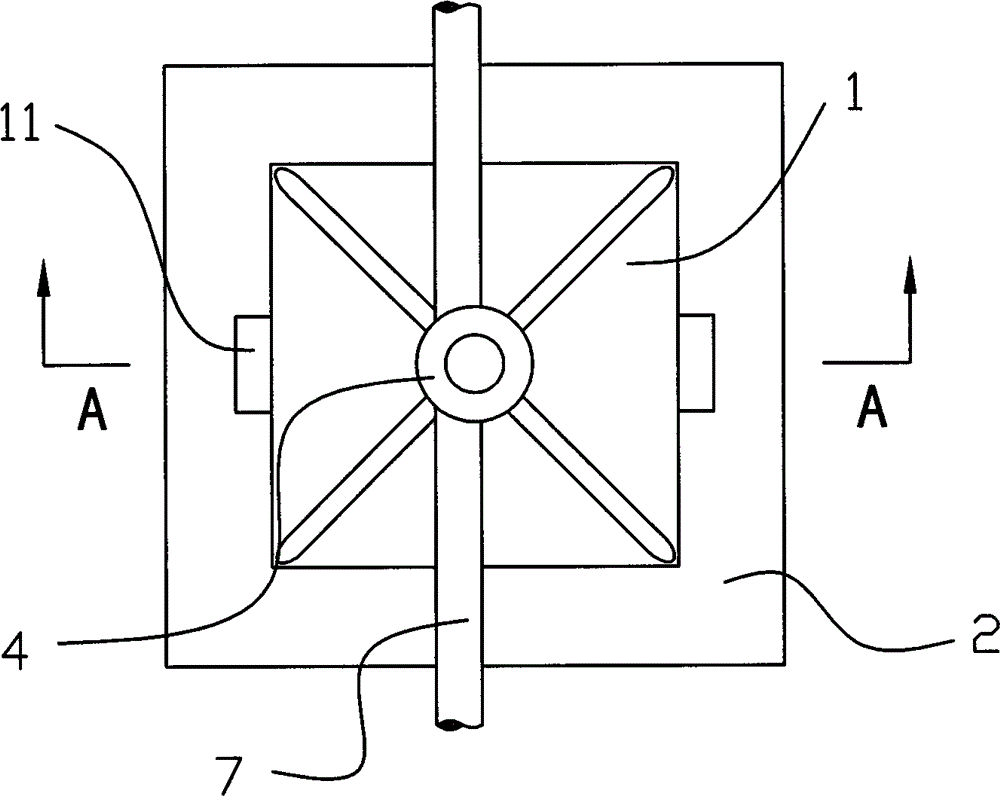

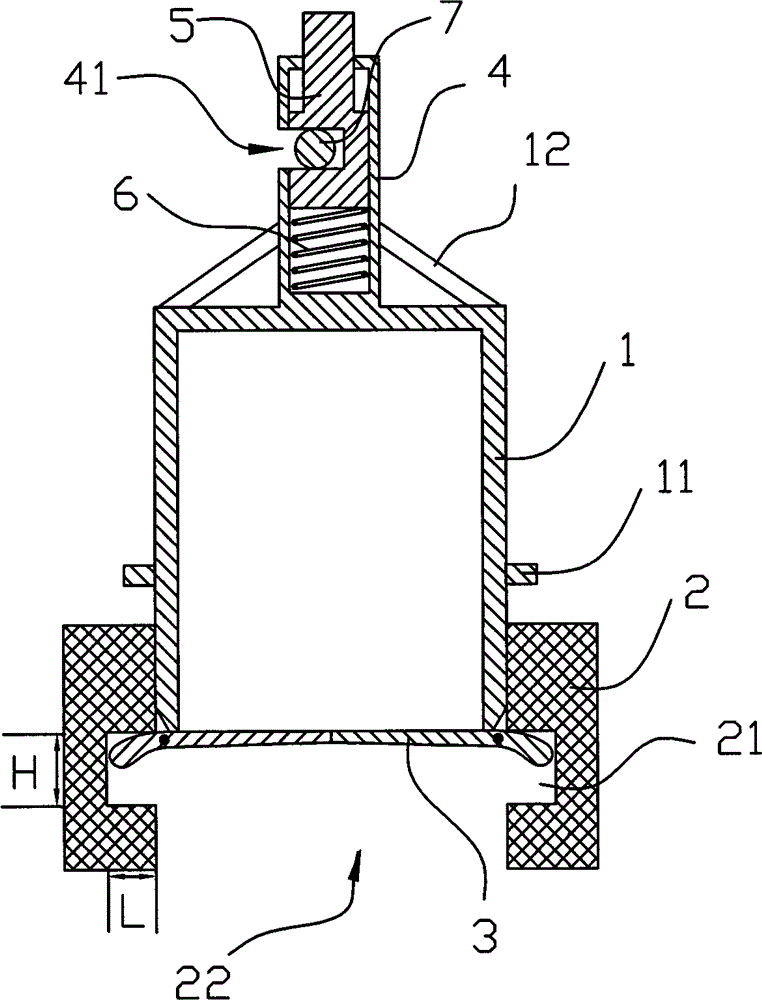

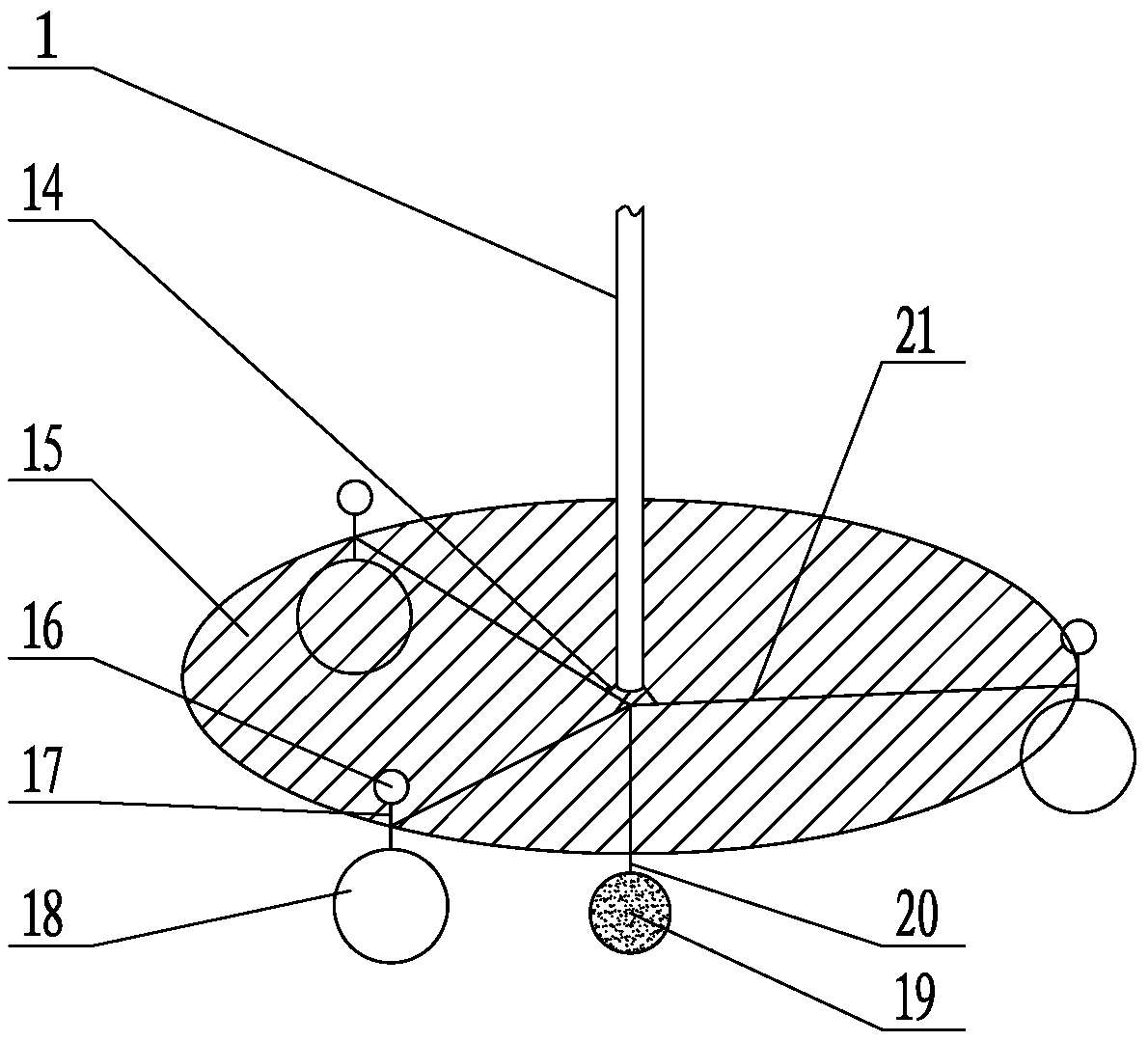

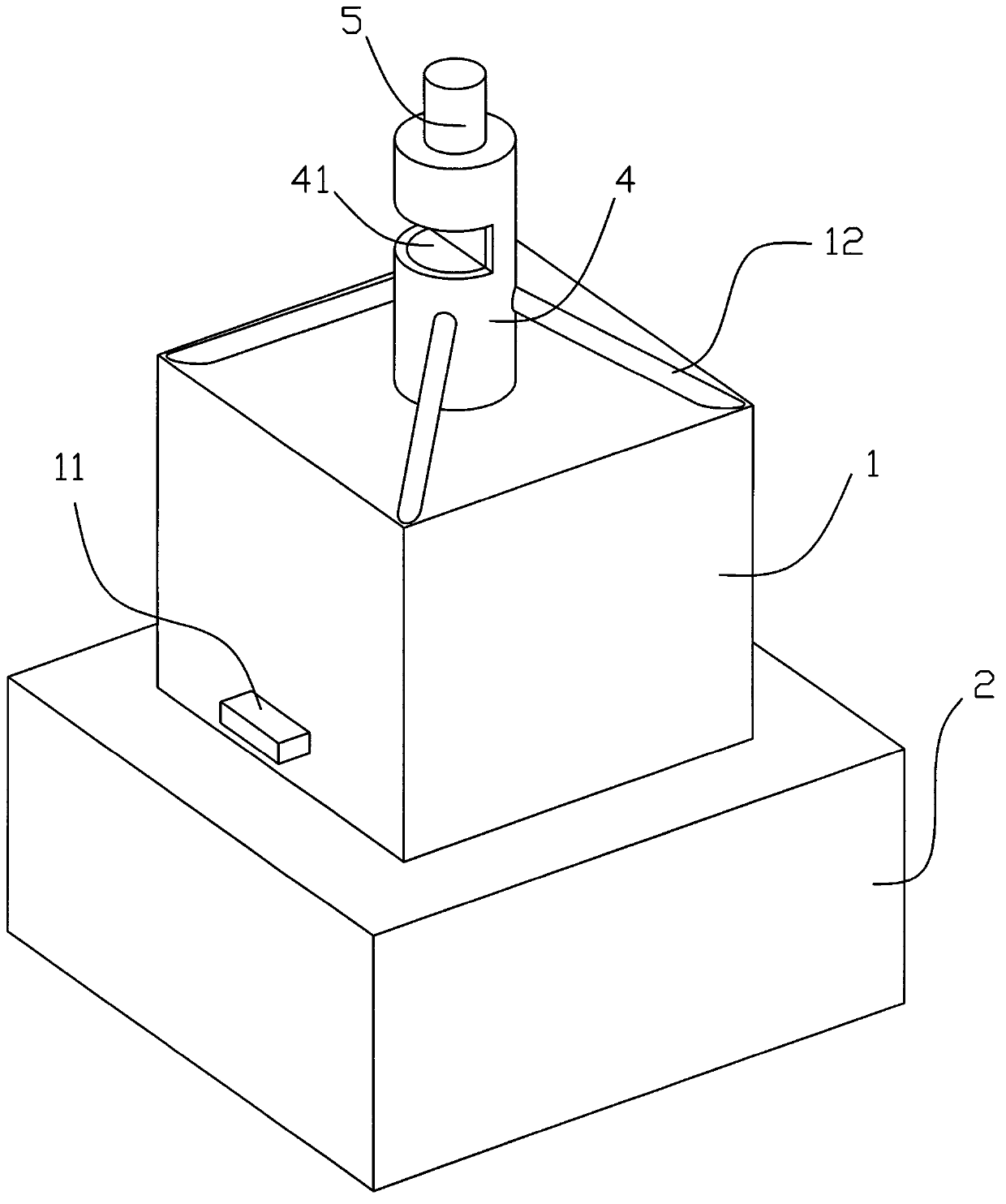

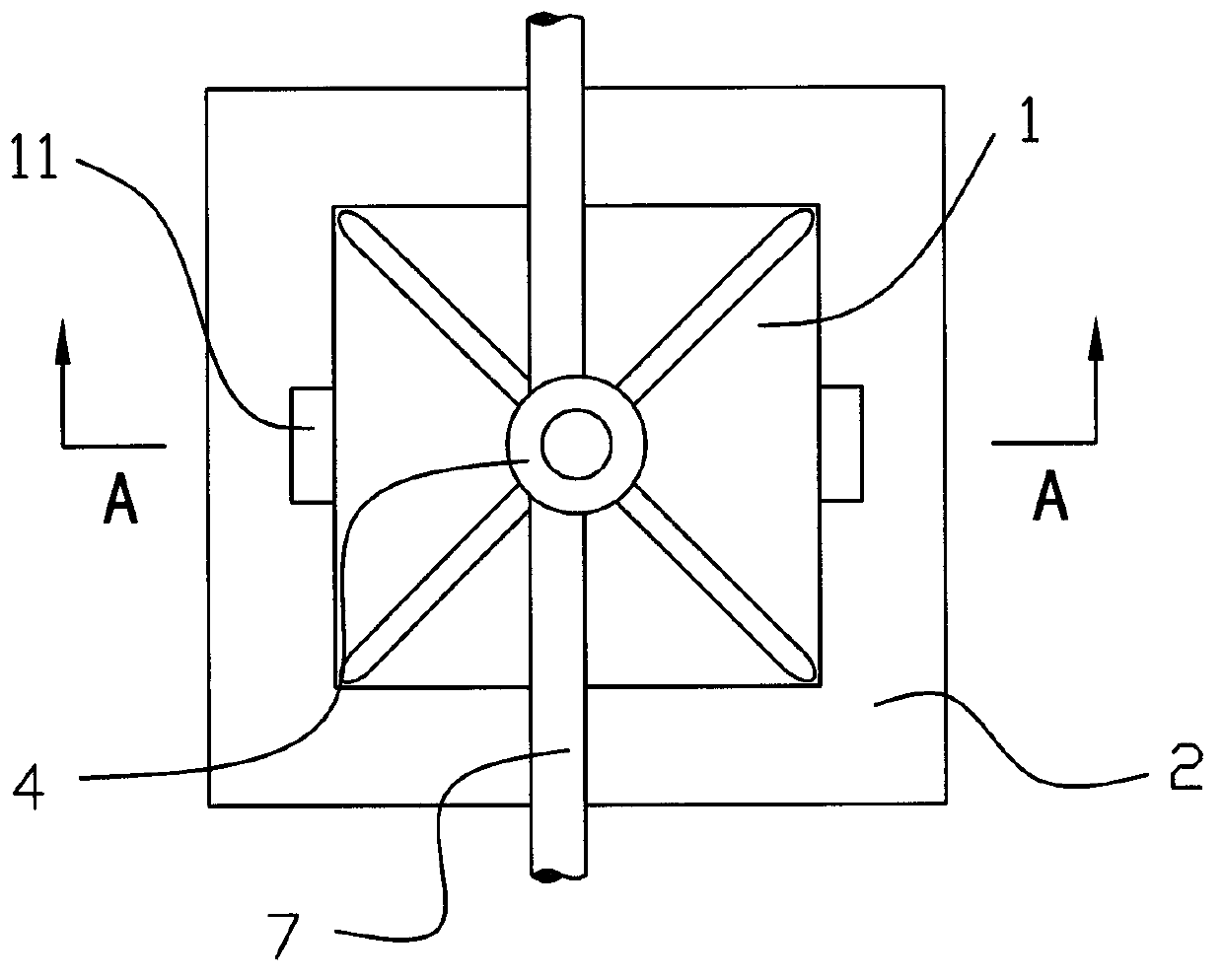

Bait-placing device for fishing

InactiveCN103329862ANo sideways rotationRealize the purpose of making nestsOther angling devicesEngineeringFishing

A bait-placing device for fishing comprises a shell (1) for placing a bait, and is characterized in that a clamping part detachably fixed with a fishing rod (7) is arranged at the top of the shell (1); the bottom of the shell (1) is provided with an opening and provided with a movable plate (3) capable of opening or closing the opening; the lower part of the shell (1) is provided with a floating block (2) capable of vertically floating along the periphery face of the lower part of the shell (1); the bottom of the floating block (2) is provided with a through port (22) communicated with outside; when the movable plate (3) opens the opening of the shell (1), the through port (22) is communicated with the opening, and when the floating block (2) arranged at the bottom of the shell (1) slides upwards, the movable plate (3) can be enabled to close an opening-closing structure of the opening when the opening slides downwards. The bait-placing device for fishing is simple in structure, convenient to operate, and capable of being directly mounted on the fishing rod and accurately performing bait-placing after being placed on a selected water face.

Owner:ZHEJIANG BUSINESS TECH INST

Automatic electronic connector capping machine

The invention discloses an automatic electronic connector capping machine, which comprises an automatic electronic connector charging device, an automatic end cap charging device and an automatic capping mechanism; the automatic capping mechanism consists of a circulating conveyor belt, and a plurality of feeding necks are arranged on the circulating conveyor belt; the feeding necks are used for receiving an electronic connector sent by the automatic electronic connector charging device and then running to an end cap neck, the end cap neck has an end cap sent by the automatic end cap charging device, and a cap pressing mechanism for axially pressing an end cap into the end of the corresponding connector is arranged at the outer side of the end cap neck. Through the automatic capping machine, the automatic charging of the electronic connector, the automatic charging of the end cap and the capping of the end cap can be realized, the full automation of capping can be achieved, the production efficiency can be increased, the cost is lowered, and the pass rate of products can be improved.

Owner:SUZHOU JUNCHANG COMM TECH CO LTD

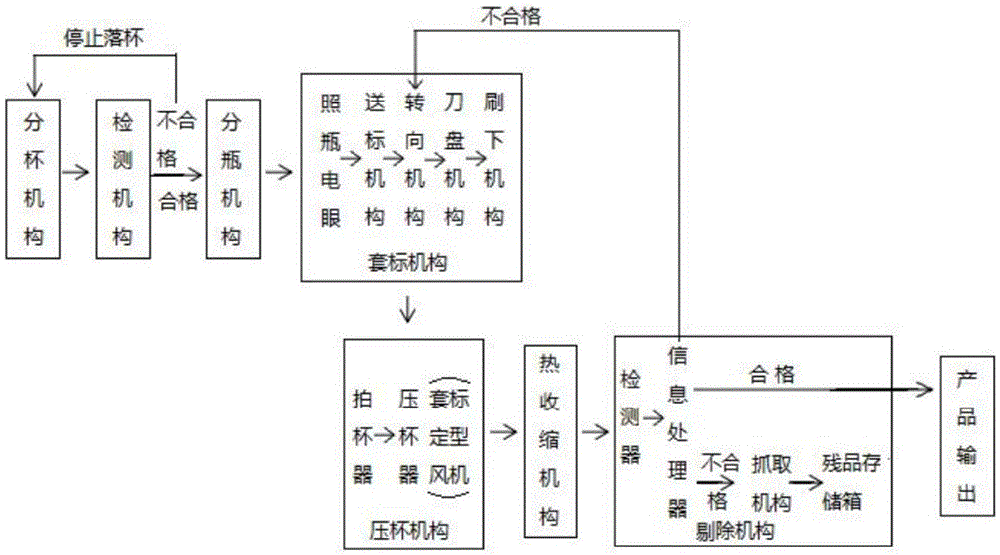

Label sleeving system

ActiveCN105416736AAccurate nestingSleeves are flexibleLabelling machinesEngineeringInformation processor

The invention provides a label sleeving system. The system comprises a conveyor belt, a cut splitting mechanism, a bottle splitting mechanism, a label sleeving mechanism, a cup pressing mechanism, and a hot shrinkage mechanism; the label sleeving mechanism comprises an irradiation bottle electric eye, a label delivering mechanism, a steering mechanism, a cutter mechanism, and a brushing-off mechanism; and an eliminating mechanism is arranged behind the hot shrinkage mechanism and comprises a detector, an information processor, and a grasping mechanism. The eliminating mechanism detects the package boxes after hot shrinkage, compares the taken images of package boxes with the image of qualified products, and then analyzes the results of comparison. If the images are unmatched, the eliminating mechanism further judges the category of the disqualified sleeved labels, obtains the results of comparison, and sends a grasping signal and a steering signal to the grasping mechanism and steering mechanism respectively. The grasping mechanism removes the disqualified products, and the steering mechanism carries out steering operation to adjust the direction of sleeved labels, so that the sleeved labels can be more precisely sleeved on the package boxes, the label sleeving becomes more flexibly, the application range becomes wider, and the yield is higher.

Owner:XIAN SHUANGJIAN PACKAGING CO LTD

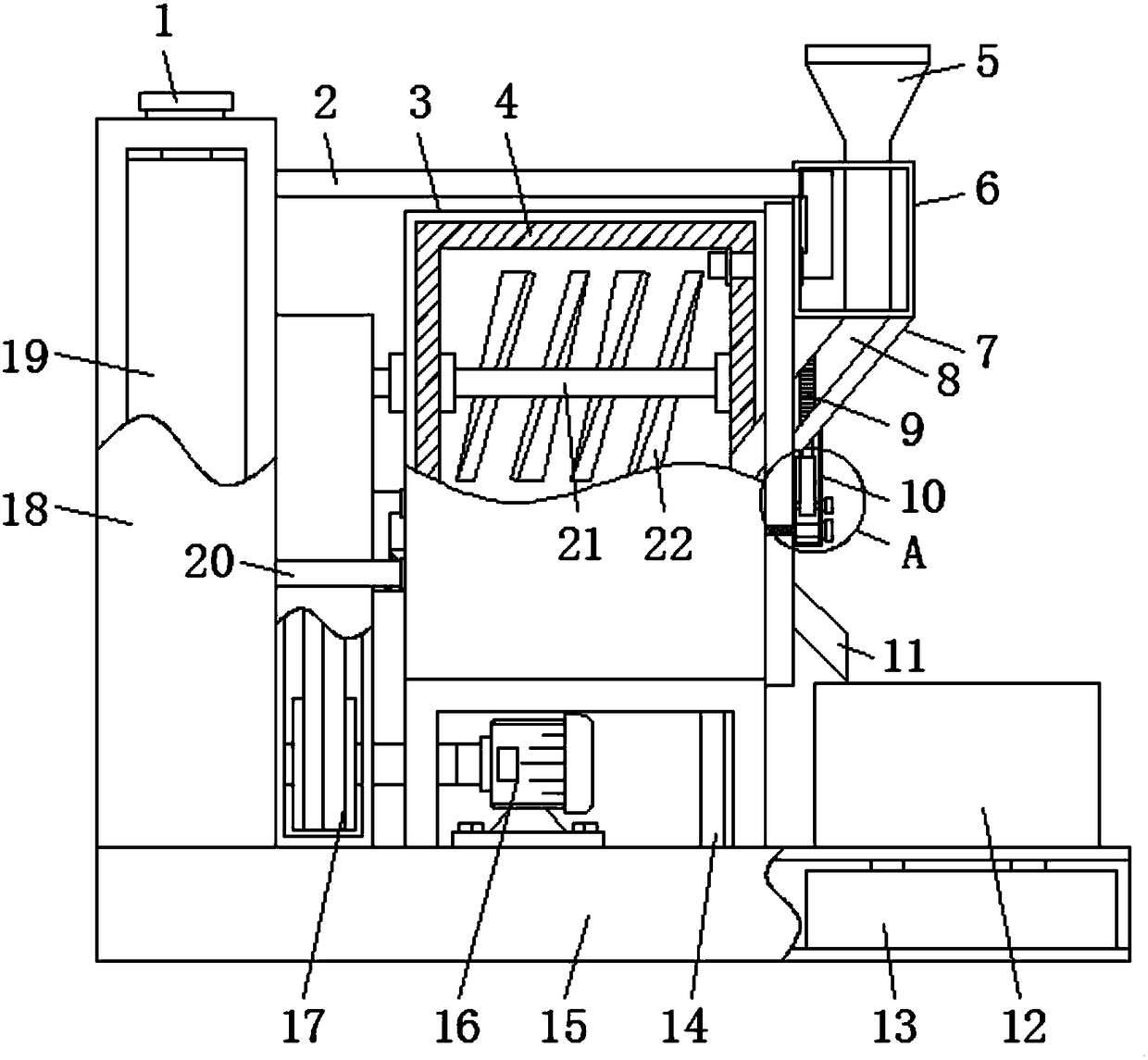

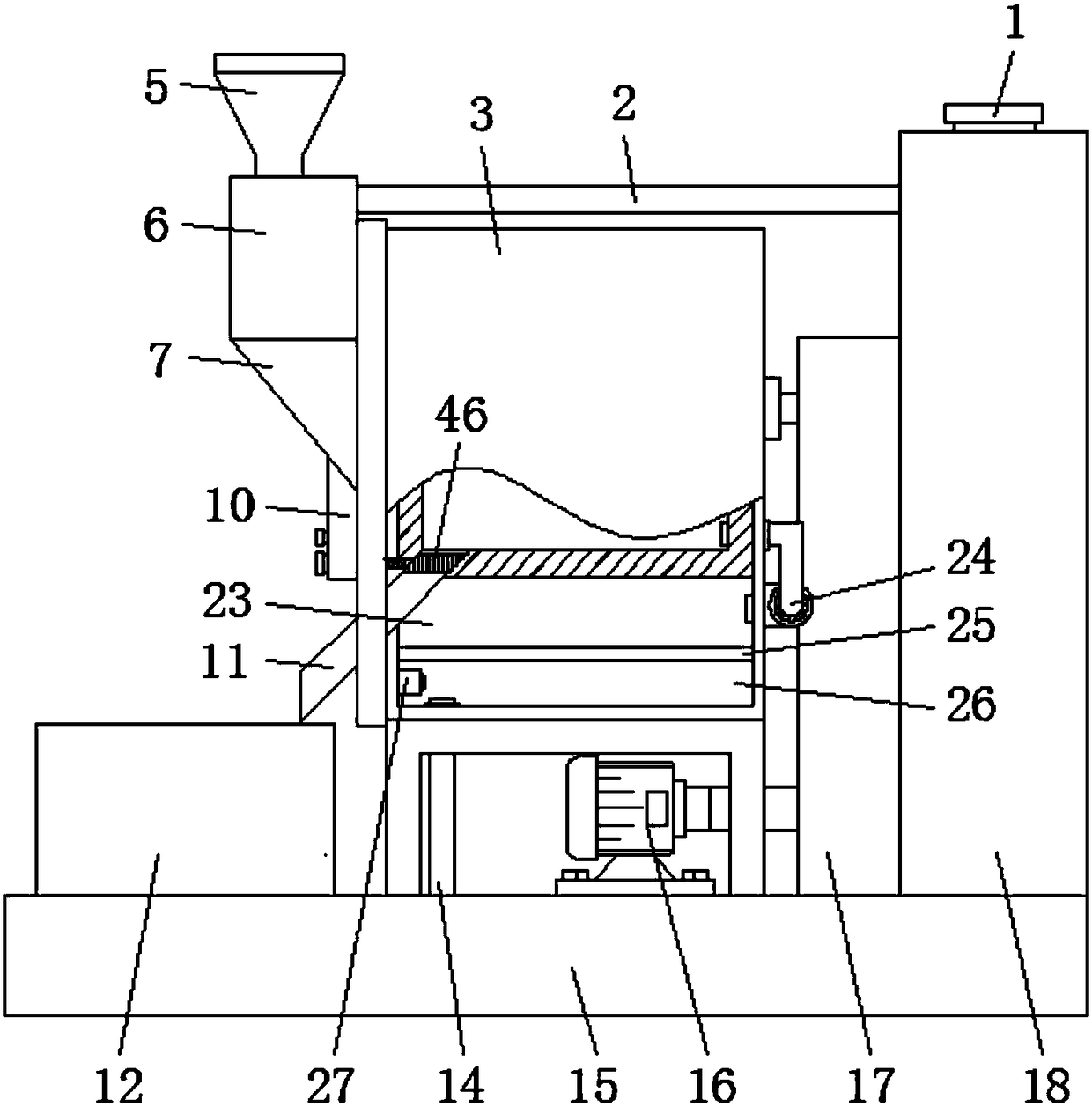

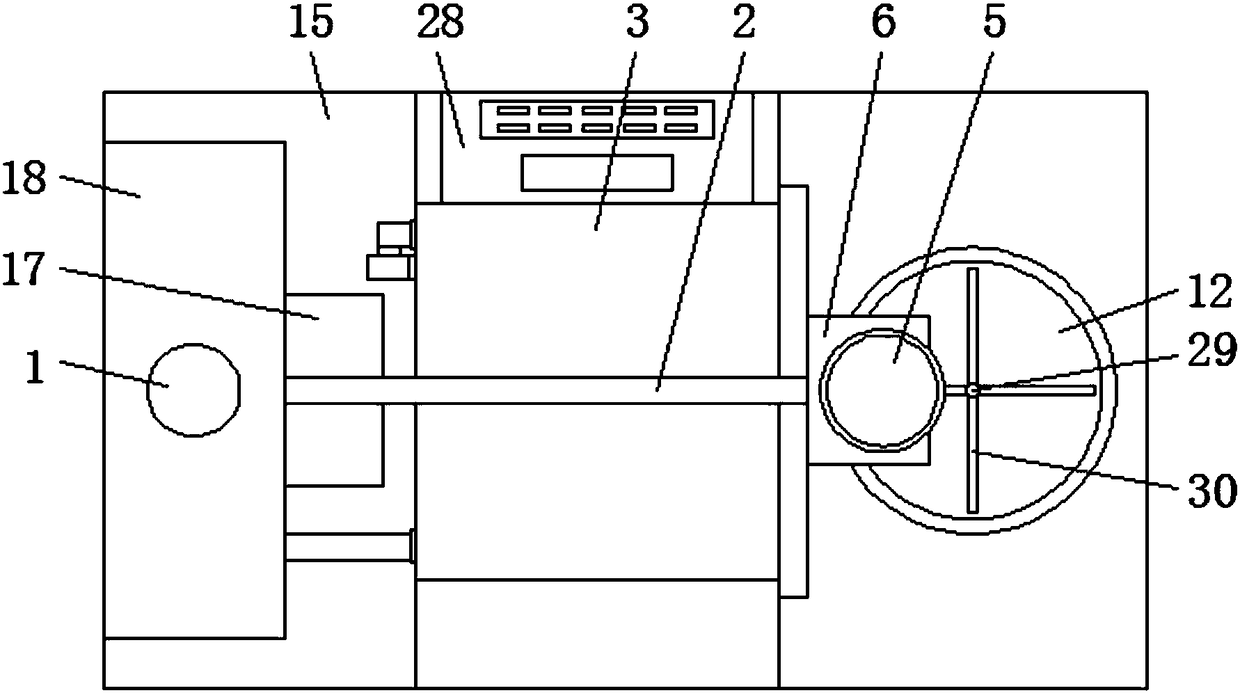

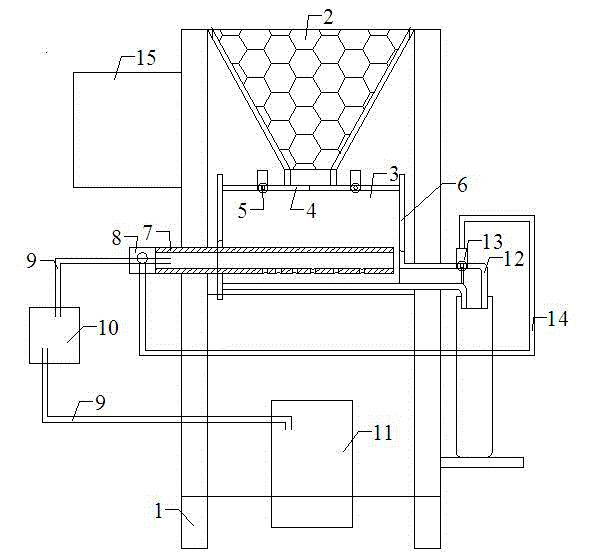

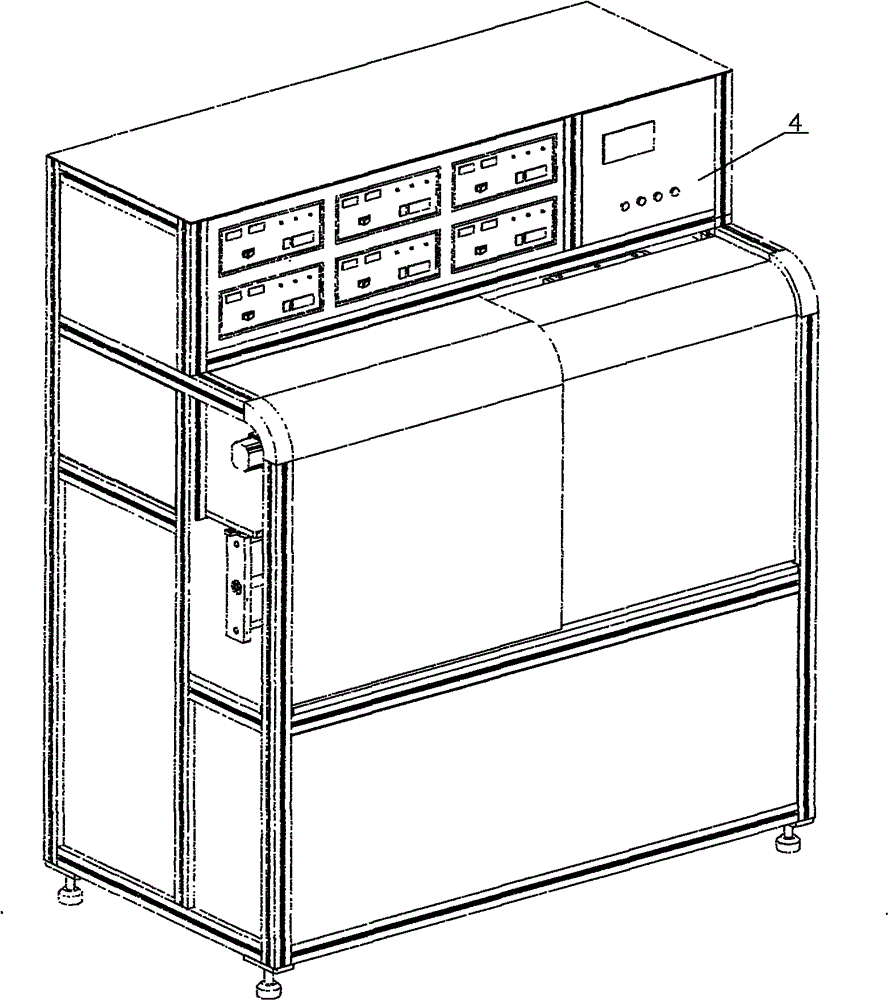

Cement bagging machine experiment table

The invention discloses a cement bagging machine experiment table. A storage hopper is fixedly arranged at the top of a rack, and a material dividing bin is fixedly arranged on the rack under the storage hopper. A feeding opening opposite to a blanking opening of the storage hopper is formed above the material dividing bin. A threaded hole is formed in one side plate of the material dividing bin, and an air pipe is screwed in the threaded hole. A discharging opening is formed in the other side plate of the material dividing bin and connected with a discharging pipeline, and a pneumatic valve is arranged on the discharging pipeline. An electric cabinet is arranged on one side of the rack, and a controller is arranged in the electric cabinet. According to the invention, gas equipment is adopted to replace a mechanical device for discharging, so that filling equipment can accurately discharge materials and can complete one-time discharging within the fixed time. The cement filling and weight control are completed within the set time period according to equipment requirements, maintenance is convenient, and manpower and material resources are saved.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

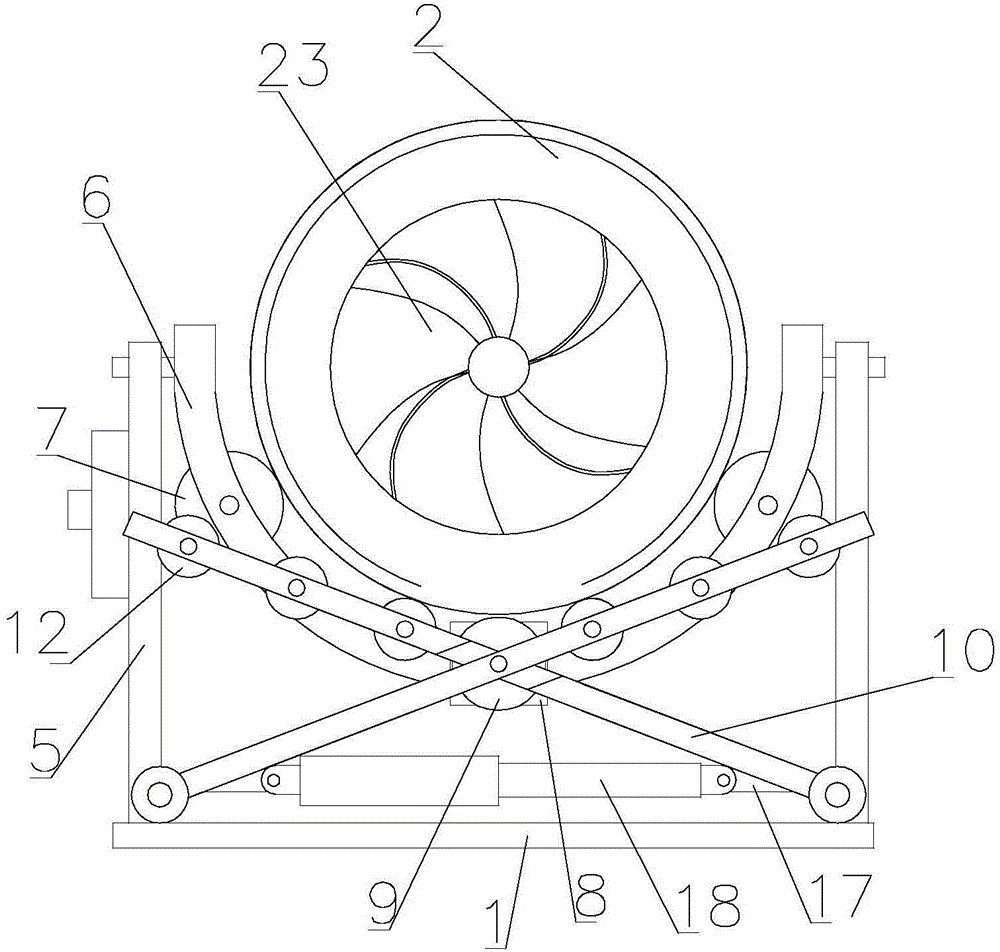

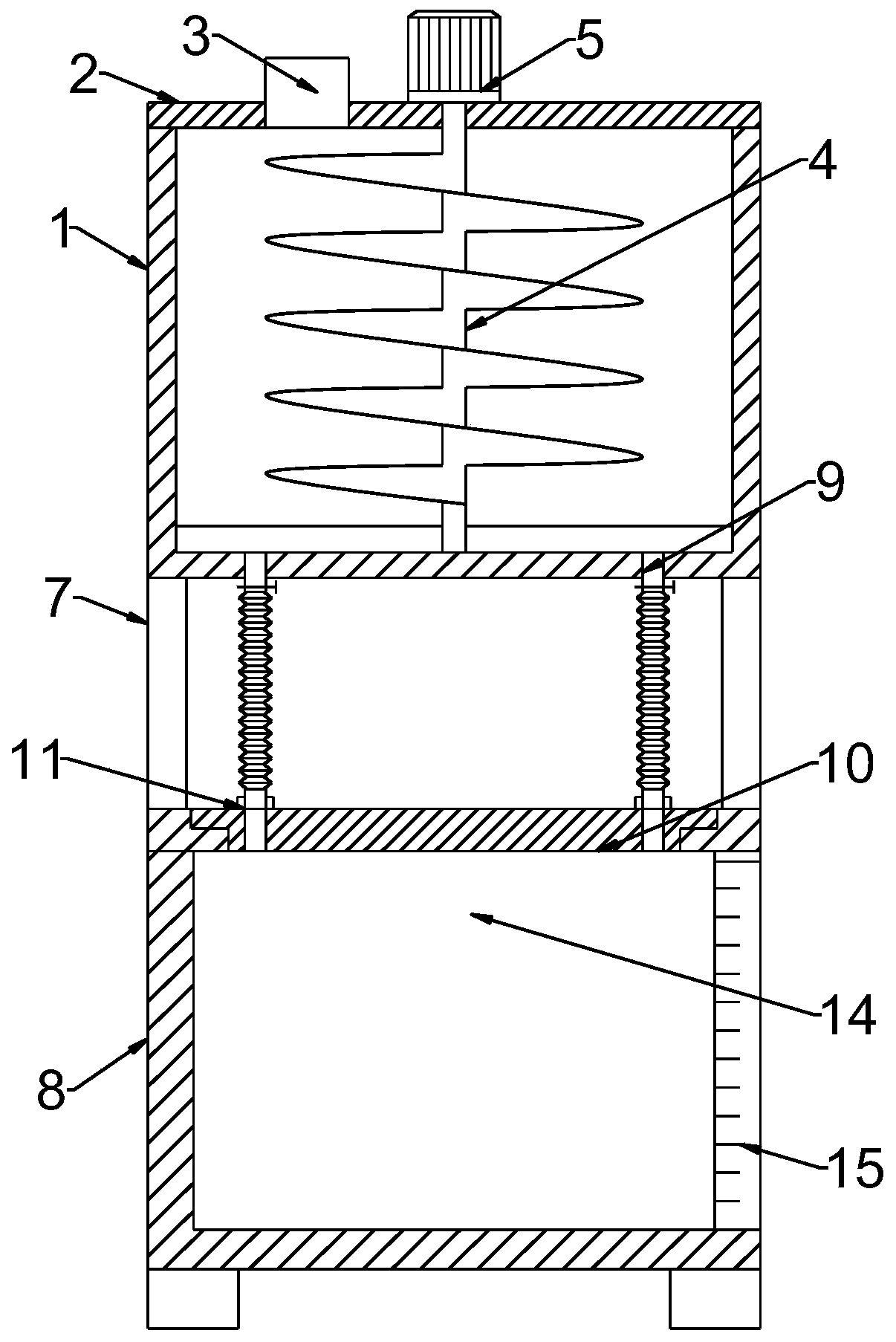

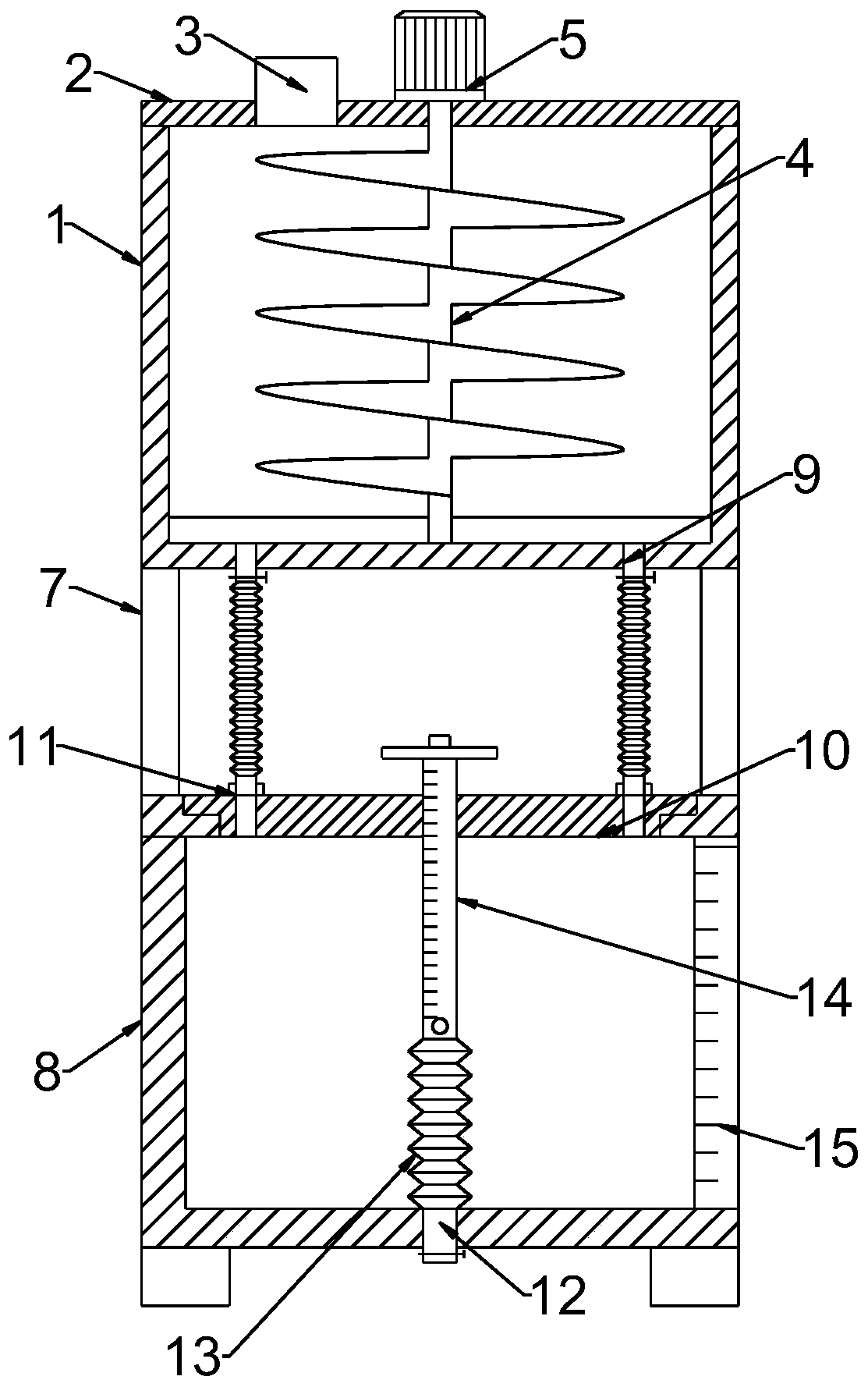

Cement mixer capable of realizing automatic feeding and accurate discharging

ActiveCN104859052AEasy to cleanReduce wasteDischarging apparatusMixing operation control apparatusHydraulic cylinderElectric machinery

The invention discloses a cement mixer capable of realizing automatic feeding and accurate discharging. The cement mixer includes an end cover hydraulic cylinder, an end cover seat, an end cover, hinge lugs, a tilt angle adjusting hydraulic cylinder and an electric control box, wherein side protective plates are respectively arranged on the two sides of a material matching box; two material conveying shafts are mounted on the side protective plates; the material conveying shafts are connected with a conveyor belt power motor; material conveying rollers are arranged on the material conveying shafts; a water pipe is arranged on a water pipe support; a sprinkler head is arranged at one end of the water pipe, and the other end of the water pipe is mounted on a water pump; a front bracket is hinged to and mounted on a front support, and the tilt angle adjusting wheel is arranged at the lower part of a rear support; the tilt angle adjusting wheel is in contact with a base; the hinge lugs are arranged at the upper part of the tilt angle adjusting wheel; the tilt angle adjusting hydraulic cylinder is hinged and mounted between the hinge lugs. The cement mixer provided by the invention can control the tilt angle of a mixing tank and is simple to operate; the mixing tank is easy to wash after being used, so that cement waste is avoided; in addition, the device is easy to operate, and the feeding automation degree is high, so that labor intensity of workers is greatly reduced.

Owner:宜兴市青象水泥有限公司

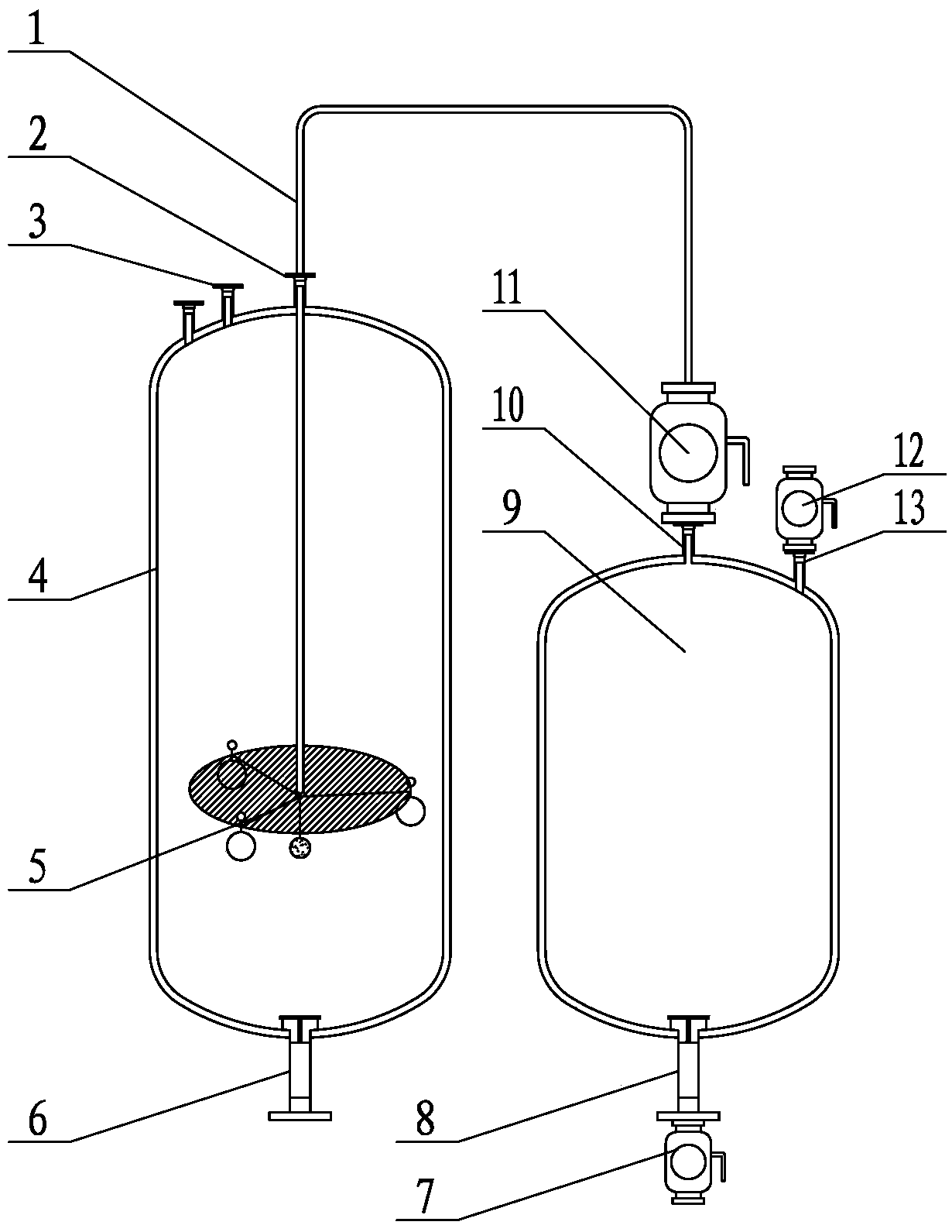

Liquid phase separation device and using method thereof

InactiveCN108939617AReduce worker laborImprove work efficiencyLiquid separationSeparation processLiquid layer

The invention discloses a liquid phase separation device and a using method thereof, and belongs to the technical field of liquid phase separation. The liquid phase separation device is characterizedby comprising a main tank, an auxiliary tank and a liquid separating and extracting device, wherein a main tank feeding hole and a main tank discharging hole are formed in the upper part of the main tank; a main tank discharging hole is formed in the lower part of the main tank; an auxiliary tank feeding hole and a vacuum-pumping nozzle are arranged at the upper part of the auxiliary tank; an auxiliary tank discharging hole is formed in the lower part of the auxiliary tank; the liquid separating and extracting device comprises a liquid absorbing pipe and a suspension device; the lower end of the liquid absorbing pipe is arranged in the main tank through the suspension device; the upper end of the liquid absorbing pipe upwards penetrates out of the main tank discharging hole, and then is connected to the auxiliary tank feeding hole through an auxiliary tank feeding valve; and a vacuum valve is arranged on the vacuum-pumping nozzle. The liquid phase separation device solves the problemsthat as the position of a liquid separation layer is invisible in the liquid phase separation process of liquid which does not dissolve each other, a worker needs to repeatedly confirm the position ofthe liquid separation layer, the amount of labor is great, and the work efficiency is low, and the automatic separation without manual operation is realized.

Owner:SHANDONG HUAAN NEW MATERIAL

Feeding and discharging mechanism

PendingCN113928842AImprove stabilityRealize integrationJigging conveyorsConveyor partsEngineeringStructural engineering

The invention discloses a feeding and discharging mechanism which comprises a fixing mechanism, a feeding mechanism and a material receiving mechanism. The feeding mechanism comprises a vibration body, a feeding bin, a material bearing mechanism and a material pushing mechanism, the vibration body is connected with the feeding bin, a direct vibration guide rail is arranged at a discharging opening of the feeding bin, the tail end of the direct vibration guide rail is connected with the material bearing mechanism, the material pushing mechanism is arranged at the position adjacent to the material bearing mechanism, a discharging port of the material bearing mechanism is connected with a feeding port of the material pushing mechanism, the material pushing mechanism and the material bearing mechanism are horizontally arranged, a material receiving mechanism is arranged at the tail end of a material pushing position of the material pushing mechanism, a material cake frame is arranged below the material receiving mechanism, and the material cake frame is arranged on the fixing mechanism. By means of the mechanism, automation of the whole feeding and discharging process can be achieved during discharging of equipment, the utilization rate, the discharging efficiency and the production efficiency of the equipment are improved to a great extent, and manpower consumption is greatly reduced.

Owner:华天科技(宝鸡)有限公司

Bait-placing device for fishing

InactiveCN103329862BNo sideways rotationRealize the purpose of making nestsOther angling devicesEngineeringFishing

A bait-placing device for fishing comprises a shell (1) for placing a bait, and is characterized in that a clamping part detachably fixed with a fishing rod (7) is arranged at the top of the shell (1); the bottom of the shell (1) is provided with an opening and provided with a movable plate (3) capable of opening or closing the opening; the lower part of the shell (1) is provided with a floating block (2) capable of vertically floating along the periphery face of the lower part of the shell (1); the bottom of the floating block (2) is provided with a through port (22) communicated with outside; when the movable plate (3) opens the opening of the shell (1), the through port (22) is communicated with the opening, and when the floating block (2) arranged at the bottom of the shell (1) slides upwards, the movable plate (3) can be enabled to close an opening-closing structure of the opening when the opening slides downwards. The bait-placing device for fishing is simple in structure, convenient to operate, and capable of being directly mounted on the fishing rod and accurately performing bait-placing after being placed on a selected water face.

Owner:ZHEJIANG BUSINESS TECH INST

Bolt fastening device

PendingCN112936150AAvoid the problem of not being able to complete the fastening workAccurate nestingSpannersWrenchesEngineeringStructural engineering

The invention relates to a bolt fastening device. The bolt fastening device comprises a driving part, a sleeve, an image acquisition apparatus and an operating rod; the driving part is provided with a rotatable output shaft; the sleeve is connected with the output shaft and used for being arranged on a to-be-fastened bolt in a sleeving mode, so that the sleeve is driven to rotate through the output shaft of the driving part, and then the bolt is tightened; the image acquisition apparatus is arranged on the driving part and is used for acquiring image information of the to-be-fastened bolt in real time, so that the position of the bolt can be accurately positioned by observing the image information, acquired by the image acquisition apparatus in real time, of the to-be-fastened bolt, and it is ensured that the bolt can be accurately sleeved with the sleeve; and the operating rod is connected with the driving part, therefore, the driving part, the sleeve on the driving part and the image acquisition apparatus can be conveyed to the position near a long-distance to-be-fastened bolt through the operating rod. According to the bolt fastening device, the position of the to-be-fastened bolt can be accurately positioned through the image acquisition apparatus, and therefore it is guaranteed that the sleeve can be accurately arranged on the bolt in a sleeving mode.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

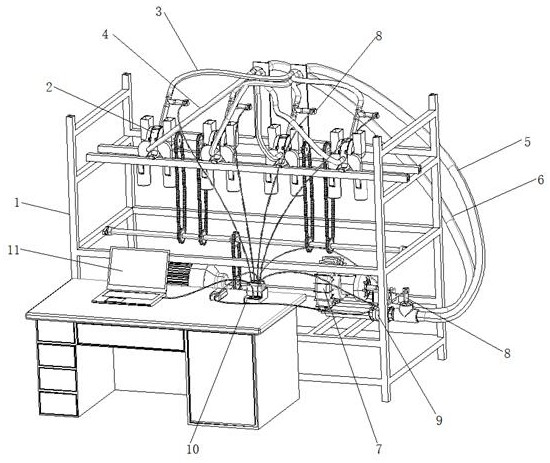

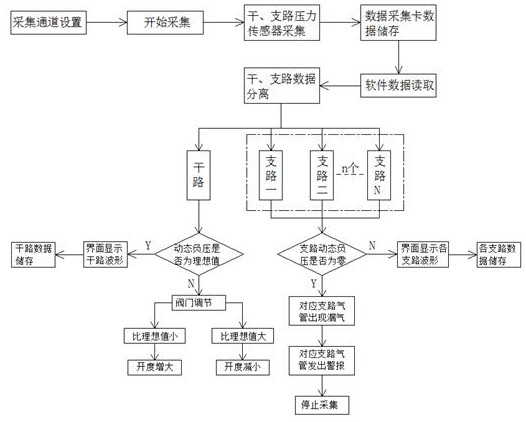

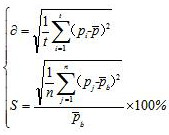

Pneumatic seed metering device multi-channel dynamic negative pressure monitoring system and method

ActiveCN113412710BReduce power consumptionReduce fan loadVacuum gaugesSeed depositing seeder partsSeederAgricultural science

The invention relates to the technical field of pneumatic seeders, and specifically discloses a multi-channel dynamic negative pressure monitoring system and method for a pneumatic seed metering device; Negative pressure air pipes, negative pressure fans, branch negative pressure air pipes and main road negative pressure air pipes are equipped with pressure sensors, main road negative pressure air pipes are equipped with electric valves, and pressure sensors are connected to data acquisition cards. Connected to the host computer; the present invention realizes the monitoring of the dynamic negative pressure value of the whole main road and each branch of the pneumatic seed metering device, including real-time collection, reading, separation, display and storage of dynamic negative pressure data, and is a seed metering device The experimental research on the seeding performance, the intelligent detection and reliability analysis of the seeding device provide the basis, make up for the existing deficiency of the multi-channel dynamic negative pressure monitoring of the pneumatic system in the seeding device, and provide the basis for realizing the precise discharge of the seeder , Stable operation has laid the foundation.

Owner:ANHUI AGRICULTURAL UNIVERSITY

An energy-saving and high-efficiency coffee bean roaster

The invention discloses an energy-saving high-efficiency coffee bean baking machine. The energy-saving high-efficiency coffee bean baking machine comprises a base, wherein a baking machine body, a cooling disk and a tail gas box are mounted at the top end of the base; the baking machine body is located between the cooling disk and the tail gas box; an inner cylinder and a gas filtering plate are mounted in the baking machine body; the gas filtering plate is located below the inner cylinder; a thermal mixing cavity and a combustion cavity are separately formed in two sides of the gas filteringplate; a combustor is mounted in the combustion cavity; and a fuel gas pipe is connected between the combustion cavity and the base. According to the energy-saving high-efficiency coffee bean baking machine disclosed by the invention, an exhaust pipe, the tail gas box, a gas return pipe, the thermal mixing cavity, a fan, the gas filtering plate and the combustion cavity are arranged, when the baking machine operates, and fuel gas enters the baking machine body, the fuel gas is combusted through ignition of the combustor, so that expansion combustion is realized in the combustion cavity, and the temperature is quickly raised; after combustion, generated high-temperature gas penetrates through the gas filtering plate to enter the thermal mixing cavity, and then the high-temperature gas is guided to the inner cylinder through the fan to heat and bake coffee beans.

Owner:扬州市生态科技新城杭集中小企业服务中心有限公司

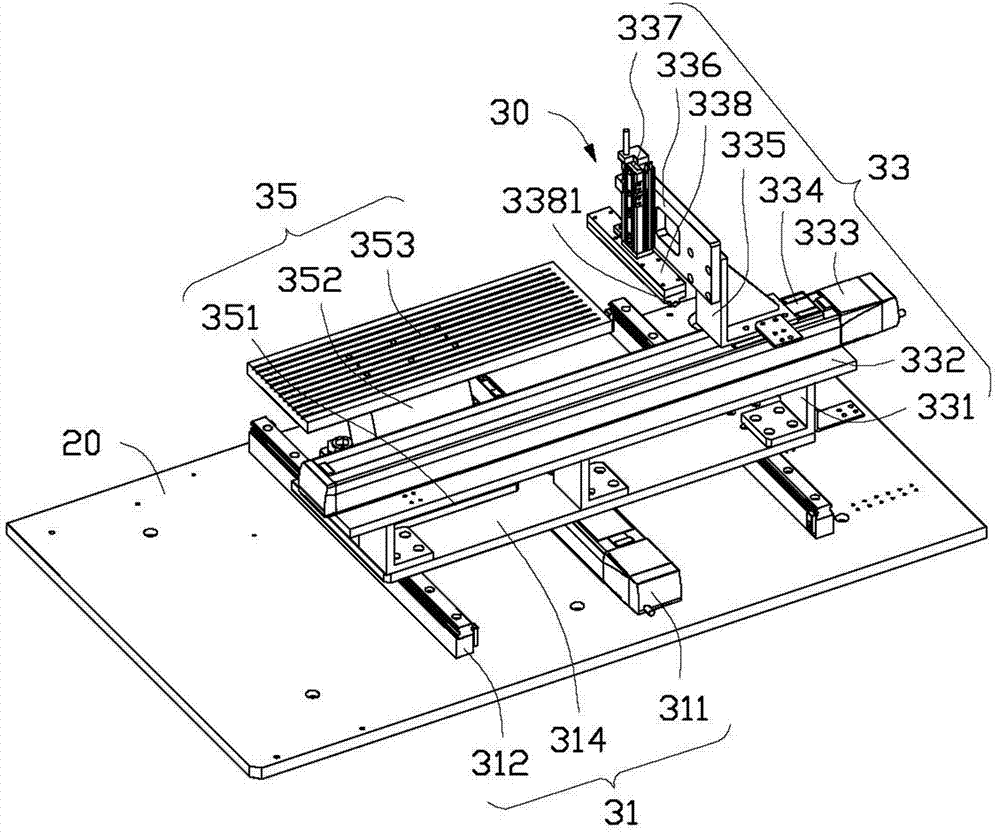

Digital controlled intersecting line cutting machine nesting module system

InactiveCN100589053CRetain the function of manual nestingAccurate nestingNumerical controlProcess moduleRemovable media

The invention relates to a numerically-controlled (NC) intersection-line cutting machine nest system used in the field of NC cutting. The system comprises a NC file processing module, a parameter-setting module, a tube-laying module, a data management module and a display module. The NC file processing module reads a NC file to be processed from a computer hard disk or a mobile memory and generates a new NC file that is stored in the computer hard disk or a mobile memory. The parameter-setting module lists the tube-laying parameters which are required for the tube-laying operation and need tobe reset or modified to allow a user to reset or modify. The data management module transmits the data to other modules. The tube-laying module receives the tube-laying parameters and the original steel tube processing data of the tubes and performs the tube-laying, and optimizes the arrangement of the tube nest by adjusting the position of the intersection-line track of each tube. The display module displays the data that are required to be viewed by the user during the tube-laying process. The NC intersection-line cutting machine nest system can not only maximize the utilization rate of theblank material but also greatly increase the time efficiency of the user.

Owner:SHANGHAI JIAOTONG UNIV

Processing method of precision components of CNC spring machine and automatic riveting of spring iron sheets

The invention discloses a numerical control spring machine precise component. The numerical control spring machine precise component comprises a rack, a feeding sliding rail, a material discharging device, pneumatic mechanical arms and riveting devices, wherein the material discharging device comprises an iron sheet baffle plate, a baffle plate cylinder and a gas needle device; each pneumatic mechanical arm comprises a pneumatic finger used for clamping a spring and a push-pull cylinder; and each riveting device comprises a stamping rod and a stamping cylinder, and the stamping cylinder drives the stamping rod to reciprocate to stamp an iron sheet on the rail. The invention aims to provide the numerical control spring machine precise component and a processing method for automatically riveting springs and iron sheets, and the component and the processing method have the advantages that the structure is simple and reliable; the requirement of a client that the electricity-conductive springs are assembled with the iron sheets can be effectively realized; and the riveting precision is high.

Owner:ZHUHAI LONGXIN TECH

Washer mounting device of brushless electronic water pump

PendingCN108397425ASave human effortImprove installation efficiencyPump componentsPumpsEngineeringMechanical engineering

The invention discloses a washer mounting device of a brushless electronic water pump. The washer mounting device comprises a rack, wherein a worktable is arranged on the rack; a mounting seat for mounting an isolating sleeve is mounted on the worktable; a feeding slide is horizontally and slidably mounted on the worktable; a discharge hole penetrating up and down is formed in the feeding slide; the feeding slide is driven by a feeding power device to slide, so that the discharge hole is vertically aligned with a central shaft of the isolating sleeve on the mounting seat; a feeding slide blockis slidably mounted on the feeding slide; a washer supply mechanism is arranged on the feeding slide; the feeding slide block is driven by the feeding power device to move horizontally to feed the washers one by one to the discharge hole; and a vertical feeding mechanism which conveys the washers vertically downward and sleeves the washers on the central shaft is arranged on the feeding slide block. The washer mounting device can sleeve the washers on the central shaft of the isolating sleeve, so that manpower is replaced, and the production efficiency is improved.

Owner:JIANGSU LANGXIN ELECTRIC

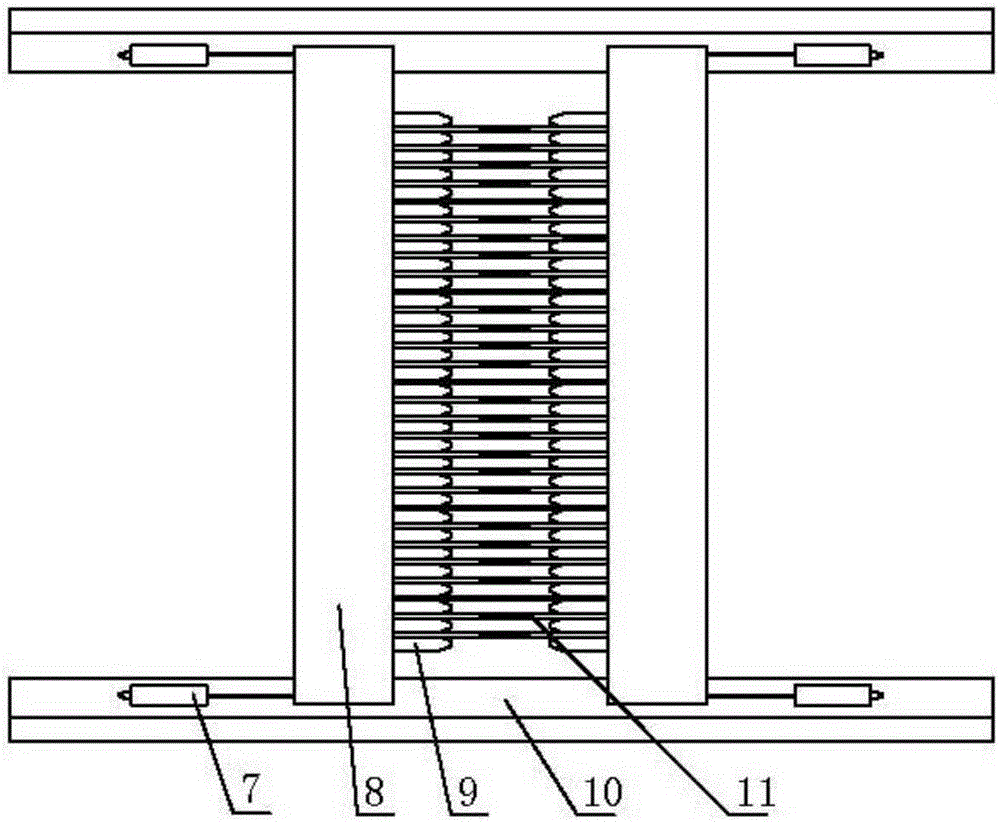

Device for stabilizing mechanical arm in in-and-out movement process of electrolytic manganese cathode plate from tank

ActiveCN103643255AGuaranteed smooth productionAvoid forceElectrolysis componentsPhotography auxillary processesEngineeringManipulator

The invention relates to a device for stabilizing a mechanical arm in an in-and-out movement process of an electrolytic manganese cathode plate from a tank. The device comprises a guide rail, walking wheels, a support beam, an in-and-out tank part and a movement part, wherein at least two walking wheels are placed on the guide rail and are capable of sliding on the guide rail; the support beam is connected to the walking wheel and suspended on the guide rail; the movement part is suspended under the support beam through two movement lifting cylinders on two sides; the in-and-out tank part is also suspended under the support bam through two in-and-out tank lifting cylinders on the two sides; the movement part is located above the in-and-out tank part. Through the device for stabilizing the mechanical arm in the in-and-out movement process of the electrolytic manganese cathode plate from the tank, the mechanical treatment of a process for taking the cathode plate in and out of the tank in a subsequent section is realized; the conventional manual driving is not used taking the cathode plate in and out of the tank; the situation of uneven stress and easiness in deflection of the cathode plate can be avoided; the balance of the cathode plate can be maintained well without extra auxiliary personnel, so that the personnel cost is reduced, and the working efficiency is improved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

A kind of conveying and sorting device for steel bar connecting sleeve

ActiveCN104097803BHigh degree of mechanization and automationReasonable layoutPackagingEngineeringRebar

The invention belongs to the technical field of rebar connecting sleeve packaging equipment and discloses a rebar connecting sleeve conveying and arranging device which is used for directionally arranging connecting sleeves. The technical scheme includes that a printing, feeding and conveying mechanism can print and convey the connecting sleeves individually, a connecting sleeve conveying and turning mechanism changes the connecting sleeves from horizontal direction to vertical direction and conveys the same onto chain plates, a chain plate conveying mechanism realizes material transmission in the process of array arrangement of the connecting sleeves, an array arranging mechanism performs array rule sequencing on the connecting sleeves on the chain plates, an array sleeve pushing mechanism conveys the connecting sleeves which are arranged well to a next workstation, and an adjusting mechanism can perform array adjusting of the connecting sleeves. The rebar connecting sleeve conveying and arranging device fills a gap in automatic packager arranging equipment for the connecting sleeves, is reasonable in layout, perfect in connection, accurate in discharging and reliable in running, and is suitable for being used as an arranging device of an automatic connecting sleeve packager, and mechanized and automated degree of the automatic connecting sleeve packager is increased greatly.

Owner:HEBEI YIDA REINFORCING BAR CONNECTING TECH

A combined trash can

Owner:HUNAN UNIV

Easy-to-separate extraction device

InactiveCN109893883AAvoid residueAccurate nestingLiquid solutions solvent extractionEngineeringMechanical engineering

The invention discloses an easy-to-separate extraction device comprising an extraction cavity and a precipitation cavity which are communicated. A stirring mechanism is arranged in the extraction cavity, a discharging structure is arranged on the precipitation cavity, a guide mechanism in synchronous rotation and for discharging is connectedly arranged on the stirring mechanism, and the discharging structure is movably mounted on the precipitation cavity and controlled at different heights for discharging through movement adjusting. During material discharging, a wafer and guide plates synchronously rotate to drive materials to flow towards the outer side to the edge of the bottom of an extraction cavity and cooperate with a guide pipeline at the edge of the lower end of the extraction cavity to discharge the materials as many as possible, so that residue is avoided; a control block can be moved on a subplate to adjust discharging height of discharging holes, accurate positions of thedischarging holes on liquid level can be known according to scales on a sliding pipe sleeve so as to complete discharging of the materials on layers different in height, and the control block is rotated to drive a plug to ascend and descend so as to control discharging, so that discharging is more accurate.

Owner:安庆市汇智科技咨询服务有限公司

A stabilizing device for the manipulator during the movement of the electrolytic manganese cathode plate in and out of the tank

ActiveCN103643255BGuaranteed smooth productionAccurate insertionPhotography auxillary processesElectrolysis componentsManganeseEngineering

The invention relates to a device for stabilizing a mechanical arm in an in-and-out movement process of an electrolytic manganese cathode plate from a tank. The device comprises a guide rail, walking wheels, a support beam, an in-and-out tank part and a movement part, wherein at least two walking wheels are placed on the guide rail and are capable of sliding on the guide rail; the support beam is connected to the walking wheel and suspended on the guide rail; the movement part is suspended under the support beam through two movement lifting cylinders on two sides; the in-and-out tank part is also suspended under the support bam through two in-and-out tank lifting cylinders on the two sides; the movement part is located above the in-and-out tank part. Through the device for stabilizing the mechanical arm in the in-and-out movement process of the electrolytic manganese cathode plate from the tank, the mechanical treatment of a process for taking the cathode plate in and out of the tank in a subsequent section is realized; the conventional manual driving is not used taking the cathode plate in and out of the tank; the situation of uneven stress and easiness in deflection of the cathode plate can be avoided; the balance of the cathode plate can be maintained well without extra auxiliary personnel, so that the personnel cost is reduced, and the working efficiency is improved.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Buzzer test separator

InactiveCN101786085BEasy to change clothesContinuously workingSortingEngineeringElectronic component

The invention relates to a buzzer test separator, belonging to the manufacturing field of electronic component test equipment. The separator comprises a rack, three groups of feeding boxes, a rotatable feeding arm, a U-shaped locating slot, a guide rail, test needles, a waste cabin, a qualified product cabin, a discharging hopper and a console, wherein the rotatable feeding arm with rotation amplitude of 0-90 degrees is provided with a material absorbing head to facilitate the absorption and delivery of a buzzer; the U-shaped locating slot with functions of vertical blanking and precise location can reciprocate along the guide rail below the material absorbing head and the test needles; the feeding box is a hollow cylindrical box with a gap, and three groups of feeding boxes work alternatively with high efficiency; the test needles arranged horizontally are used for vertical test with higher test accuracy than horizontal test; and the flexible discharging hopper is controlled by a discharging cylinder. The invention has the advantages of simple structure, accurate discharging and high reliability and practicability.

Owner:肇庆信泰机电科技有限公司

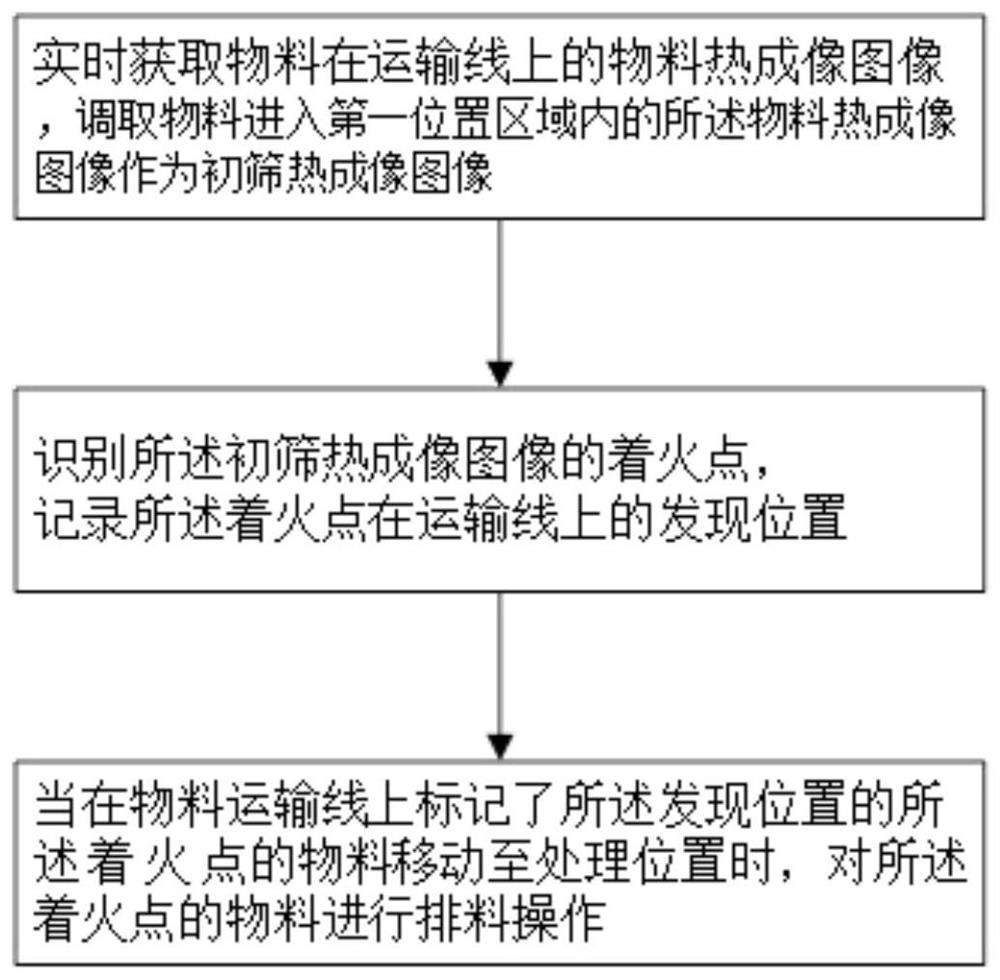

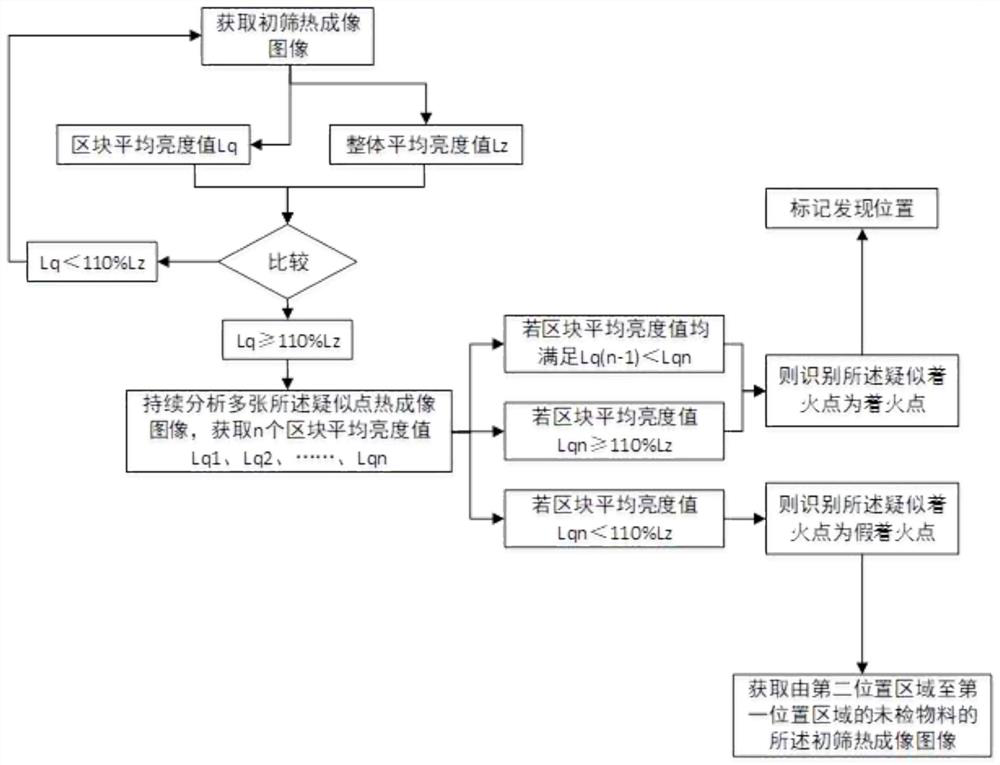

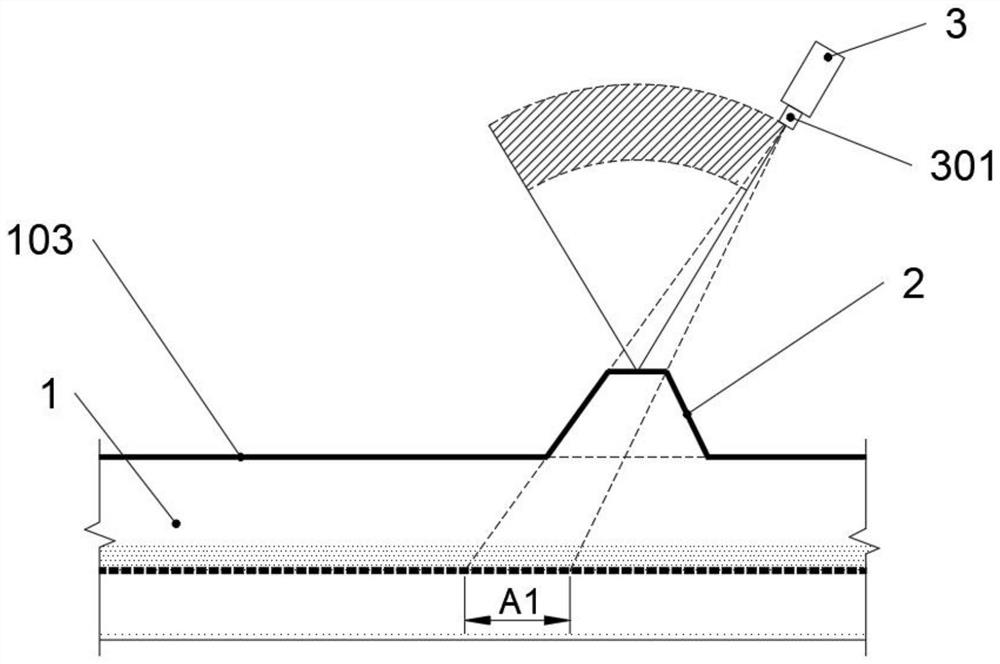

High-temperature detection-discharge treatment method and system for activated carbon flue gas purification device

ActiveCN112857580AAccurately judge the dataImprove transportation efficiencyGas treatmentDispersed particle separationActivated carbonThermodynamics

The invention relates to a high-temperature detection-discharge treatment method for an activated carbon flue gas purification device; the method comprises the following steps that (1), material thermal imaging images of materials on a material conveying line are obtained in real time, the materials with the material thermal imaging images obtained are detected materials, and the materials with the material thermal imaging images not obtained are undetected materials; a material thermal imaging image of the material entering the first position area is called as a primary screening thermal imaging image; (2), analyzing is performed and whether the primary screening thermal imaging image has a suspected high-temperature point is determined, and a discovery position of a high-temperature point material on a material conveying line is marked; and (3), when the high-temperature point material marked with the finding position on the material conveying line moves to a processing position, discharging operation is executed. According to the technical scheme provided by the invention, the process of identifying the high-temperature point material can be divided into preliminary doubts, and tracking judgment is carried out, so that accurate judgment data of the high-temperature point are obtained; and therefore, discharging can be accurate, the discharging amount is reduced, and the conveying efficiency of the conveying line is improved.

Owner:HUNAN ZHONGYE CHANGTIAN ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com