Cement bagging machine experiment table

It is a technology of test bench and packaging, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of not easy to realize control, high operating cost, and high labor intensity, so as to save manpower and material resources and discharge materials. Precise, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

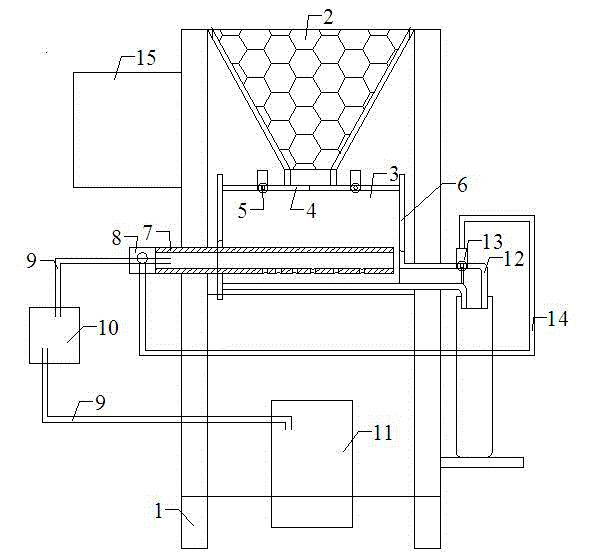

[0008] Embodiments are described in detail with reference to the accompanying drawings. A cement packing machine test bench, a storage funnel 2 is fixed on the top of the frame 1, a distribution bin 3 is fixed on the frame 1 below the storage funnel 2, and a storage funnel is arranged above the distribution bin 3 2. The feed port opposite to the feed port. The feed port is provided with a butt-closed bin door 4, and the bin door 4 is driven by a drive motor 5 arranged on the distribution bin 3. One side of the distribution bin 3 The plate 6 is provided with threaded holes, and the threaded holes are screwed with an air pipe 7, and the air pipe 7 on the outside of the material distribution bin 3 is connected to the air inlet pipe 9 through the air circuit control valve 8, and the air inlet pipe 9 is provided with an air storage tank 10. The end of the trachea 9 is connected to the air pump 11 arranged at the bottom of the frame 1, the end of the trachea 7 inside the distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com