High-temperature detection-discharge treatment method and system for activated carbon flue gas purification device

A flue gas purification and treatment method technology, applied in the field of sintering flue gas purification, can solve the problems of detection, positioning and treatment of high-temperature activated carbon particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

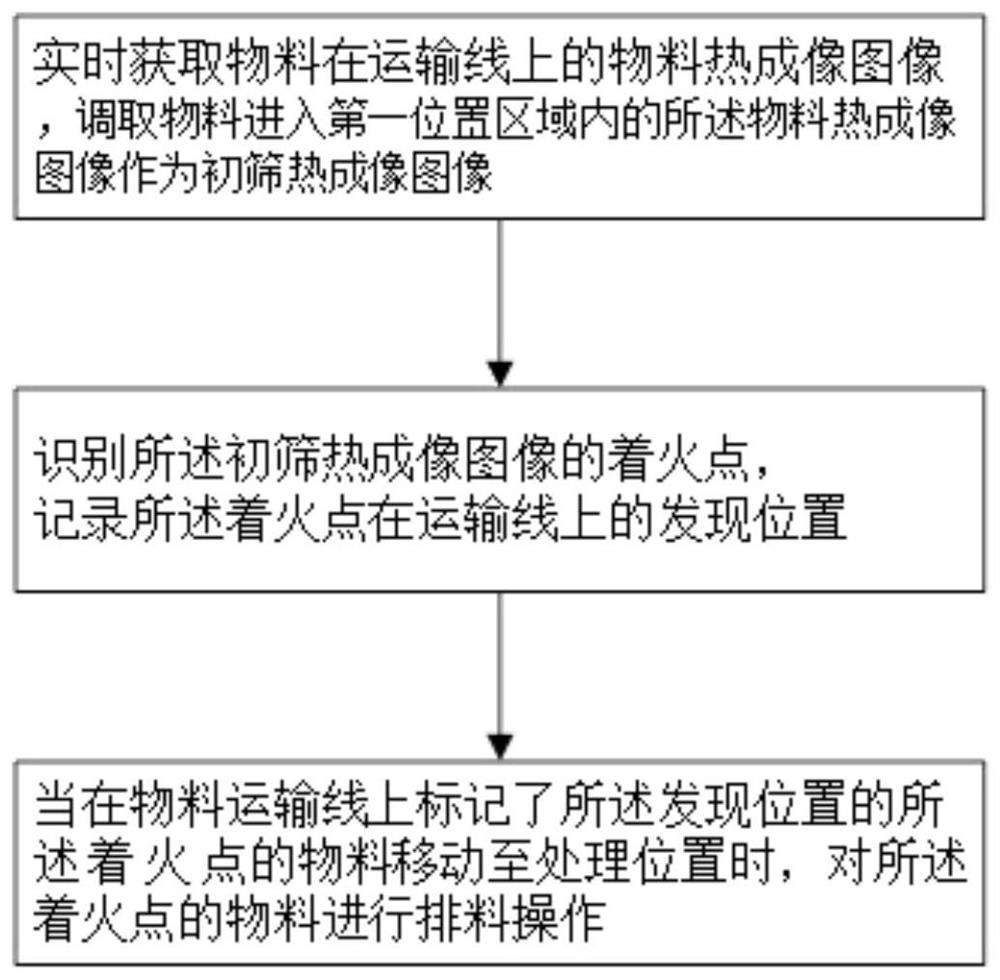

[0130] According to the first embodiment of the present invention, a kind of activated carbon flue gas purification device high temperature detection-exhaust processing method is provided:

[0131] A high-temperature detection-exhaust processing method of an activated carbon flue gas purification device, the method comprising the following steps:

[0132] 1) Obtain the material thermal imaging image of the material on the material transportation line 1 in real time. The material whose thermal imaging image has been acquired is the inspected material, and the material whose thermal imaging image has not been acquired is the uninspected material. Taking the thermal imaging image of the material entering the first position area A1 as the thermal imaging image of the primary screening;

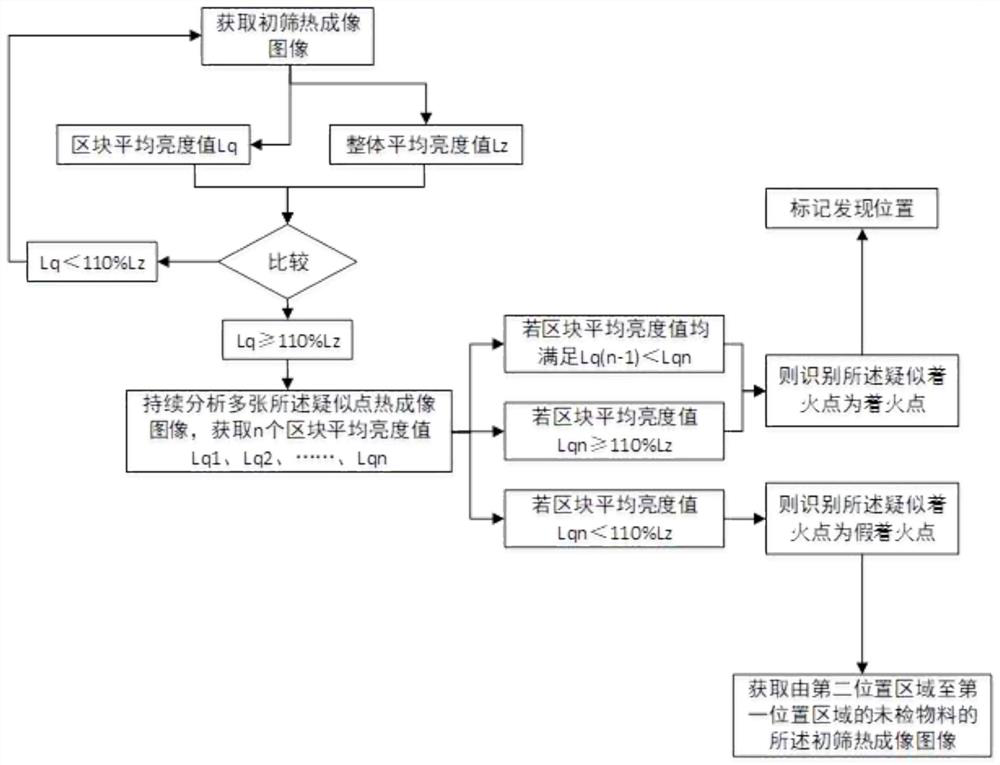

[0133] 2) Analyzing and judging whether the thermal imaging image of the preliminary screening has a suspected high temperature point,

[0134] 2a) If the thermal imaging image of the primary scr...

Embodiment 1

[0206] A high-temperature detection-discharge processing method of an activated carbon flue gas purification device, the method comprising the following steps: 1) Obtaining a material thermal imaging image of a material on a material transportation line 1 in real time, and the material whose thermal imaging image of the material has been acquired is already The materials whose thermal imaging images have not been acquired are uninspected materials, and the thermal imaging images of the materials entering the first position area A1 are transferred as the thermal imaging images of the preliminary screening; 2) analyze and judge the thermal imaging images of the preliminary screening Whether the thermal imaging image of the screening has a suspected high temperature point, 2a) if the thermal imaging image of the preliminary screening does not have a high temperature point, continue to call the thermal imaging image of the primary screening of the material newly entering the first l...

Embodiment 2

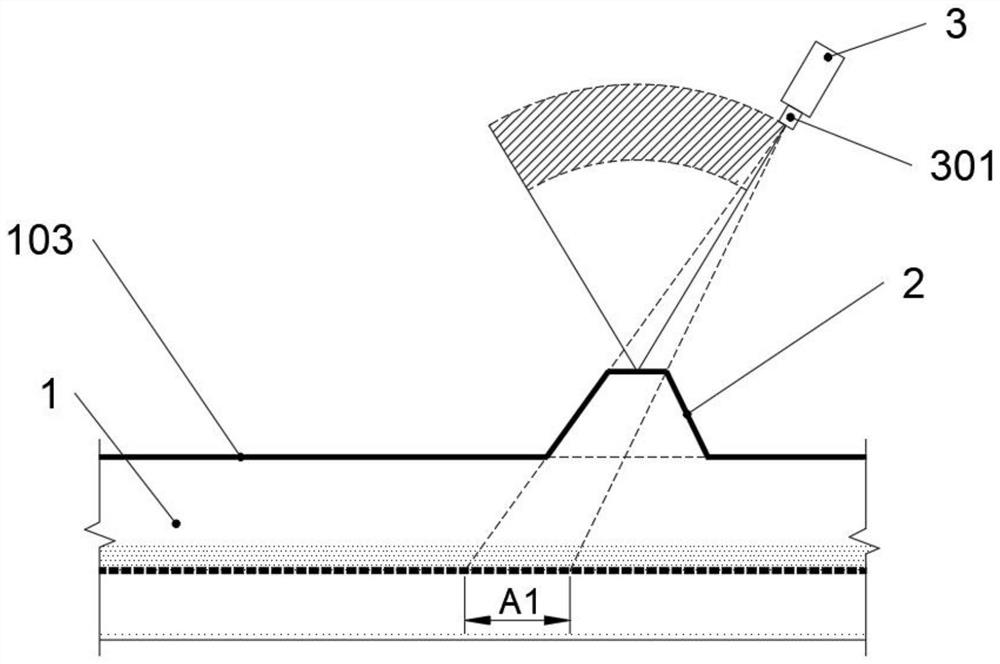

[0208] Repeat Example 1, except that the material transport line 1 is a sealed material transport line 1 . The upper cover of the material transportation line 1 is provided with a transportation cover 103; the material moves along the length direction of the material transportation line 1; step 1) obtaining the material thermal imaging image of the material on the material transportation line 1 in real time includes the following steps: 1a) converting the thermal imaging The instrument 3 is arranged above the transportation cover 103, and the first observation device 2 is arranged on the transportation cover 103; The vertical plane where the central axis is located reciprocates, and the photosensitive component 301 of the thermal imager 3 points to the first observation device 2 all the time, and the thermal imager 3 acquires The thermal imaging image of the material from the first location area A1 to the second location area A2 on the material transportation line 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com