Method and system for secondary detection and secondary treatment of high-temperature activated carbon

A technology of secondary detection and secondary treatment, which is used in the secondary detection and secondary treatment of high-temperature activated carbon, and the detection and treatment of high-temperature activated carbon particles. The effect of hidden danger, suitable temperature and easy detection and identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

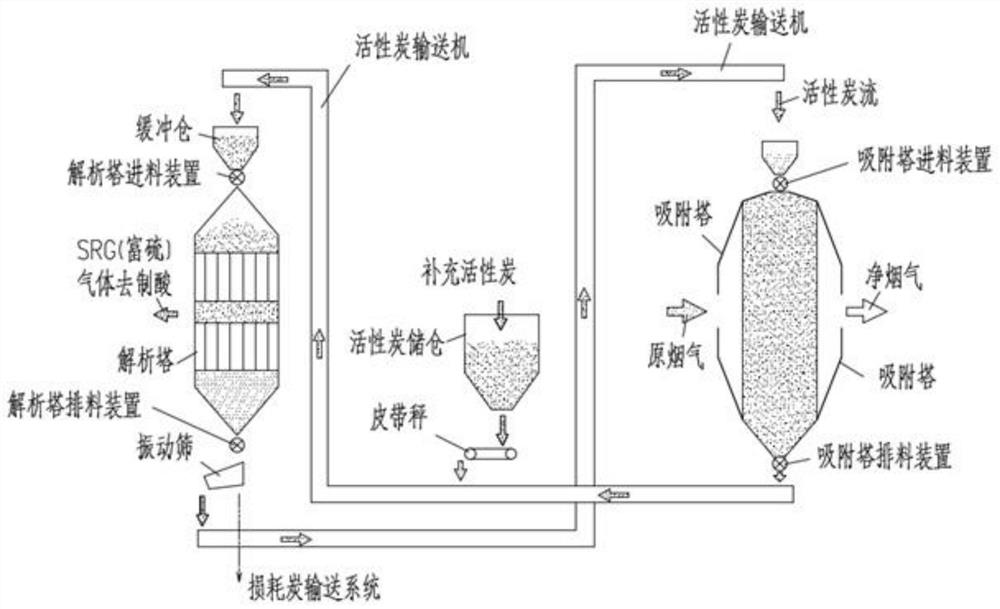

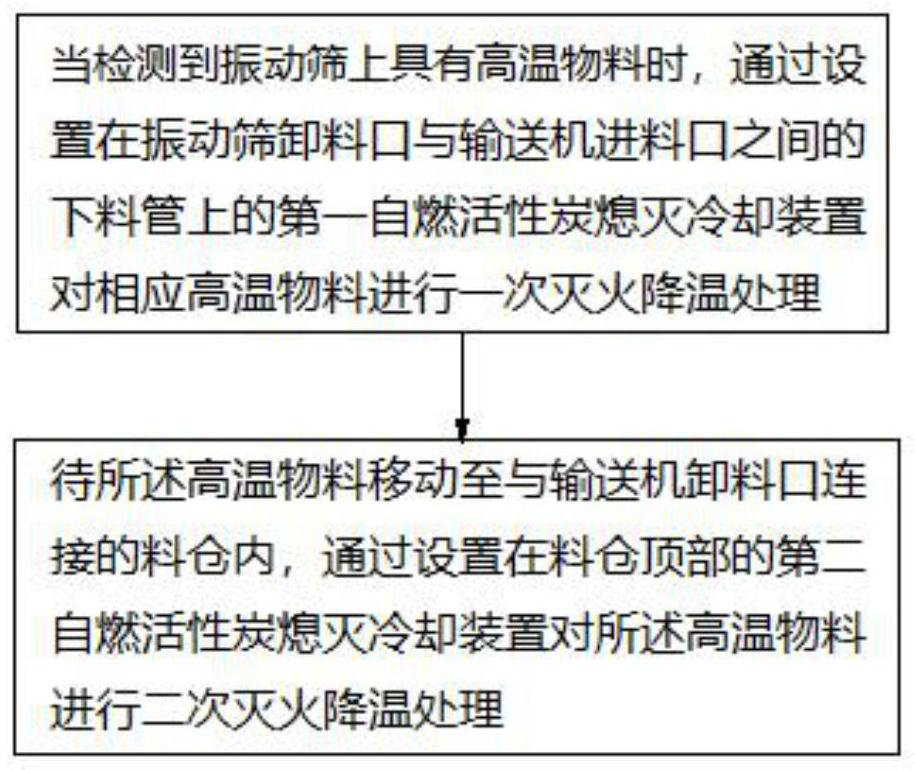

[0163] A system for secondary detection and secondary treatment of high-temperature activated carbon, the system includes a vibrating screen 1, a conveyor 2, a feeding pipe 3, a silo 4, a first self-ignition activated carbon extinguishing cooling device, and a second self-igniting activated carbon extinguishing cooling device. The discharge port of the vibrating screen 1 is connected with the feed port of the conveyor 2 through a discharge pipe 3 . The discharge port of the conveyor 2 is connected with the silo 4 . The first self-igniting activated carbon extinguishing cooling device is arranged on the feeding pipe 3 . The second self-igniting activated carbon extinguishing cooling device is arranged on the top of the feed bin 4 .

Embodiment 2

[0165] Such as Figure 13 and 14 As shown, Embodiment 1 is repeated, except that the system further includes a first thermal imager 5 and a first light shield 13 . The vibrating screen 1 is provided with a cover plate 101 . The first light shield 13 is arranged on the cover plate 101 at the rear of the vibrating screen 1 . The first thermal imager 5 is arranged on the top of the first light shield 13 . The rear part of the vibrating screen 1 is provided with an imaging I zone 6 . The imaging zone I 6 includes a first imaging zone 601 and a second imaging zone 602 , and the first imaging zone 601 is located upstream of the second imaging zone 602 . Taking the connection position of the first thermal imager 5 and the first shading cover 13 as a base point, the first thermal imager 5 swings back and forth around the base point. The first thermal imager 5 takes real-time pictures of the materials entering the first imaging area 601 and the second imaging area 602 at the tail ...

Embodiment 3

[0167] Such as Figure 15 and 16 As shown, embodiment 2 is repeated, except that the system further includes a second thermal imager 8 and a second hood 14 . A discharge hopper 7 is also provided between the conveyor 2 and the silo 4 . The discharge port of the conveyor 2 is connected with the inlet of the discharge hopper 7 through a discharge conduit 701 . The outlet of the unloading hopper 7 is connected with the inlet of the feed bin 4 through a feed pipe. The discharge conduit 701 is arranged on one side of the upper part of the discharge hopper 7 . The discharge conduit 701 includes an inclined section and a vertical section, and the vertical section is located downstream of the inclined section. The second shading cover 14 is arranged on the upper edge of the inclined section of the discharge conduit 701 . The second thermal imager 8 is arranged on the top of the second light shield 14 . An imaging II zone 9 is provided in the inclined section of the discharge con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com