A method and system for extinguishing and cooling treatment of high-temperature activated carbon in the unloading section after analysis

A technology of activated carbon and high temperature, which is applied in the detection and treatment of high-temperature activated carbon particles, and in the field of extinguishing and cooling treatment of high-temperature activated carbon in the unloading section after analysis. Accuracy, safety-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

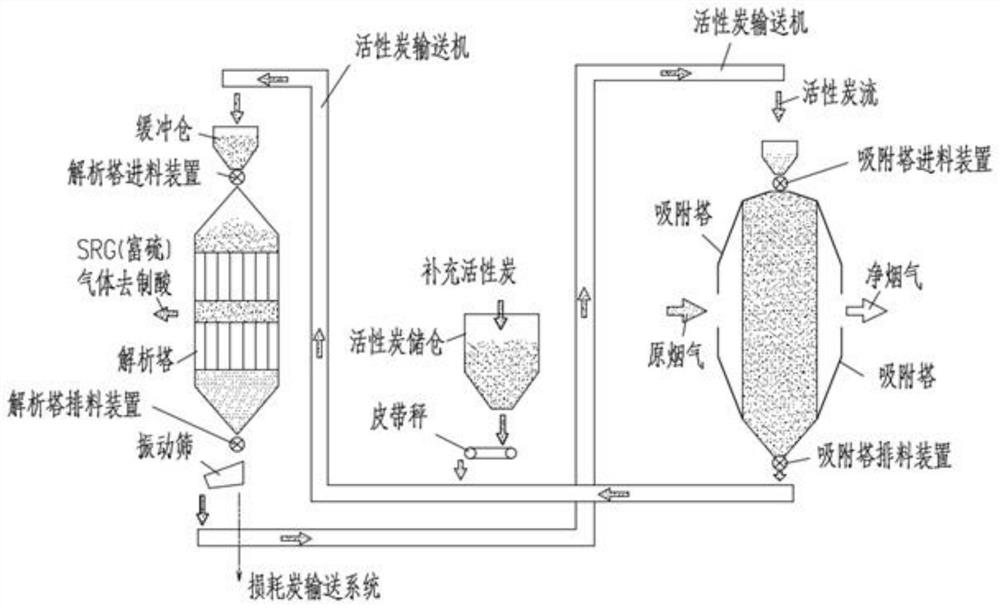

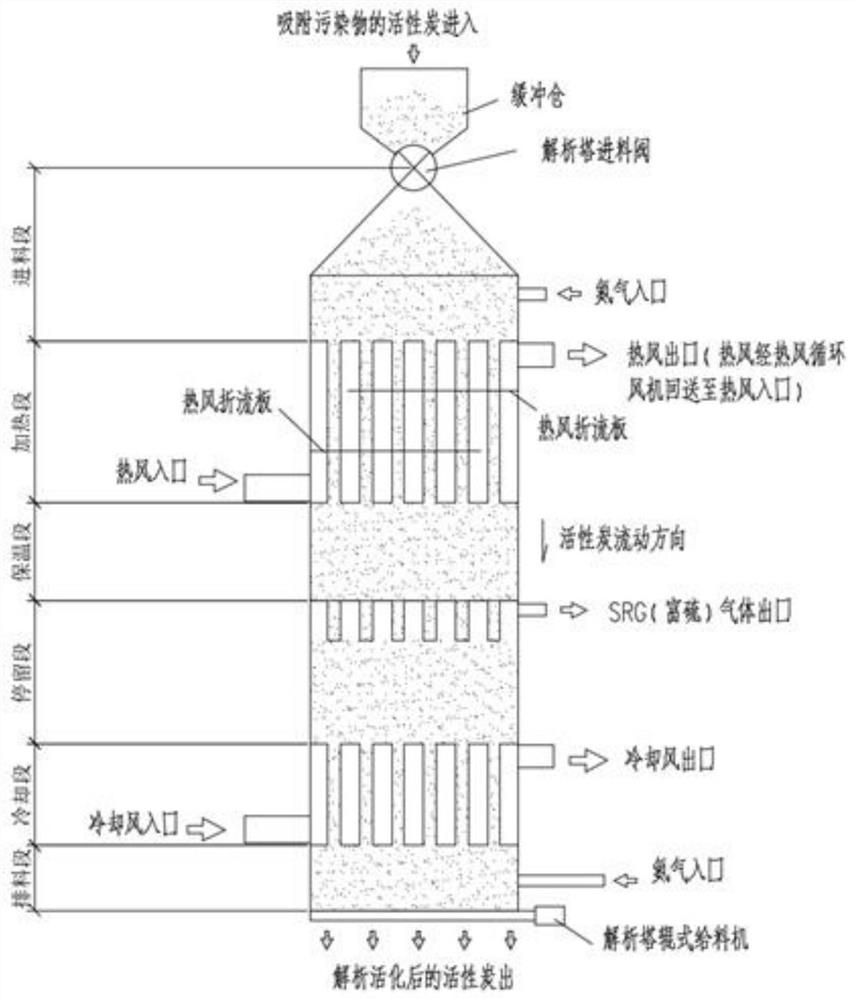

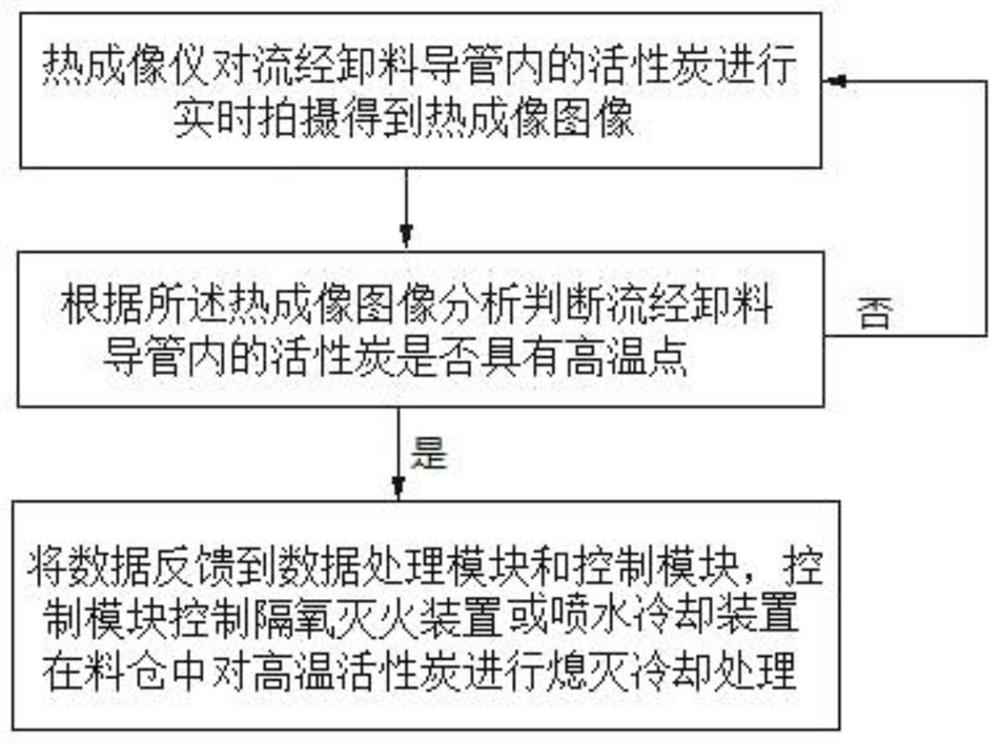

[0131] Such as Figure 4 , 5 , Shown in 10, a system for extinguishing and cooling treatment of high-temperature activated carbon in the discharge section after analysis, the system includes a discharge conduit 1, a discharge hopper 2, a hopper 3 and a conveyor 4. The discharge port of the conveyor 4 is connected with the feed port of the discharge conduit 1 . The discharge port of the discharge conduit 1 is connected with the feed port of the discharge hopper 2 . The discharge port of the discharge hopper 2 is connected with the feed port of the silo 3 . A thermal imager 5 is arranged on the discharge conduit 1 . The silo 3 is provided with an oxygen barrier fire extinguishing device 6 .

Embodiment 2

[0133] Such as Figure 12 Shown, repeat embodiment 1, just replace the oxygen barrier fire extinguishing device 6 on the described silo 3 with the spray cooling device 7.

Embodiment 3

[0135] Such as Figure 5 As shown, embodiment 2 is repeated, except that an observation port 101 is opened on the upper side wall of the discharge conduit 1 . A light shield 102 is provided on the observation port 101 . The thermal imager 5 is arranged on the top of the light shield 102 . The thermal imager 5 takes real-time pictures of the activated carbon material entering the discharge conduit 1 through the observation port 101 to obtain a thermal imaging image.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com