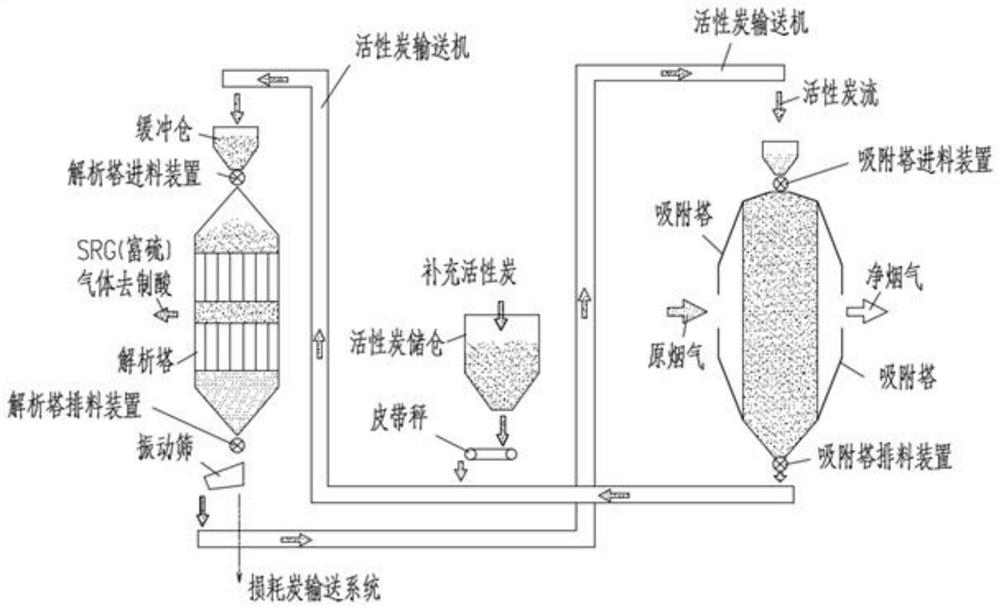

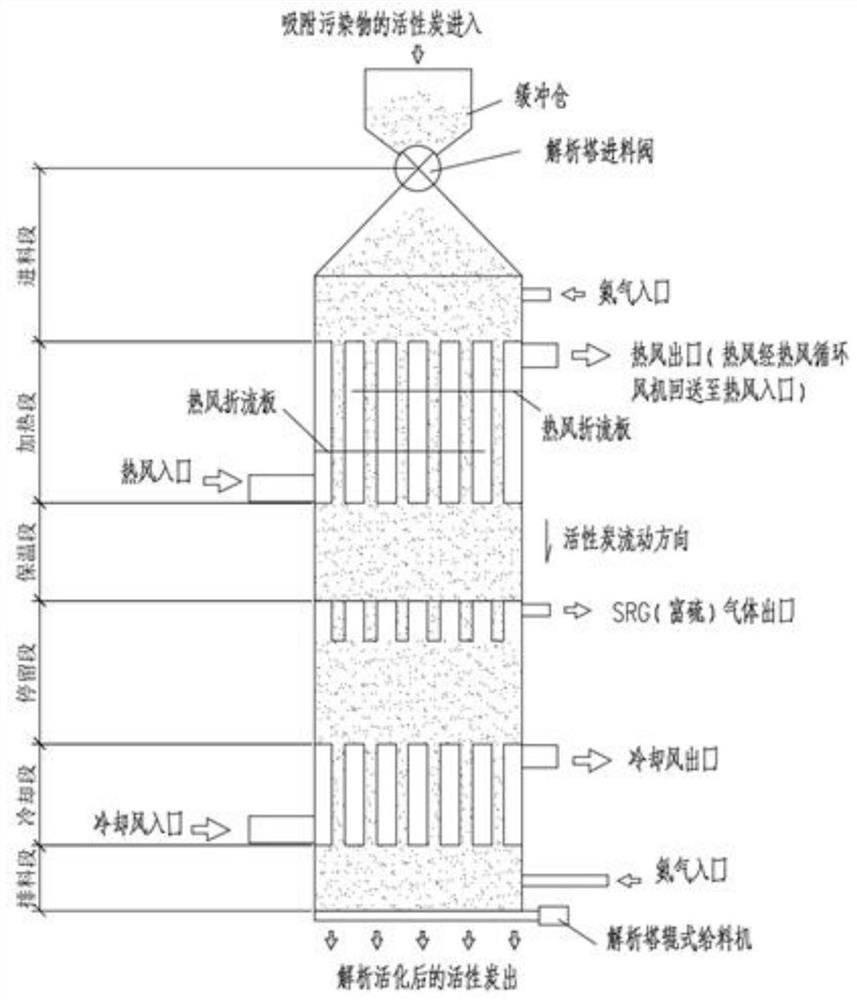

Method and system for high-temperature detection of activated carbon and cooling and extinguishing of spontaneous combustion activated carbon

An activated carbon, high temperature technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of difficult detection and disposal of high temperature activated carbon particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

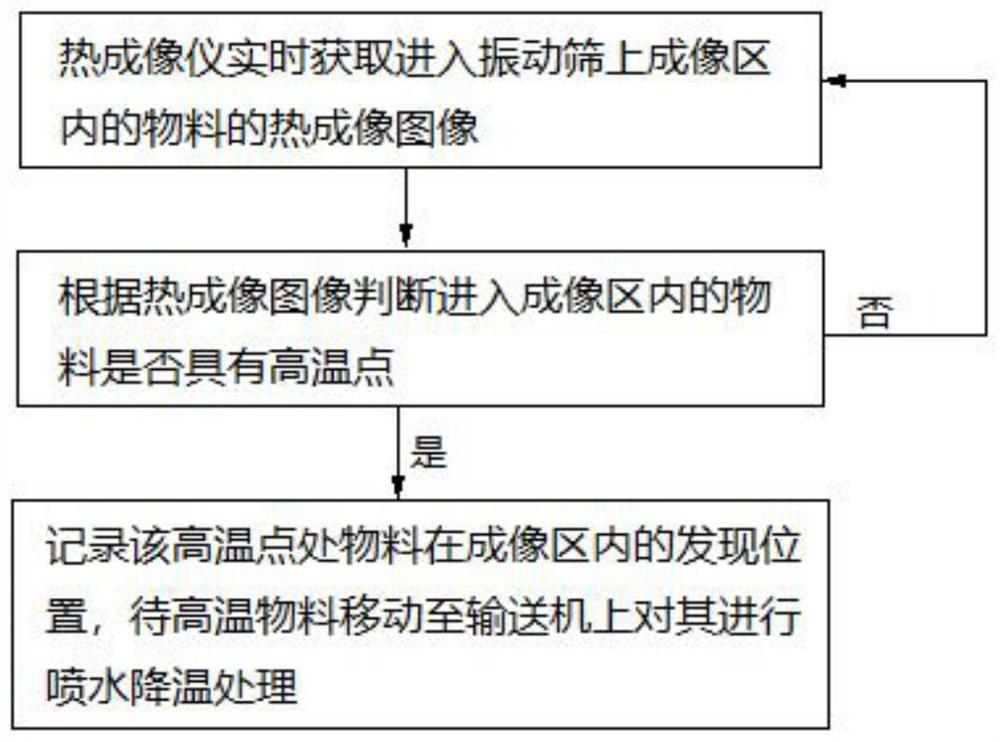

[0121] like Figure 9 As shown, a system for high-temperature detection of activated carbon and cooling and extinguishing of spontaneously ignited activated carbon, the system includes a thermal imager 1, a vibrating screen 2, a conveyor 5, and a cooling device for extinguishing spontaneously ignited activated carbon. The discharge port of the vibrating screen 2 is connected with the feed port of the conveyor 5 . The vibrating screen 2 is provided with a cover plate 201 . The thermal imager 1 is arranged above the cover plate 201 of the vibrating screen 2 . The conveyor includes a horizontal section and a vertical section, and the self-igniting activated carbon extinguishing cooling device is arranged above the horizontal section of the conveyor 5 . The vibrating screen 2 is provided with an imaging area 3 .

Embodiment 2

[0123] like Figure 12 and 13 As shown, embodiment 1 is repeated, except that the self-igniting activated carbon extinguishing cooling device is the cooling water spraying device 6 arranged above the horizontal section of the conveyor 5 . The conveyor 5 is a chain-bucket conveyor, and a plurality of chain buckets 501 are evenly arranged in the chain-bucket conveyor, and each chain bucket 501 opens upward. The cooling water spraying device 6 includes a cooling water main pipe 601 and a cooling water branch pipe 602 . Both the cooling water main pipe 601 and the cooling water branch pipe 602 are arranged directly above the horizontal section of the conveyor 5 . One end of the cooling water main pipe 601 is provided with a cooling water inlet, and the other end of the cooling water main pipe 601 is connected with a cooling water branch pipe 602 . The lower edge of the cooling water branch pipe 602 is provided with a spray hole 603 .

Embodiment 3

[0125]Embodiment 2 is repeated, except that the cooling water main pipe 601 is further provided with a cooling water valve 604 , and the cooling water valve 604 controls the opening and closing of the cooling water spraying device 6 . The cooling water branch pipe 602 is arranged parallel to the upper part of the chain bucket 501 and perpendicular to the length direction of the conveyor 5 . A plurality of spray holes 603 are opened on the cooling water branch pipe 602, and the plurality of spray holes 603 are evenly distributed. The length of the cooling water branch pipe 602 is equal to the width of the chain bucket 501 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com