High-temperature detection method and high-temperature detection system for activated carbon flue gas purification device

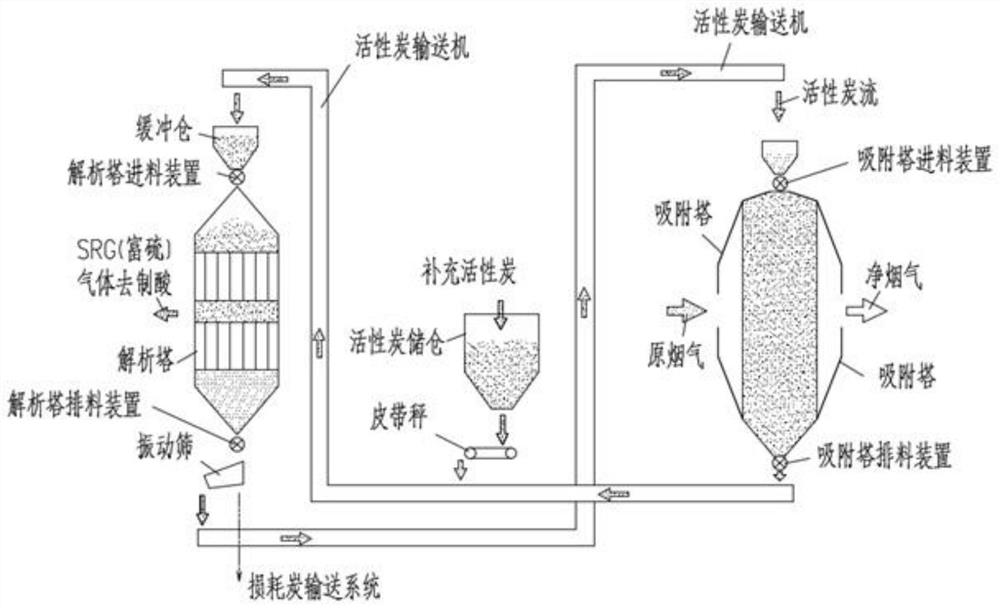

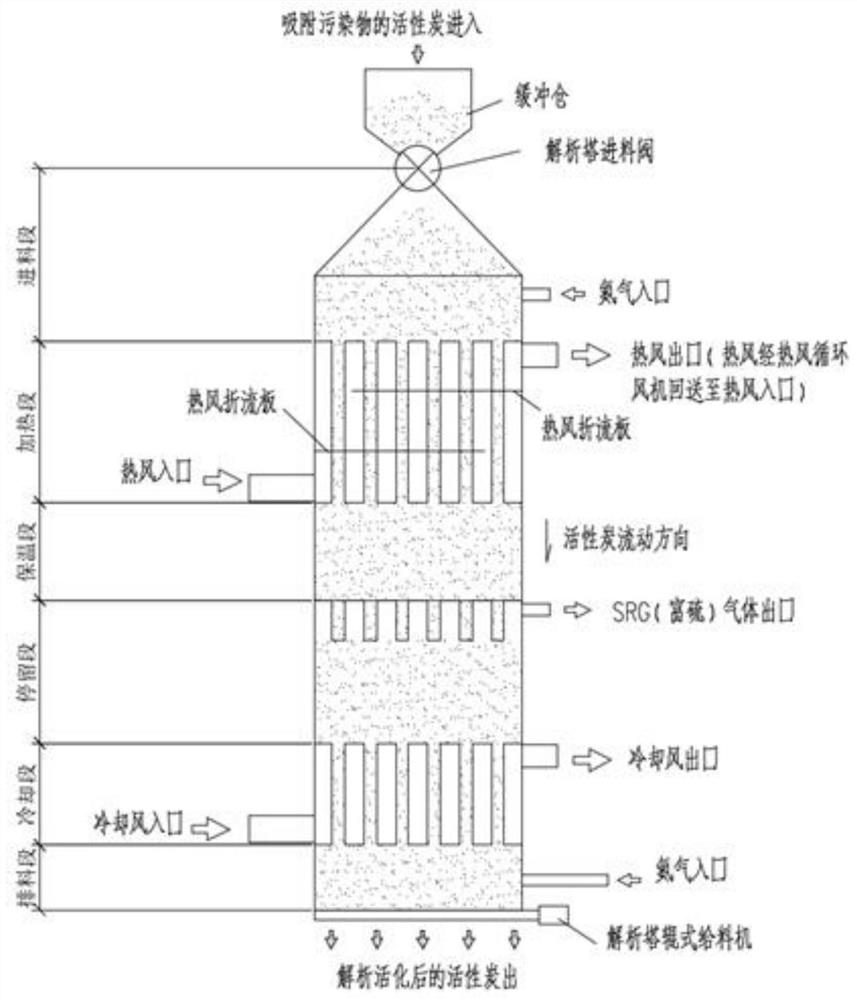

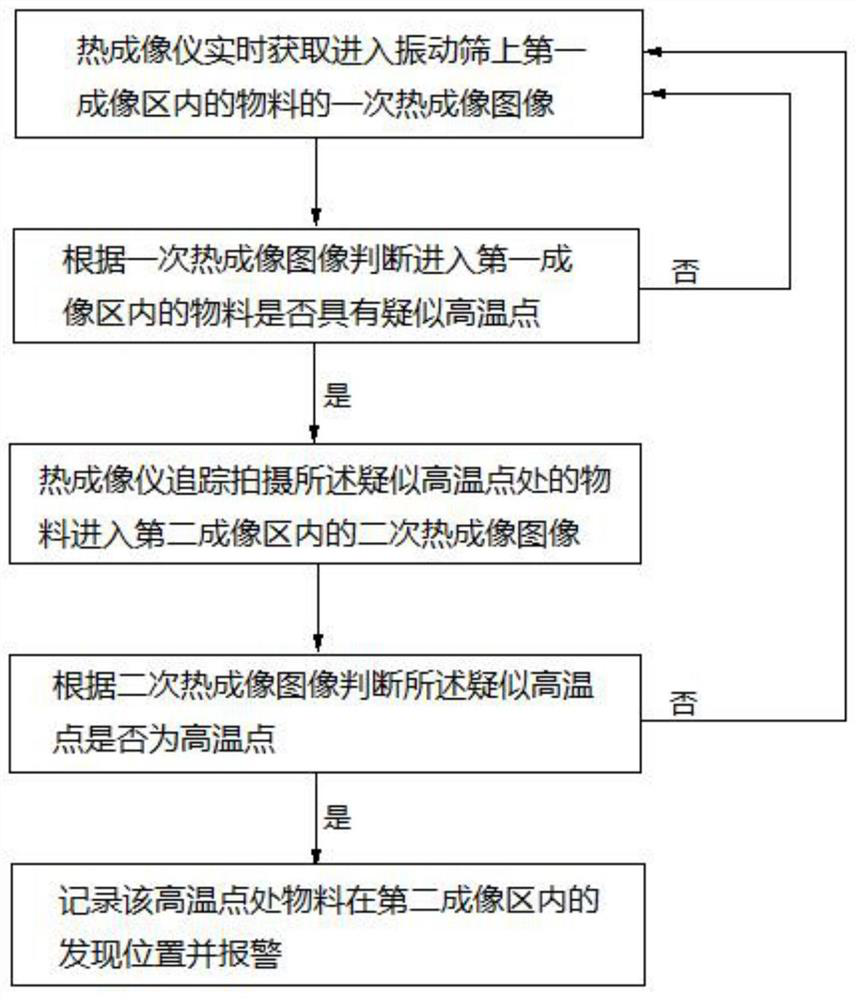

A flue gas purification and detection method technology, applied in the direction of radiation pyrometry, chemical instruments and methods, separation methods, etc., can solve the problems of inaccurate and incomplete detection of high-temperature activated carbon particles, so as to eliminate observation obstacles and improve safety performance, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0088]According to a second embodiment of the present invention, a high temperature detection system for activated carbon flue gas purification means is provided.

[0089]An active carbon smotting device high temperature detection system or a high temperature detection system for the active carbon flue gas purification apparatus for the method of the first embodiment, the system including thermal imaging instrument 1, vibrating screen 2, and observation device 4. A cover sheet 201 is provided on the vibrating screen 2. The thermal imager 1 is disposed above the vibrating screen 2 cover. The observation apparatus 4 is disposed at the upper portion of the vibrating screen 2 cover 201, and is located between the vibrating screen 2 cover 201 and the thermal imaging device 1. The vibrating screen 2 is provided with a first imaging region 301 and a second imaging region 302, and the first imaging region 301 is located upstream of the second imaging region 302. The thermal imaging device 1 su...

Embodiment 1

[0098]Such asFigure 4 with5As shown, a high temperature detection system of activated carbon flue gas purification means includes a thermal imaging device 1, a vibrating screen 2, and a viewing device 4. A cover sheet 201 is provided on the vibrating screen 2. The thermal imager 1 is disposed above the vibrating screen 2 cover. The observation apparatus 4 is disposed at the upper portion of the vibrating screen 2 cover 201, and is located between the vibrating screen 2 cover 201 and the thermal imaging device 1. The vibrating screen 2 is provided with a first imaging region 301 and a second imaging region 302, and the first imaging region 301 is located upstream of the second imaging region 302. The thermal imaging device 1 is performed on the vertical plane in a vertical plane around the viewing device 4, and the thermal imager 1 is performed by the observation device 4 on the first imaging region 301 and the second imaging region 302 in the vibrating screen 2. Real-time shooting, ...

Embodiment 2

[0100]Such asFigure 6 As shown, the Example 1 is repeated, except that the observation device 4 is observed in the thermal imaging. The thermal imager observer includes a side wall cover body 401, a top viewing hole 402, and a bottom viewing aperture 403. Wherein, the area formed by the top edge edge of the side wall cover 401 is the top viewing hole 402. The area enclosed by the bottom end edge of the side wall cover 401 is the bottom viewing hole 403. The thermal imaging device 1 performs real-time shooting of the first imaging region 301 and the bottom viewing region 301 and the bottom viewing hole 403, and then acquires a thermal imaging image and a secondary thermal imaging. image.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com