Buzzer test separator

A technology for testing sorting machines and buzzers, which is applied in sorting and other directions, can solve the problems of high misjudgment rate and the inability of testing equipment to improve the testing speed, etc., and achieve the effects of high testing accuracy, simple structure, and accurate nesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

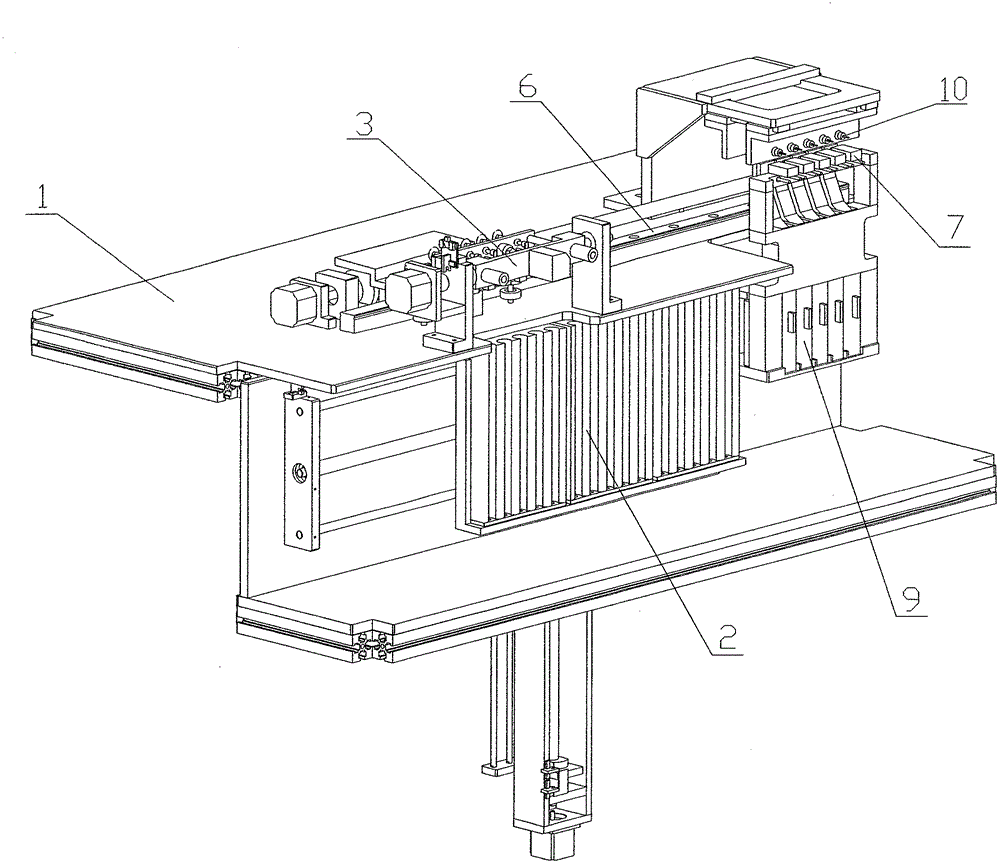

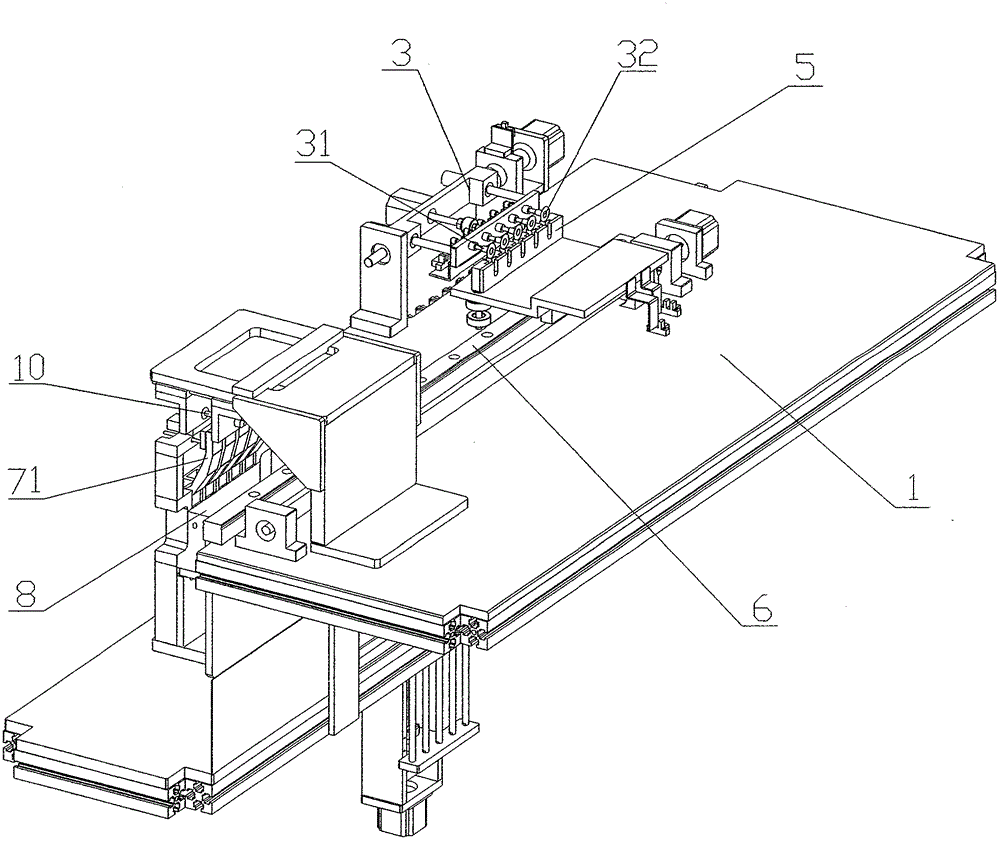

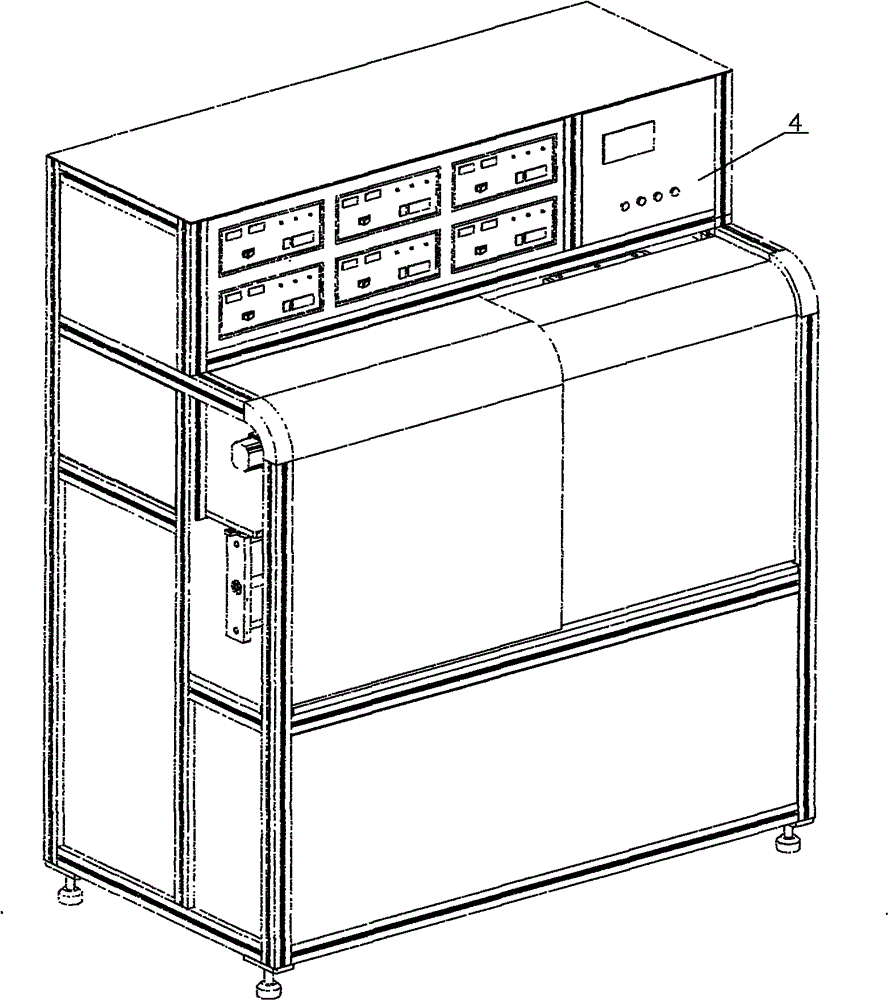

[0045] figure 1 , Figure 4 , Figure 5 , Figure 6 Schematic diagram of the appearance, structure and front view of the buzzer test sorter, including the frame, and three sets of feeding boxes installed on the frame, rotating feeding arm, U-shaped positioning groove, guide rail, test needle, waste bin, Qualified product warehouse, discharge hopper, console.

[0046]The three groups of feeding boxes 2 are hollow cylindrical structures with gaps. There are fifteen in total, five in each group. They are switched by stepping motors. One group of feeding boxes is in working state, and the other two groups of feeding boxes are in loading State; there is a ejector rod at the bottom of the feeding box, and the stepping motor controls the lifting of the ejector rod.

[0047] Five suction heads 31 are set on the rotating feeding arm 3, see Figure 5 , Figure 7 , Figure 9 , The suction head is guided by linear bearings and spring buffer structure. The rotating feeding arm can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com