Semi-submersible LNG replacement shipment and marine LNG shipment application method

An application method, semi-submersible technology, applied in the direction of hull, ship construction, and cargo, etc., can solve the problems of large investment, long approval period, and difficult site selection, and achieve the effect of low cost, easy operation, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

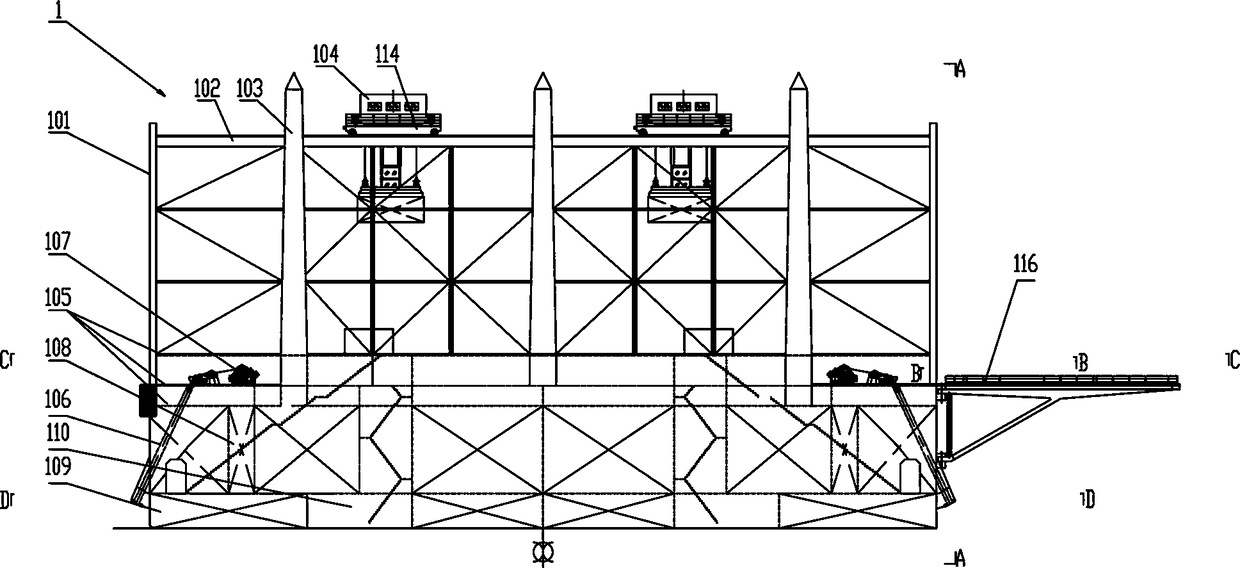

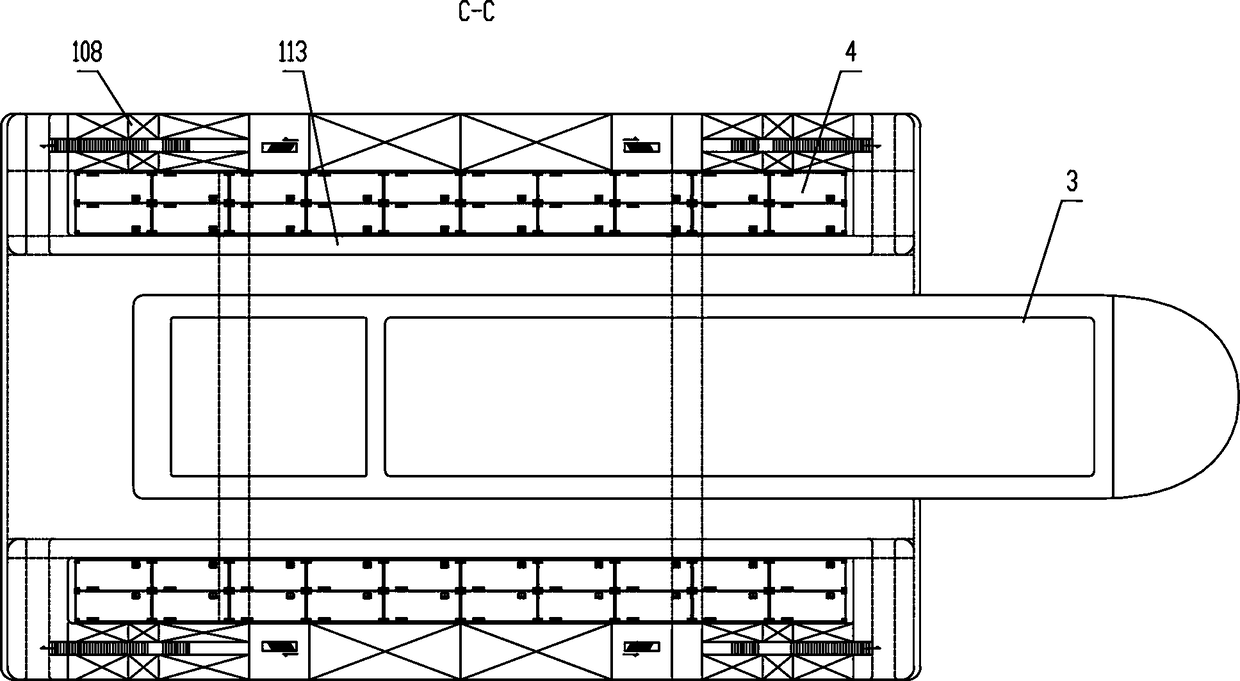

[0040] Such as Figure 2~6 Among them, a semi-submersible LNG reloading ship, the cross-section of the hull is a frame structure, the middle of the frame structure forms a space for the ship to enter, and a lifting device is provided on the top of the hull. During use, make the hull part of the frame structure be located below the water level line 7, the ship sails into the space of the frame structure, and utilize the lifting device to load and unload the LNG tank container 4. In this way, a stable semi-permanent and stable platform on water can be obtained, which can conveniently supply fuel for LNG fuel ships, and LNG tank container carriers can also easily load and unload LNG tank containers.

[0041] The preferred solution is as Figure 4 , 5Among them, at the bottom of the hull, a plurality of ballast water tanks 109 form the bottom of the frame structure, the top of the ballast water tanks 109 is the buoyancy tank deck 115, and a pump room 110 is also arranged near th...

Embodiment 2

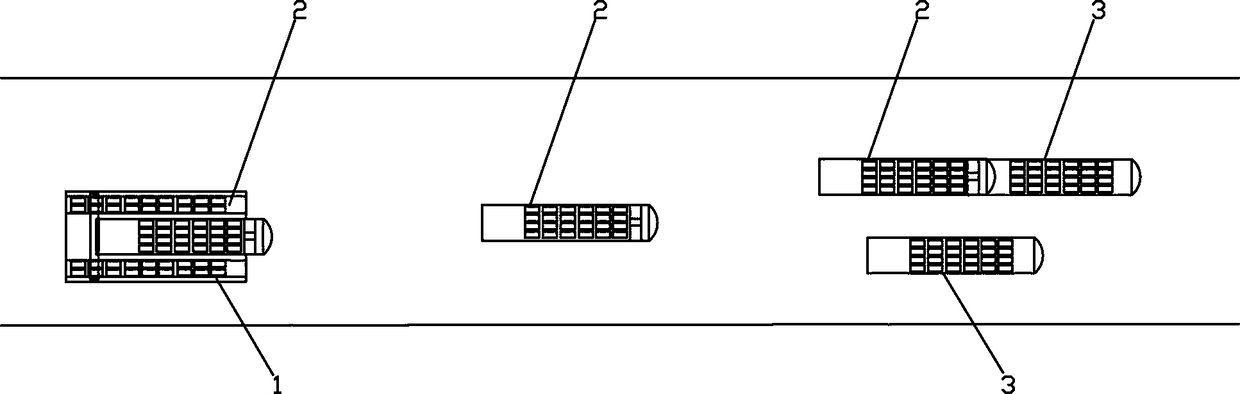

[0052] Such as Figure 1~12 Among them, a marine LNG loading application method adopting the above-mentioned semi-submersible LNG reloading ship, a plurality of semi-submersible LNG reloading ships 1 are arranged along the river, so that the pontoon deck 115 of the semi-submersible LNG reloading ship 1 Below the water level line 7, the ship or container ship that adopts the LNG tank container 4 as fuel enters the frame-shaped structural space of the semi-submersible LNG transshipment ship 1, and utilizes the lift on the top of the semi-submersible LNG transshipment ship 1. Heavy equipment, replacing the LNG tank container 4 for the LNG fuel ship, or loading and unloading the LNG tank container 4 from the container ship. This solution overcomes the difficulties in the approval of shore facilities and the inconvenience of berthing ships on the water, especially the inconvenience of berthing large container ships with deep draft.

[0053] The preferred solution is as Figure 7~...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com