A kind of conveying and sorting device for steel bar connecting sleeve

A steel connecting sleeve and connecting sleeve technology, which is applied in the field of directional arrangement equipment for connecting sleeves, can solve the problems of low production efficiency, high labor intensity, and large number of workers, and achieve the effects of improved mechanization and automation, reliable operation, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

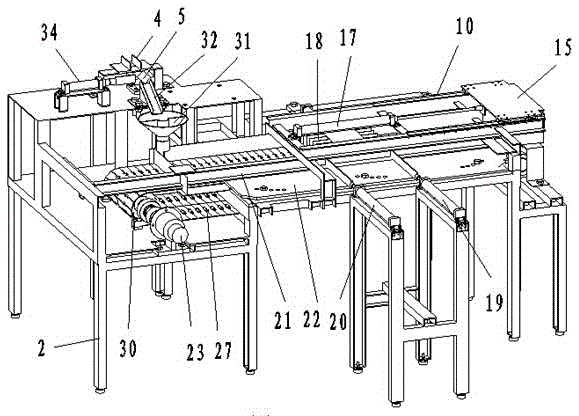

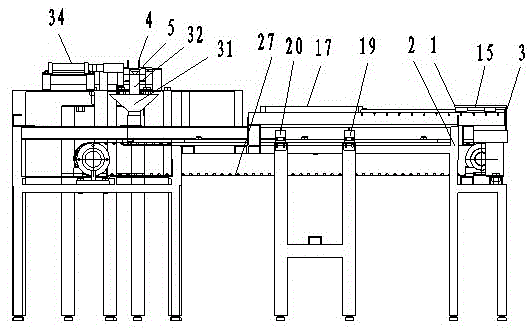

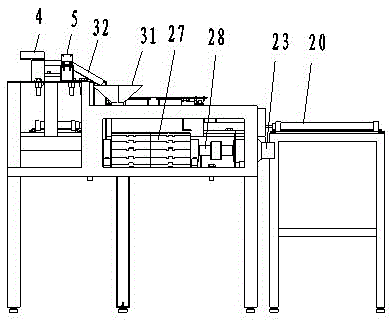

[0018] The invention is composed of a connecting sleeve printing feeding and conveying mechanism, a connecting sleeve conveying direction changing mechanism, a plate chain conveying mechanism, an array arrangement mechanism, an array sleeve pushing mechanism, and an adjustment mechanism.

[0019] As shown in the figure, the printing feeding and conveying mechanism of the connecting sleeve is composed of a printing stopper cylinder 34, a slider baffle 33, a transition plate 4, a V-shaped groove block 5, and a printer fixing bracket 6. The transition plate 4 is connected to the V-groove block 5, the front end of the printing stopper cylinder 34 is connected to the slider baffle 33, and the slider baffle 33 is opposite to the back end of the V-groove block 5. The printer fixing bracket 6 is installed in the V-groove On the side of block 5, install the printer on the printer fixing bracket 6.

[0020] In operation, the connecting sleeve automatically grabs the directional conveying mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com