Rocker arm welding gun with secondary switch-on function

A secondary opening and welding torch technology, which is applied in the direction of manufacturing tools, welding equipment, resistance welding equipment, etc., can solve the problems of high labor intensity, low effective efficiency, easy wear or damage of welding electrode heads, etc., and achieve a high degree of mechanization and automation , low cost, good welding proximity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

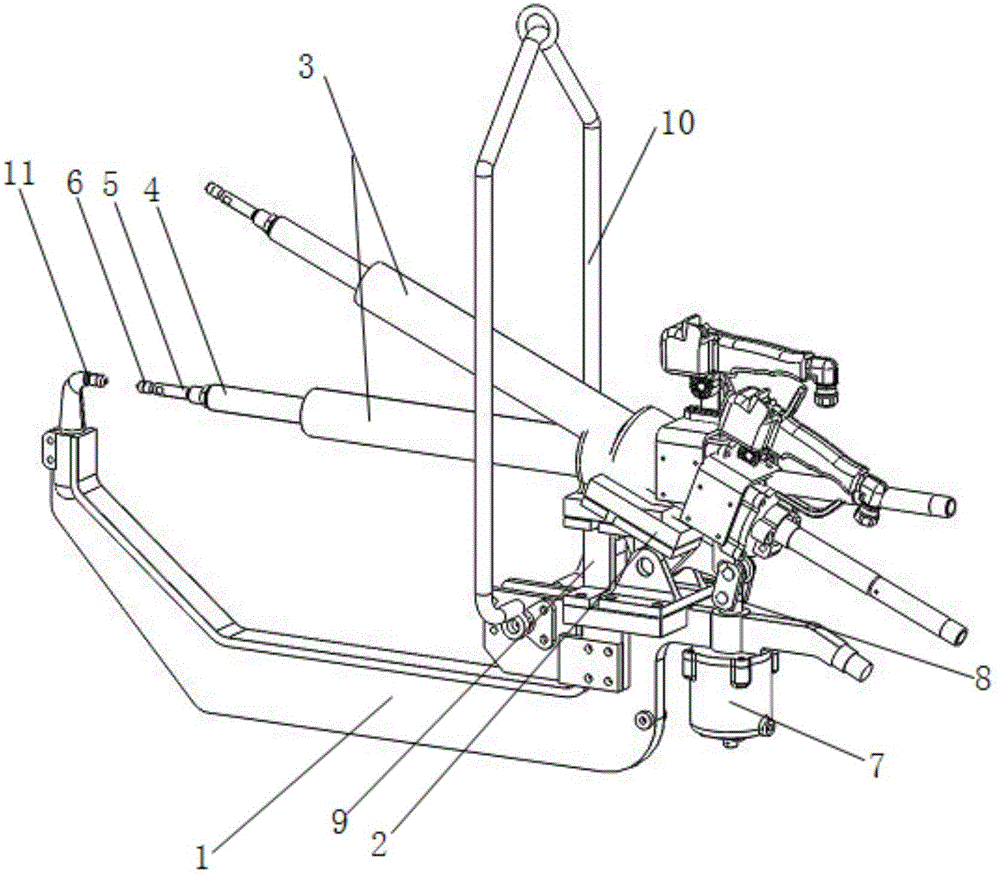

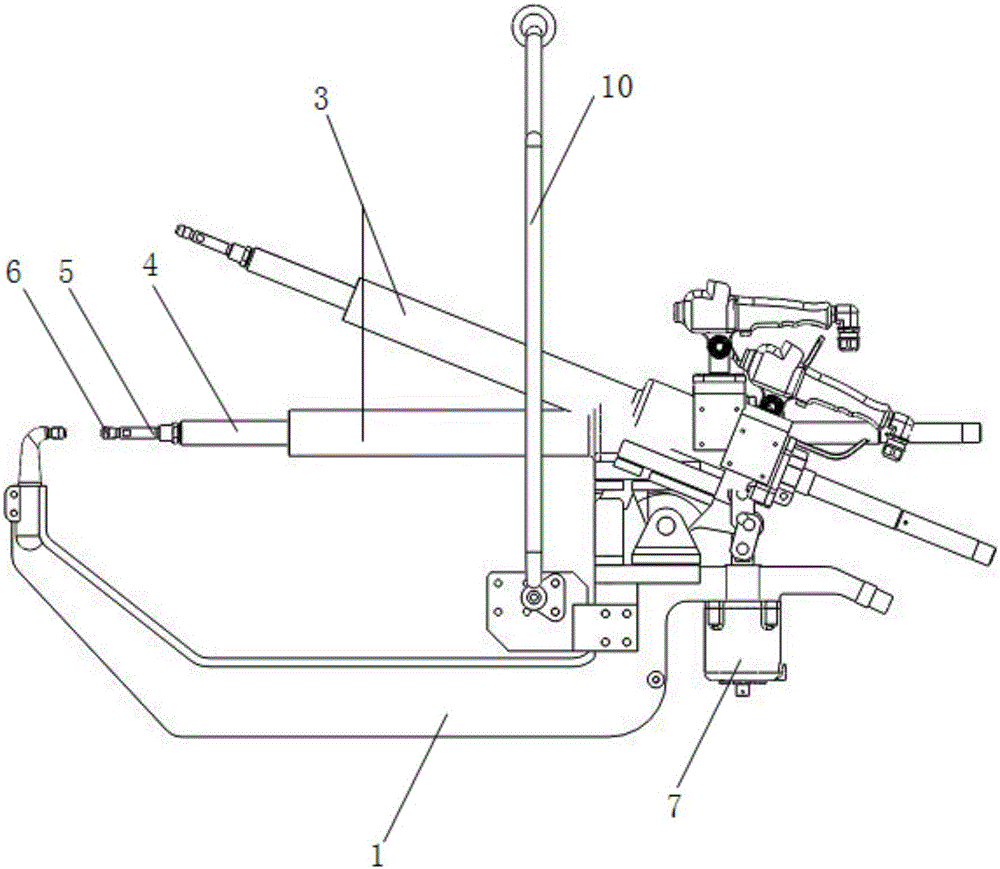

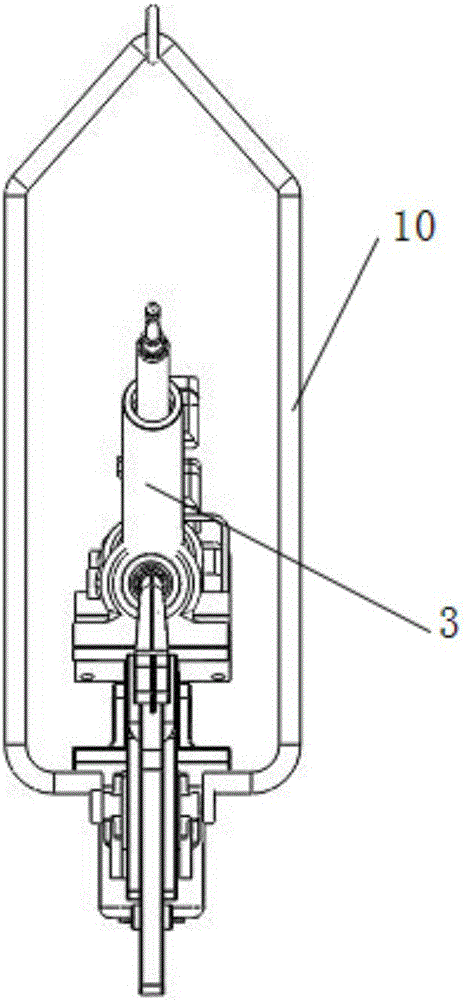

[0016] See attached Figure 1-5 As shown, a rocker arm welding torch with secondary opening includes a rocker arm base 1 and a welding torch device and an exchange device arranged on the rocker arm base 1. The welding torch device includes a mounting seat 2, a pressurized cylinder 3. Electrode arm 4, electrode head 1 5 and electrode cap 6. The pressurized cylinders 3 are two and installed on the mounting seat 2 at an angle of 30 degrees. The mounting seat 2 and the The rocker arm base 1 is movably connected, the electrode arm 4 is installed on the pressurized cylinder 3, the electrode head one 5 is installed on the electrode arm 4, and the electrode cap 6 is installed on the On the electrode head one 5; the exchange device includes a cylinder 7, a moving column 8 and a fixed seat 9, the cylinder 7 is connected with the moving column 8, and the moving column 8 is connected with the The mounting seat 2 is connected, and the fixed seat 9 and the cylinder 7 are fixed on the rocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com