Patents

Literature

56results about How to "High degree of mechanization and automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

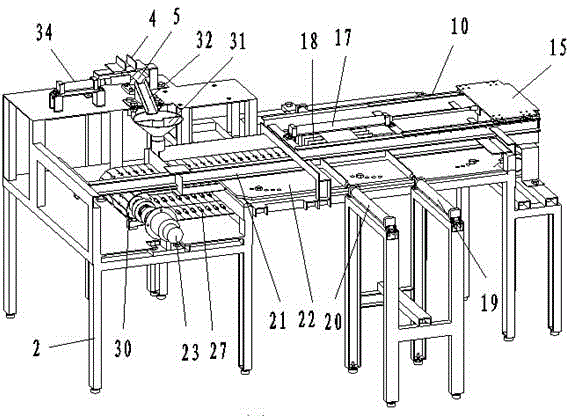

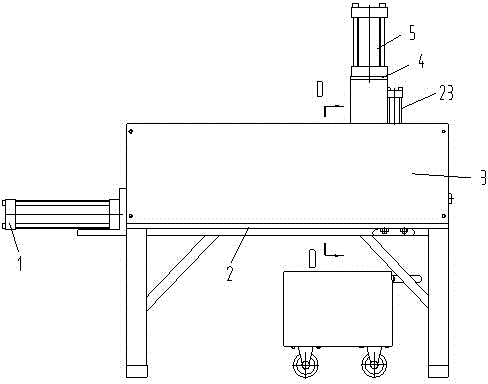

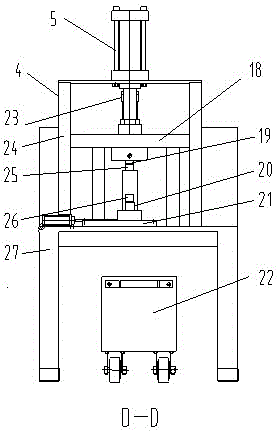

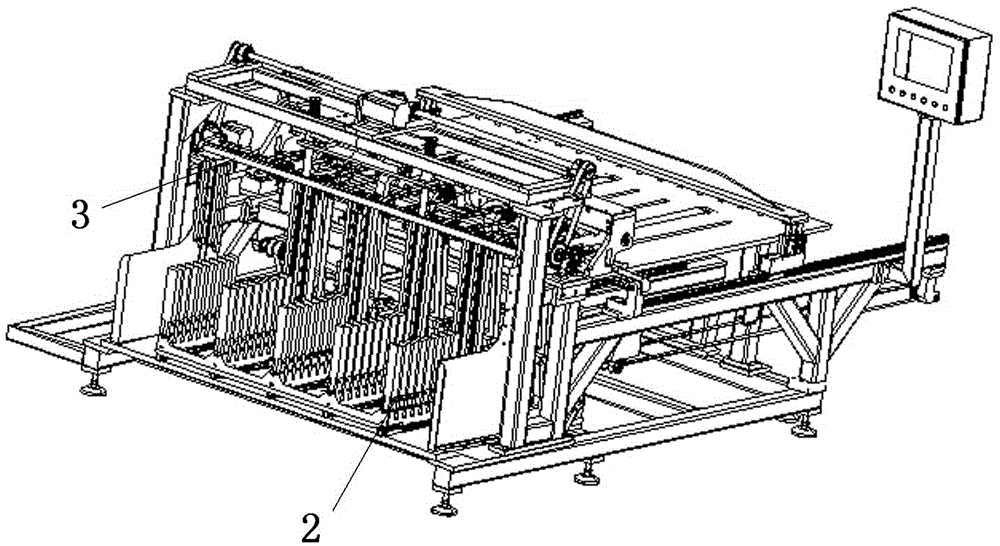

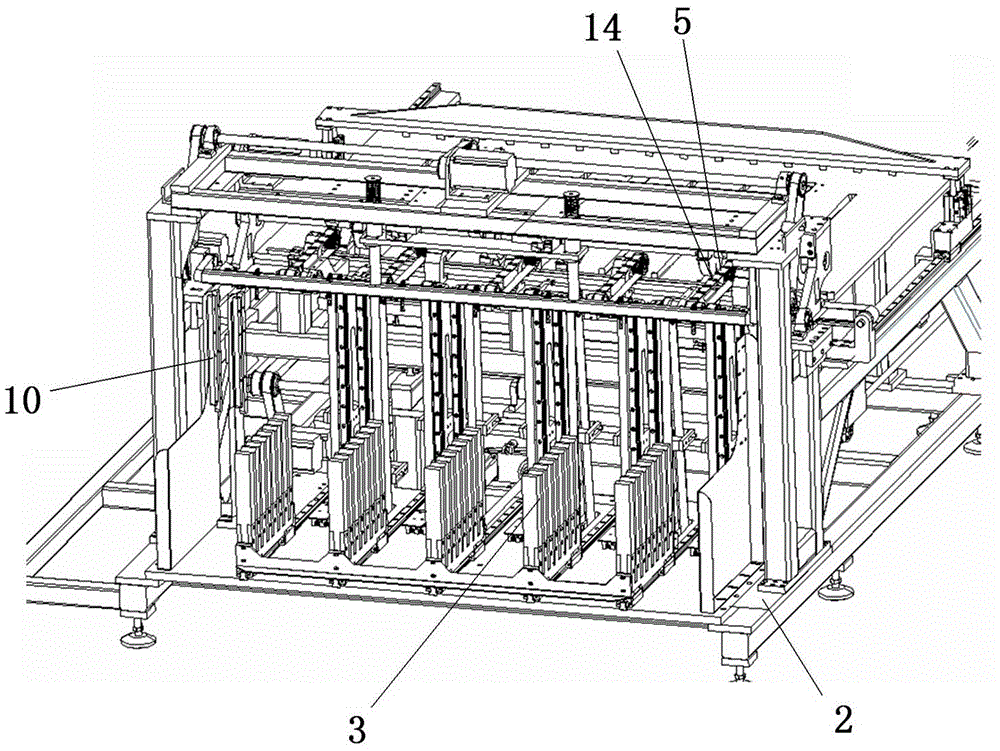

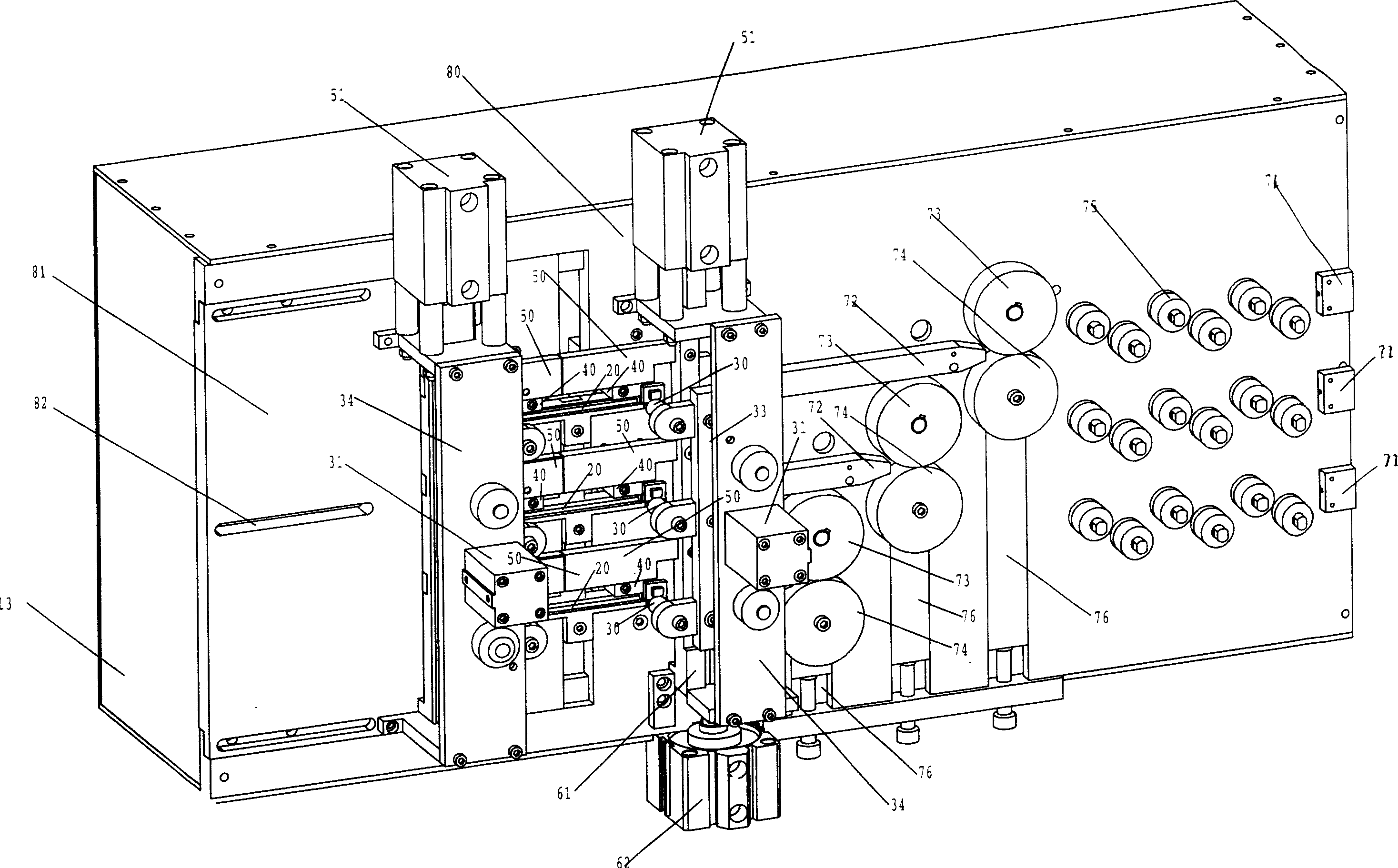

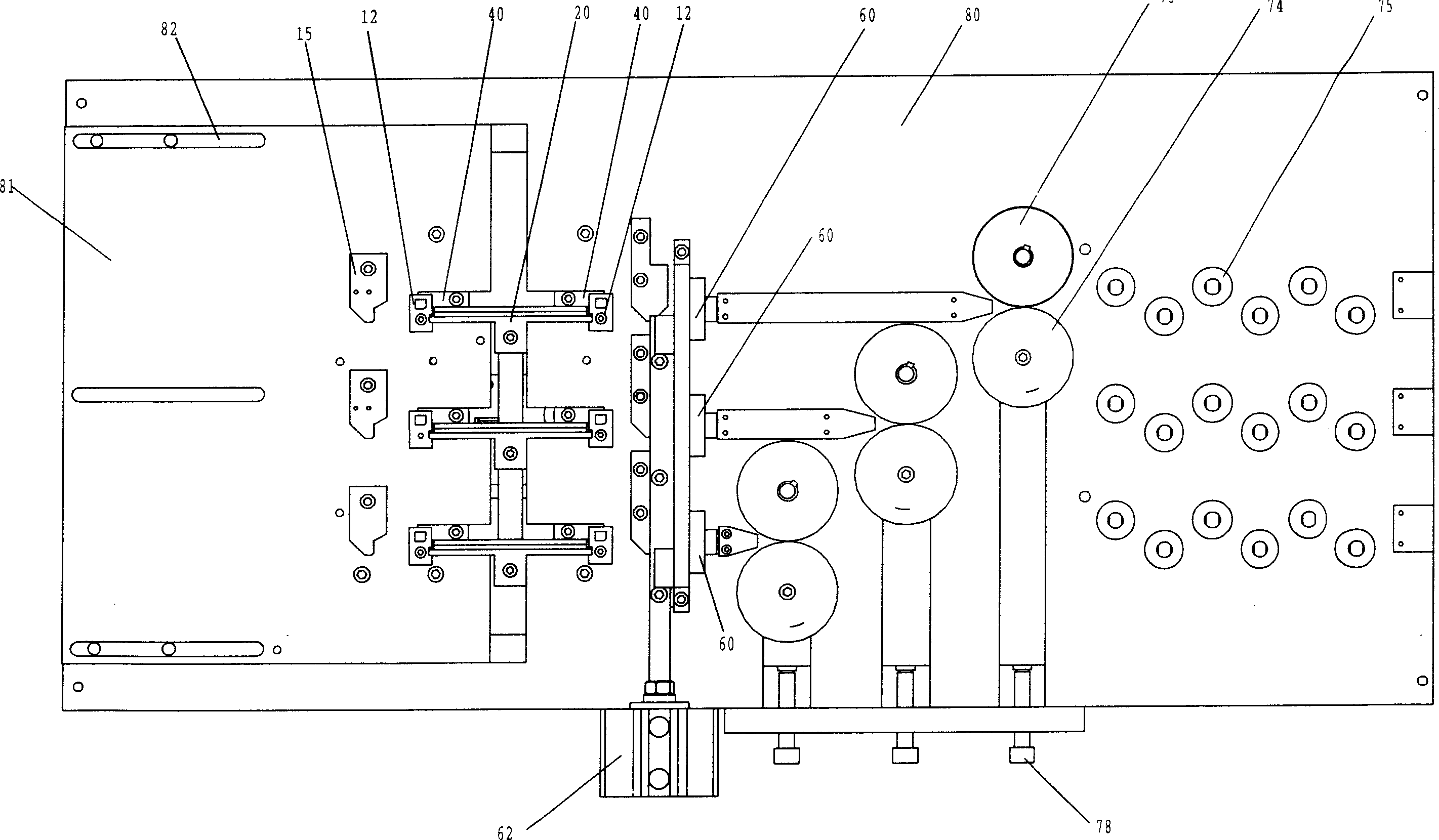

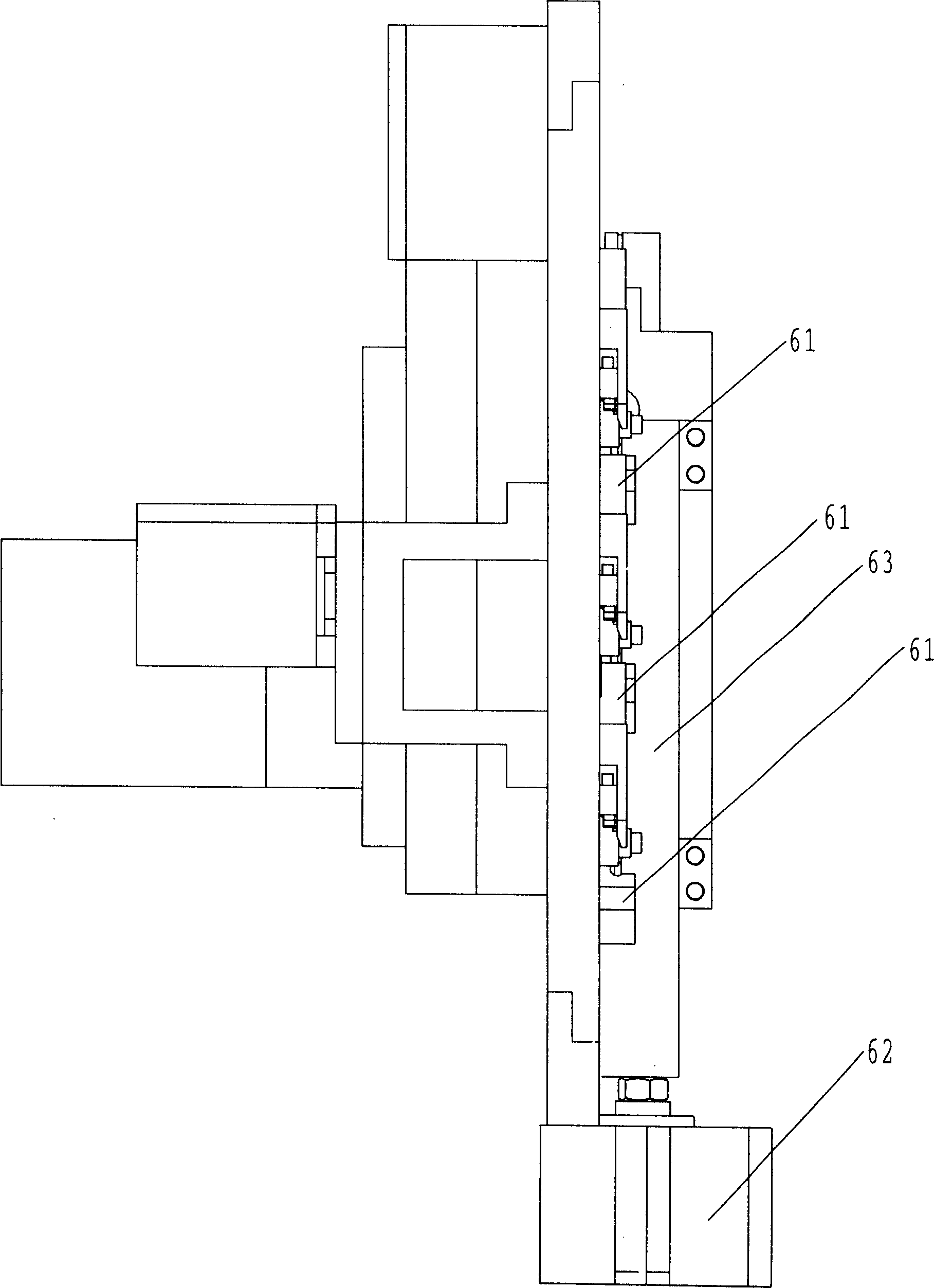

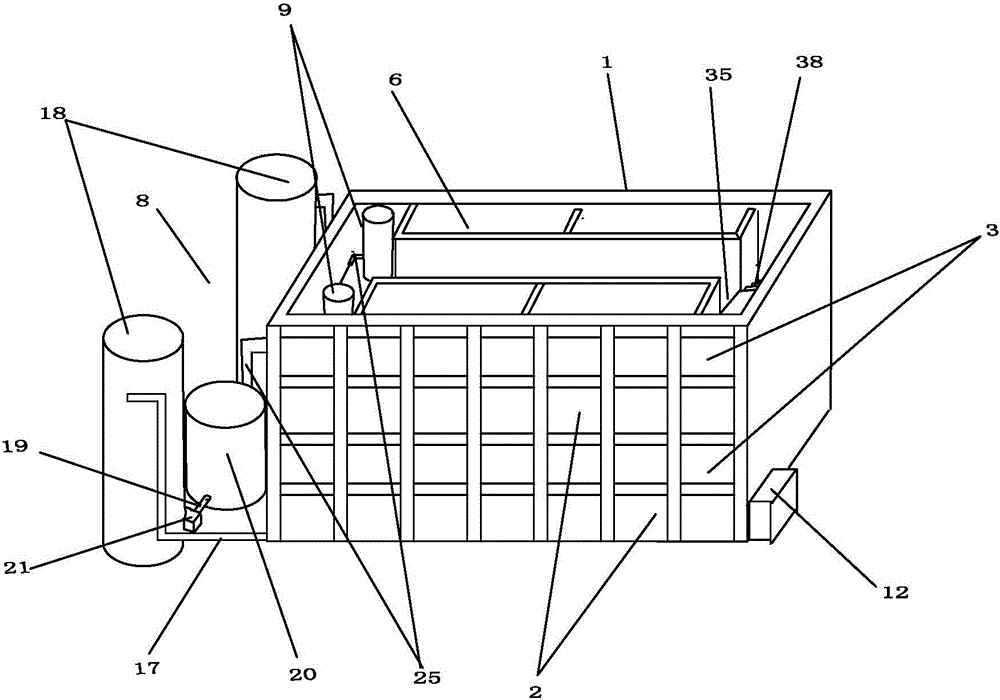

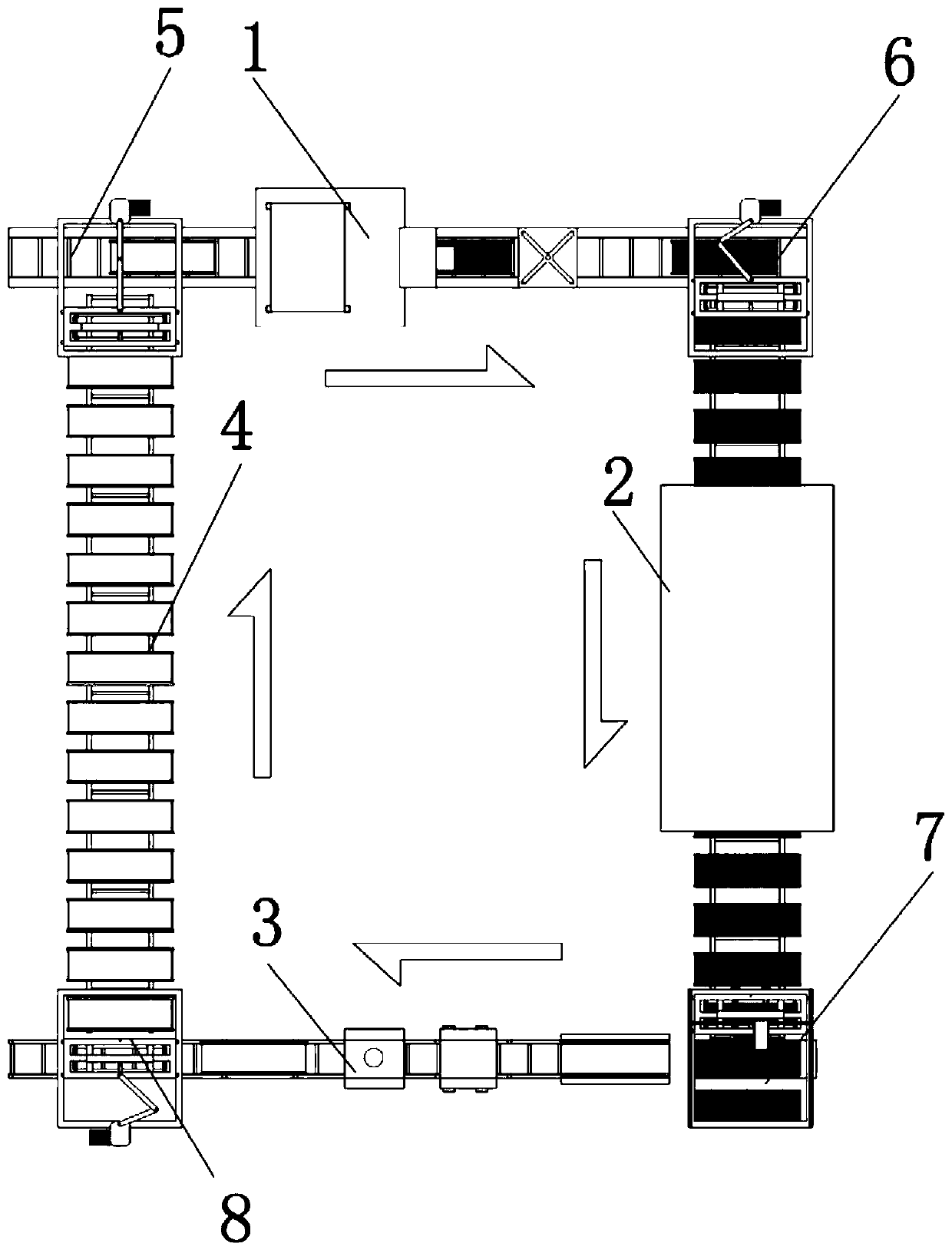

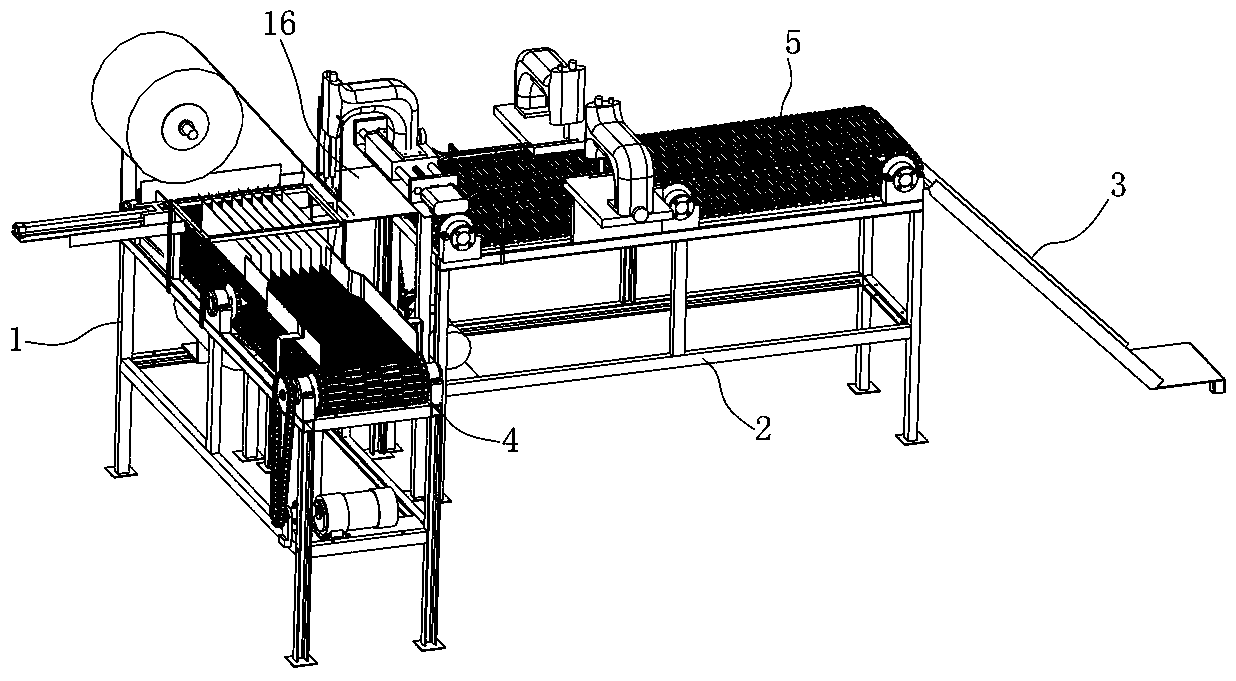

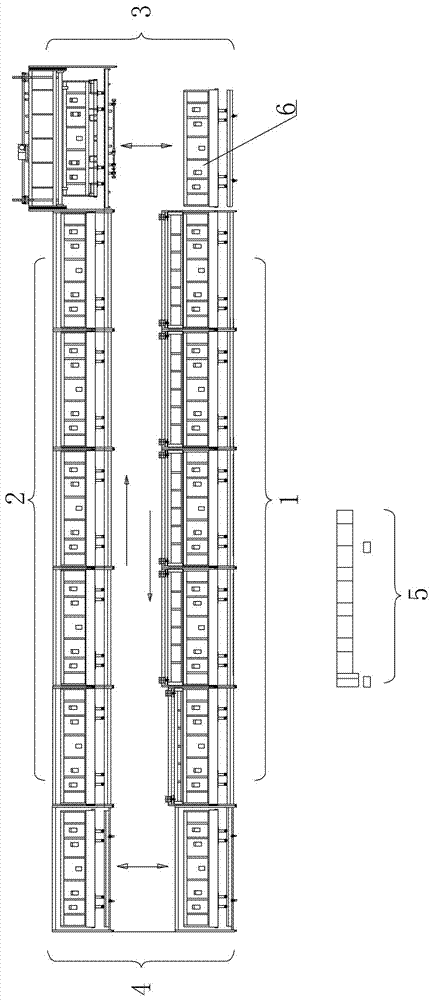

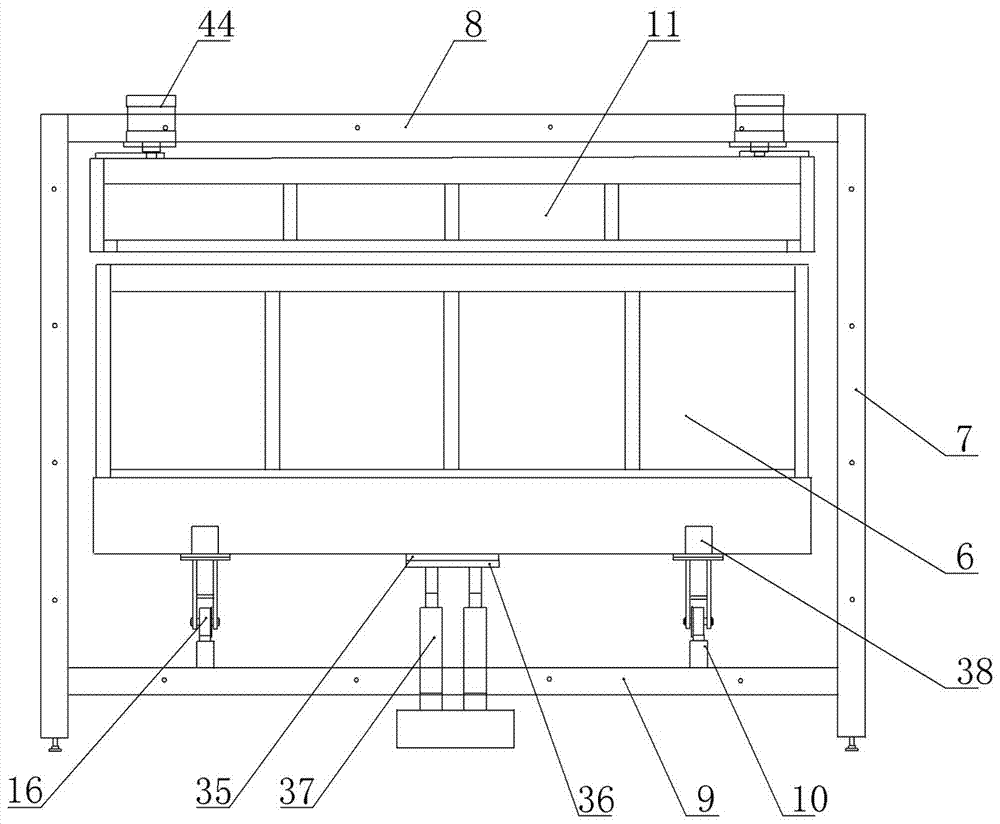

Rebar connecting sleeve conveying and arranging device

ActiveCN104097803AHigh degree of mechanization and automationReasonable layoutPackagingEngineeringWorkstation

The invention belongs to the technical field of rebar connecting sleeve packaging equipment and discloses a rebar connecting sleeve conveying and arranging device which is used for directionally arranging connecting sleeves. The technical scheme includes that a printing, feeding and conveying mechanism can print and convey the connecting sleeves individually, a connecting sleeve conveying and turning mechanism changes the connecting sleeves from horizontal direction to vertical direction and conveys the same onto chain plates, a chain plate conveying mechanism realizes material transmission in the process of array arrangement of the connecting sleeves, an array arranging mechanism performs array rule sequencing on the connecting sleeves on the chain plates, an array sleeve pushing mechanism conveys the connecting sleeves which are arranged well to a next workstation, and an adjusting mechanism can perform array adjusting of the connecting sleeves. The rebar connecting sleeve conveying and arranging device fills a gap in automatic packager arranging equipment for the connecting sleeves, is reasonable in layout, perfect in connection, accurate in discharging and reliable in running, and is suitable for being used as an arranging device of an automatic connecting sleeve packager, and mechanized and automated degree of the automatic connecting sleeve packager is increased greatly.

Owner:HEBEI YIDA REINFORCING BAR CONNECTING TECH

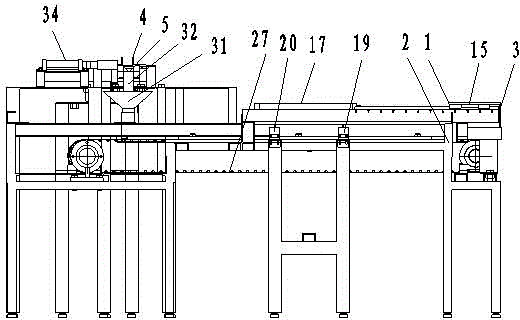

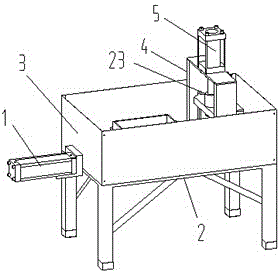

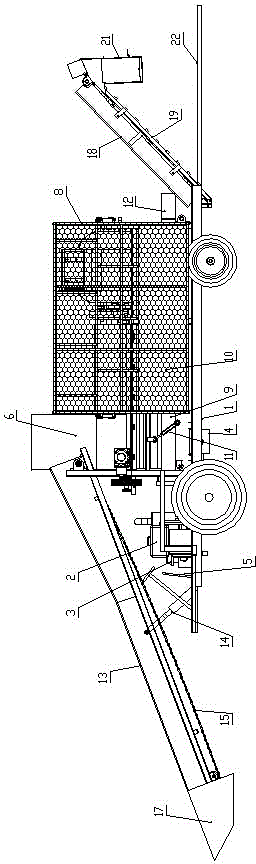

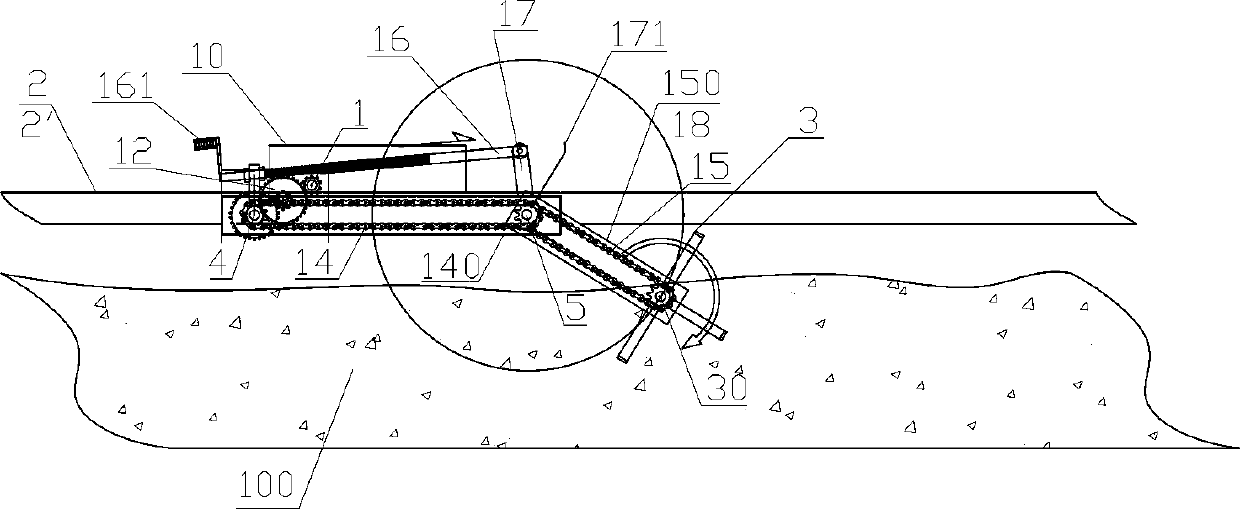

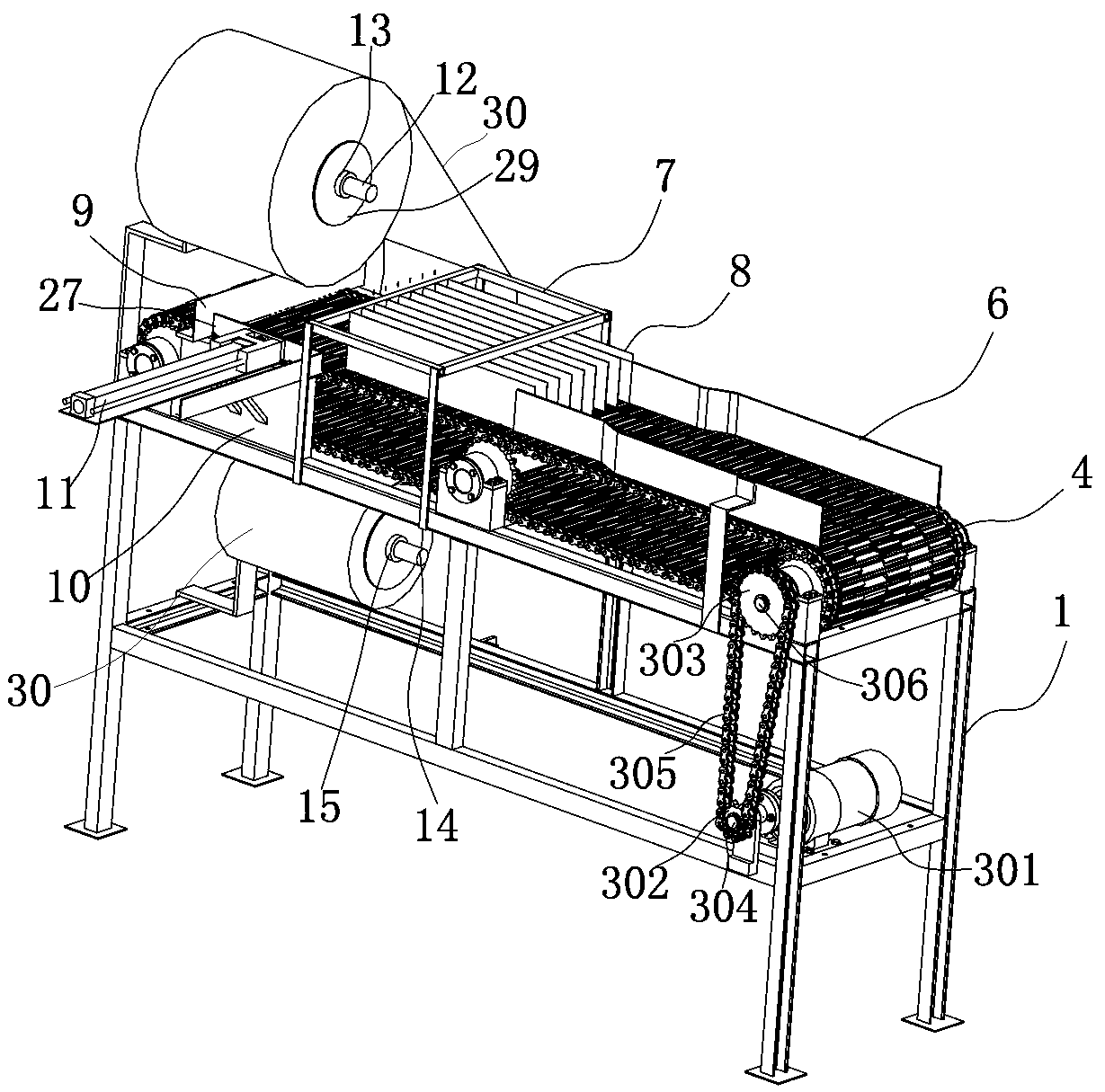

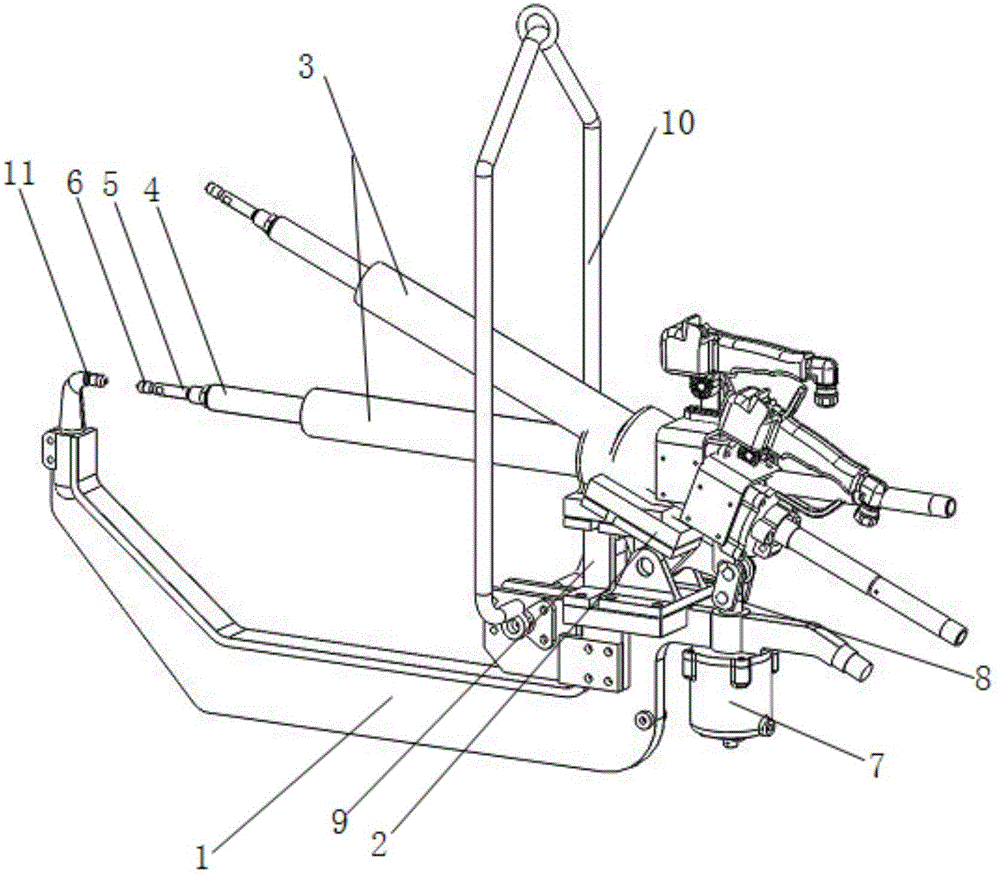

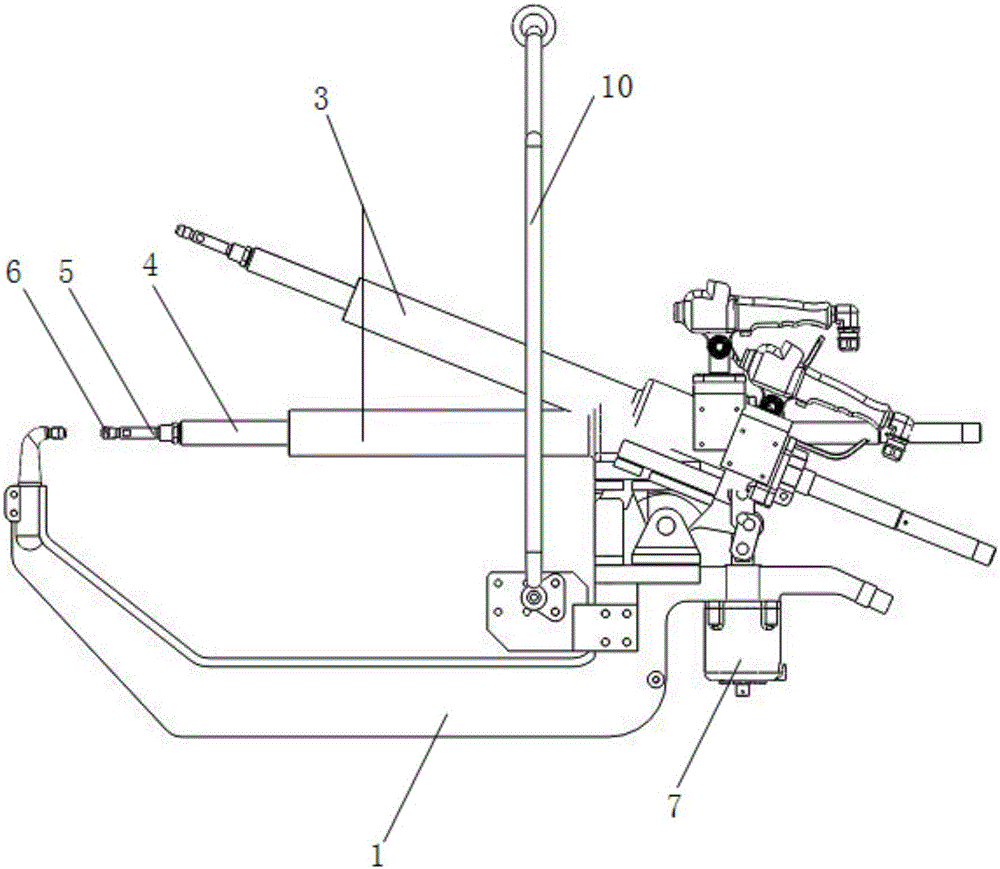

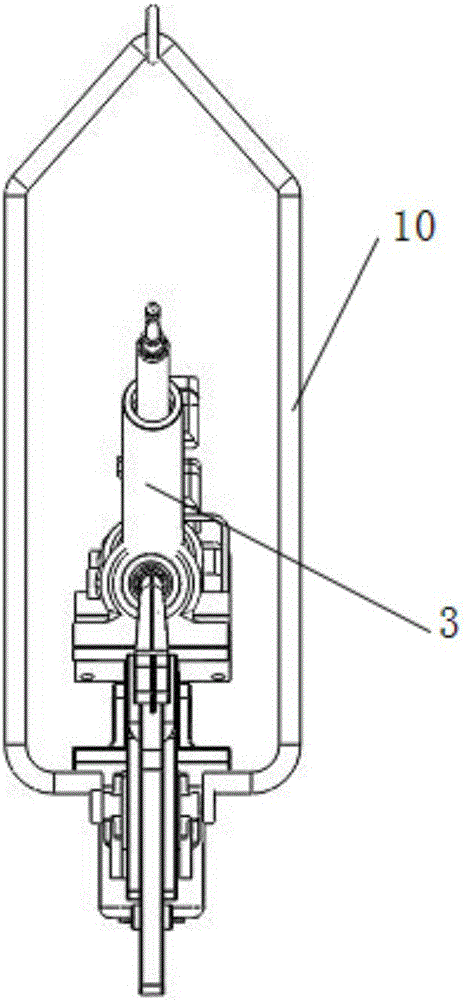

Handgrip releasing straightening device for recycling waste steel wire rope

InactiveCN104148362AReasonable layoutHigh degree of mechanization and automationSolid waste disposalRope making machinesFixed lengthAutomation

The invention relates to a handgrip releasing straightening device for recycling a waste steel wire rope and belongs to the technical field of equipment for recycling the waste steel wire rope and the handgrip releasing straightening device is used for performing handgrip releasing straightening on the waste steel wire rope. According to the handgrip releasing straightening device, the steel wire rope is held by utilizing a feeding clamping mechanism, the head of the steel wire rope is clamped at a feed hole in the front end of the clamping mechanism, an actuating cylinder of a traction mechanism is retracted, the steel wire rope is continuously pulled out and straightened, simultaneously, an elastic clamping head of the clamping mechanism is driven to rotate by a straight gear and a rack of the traction mechanism by virtue of a pair of conical gears, so as to complete handgrip releasing movement, and the steel wire rope is cut off by a movable cutter blade and a sliding cutter platform of a fixed-length cutting mechanism and then falls into a blanking recycling device. The proper automation equipment for recycling the waste steel wire rope has the advantages of reasonable layout, perfect connection, accuracy in wire division, reliability in operation and the like. The handgrip releasing straightening device is suitable for being used as recycling equipment of the waste steel wire rope, so that the mechanical automation degree in recycling the waste steel wire rope is greatly increased.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

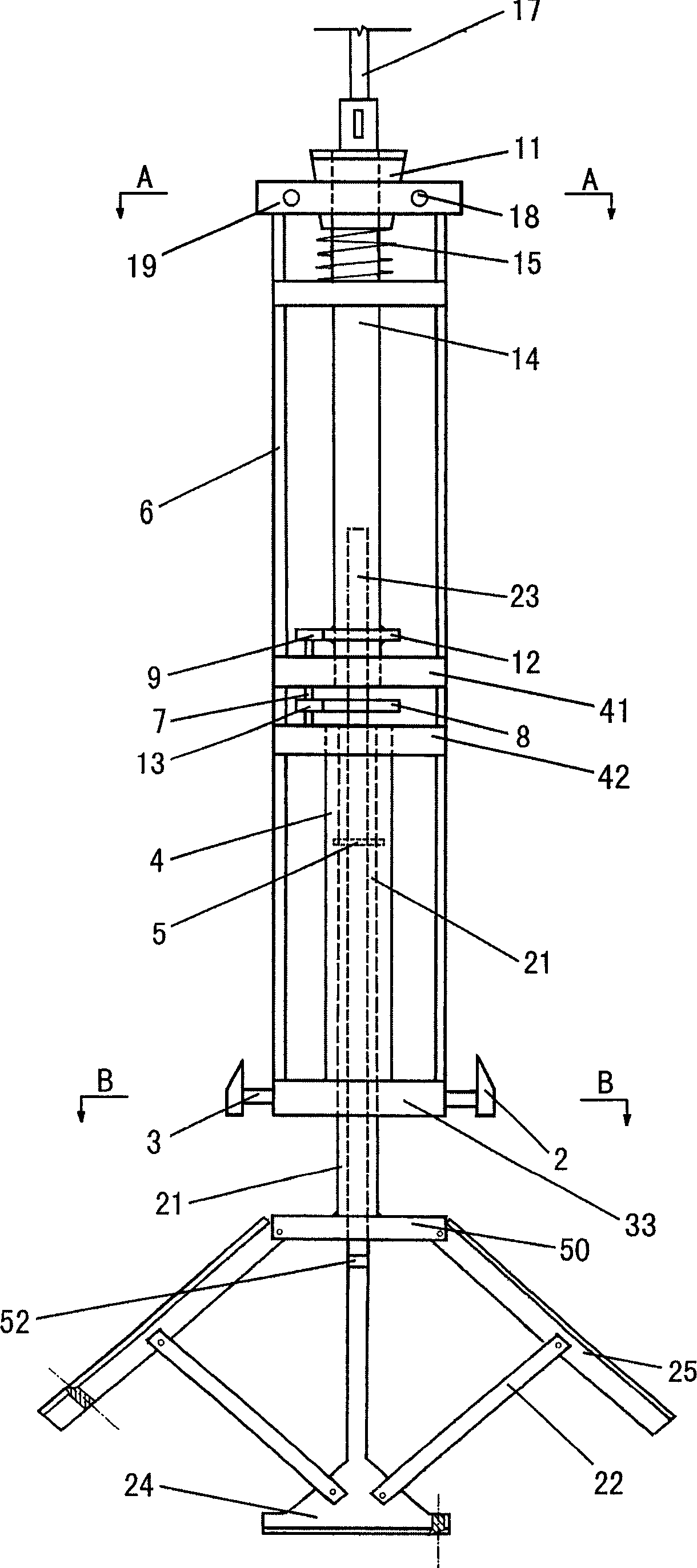

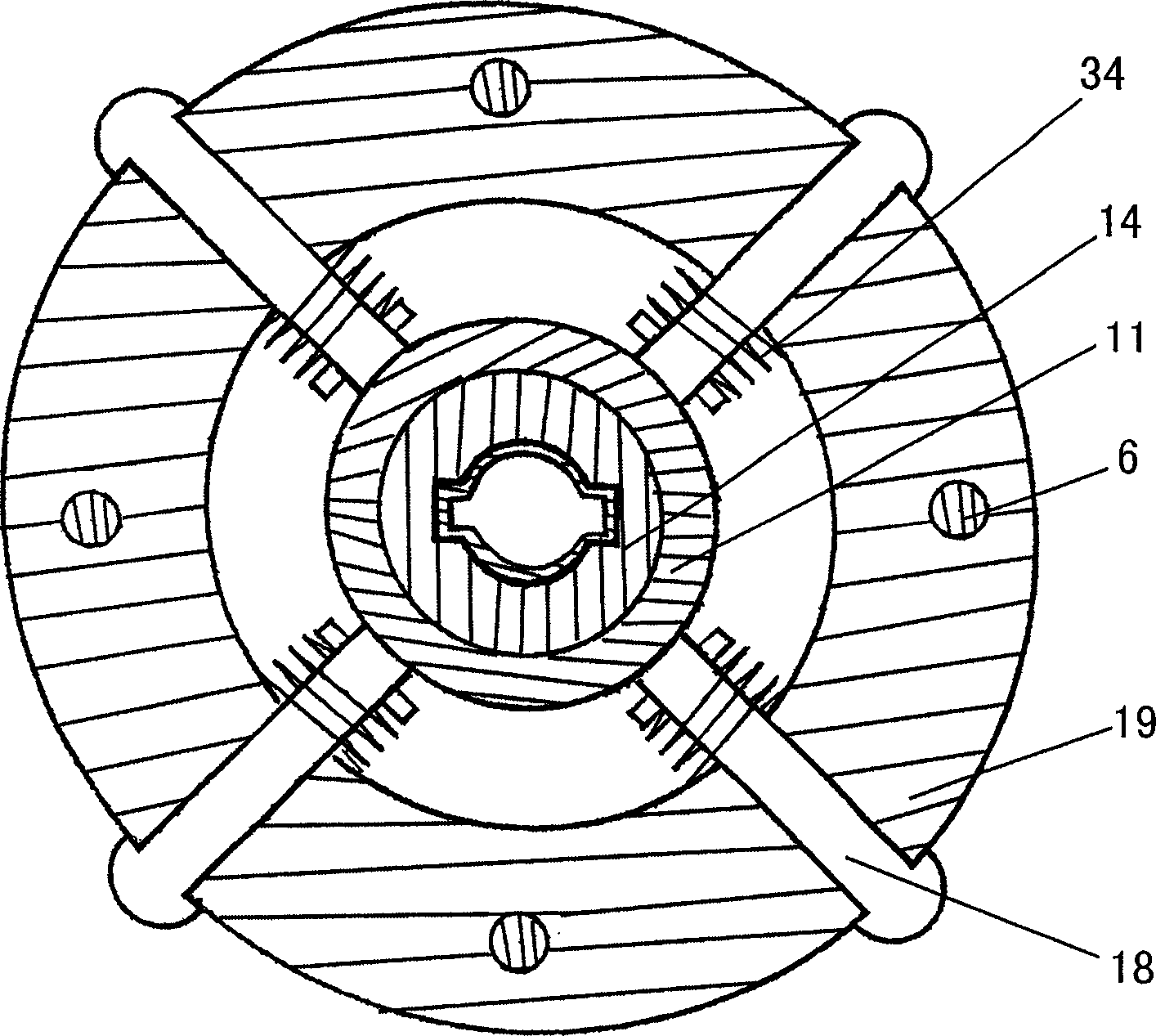

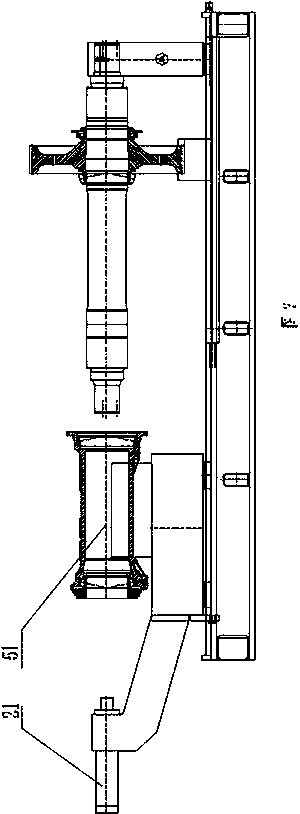

Bottom-expanding equipment for pipeline sinking precast reinforced concrete pile

InactiveCN1776113AHigh concentricityImprove crushing effectBulkheads/pilesDrilling machines and methodsReinforced concreteCurrent technology

This invention discloses a under-reamed pile equipment for foundation construction, especially the equipment for immersed tube fabricated steel-concrete under-reamed pile. It includes frame positioned with immersed tube, power source, driving mechanism and cutting rest. Compared with current technology, said invention has advantages of precision positioning, high single pile load bearing ability, convenient operation, high efficiency and engineering quality.

Owner:王国奋

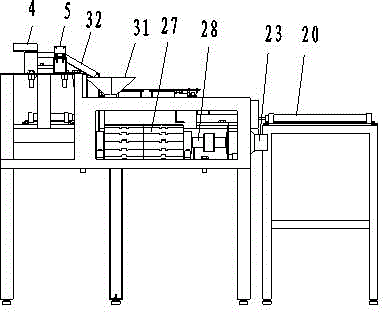

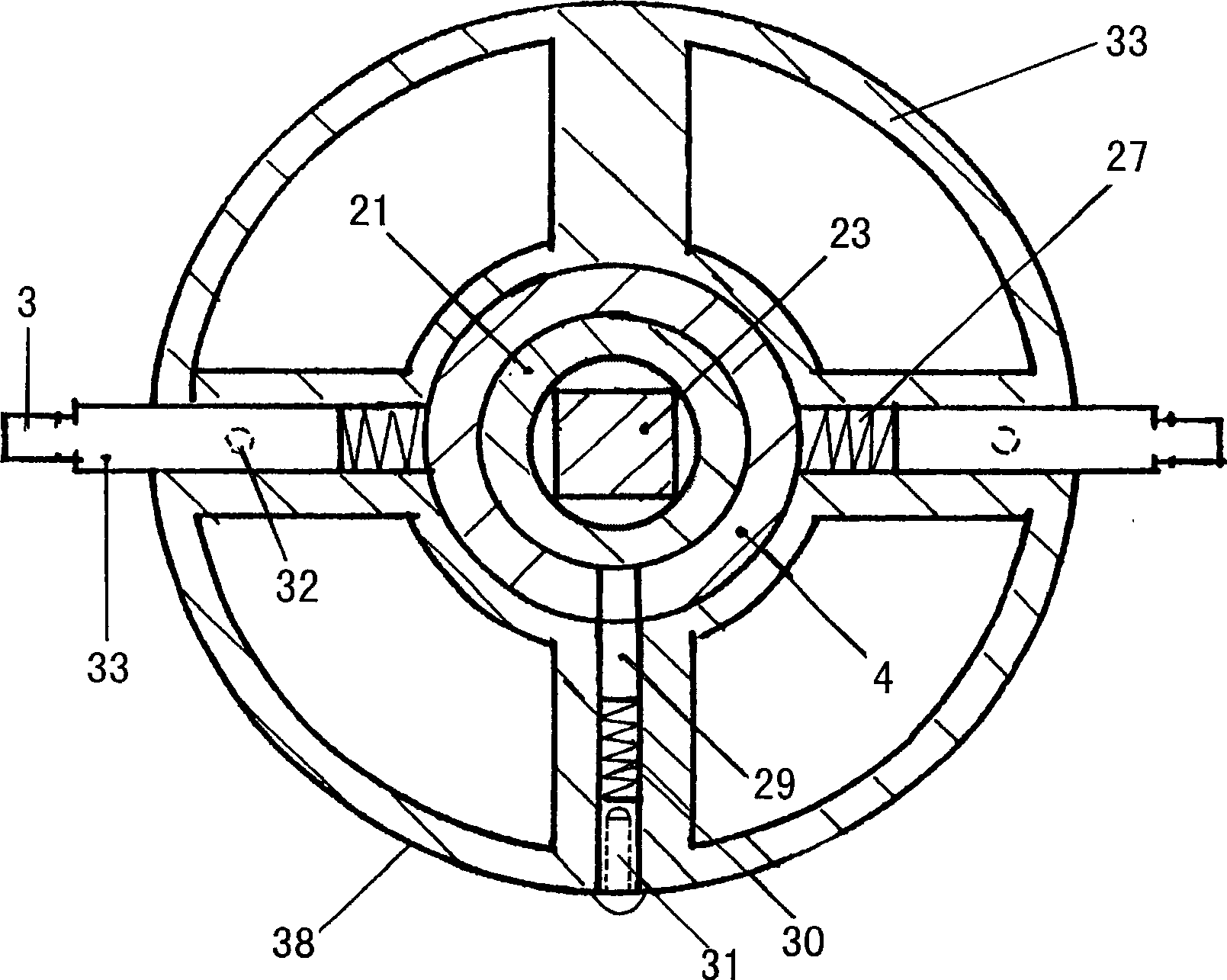

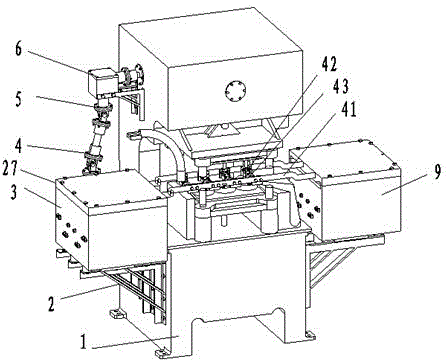

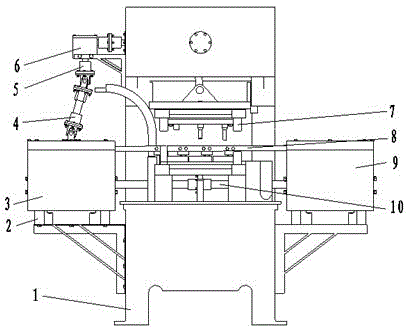

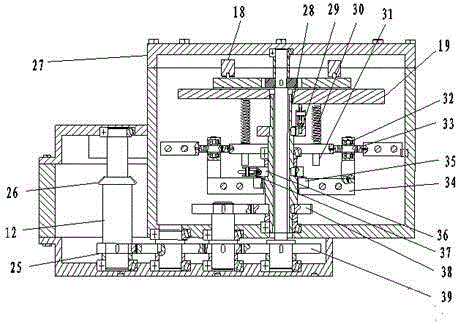

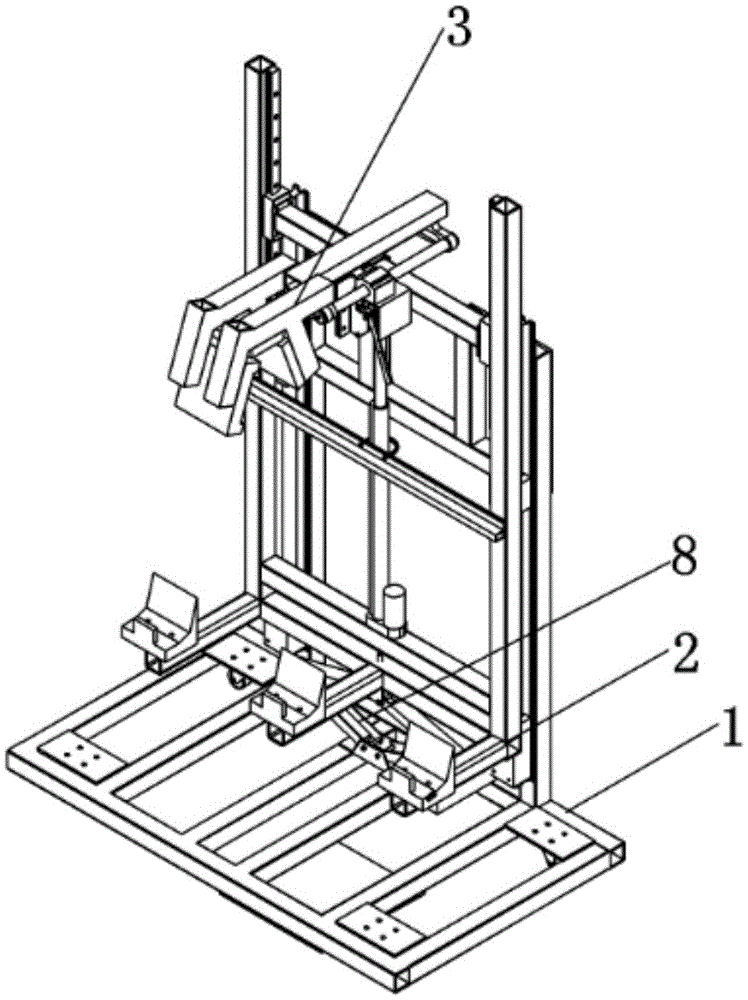

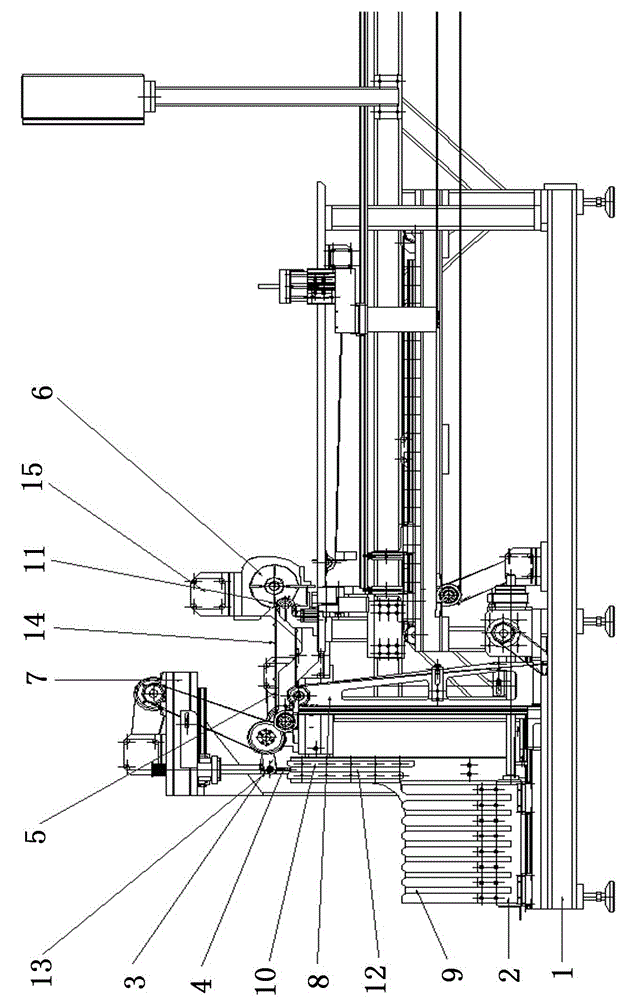

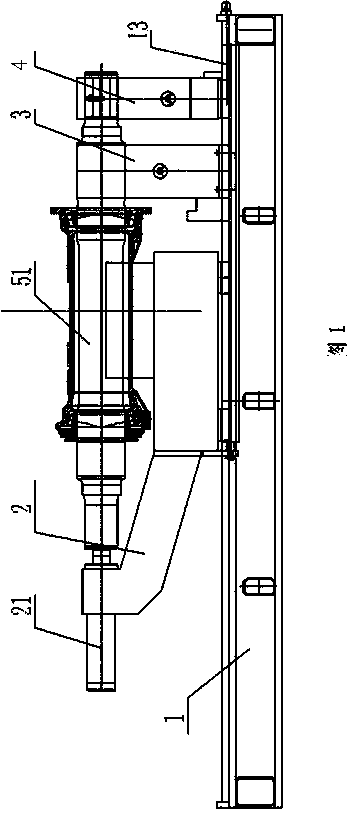

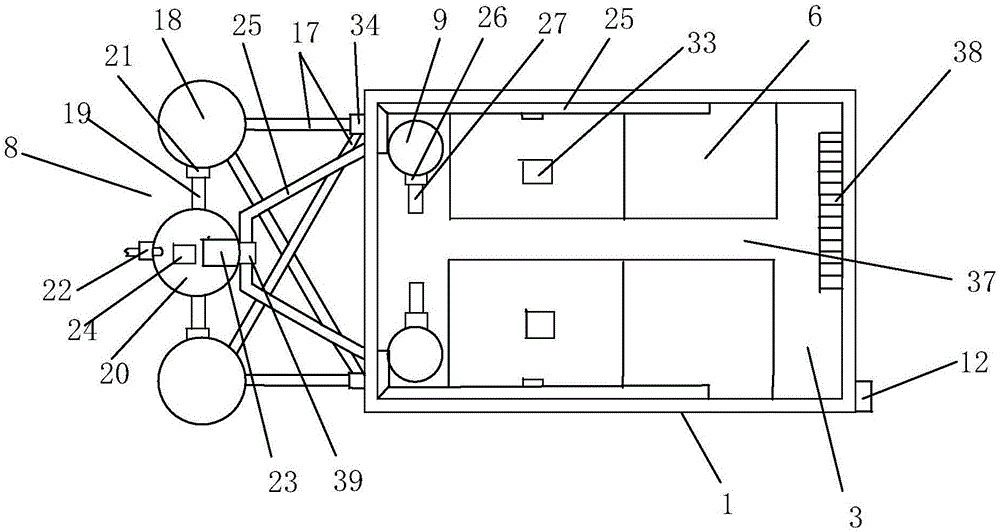

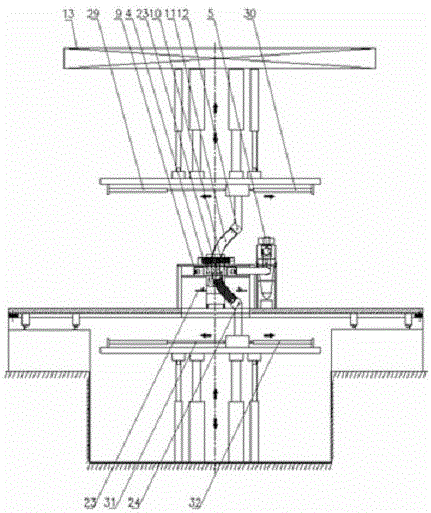

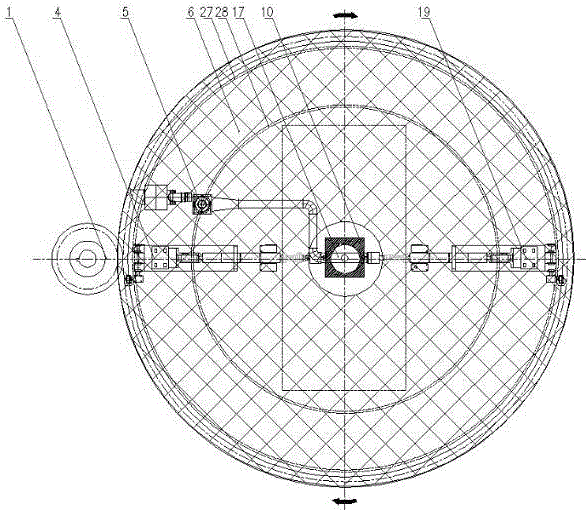

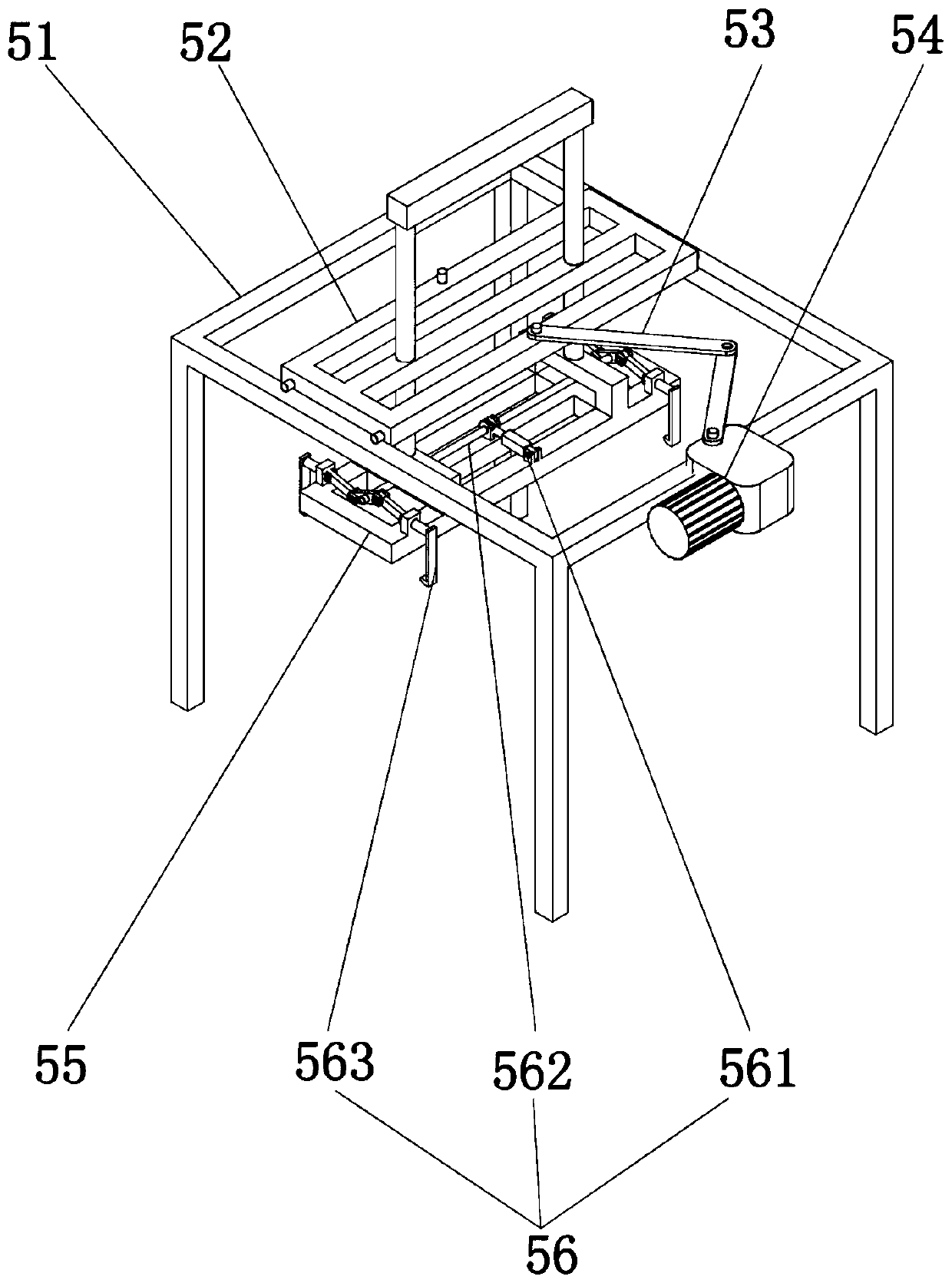

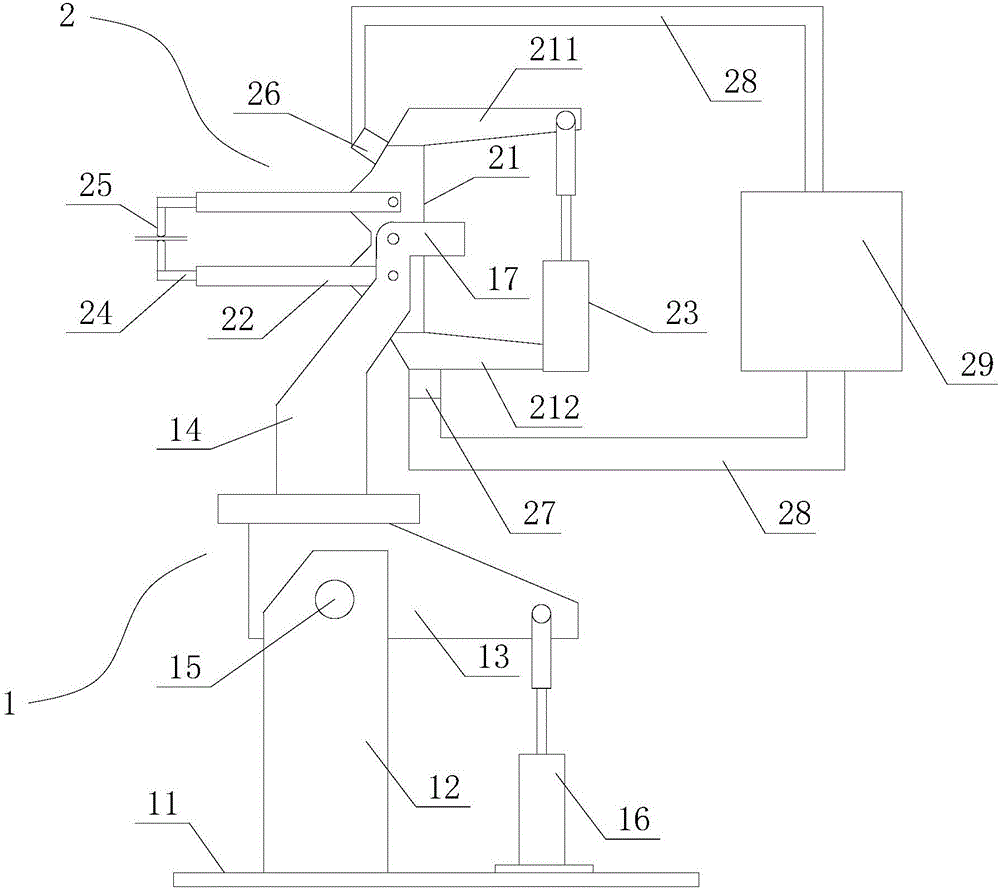

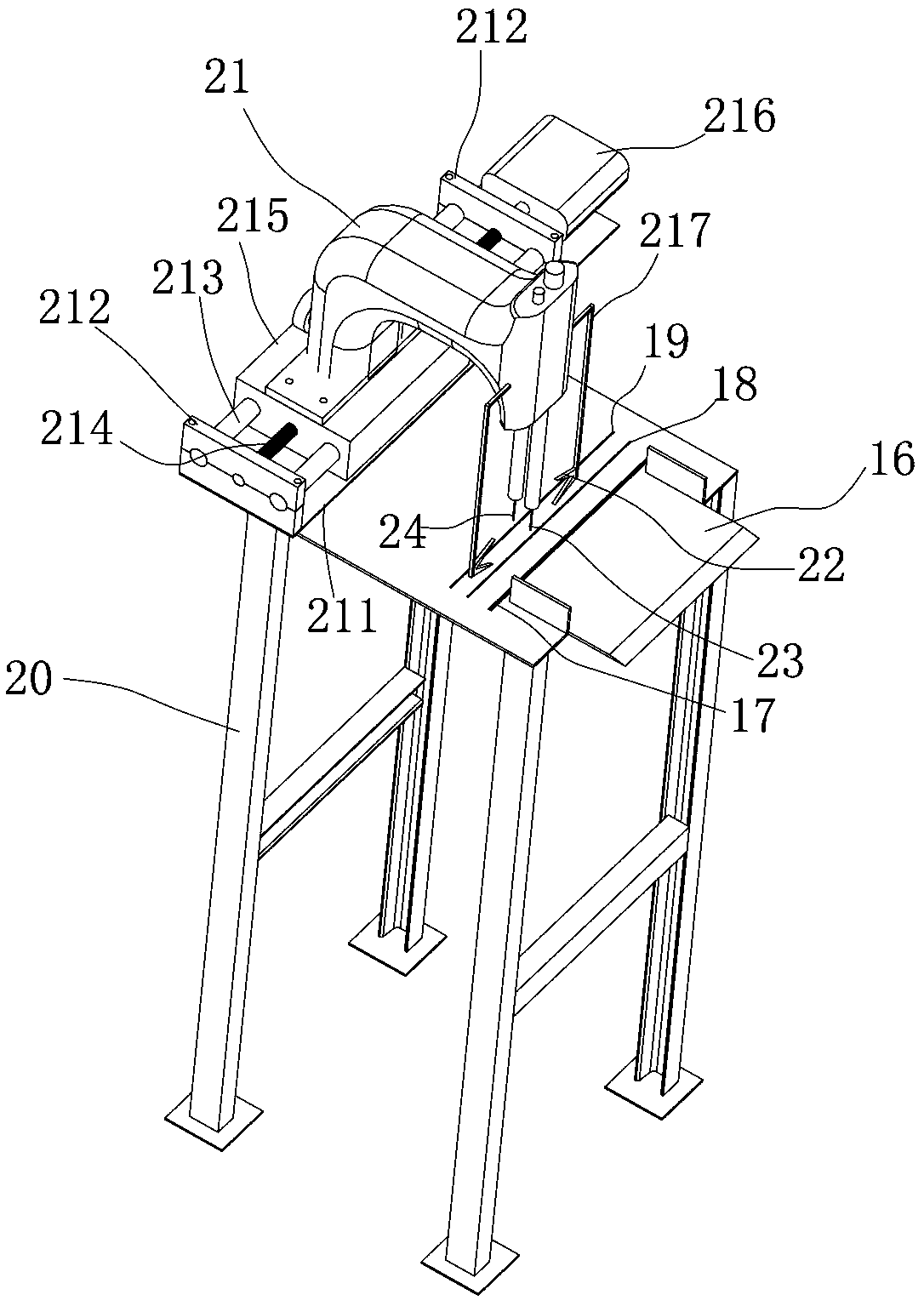

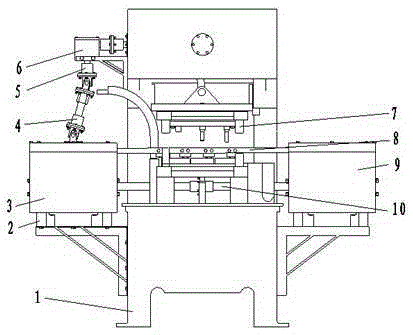

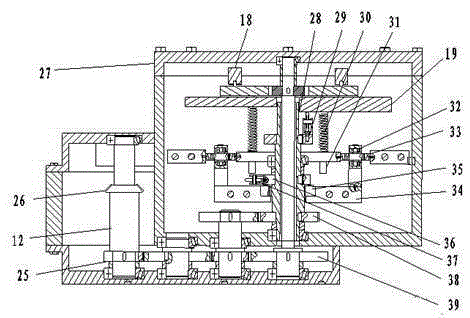

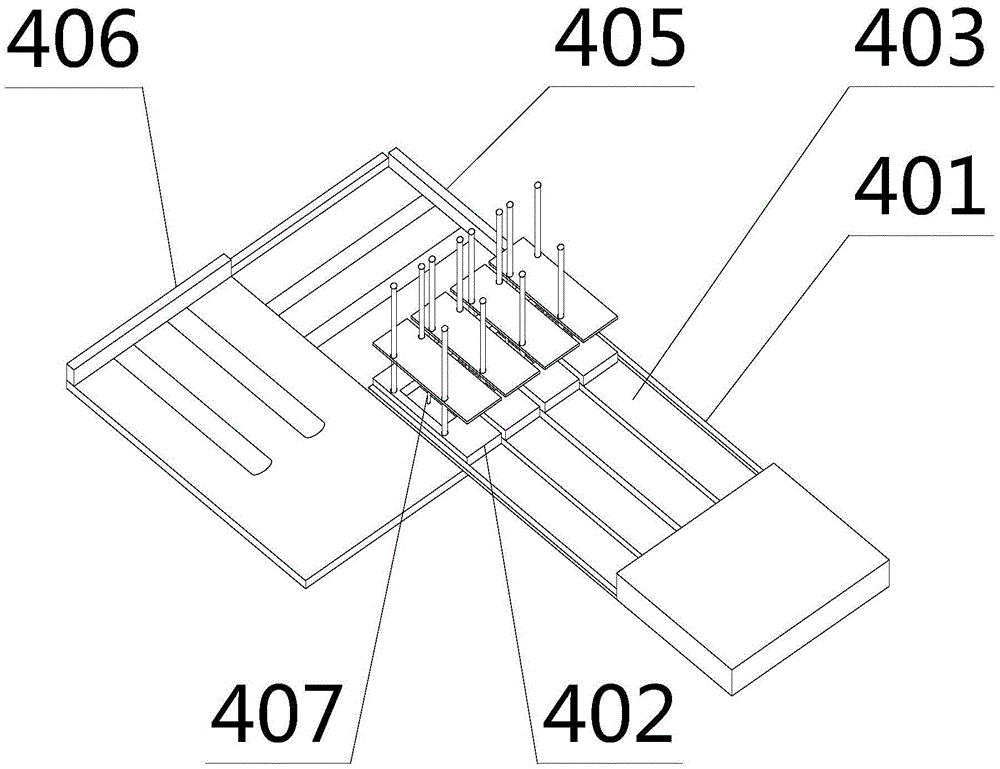

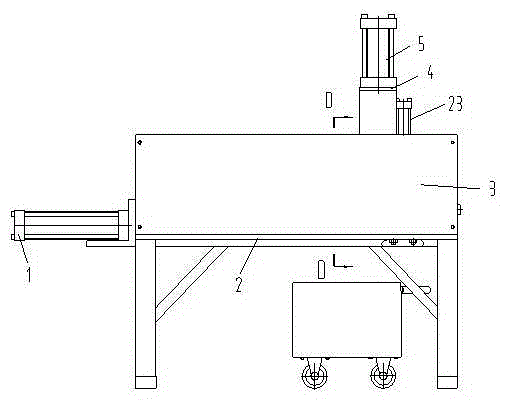

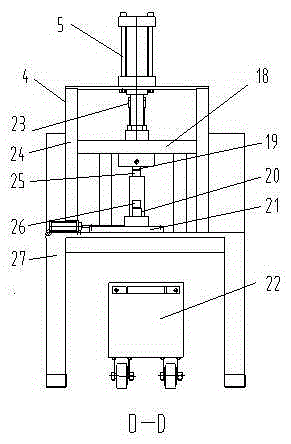

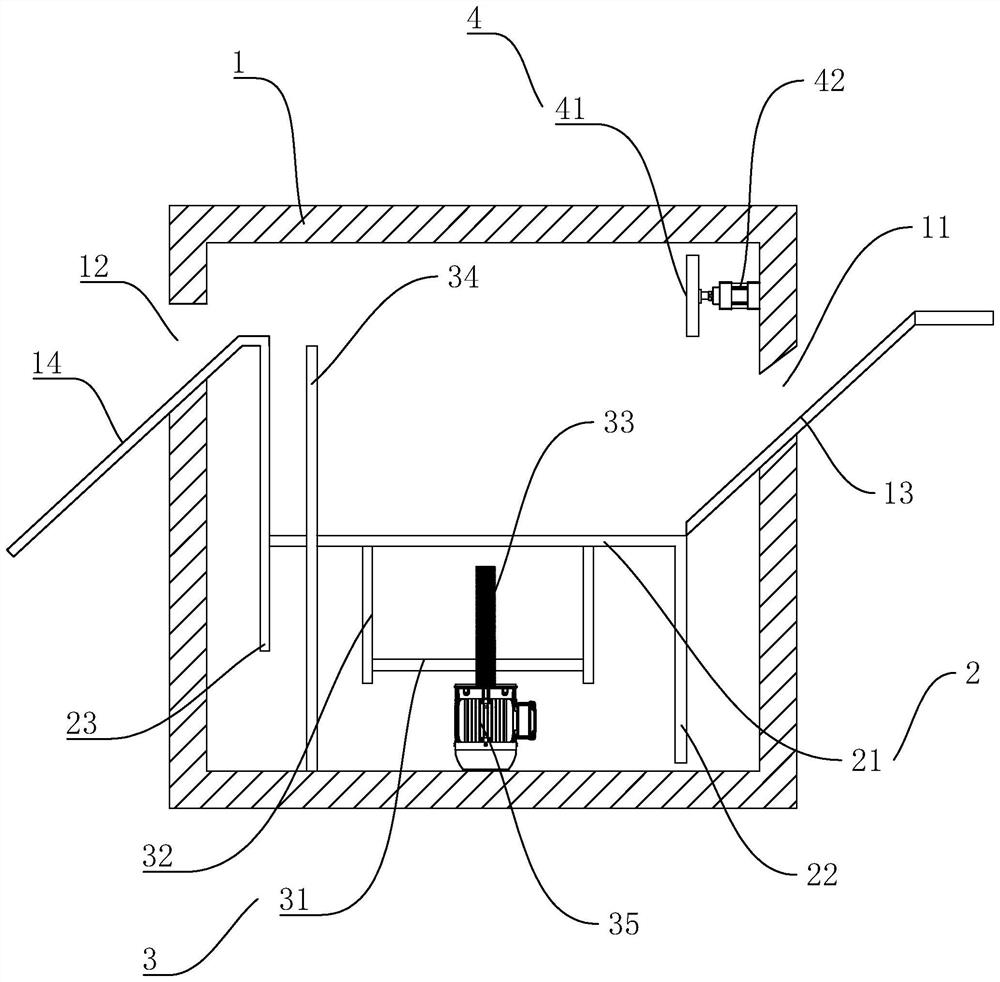

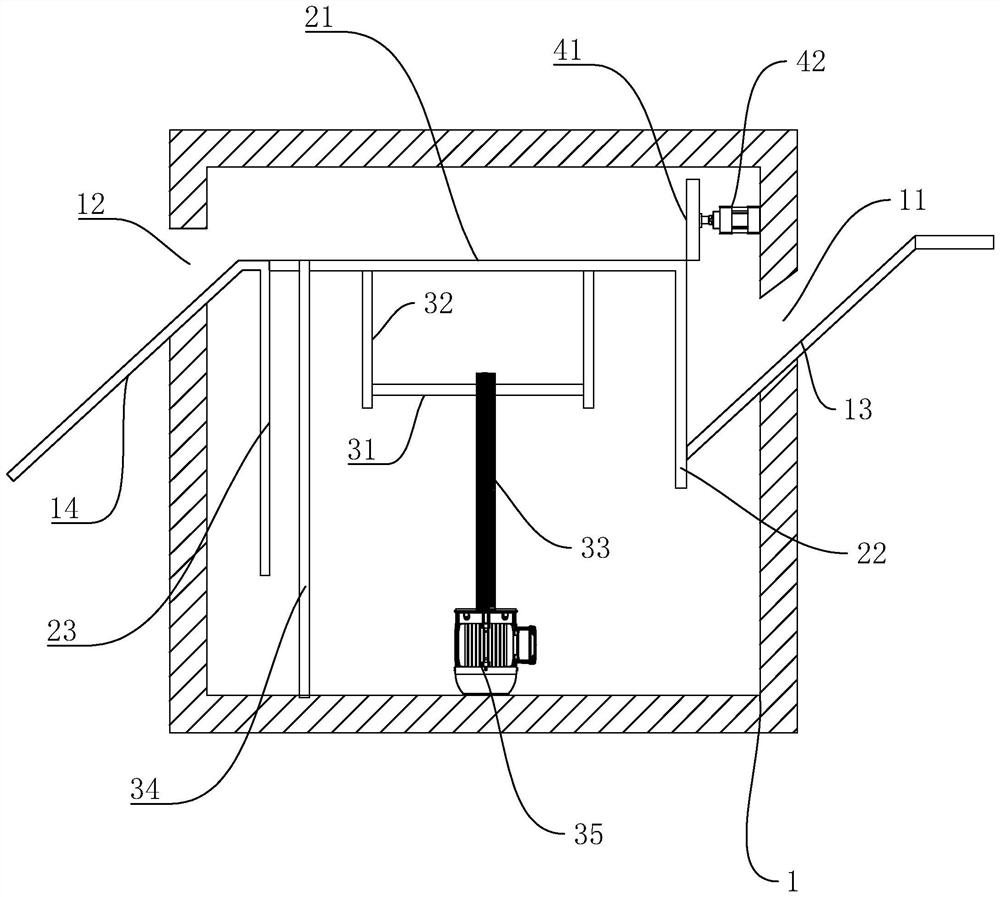

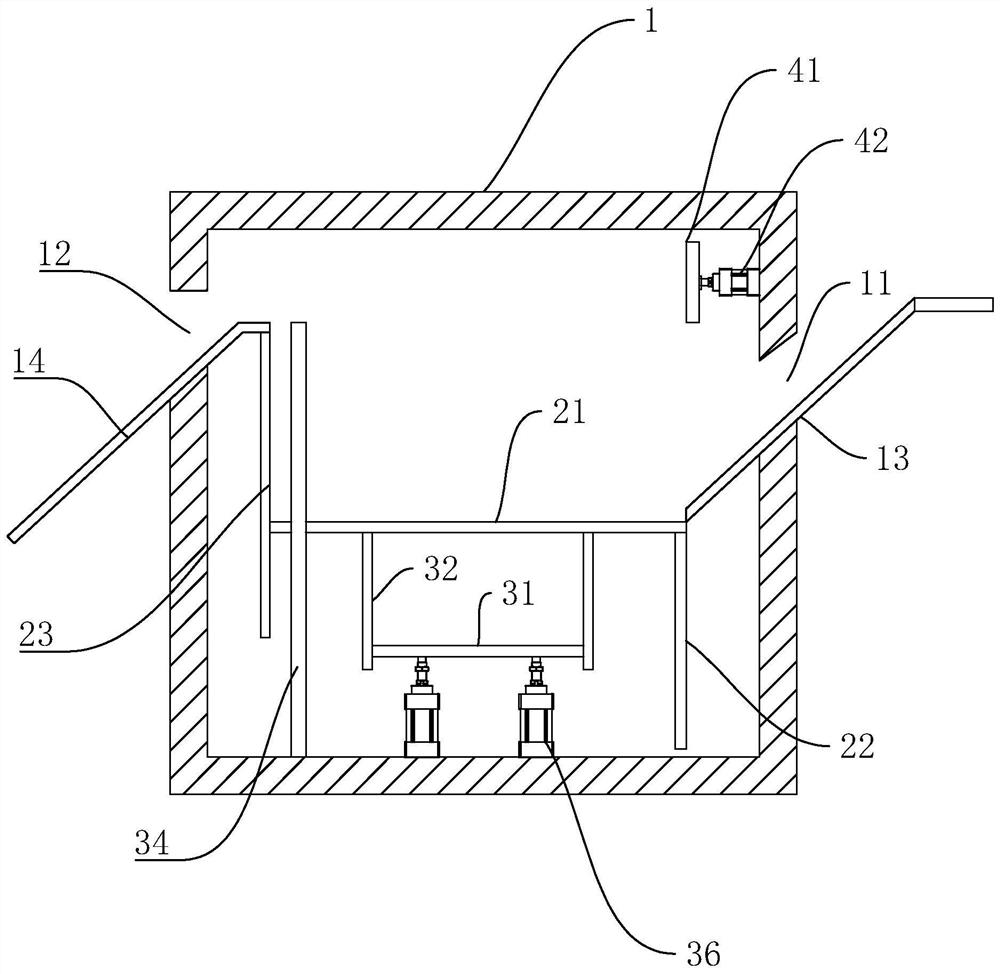

Extrusion forming feeding device for rebar connecting sleeve blank

The invention relates to an extrusion forming feeding device for a rebar connecting sleeve blank and belongs to the technical field of extrusion forming equipment for the rebar connecting sleeve blank and the extrusion forming feeding device is used for conveying materials among stations in the extrusion forming process of the rebar connecting sleeve blank. According to the extrusion forming feeding device, a crank shaft of a pressure machine is utilized to output power which is transferred to a left case body and a right case body, and a manipulator execution part is driven to move by two gear transmission mechanisms, transverse transmission mechanisms, lifting transmission mechanisms and longitudinal clamping transmission mechanisms of the same structures, so as to complete conveying of the connecting sleeve blank among the stations. The extrusion forming feeding device fills up the blank of extrusion forming feeding equipment for the rebar connecting sleeve blank, provides a proper material conveying device for extrusion forming of the rebar connecting sleeve blank and has the advantages of reasonable layout, accuracy in feeding, reliability in operation. By using the extrusion forming feeding device, the mechanical automation degree in the extrusion forming of the rebar connecting sleeve blank can be greatly increased, and the extrusion forming feeding device has obvious meanings and effects on improving the production efficiency and increasing the economic benefits.

Owner:HEBEI YIDA REINFORCING BAR CONNECTING TECH

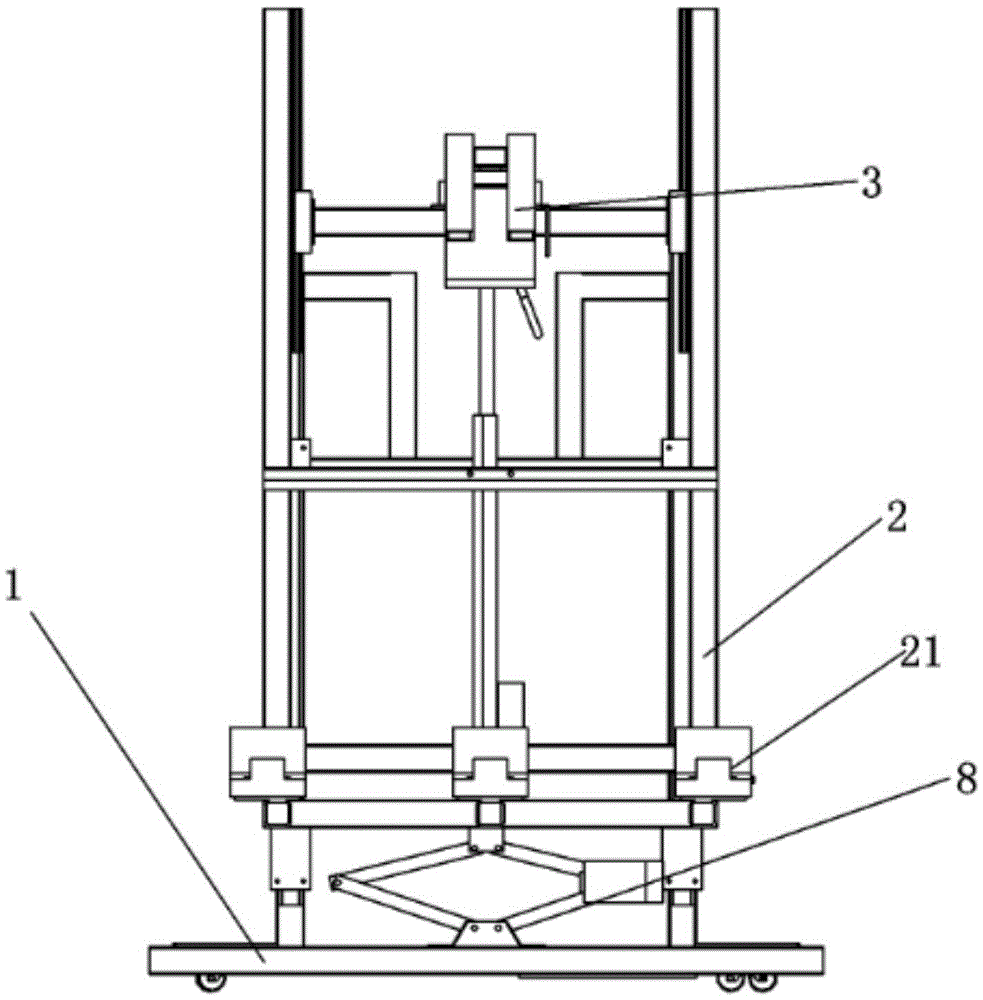

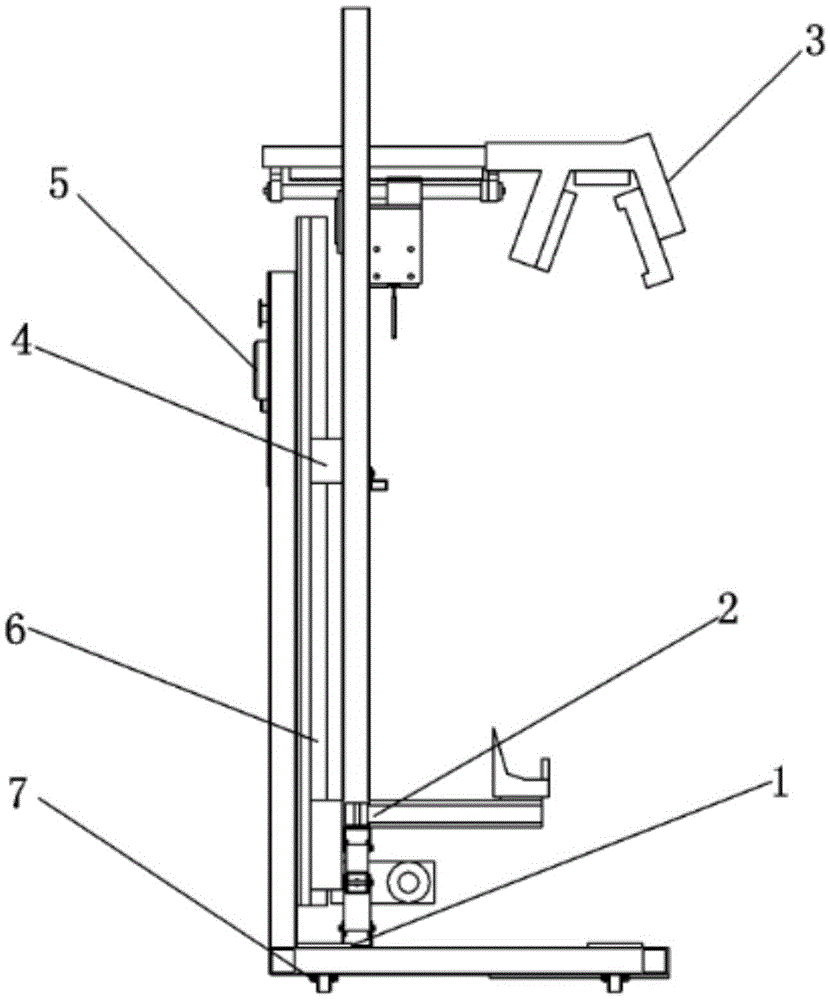

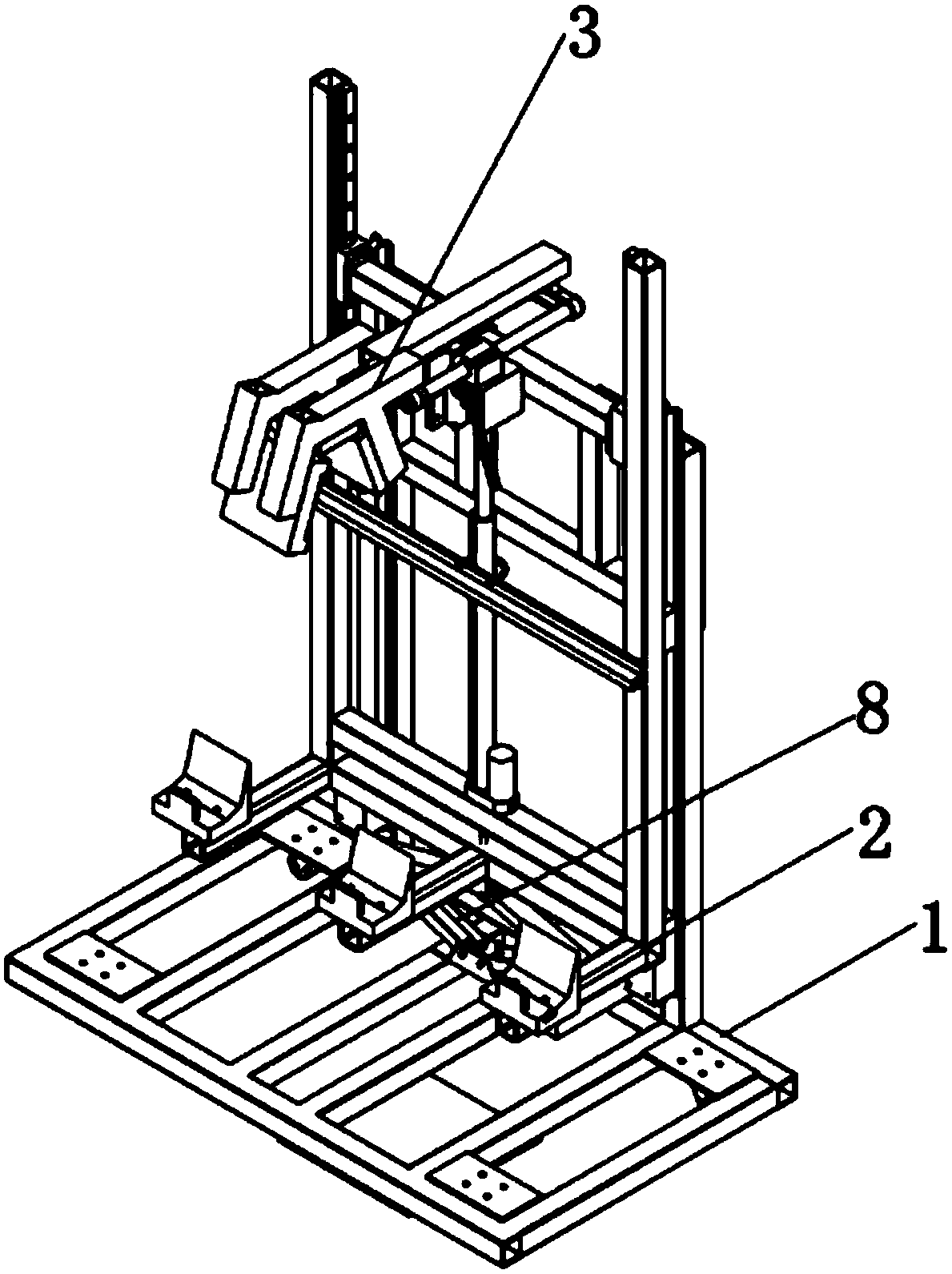

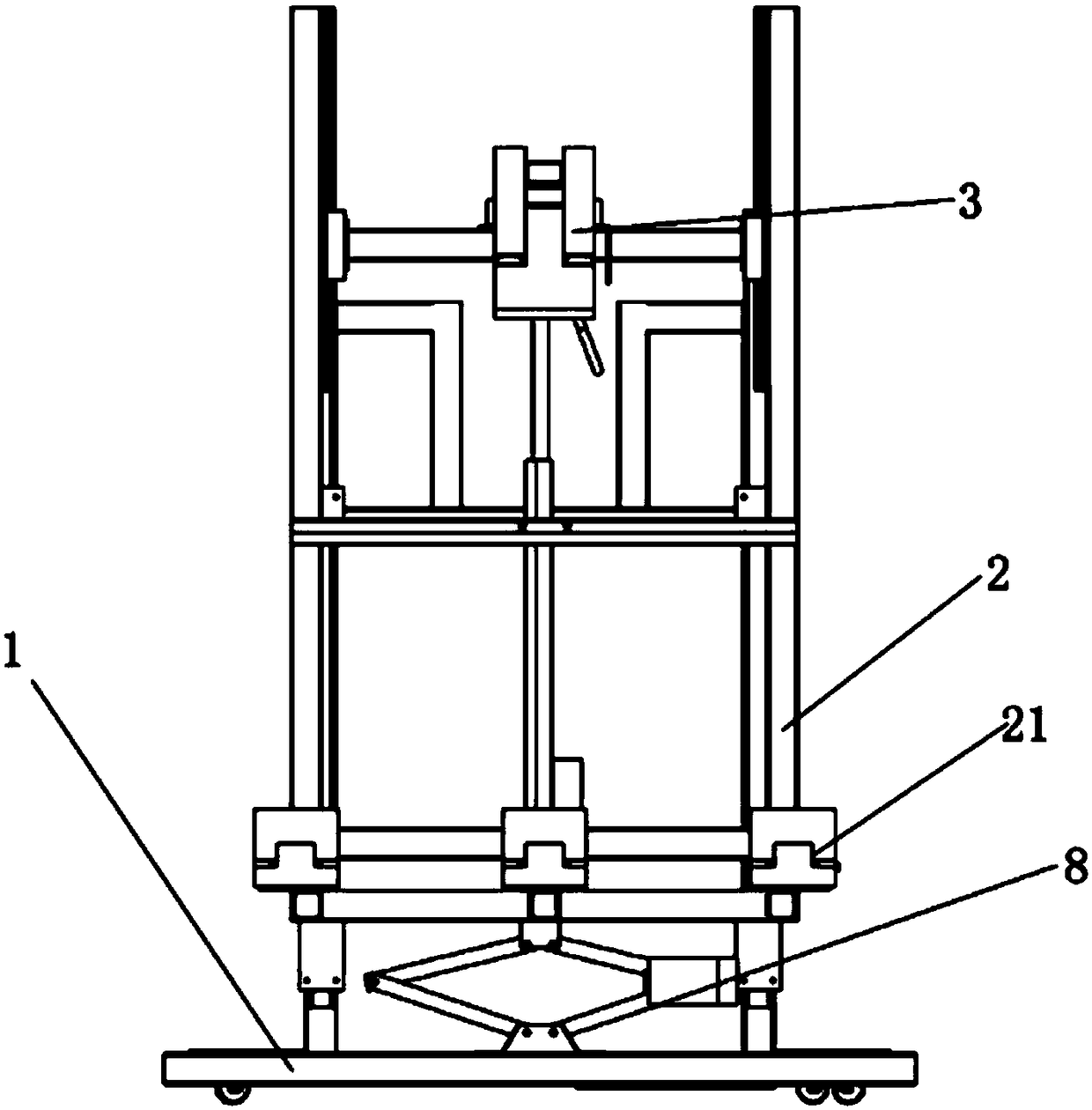

Movable electric device for car door detachment

ActiveCN105598682AHigh degree of mechanization and automationGuaranteed uptimeVehicle componentsMetal working apparatusCar doorCar manufacturing

The invention relates to the technical field of car manufacturing, in particular to a movable electric device for car door detachment. The device comprises a supporting framework, a lifting component arranged on the supporting framework, a clamp arm component and a control panel used for switching on a power supply and controlling the lifting component and the clamp arm component to move, wherein the lifting component comprises a lower clamping jaw used for clamping the lower portion of a car door, the clamp arm component comprises an upper clamping jaw used for clamping the upper portion of the car door, and a first driving mechanism used for driving the upper clamping jaw to rise and fall and a second driving mechanism used for driving the upper clamping jaw to rise and fall are arranged on the supporting framework. By the adoption of the device, the mechanical degree and the automation degree are high, labor cost is reduced, repair work time can be shortened, and quality hazards and safety hazards are eliminated.

Owner:GUANGQI HONDA

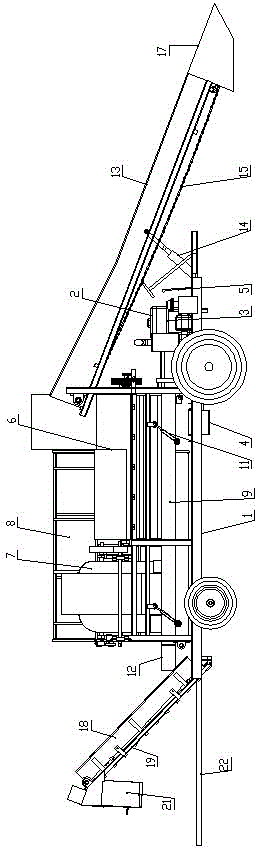

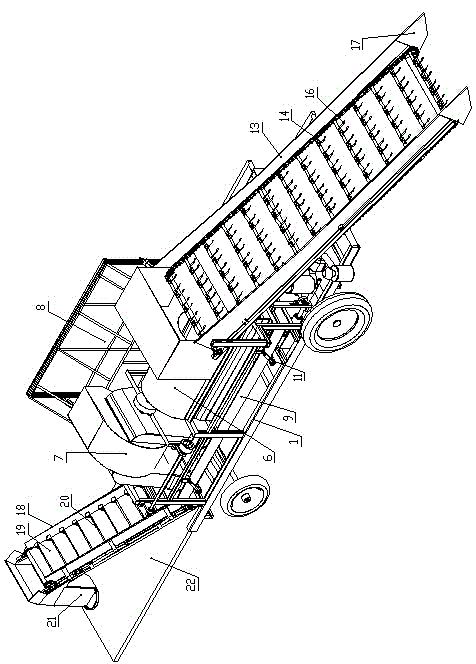

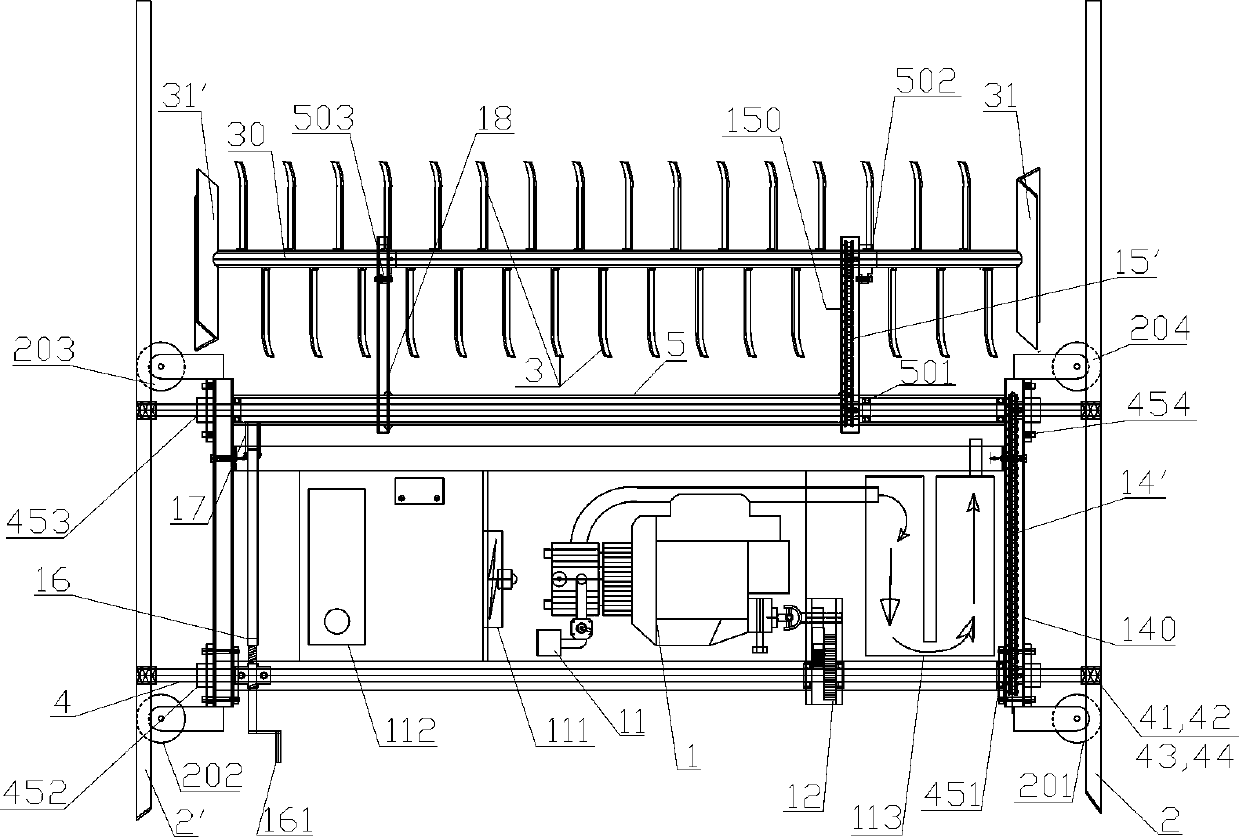

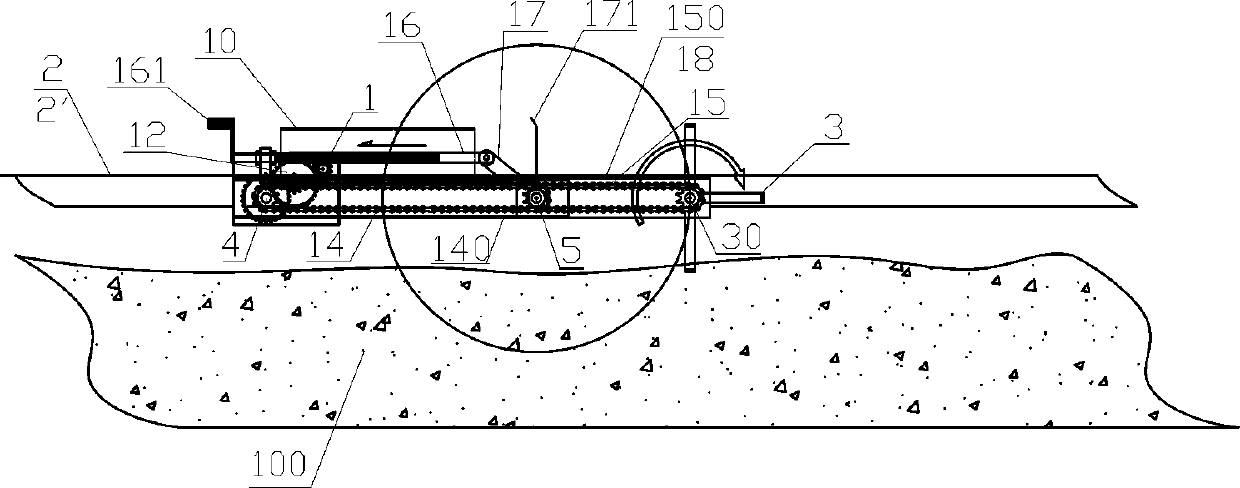

Self-propelled picker for picking up peanuts

A self-propelled picker for picking up peanuts comprises a rack, a power system is arranged on the rack, a walking system in transmission connection with the power system is arranged on the lower portion of the rack, a driving seat, a power output speed regulation mechanism and a control mechanism are arranged on the upper portion of the front end of the rack, and a peanut seedling fruit pickup and conveying system, a picking system, an air draft device, a grass collection box, a vibration sorting screen and a peanut lifting and collection device are further arranged on the rack. The self-propelled picker is reasonable in design, compact in structure, convenient to operate and low in energy consumption, especially through the design of the self-propelled shutter-type peanut seedling fruit pickup and conveying system, in the work process, fuel and labor are saved, decayed fruits are reduced, the functions of pickup, fruit picking, collecting and the like are integrated, the mechanical automation degree is greatly improved, the picker is especially suitable for large farmer households and professional planting cooperation, economic benefits are improved, the use cost is lowered, high practicality is achieved, and application and popularization are easy.

Owner:盖南南

Automatic livestock manure rake turnover machine

ActiveCN103387424AHigh degree of mechanization and automationClimate change adaptationExcrement fertilisersAgricultural scienceLivestock manure

The invention relates to an automatic livestock manure rake turnover machine, comprising a rack arranged on guide rails at two sides of a livestock manure fermentation bed surface, as well as a power machine, a main shaft and a couple axle which are arranged in the rack, wherein the power machine is provided with a reduction box and a controller, is linked with the main shaft through the reduction box, and then is linked to rake turnover teeth on a rake turnover tooth shaft and a shaft through first and second transmission gear sets or transmission chains / chain wheels, so rows of rake turnover teeth can be perform rake turnover on the fermentation bed. During operation, a holding arm is driven by rotating an internal thread screw through a hand crank, so as to adjust the rake turnover tooth shaft to swing up and down, and drive the rows of rake turnover teeth for gradually deep tillage from horizontal rake turnover, middle rake turnover and deep rake turnover or for retroregulation. The automatic livestock manure rake turnover machine can automatically travel, is thin in body, adjustable in rake turnover depth, large in power, high in efficiency and good in leakproofness, is labor-saving and is applicable to livestock manure treatment of multiplayer poultry houses in farms.

Owner:WENS FOODSTUFF GRP CO LTD

Flat tube conveying mechanism in assembly process of heat exchanger core

ActiveCN104944156AAvoid damageSimple structureConveyorsConveyor partsTransfer mechanismMechanization

The invention discloses a flat tube conveying mechanism in the assembly process of a micro-channel heat exchanger core. The flat tube conveying mechanism comprises a rack and is characterized in that a flat tube placing base is installed on the rack through a lifting device, flat tube transferring mechanisms are arranged above the flat tube placing base, vacuum suction cups are arranged on the flat tube transferring mechanisms, flat tube conveying belts matched with the flat tube transferring mechanisms are arranged behind the flat tube transferring mechanisms, and flat tube assembly rotating discs matched with the flat tube conveying belts are arranged at the rears of the flat tube conveying belts. The flat tube conveying mechanism has the advantages that the structure is simple and reliable, efficiency is high, the mechanization and automation degree is high, flat tube deformation and contact between flat tubes and other hard substances (such as steel) are avoided to the maximum degree, damage to the flat tubes by mutual friction between the flat tubes is avoided to the maximum degree, and the damage is definitely not allowed for the high-quality micro-channel heat exchanger core.

Owner:浙江其承自动化设备有限公司

Shaft hugging box withdrawing machine

ActiveCN103753173AHigh degree of mechanization and automationImprove work efficiencyMetal working apparatusElectrical controlEngineering

The invention discloses a shaft hugging box withdrawing machine which comprises a machine seat, a withdrawing device, a hydraulic system and an electric control system. The withdrawing device which is in the shape of a Z is arranged on the machine seat, a main oil cylinder is arranged at the head of the Z, supporting box seats are arranged at the belly of the Z, an inserting pin hole corresponding to a shaft hugging box is arranged on each supporting box seat, guide rails and a long oil cylinder are arranged on the machine seat under the Z, a supporting shaft seat and a locking seat are arranged on the right side of the machine seat, a lifting device is arranged in the locking seat, the supporting shaft seat is fixed above the machine seat, a lead screw is arranged on the machine seat below the locking seat, and a locking device is arranged on the locking seat. The shaft hugging box withdrawing machine has the advantages that mechanical and automatic level of withdrawing is high; after a workpiece is placed on the machine, the whole withdrawing process can be completed only by one person, so that time and labor are saved, and working efficiency is high; an electromechanical-hydraulic centralized control mode is adopted, so that the machine is simple and convenient to operate; due to horizontal withdrawing, safety and reliability are realized.

Owner:HUBEI HEQIANG MACHINERY DEV LIMITED BY SHARE

Forming machine for screw thread

InactiveCN1915555ASolve the problem of misalignment sticking outRealize mechanized workWire articlesScrew threadHorizontal and vertical

A machine for manufacturing the fastening wire used as binding part is composed of machine frame, wire bending unit with symmetrically arranged wire bending head and rotation driver, wire guider, fastening unit, primary shaping unit, final shaping unit, and the telescopic cylinder matched with the push press plates used by the last 4 units for bending by 270 degrees and horizontal and vertical 90 degrees.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

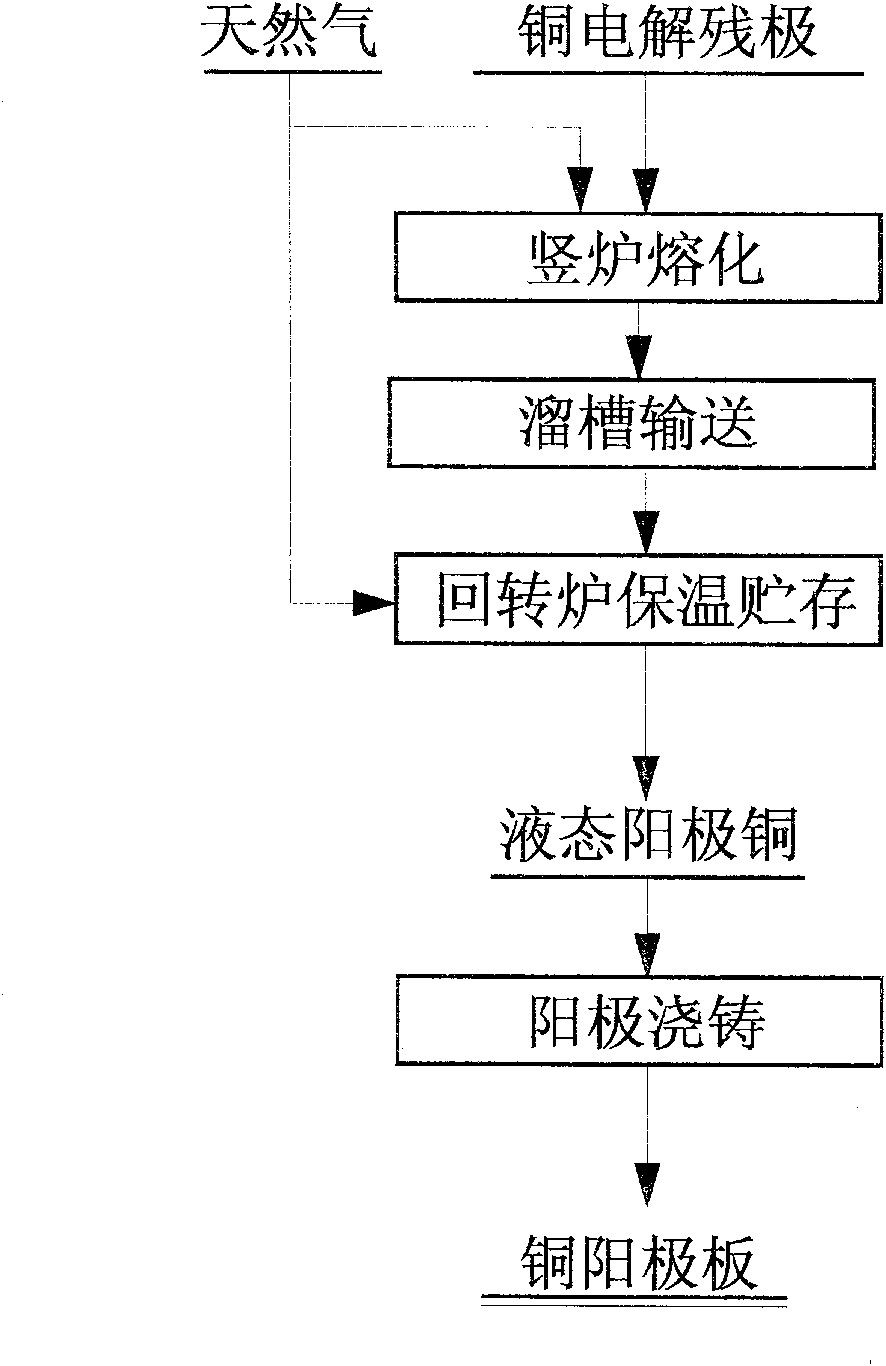

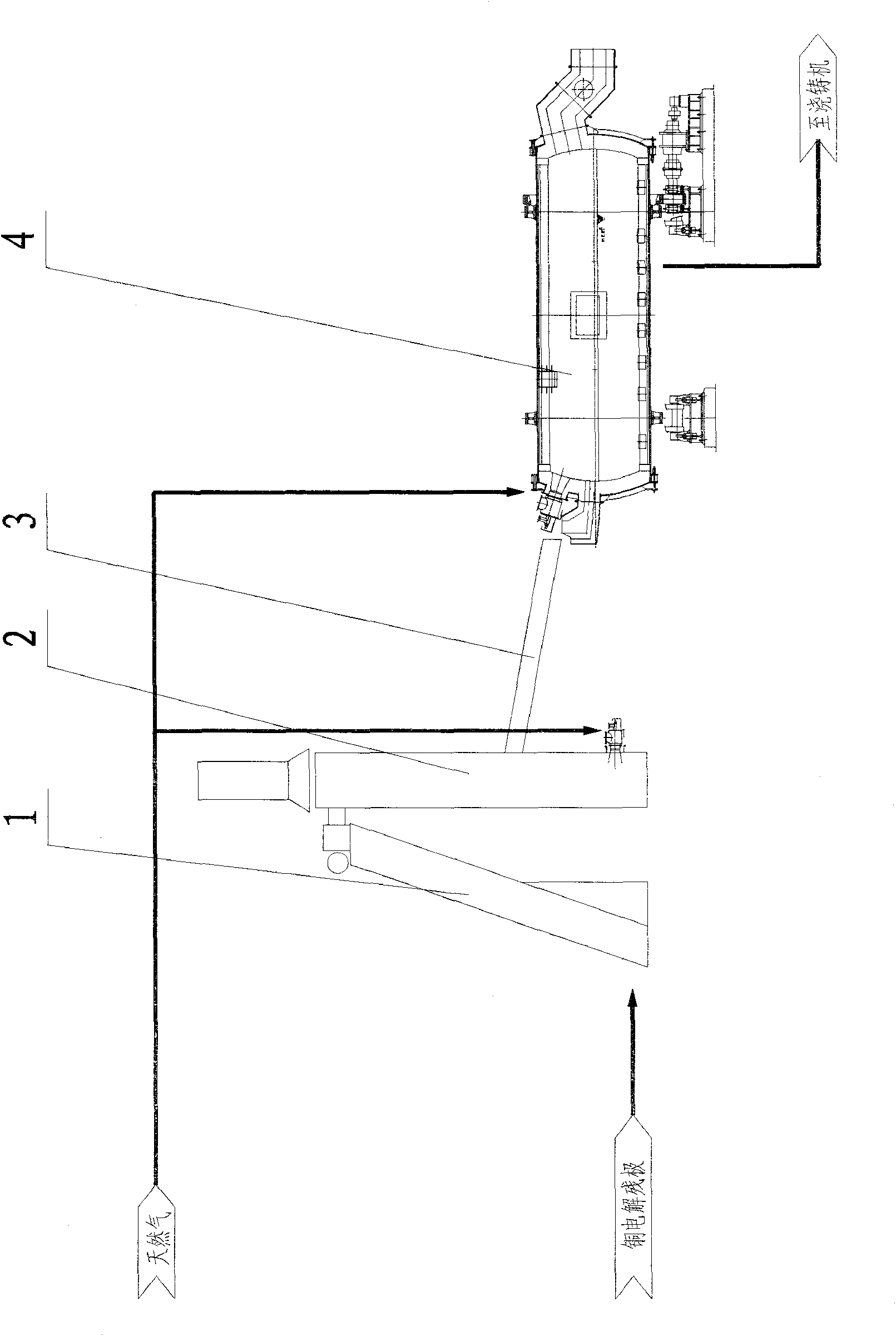

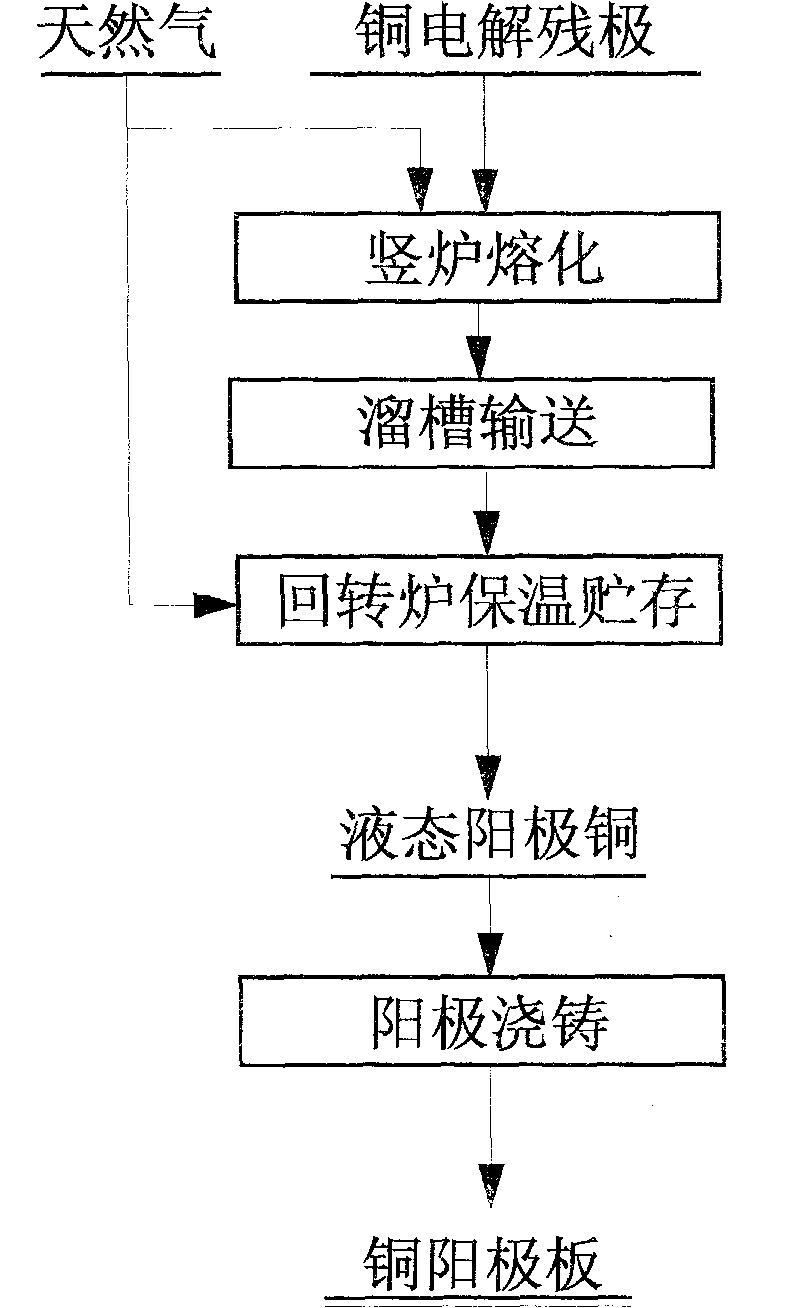

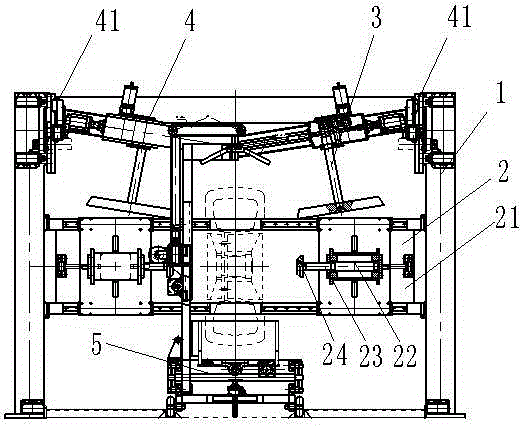

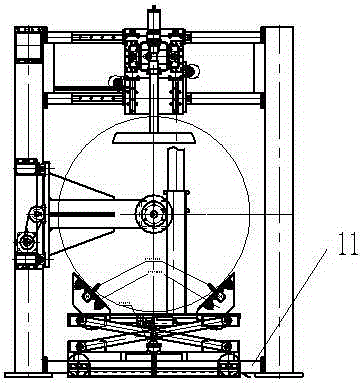

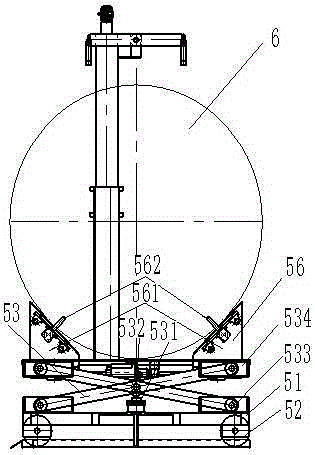

Cupric electrolysis remnant pole processing method and device thereof

InactiveCN101880892AImprove efficiencyReduce energy consumptionPhotography auxillary processesProcess efficiency improvementLiquid copperOperational safety

Owner:CHINA NERIN ENG

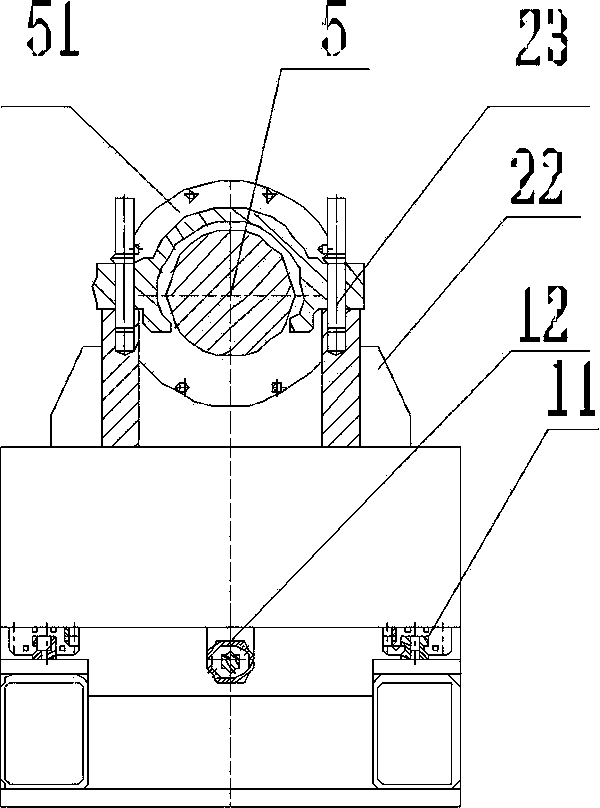

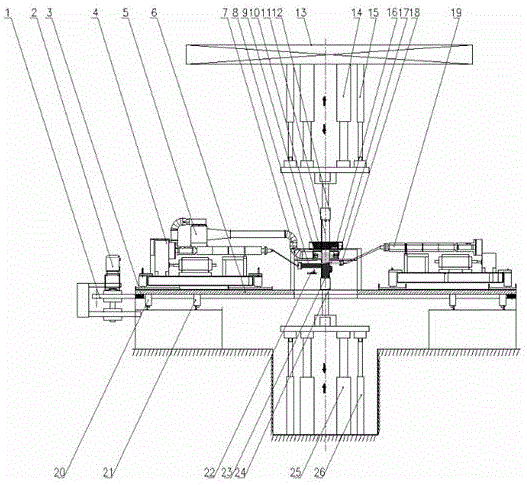

Numerical control press fitting and disassembly machine for aero tires

The invention discloses a numerical control press fitting and disassembly machine for aero tires. The numerical control press fitting and disassembly machine comprises a frame, a clamping device, a rolling wheel device, a V-shaped beam and a control system. The rolling wheel device is arranged on the V-shaped beam. The middle of the frame is provided with the aero tire clamping device. The aero tire clamping device is provided with a left slide table and a right slide table on the frame symmetrically. Rotation shaft boxes and screw rods are installed in the left slide table and the right slide table symmetrically. The two ends of the screw rods are in the left-right turning direction. Rotation shafts are installed on the screw rods. The V-shaped beam device is installed on the upper portion of the frame. The center of the V-shaped beam is connected through a bolt. The two ends of the V-shaped beam are each provided with a set of cross-shaped slide table, and the V-shaped beam is provided with a front-back and lifting slide drive device. The numerical control press fitting and disassembly machine is high in universality. Not only can press fitting and disassembly be achieved on one numerical control press fitting and disassembly machine, but also the numerical control press fitting and disassembly machine is suitable for various types and sizes of aero tires. The mechanization and automation degree are high. No matter the press fitting process or the disassembly process, the processes are both completed through control of a numerical control system started from the tires entering the press fitting and disassembly machine from a carrier loader. The working efficiency is improved, and the labor intensity is lowered.

Owner:HUBEI HEQIANG MACHINERY DEV LIMITED BY SHARE

Intelligent stereoscopic ecological recycling culture pig house

InactiveCN105993979AReduce transportationSave manpower and other costsAnimal housingAgriculture gas emission reductionFecesAnimal science

The invention provides an intelligent stereoscopic ecological recycling culture pig house and belongs to the technical field of ecological pig culture. The intelligent stereoscopic ecological recycling culture pig house comprises a pig house main body and is characterized in that the pig house main body comprises more than one pig house layer and more than one aquiculture crop layer; each pig house layer is provided with a pig manure cleaning and discharging system; each pig manure cleaning and discharging system is connected with a pig manure fermentation and harmless treatment device; and each aquiculture crop layer is connected with the pig manure fermentation and harmless treatment device, so that pig manure subjected to fermentation and harmless treatment is conveyed back to the aquiculture crop layer and is used as culture liquid of aquiculture crops, and furthermore, the aim of recycling the pig manure is realized. The intelligent stereoscopic ecological recycling culture pig house not only has a pig culturing function but also has a green feed planting function, so that a pig culture land is saved; organic matters obtained by carrying out the fermentation and harmless treatment on the pig manure forms culture liquid for culturing the green feed, and on-site recycling of the pig manure is realized after the harmless treatment; and the mechanical and automatic degrees are high.

Owner:陈明红

Steel bent pipe facade transmission hot winding 3PE molding method

The invention relates to a steel bent pipe facade transmission hot winding 3PE molding method which is characterized in that steel bent pipes of which the surfaces are cleaned are hoisted to an erosion resistant coating operating zone; after being clamped by an upper hydraulic pipe sending mechanism and a lower hydraulic pipe sending mechanism for fixation, the steel bent pipes slowly and vertically move downwards to sequentially pass through the stations such as a medium frequency heating coil, an epoxy powder spraying device, an adhesive extruder, a polyethylene extruder, a roller and a water cooling device; after bent pipe outer surface heating, epoxy powder spraying, adhesive side winding and polyethylene side winding, the steep bent pipes are rolled through the roller and are adhered into an integral structure; and water cooling is carried for shape setting. The method is high in mechanization and automation degree, applicable to steel bent pipe 3PE erosion resistant coating hot winding molding, and high in working efficiency, saves raw materials, overcomes the defects that the quality of the erosion resistant coating is low and is hard to control or the erosion resistant coating is unmatched with a straight pipe 3PE erosion resistant coating due to the traditional technologies of manual liquid epoxy spraying for corrosion prevention, manual heat shrinking sleeve baking for corrosion prevention, dual-layer epoxy powder spraying and bent pipe cold belt winding heat fusion method.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

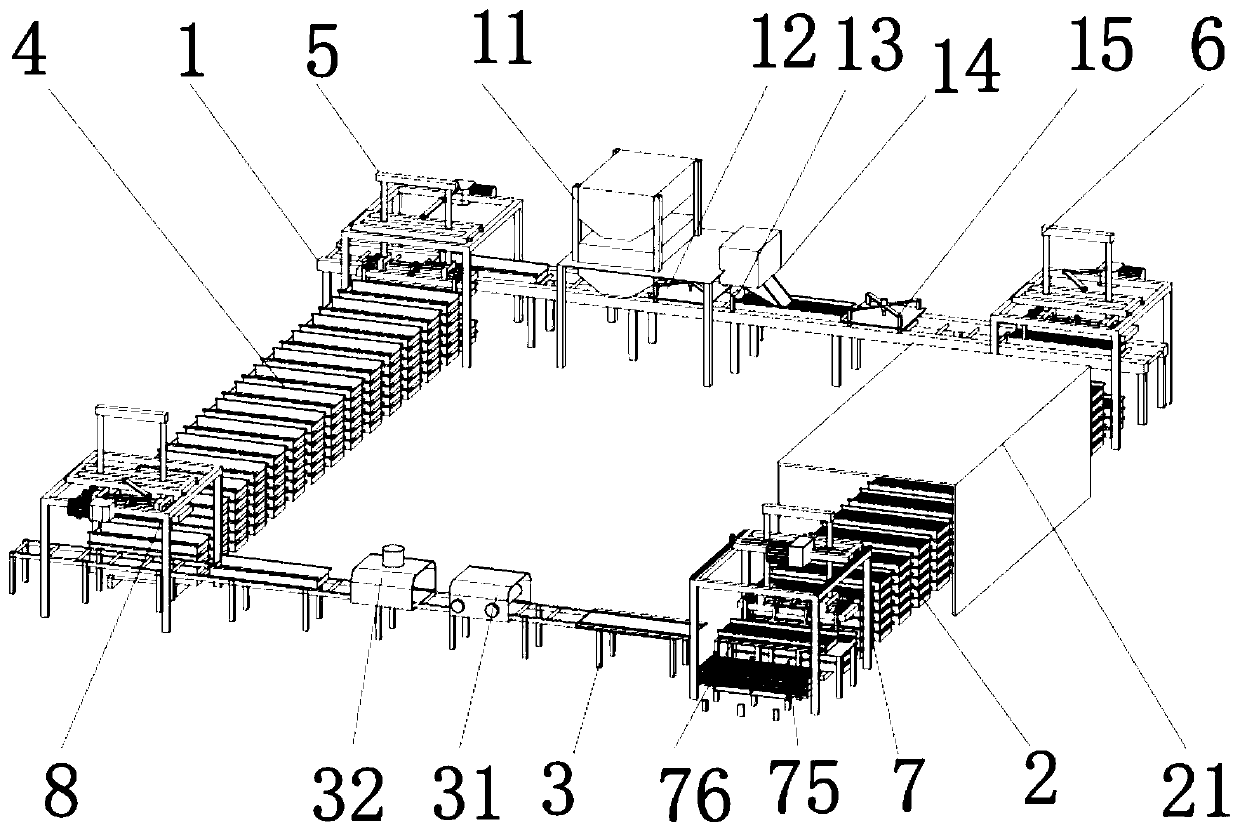

Plate production line

PendingCN111203973AHigh degree of mechanization and automationLabor demand is lowDischarging arrangementCeramic shaping plantsProcess engineeringMold removal

The invention discloses a plate production line. The plate production line comprises a production pouring conveying line, a steam-curing conveying line, a demolding cleaning line and an empty mold conveying line which are sequentially connected, wherein a first grabbing and lifting mechanism used for grabbing and lifting a mold to be produced to the production pouring conveying line is arranged atthe inlet end of the production pouring conveying line, a second grabbing and lifting mechanism used for grabbing and lifting the poured mold to the steam-curing conveying line is arranged between the production pouring conveying line and the steam-curing conveying line, and a demolding mechanism used for carrying the steam-cured mold to the demolding cleaning line is arranged between the steam-curing conveying line and the demolding cleaning line, and a third grabbing and lifting mechanism used for placing the assembled empty mold on the empty mold conveying line is arranged between the demolding cleaning line and the empty mold conveying line. According to the plate production line, high mechanization and automation degree can be achieved, and the demand for labor force is small; and automatic conveying and automatic demolding are achieved, manpower is saved, steam-curing equipment is arranged, and a wallboard can be formed and discharged within fixed time.

Owner:陕西鸥克建材科技有限公司

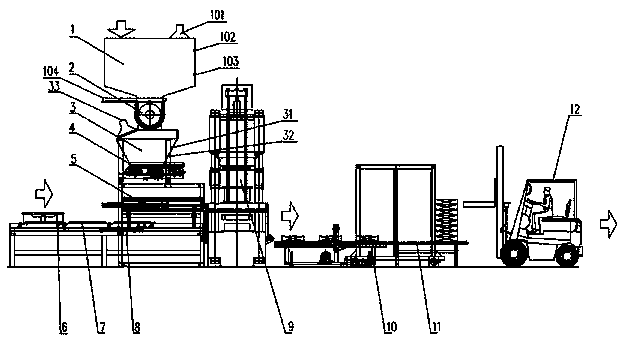

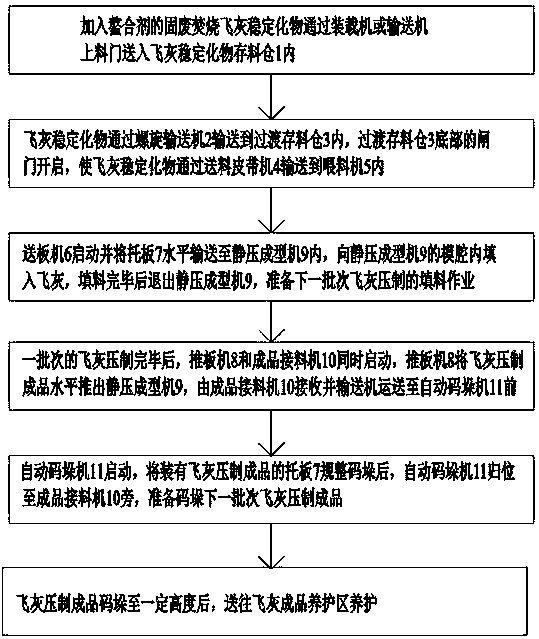

Volume reduction method and device aiming at fly ash stabilization substance

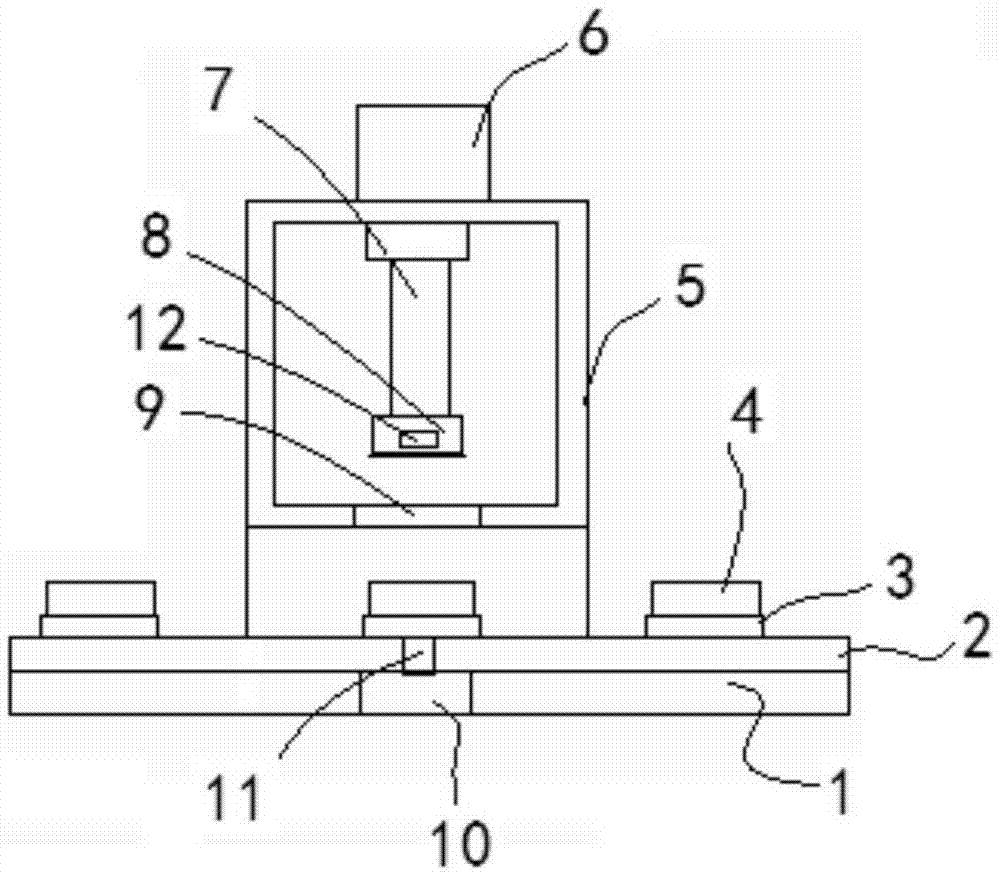

PendingCN108909002AHigh densityHigh degree of mechanization and automationSolid waste disposalShaping pressVolumetric Mass DensityEngineering

The invention discloses volume reduction method and device aiming at a fly ash stabilization substance. The method comprises the steps of step 1, feeding a fly ash stabilization substance added with achelating agent into a fly ash stabilization substance storage silo (1); step 2, conveying the fly ash stabilization substance into a transition storage silo (3) through a screw conveyor (2), and then feeding into a feeder (5) through a feeding belt conveyor (4); step 3, starting a plate feeder (6), and feeding a support plate (7) to a static pressure forming machine (9); step 4, pushing a finished product out of the static pressure forming machine through a plate pusher (8), receiving through a finished product receiving machine (10), and sending to an automatic stacker crane (11); step 5, stacking the finished products in order through the automatic stacker crane; step 6, after stacking, sending to a fly ash finished product maintenance area. According to the volume reduction method andthe device aiming at the fly ash stabilization substance provided by the invention, a high-pressure forming method is adopted, and cement has no need to be added for curing fly ash, so that the density of the fly ash stabilization substance is increased, the regular shape is formed, the transportation efficiency is improved, the utilization efficiency of landfilling storage capacity is improved,the service life of a landfill is prolonged, and the shortage of land planning of the landfill is relieved.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

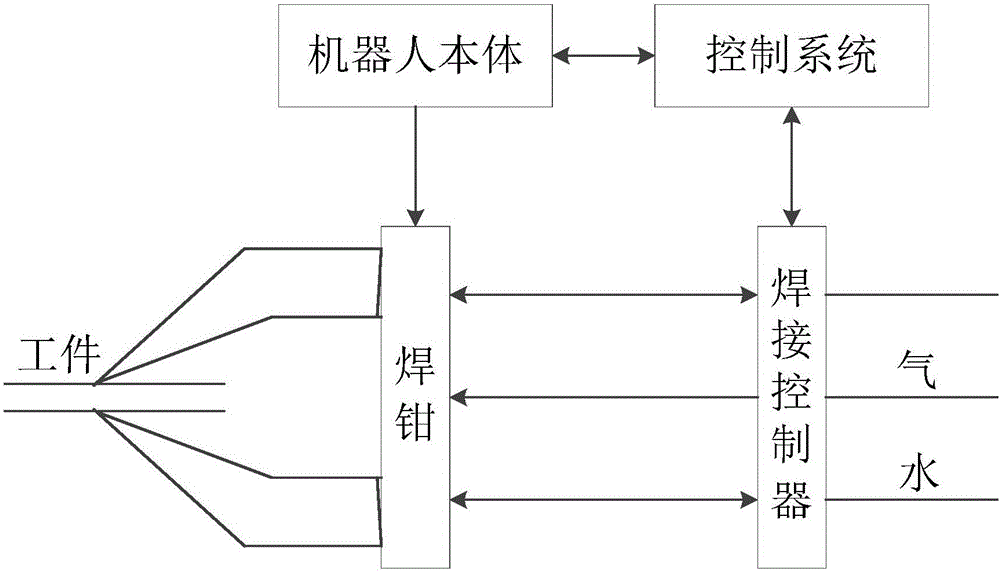

Flexible agile production line for new energy pure electric car body

InactiveCN105881033AIncrease productivityHigh degree of mechanization and automationOther manufacturing equipments/toolsVehicle componentsSteel platesAutomotive engineering

The invention provides a flexible and agile production line for a new energy pure electric vehicle body. A cutting machine is used to cut the entire steel plate into a required size; a stamping machine is used to reshape and press the flat steel plate cut by the cutting machine into a car. Various stamping parts on the body; and spot welding robots, which are used to weld various body stamping parts into a complete body. A flexible and agile production line for new energy pure electric vehicle bodies provided by the present invention uses automatic production equipment such as cutting machines, stamping machines, and spot welding robots to cooperate with each other to realize rapid production of new energy electric vehicle bodies and improve production efficiency. The flexible production of automobile bodies can be realized by configuring different quantities of equipment in the process link.

Owner:江苏瑞普车业有限公司

Mobile door removal electric equipment

ActiveCN105598682BHigh degree of mechanization and automationGuaranteed uptimeVehicle componentsMetal working apparatusCar manufacturingEngineering

Owner:GAC HONDA AUTOMOBILE CO LTD

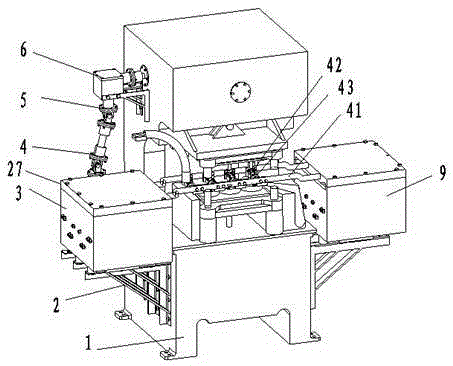

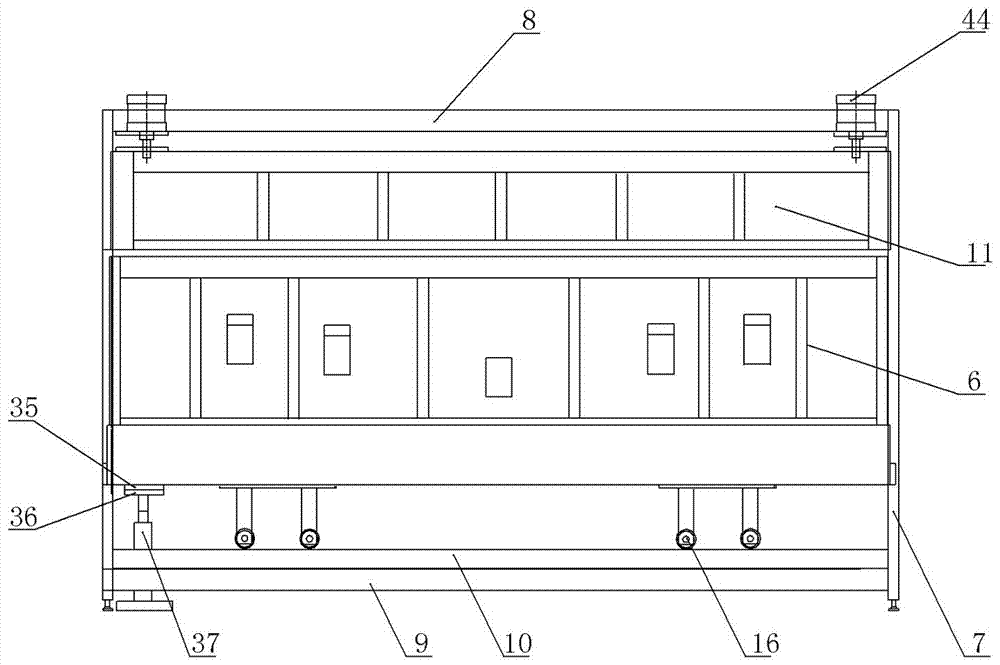

Automatic packaging machine for reinforcing steel bar connecting sleeve

InactiveCN109911307AAutomate the packaging processHigh degree of mechanization and automationWrapper twisting/gatheringIndividual articlesEngineeringRebar

The invention relates to an automatic packaging machine for a reinforcing steel bar connecting sleeve. The automatic packaging machine for the reinforcing steel bar connecting sleeve comprises a rack,a conveyor belt, a sorting device, a pushing device, a packaging device, a sealing device and an inclined slideway, wherein the rack comprises a left rack and a right rack; the conveyor belt comprises a left conveyor belt and a right conveyor belt with the same structure; an operation platform is arranged between the discharge end of the pushing device and the feeding end of the right conveyor belt; the sorting device and the pushing device are arranged above the left conveyor belt; the packaging device is arranged on the outer side of the left conveyor belt; the sealing device comprises a horizontal seal cutting device and longitudinal sealing device; and the inclined slideway is arranged at the tail end of the right rack. The automatic packaging machine for the reinforcing steel bar connecting sleeve provided by the invention is arranged left and right, and is reasonable in layout, compact in connection, fast in packaging speed, accurate, reliable in operation, and high in automation degree, the labor intensity of workers is greatly reduced, the packaging efficiency is improved, the packaging speed is accelerated, and the mechanized automation degree of the reinforcing steel barconnecting sleeve packaging field can be greatly improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

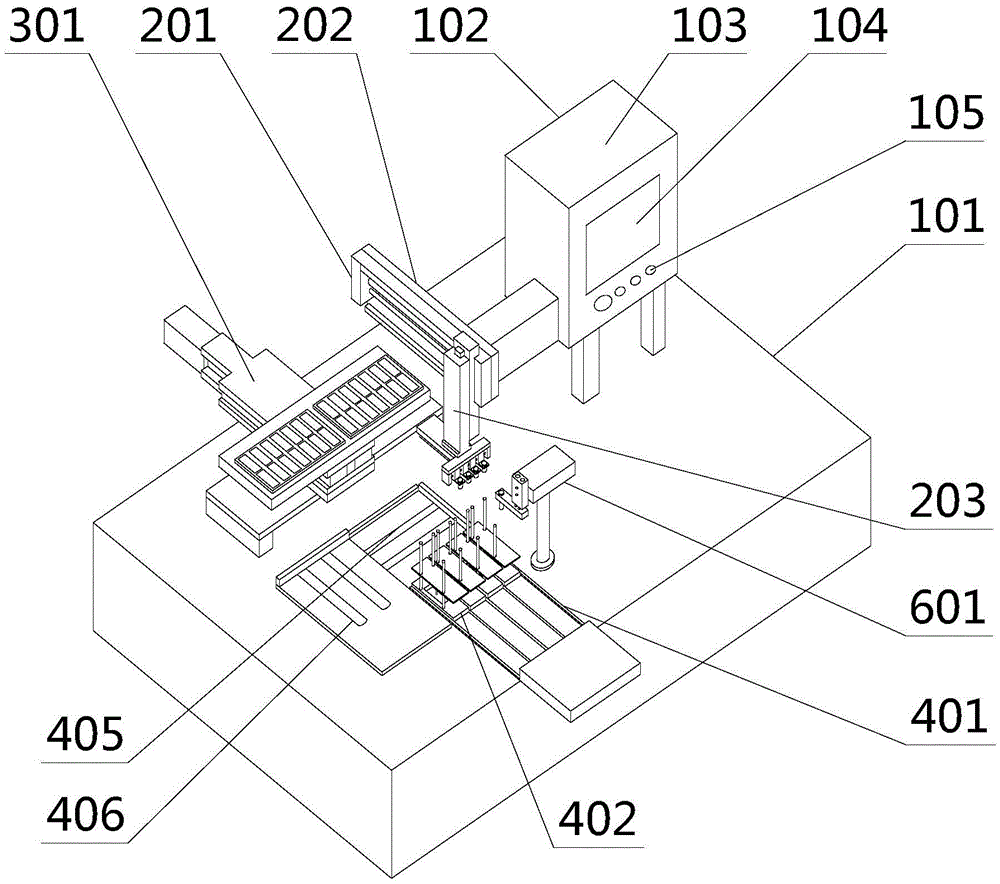

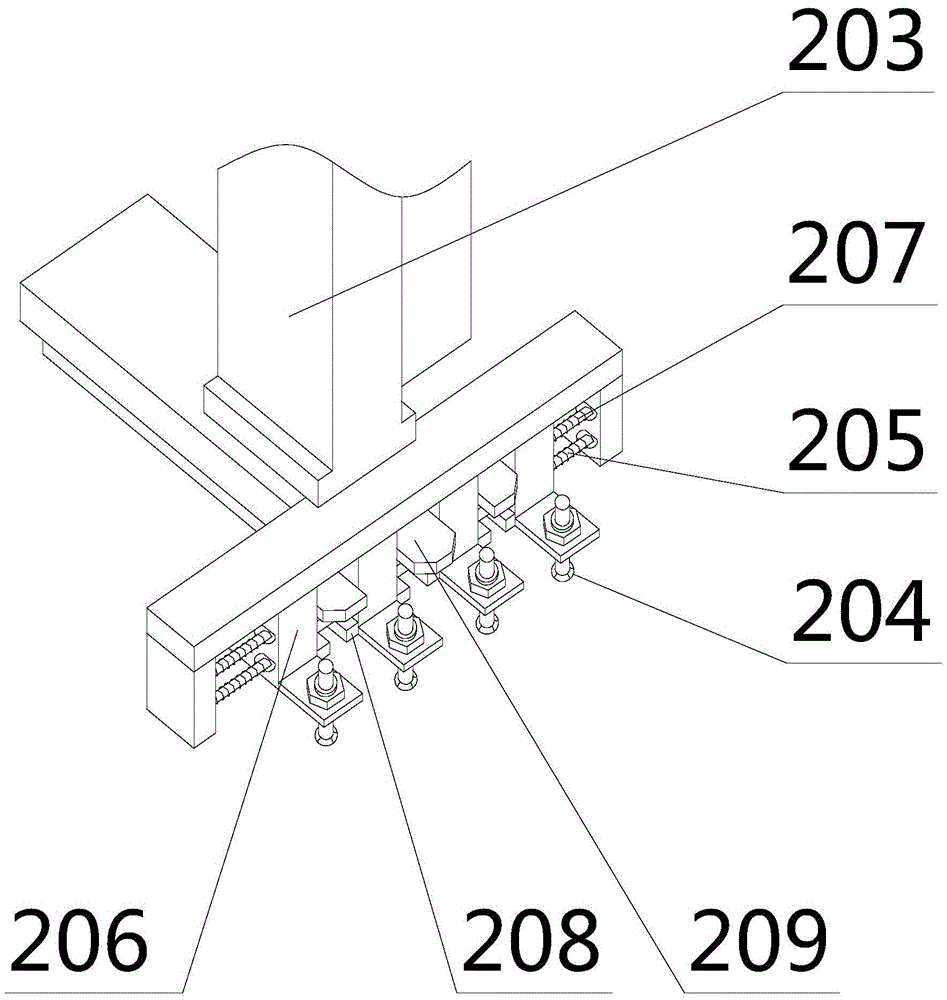

A feeding device for steel bar connecting sleeve blank extrusion molding

The invention relates to an extrusion forming feeding device for a rebar connecting sleeve blank and belongs to the technical field of extrusion forming equipment for the rebar connecting sleeve blank and the extrusion forming feeding device is used for conveying materials among stations in the extrusion forming process of the rebar connecting sleeve blank. According to the extrusion forming feeding device, a crank shaft of a pressure machine is utilized to output power which is transferred to a left case body and a right case body, and a manipulator execution part is driven to move by two gear transmission mechanisms, transverse transmission mechanisms, lifting transmission mechanisms and longitudinal clamping transmission mechanisms of the same structures, so as to complete conveying of the connecting sleeve blank among the stations. The extrusion forming feeding device fills up the blank of extrusion forming feeding equipment for the rebar connecting sleeve blank, provides a proper material conveying device for extrusion forming of the rebar connecting sleeve blank and has the advantages of reasonable layout, accuracy in feeding, reliability in operation. By using the extrusion forming feeding device, the mechanical automation degree in the extrusion forming of the rebar connecting sleeve blank can be greatly increased, and the extrusion forming feeding device has obvious meanings and effects on improving the production efficiency and increasing the economic benefits.

Owner:HEBEI YIDA REINFORCING BAR CONNECTING TECH

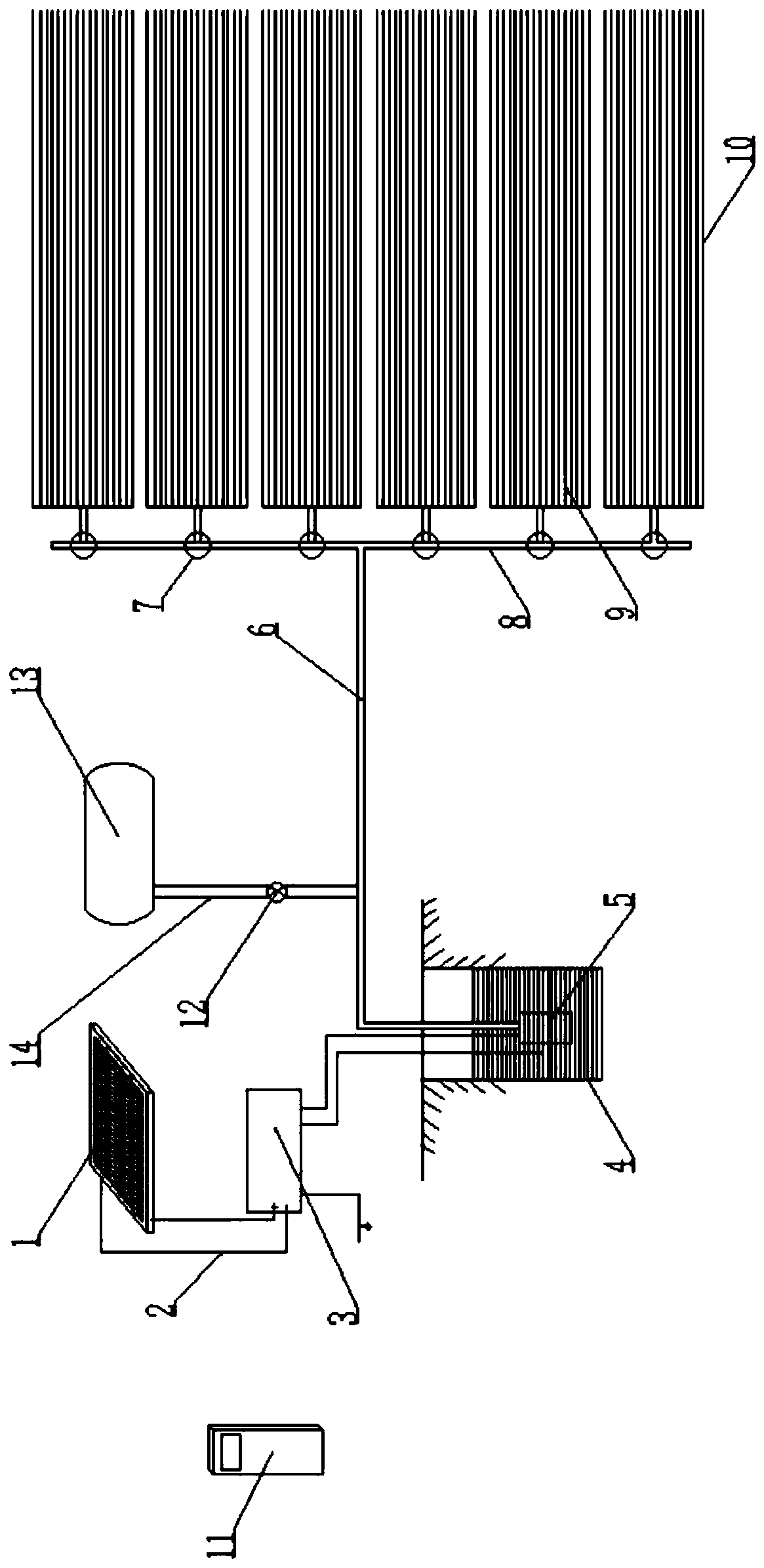

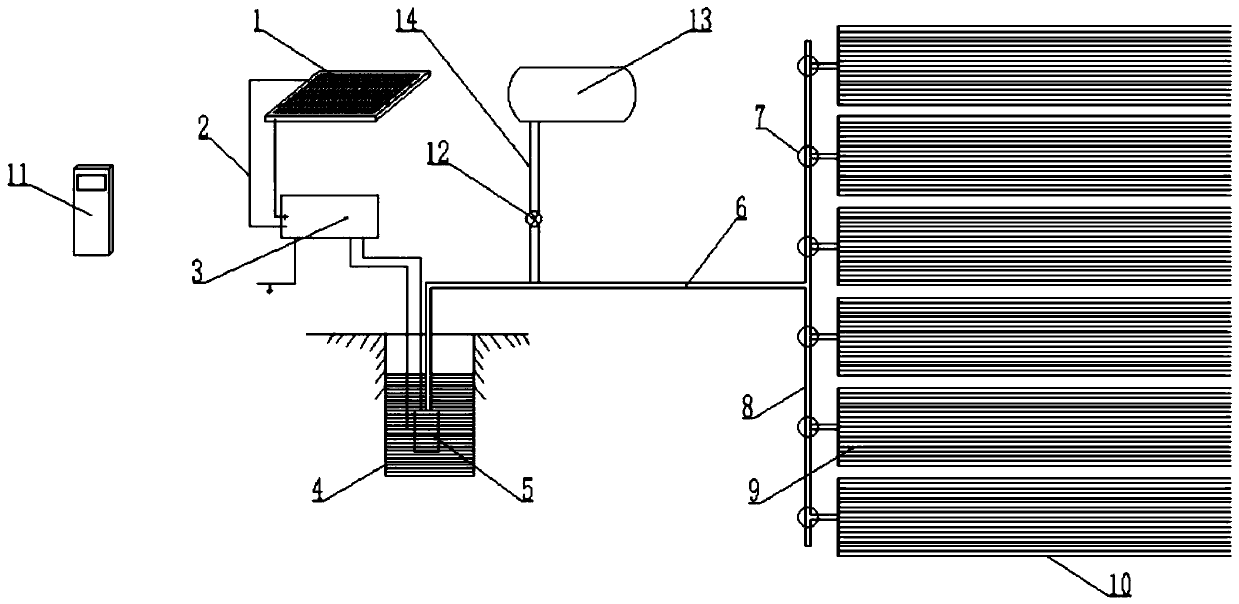

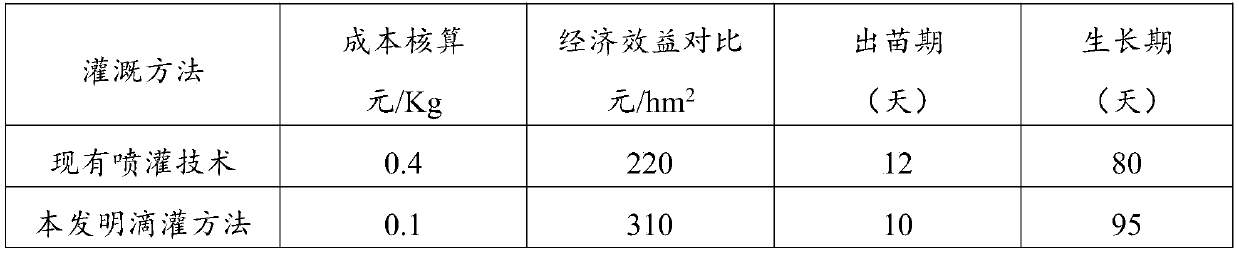

Solar intelligent dripping irrigation grassland improvement method

InactiveCN110024629ASolve intensive and improved productionGuaranteed outputHops/wine cultivationClimate change adaptationWater savingSolenoid valve

The invention provides a solar intelligent dripping irrigation grassland improvement method, and relates to the technical field of plant cultivation. The method includes the steps: grassland planning;grassland deeply loosening and shallowly plowing; grass seed re-sowing; intelligent dripping irrigation management. The grassland planning includes that one group of intelligent dripping irrigation facilities arranged on grasslands of every 33.4hm<2> and comprise photovoltaic batteries, cables, main control boxes, remote controls, pumping wells, submerged pumps, water outlet main pipelines, intelligent solenoid valves, water supply pipelines and dripping irrigation pipelines. According to the grassland improvement method, device investment is less, water is saved, cost accounting is low, economic benefits are remarkable, devices are convenient to mount and can be intelligently operated, and the improvement method is suitable for improvement of grasslands in north dry areas.

Owner:呼和浩特市博洋可再生能源有限责任公司 +1

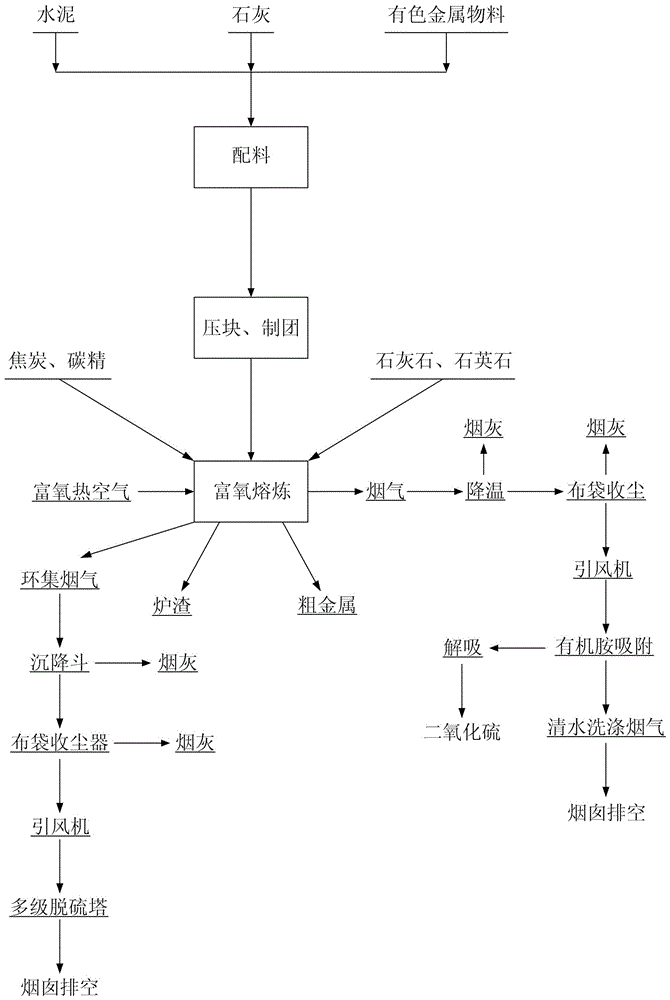

Process method for treatment of nonferrous metal material through energy-saving and environmental protection-type oxygen-rich smelting furnace

InactiveCN106498164AHigh strengthImprove melting efficiencyTransportation and packagingSolid waste disposalMixed materialsWater jacket

The invention discloses a process method for treatment of a nonferrous metal material through an energy-saving and environmental protection-type oxygen-rich smelting furnace. The method includes the following steps that (1) cement, lime and the nonferrous metal material are mixed to be blended, and then the mixed material is made to be in a block shape or pellet shape to obtain a block-shaped or pellet-shaped material; and (2) the obtained block-shaped or pellet-shaped material, limestone, quartz stone and coke or carbon buttons are added into the oxygen-rich smelting furnace to be smelted, oxygen-rich hot air is connected into the oxygen-rich smelting furnace in the smelting process, oxygen-rich concentration of the connected-in oxygen-rich hot air is adjusted through a distributed control system, a shell of the oxygen-rich smelting furnace is provided with a water jacket, the inner side of the water jacket is provided with a refractory concrete protecting layer, most rare and noble metals are gathered into crude metal after smelting is completed, and flue gas, cyclic collection flue gas, crude metal, soot and slag are obtained after smelting is over. By the adoption of the process method, smelting strength and smelting efficiency are high, the amount of flue gas is small, and energy saving and environmental protection can be realized.

Owner:HUNAN ZHONGDA JOINT INNOVATION & TECH DEV CO LTD

Autoloader

ActiveCN104477647BPrecise suctionHigh degree of mechanization and automationConveyor partsControl systemManipulator

The invention provides an automatic tray filler and belongs to the technical field of automatic tray filling of mobile phone shielding cases. The automatic tray filler is used for placing a shielding case to a corresponding position of a tray and comprises a filler body, a mobile platform device, a manipulator, a feed device and a controlling system. The manipulator comprises a mechanical arm and a grasping portion, wherein the grasping portion comprises a grasping body, a plurality of suction nozzles and a distance adjusting device. The grasping body is provided with a rail, the suction nozzles are slidingly connected with the rail through connecting blocks, reset springs are respectively arranged at the two ends of the rail in a sleeved mode, the connecting blocks are provided with limiting blocks, and the limiting blocks are arranged between two adjacent connecting blocks. The distance adjusting device comprises a slant wedge and an executive element, the executive element is used for driving the slant wedge to stretch out of and retract from the interval between two adjacent connecting blocks. By the automatic tray filler, automatic tray filling of the shielding case is achieved, level of mechanization and automatization is high, tray filling efficiency is improved, and the automatic tray filler is suitable for the tray filling when the interval between the feed device and the shielding case is larger.

Owner:CHENGDU HOMIN TECH

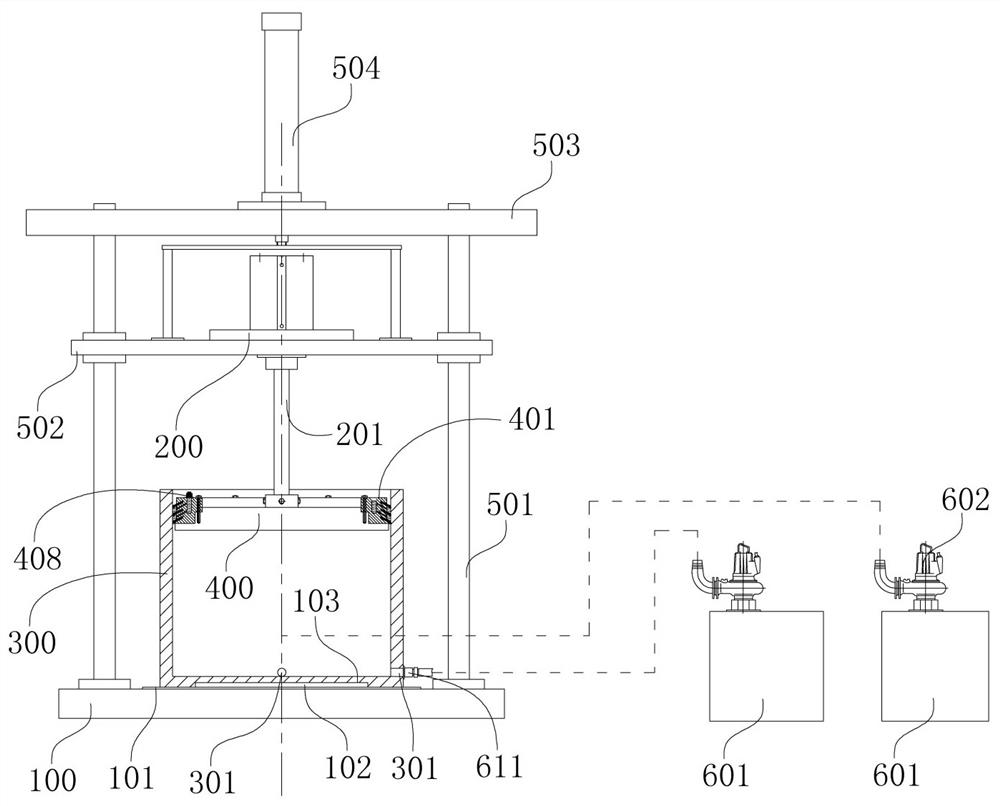

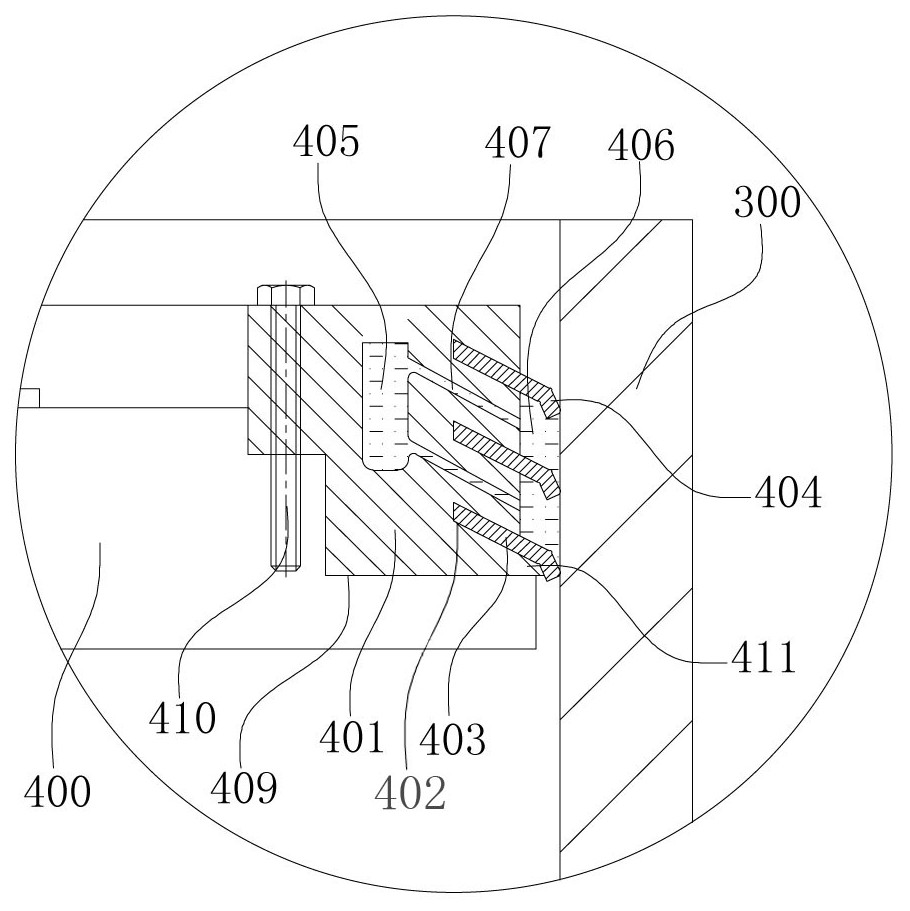

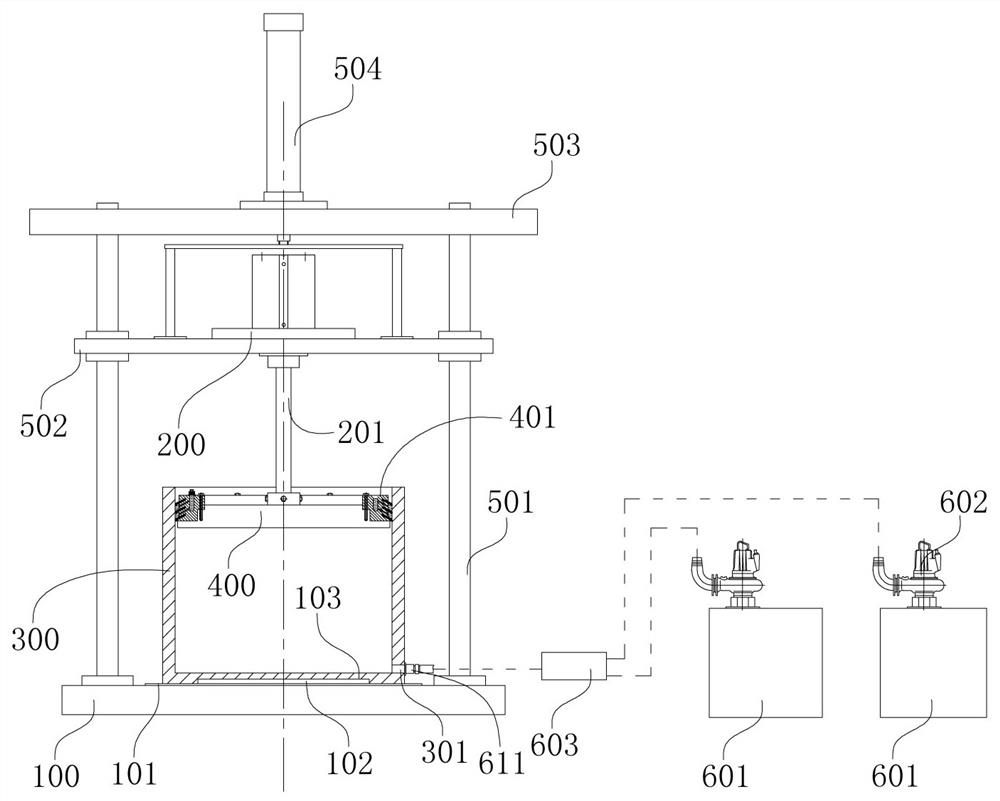

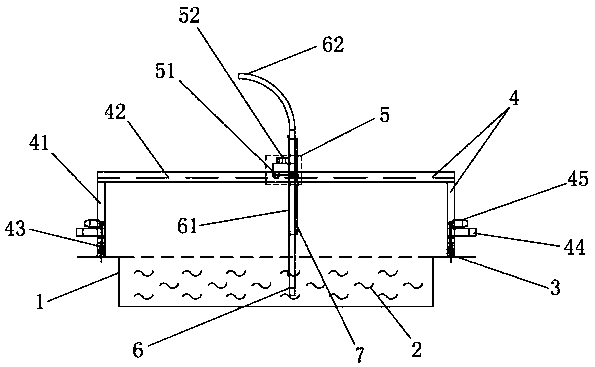

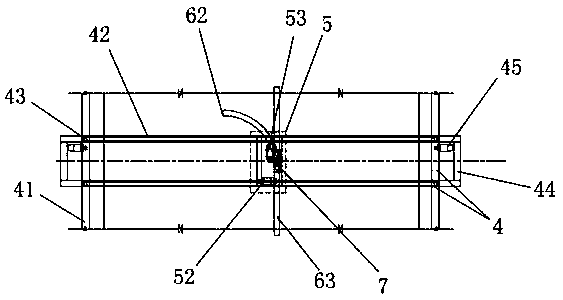

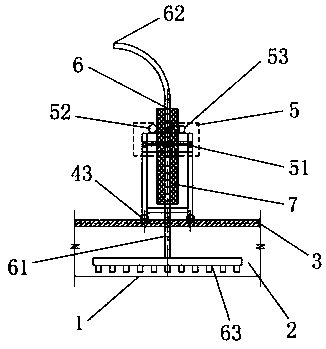

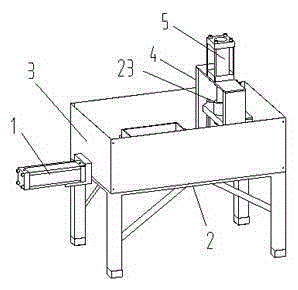

Polyurethane rheological property testing device and method

The invention belongs to the technical field of rheological property testing and relates to a polyurethane rheological property testing device. The polyurethane rheological property testing device comprises a base, a rheometer, a mold shell and a shearing plate; a rotating shaft corresponding to the base is arranged at the lower part of the rheometer; the mold shell is arranged on the base; the top of the mold shell is open; the shearing plate is arranged at the lower part of the rotating shaft; the shearing plate is arranged at the top of the mold shell in a matched manner; a sealing unit isarranged between the shearing plate and the side wall of the mold shell; the rotating shaft drives the shearing plate to rotate in the mold shell; the sealing unit is used for sealing the top of the mold shell; and a grouting hole is formed in the mold shell or the shearing plate and is connected with a slurry unit. The invention further discloses a polyurethane rheological property testing method. The density of a material can be controlled by controlling a grouting amount, and meanwhile, the difference between rheological properties of grout formed after grouting and rheological properties of grout formed by stirring and mixing can be tested.

Owner:ZHENGZHOU UNIV

Rubber gasket framework reshaping device

The invention relates to an apron skeleton shaping device. A linear plate conveying device is provided under the frame through a support frame. A first manipulator and a second manipulator are arranged on both sides of the plate conveying device. The linear plate conveying The device is provided with a plurality of positioning slots for placing the apron skeleton positioning device at intervals, the lower part of the frame is provided with cutting positioning holes, and the support frame is provided with a linear plate that can pass through the push rod. A lifting device that jacks up the apron skeleton positioning device into the cutting positioning hole through a reserved hole on the conveying device. The invention can automatically sense the position of the positioning groove, and when it senses that the positioning groove moves below the cutting positioning hole, it controls the hydraulic cutting device to move downward, and completely removes and cleans the burrs on the inner wall of the rubber ring at one time, greatly improving the processing efficiency.

Owner:TIANJIN FULIDA RUBBER PROD

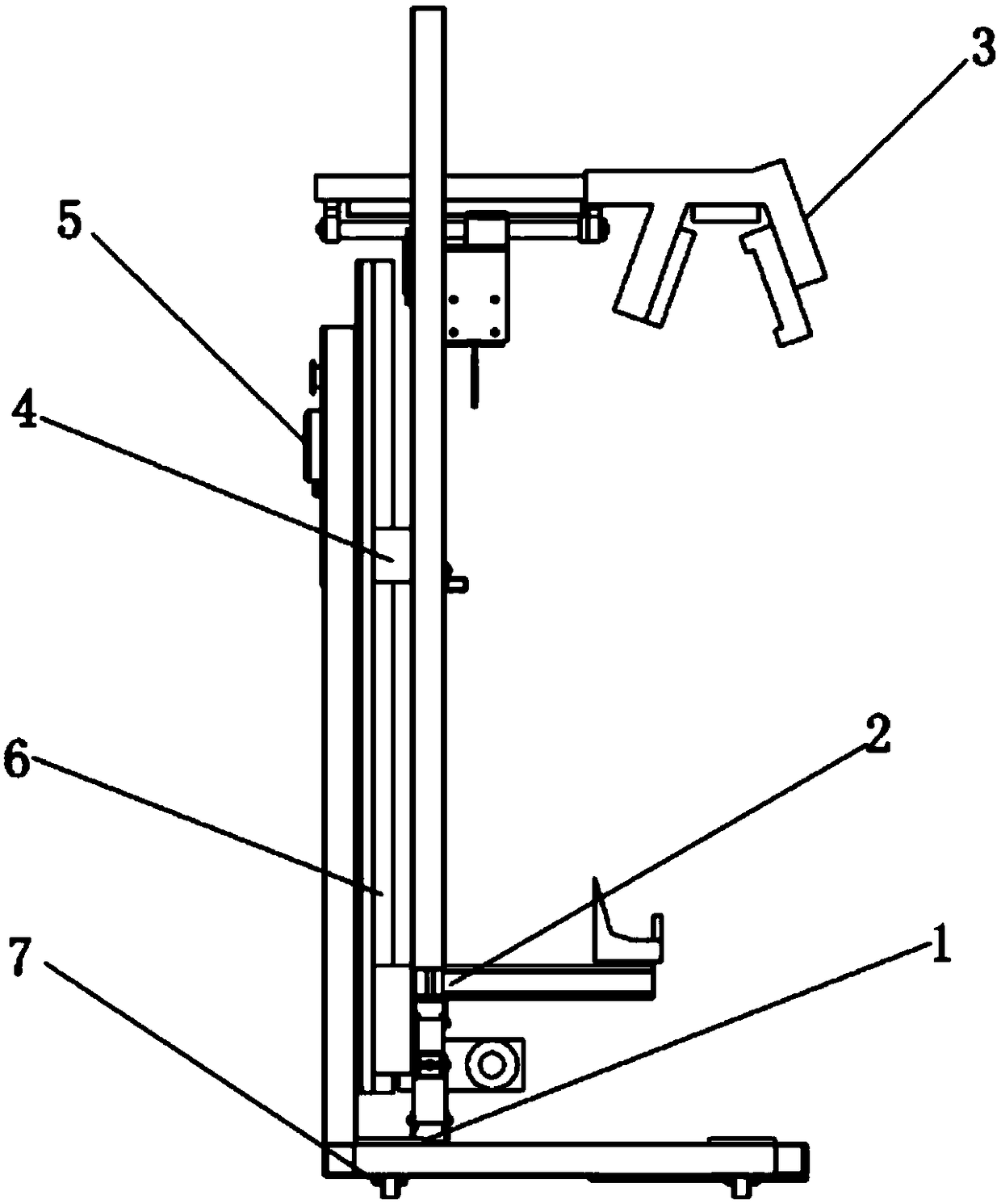

Rocker arm welding gun with secondary switch-on function

InactiveCN106041286AEasy to useHigh degree of mechanization and automationResistance electrode holdersRocker armStructural dimension

The invention belongs to car part welding devices, and particularly relates to a rocker arm welding gun with a secondary switch-on function. The rocker arm welding gun comprises a rocker arm base, a welding gun device and an exchange device, and the welding gun device and the exchange device are arranged on the rocker arm base. The welding gun device comprises a mounting seat, a pressurizing air cylinder, an electrode arm, a first electrode tip and an electrode cap. The exchange device comprises an air cylinder, a movable column and a fixed seat. The rocker arm welding gun with the secondary switch-on function is novel point welding equipment applied to modern car body welding lines, two sets of welding gun bodies are integrated on the exchange device, and when one welding gun body is abraded or breaks down in the welding process, secondary switch-on welding can be carried out through the exchange device, so that the whole device is convenient to use, high in mechanization and automation degree and stable in welding quality. Compared with a point welding robot, the rocker arm welding gun has the beneficial effects of being low in cost and investment, small in structural dimension and good in welding proximity.

Owner:合肥亿翔智能制造有限公司

Multi-sprayer foam concrete spreading device and operation method

PendingCN108691417AEasy to operateGood fabric effectBuilding material handlingComplex mathematical operationsFoam concreteSprayer

The invention discloses a multi-sprayer foam concrete spreading device and operation method, and belongs to the field of foam concrete construction. The multi-sprayer foam concrete spreading device mainly comprises a moving frame, a mobile station, a spreading rod and the like; and is characterized in that 1, the number and inner diameters of sprayers can be selected from multiple schemes, the universality is high, the device is suitable for various types of foaming machines and delivery pumps, the flow velocity of foam concrete slurry is adjustable, and a best foam concrete spreading effect can be achieved; 2, the sprayers disperse the kinetic energy of the slurry intensively ejected from the tail end of a delivery hose, weaken the impact force, reduce the probability that multiple smallpores are communicated with one other to form big pores, and improve the compressive strength of foam concrete; 3, the mechanical automation degree is high, operators are reduced, the labor intensityis reduced, the sanitary conditions of environmental protection are improved, artificial disturbance is avoided, and the solidification quality of the foam concrete is improved. The multi-sprayer foamconcrete spreading device is combined with the corresponding operation method, so that the spreading efficiency and quality can be improved, energy is saved, emission is reduced, and the economic benefits and social benefits are significant.

Owner:NINGBO COMM ENG CONSTR GRP

A Loose Handle Straightening Device for Recycling Waste Steel Wire Rope

InactiveCN104148362BReasonable layoutHigh degree of mechanization and automationSolid waste disposalRope making machinesFixed lengthAutomation

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

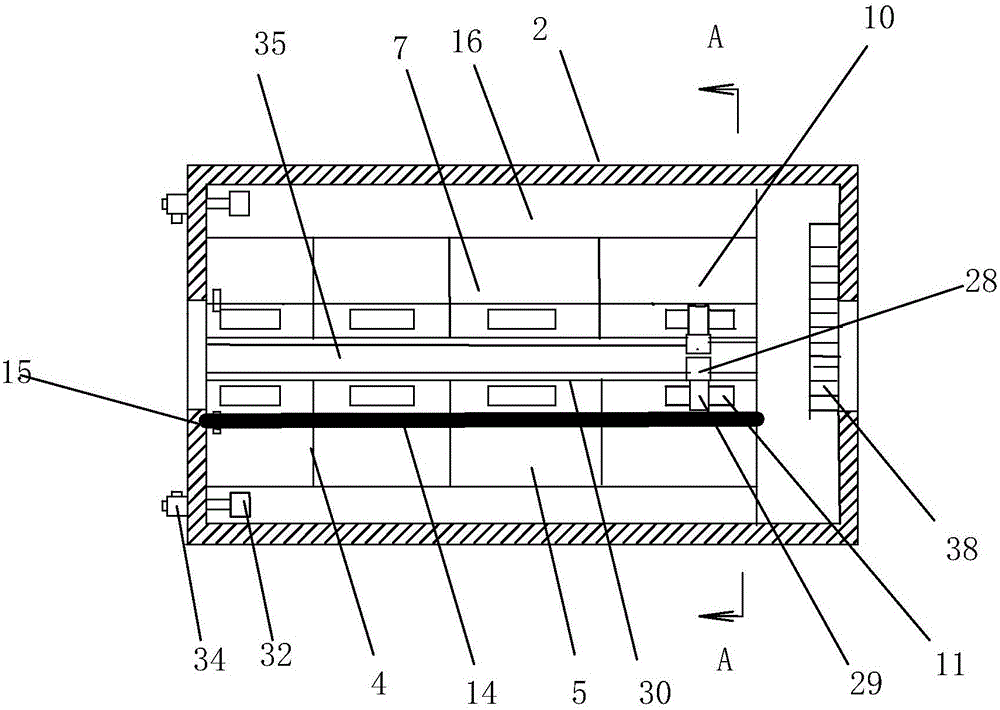

Continuous hot bending furnace for front windshield of large passenger car

ActiveCN104773948BReasonable structural designMove steadily and safelyGlass reforming apparatusAutomatic controlCooling chamber

The invention relates to hot bending furnace equipment, in particular to a continuous hot bending furnace for large bus front windshield. The continuous hot bending furnace is in a circulated rectangular ring shape and comprises a plurality of heating chamber units, cooling chamber units, an upper piece ferry unit, a ferry channel unit, a glass car and an automatic control system, wherein the heating chamber units are transversely arranged side by side, the cooling chamber units are parallel to the heating chamber units, and the upper piece ferry unit and the ferry channel unit are arranged at the two ends of the heating chamber units and the cooling chamber units. The continuous hot bending furnace is reasonable in structural design and is of a rectangular circulated structure on the whole, a ferry carrier vehicle and a traction vehicle are matched for solving the turning problem in the circulated structure, turning movement can be stably and safely achieved, meanwhile, the traction vehicle is the running power of the whole system, the overall structure is reasonable in design, and operation control is convenient.

Owner:山西利虎玻璃(集团)有限公司 +1

Feeding device of thread rolling machine

InactiveCN112775367ARealize automatic feeding processAvoid shakingMetal-working feeding devicesScrew-threads articlesMachineIndustrial engineering

The invention discloses a feeding device of a thread rolling machine, and relates to the technical field of bolt manufacturing equipment. A machine body of the device comprises a feeding port and a discharging port, wherein an inclined feeding track is arranged on the feeding port; an inclined discharging track is correspondingly arranged on the discharging port; the feeding port is lower than the discharging port; a conveying mechanism is arranged at the position, between the feeding port and the discharging port, in the machine body; the conveying mechanism comprises a conveying plate; one end of the conveying plate makes contact with the feeding port while the other end of the conveying plate is flush with the discharging port; and the conveying mechanism further comprises a lifting part used for driving the conveying plate to ascend and descend back and forth between the feeding port and the discharging port. According to the feeding device, semi-finished parts can be automatically fed, the semi-finished parts are continuously conveyed to a feeding channel at a constant speed, it is guaranteed that the thread rolling machine is in a working state all the time, manual carrying is not needed, the manpower consumption is greatly reduced, the overall machining efficiency is improved, meanwhile, the overall mechanization and automation degree of the thread rolling machine is improved, the cost is reduced, and the yield is increased.

Owner:无锡泓明固科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com