Cupric electrolysis remnant pole processing method and device thereof

A technology for processing equipment and processing methods, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of high energy consumption, slow melting speed, and low thermal efficiency, and achieve the effects of low cost, accelerated melting speed, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings and in conjunction with specific embodiments.

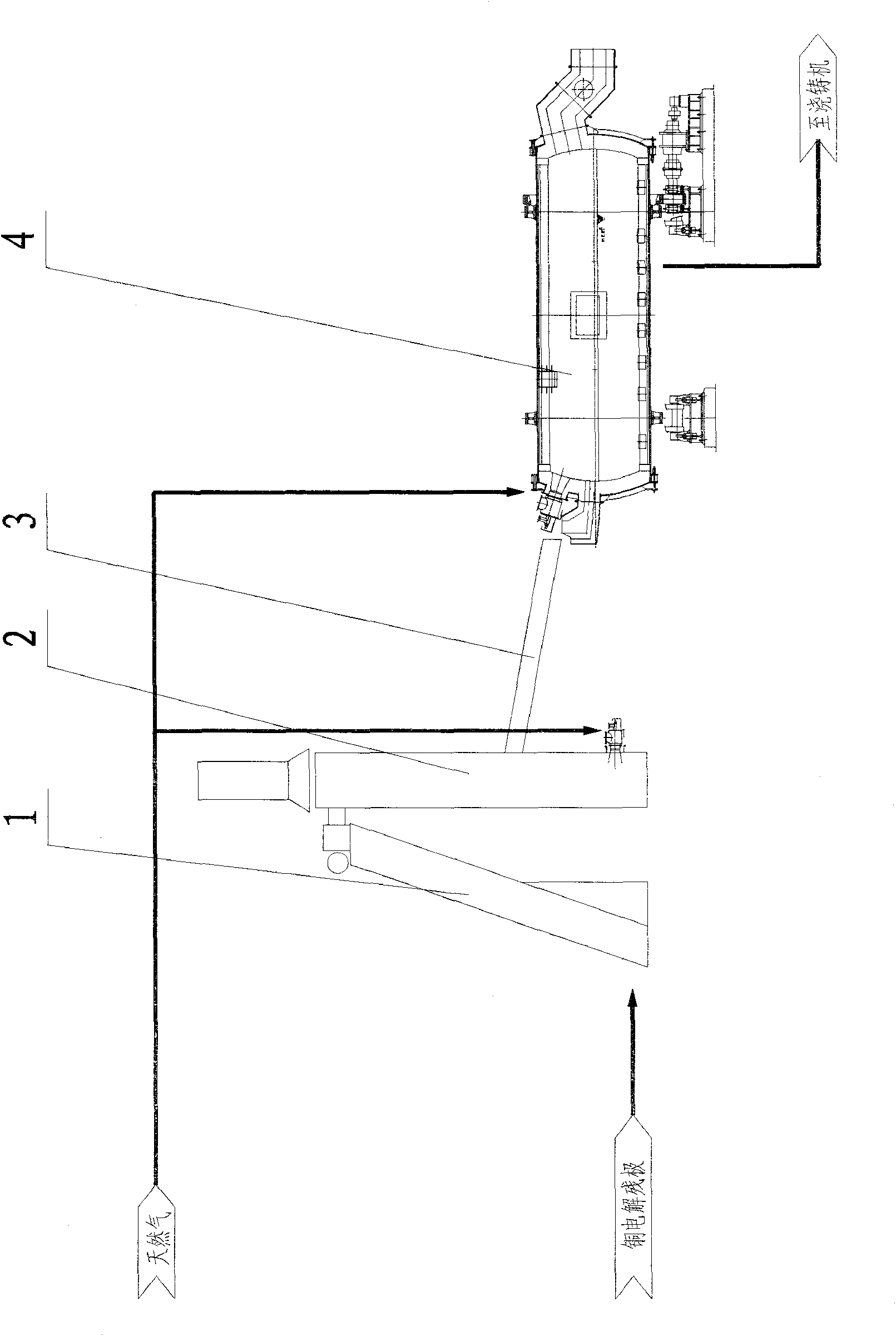

[0028] A device for processing copper electrolytic residual poles in a large-scale copper smelting plant using a continuous blowing process, including a bucket elevator 1, a shaft furnace 2 with a height of 20m, and a heat-insulating furnace between the shaft furnace 2 and the heat-insulating rotary furnace 4 Chute 3, insulation rotary furnace 4 and casting machine ( figure 2 not shown in).

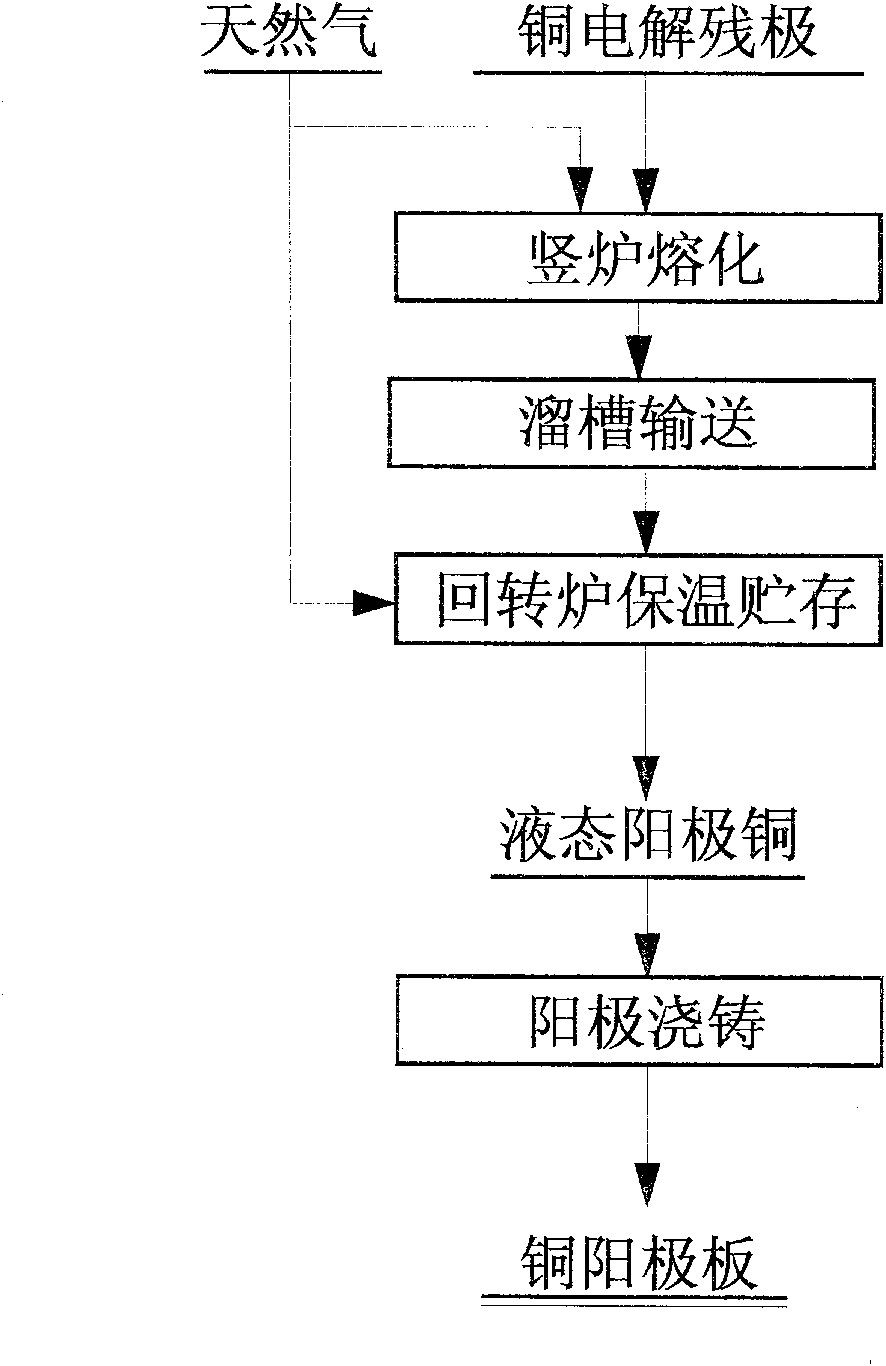

[0029] The method for the equipment of this specific embodiment to process copper electrolytic residual poles has the following steps:

[0030] Feeding and melting: Put the packaged copper electrolytic residues into the hopper through a forklift, and then lift them along the track through the bucket elevator 1 to the feeding port of the shaft furnace 2. The shaft furnace 2 uses natural gas or coal gas as a fuel to provide heat source. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com