Process method for treatment of nonferrous metal material through energy-saving and environmental protection-type oxygen-rich smelting furnace

A non-ferrous metal, energy-saving and environment-friendly technology, applied in the field of metallurgy, can solve the problems of insufficient smelting flue gas desulfurization depth, substandard tail gas emissions, and low smelting intensity, and achieve the effects of good production environment, improved smelting intensity, and improved smelting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

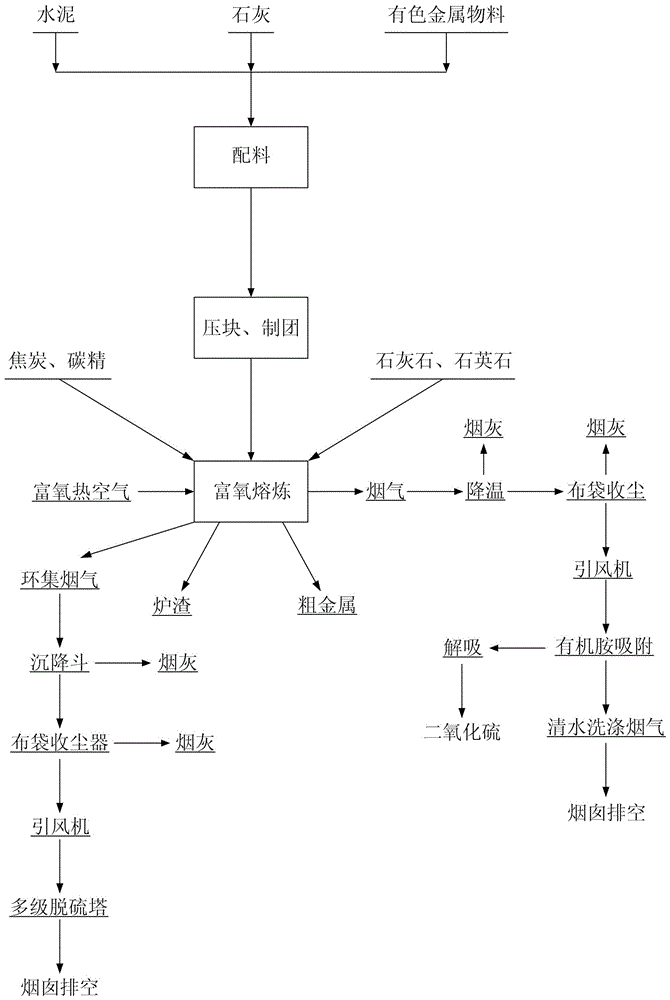

[0028] An embodiment of the process method of the present invention using an energy-saving and environment-friendly oxygen-enriched smelting furnace to process non-ferrous metal materials, the process flow chart is as follows figure 1 shown. This processing method specifically comprises the following steps:

[0029] (1) Mix 30 kg of cement, 20 kg of lime, 50 kg of electronic sludge, 100 kg of copper slag, 20 kg of gold and silver-containing slag, 30 kg of iron oxide powder and 150 kg of copper oxide ore, and then mix the ingredients Made into agglomerates to obtain lumps or pellets.

[0030] (2) After natural air-drying or drying of the block or pellet-like materials obtained in step (1), add them together with 40kg of limestone, 10kg of quartz stone and 80kg of carbon essence into an energy-saving and environment-friendly oxygen-enriched smelting furnace for smelting; The main chemical components contained in the added mixed material and their mass percentages are: Cu 18%, ...

Embodiment 2

[0033] An embodiment of the process method of the present invention using an energy-saving and environment-friendly oxygen-enriched smelting furnace to process non-ferrous metal materials, the process flow chart is as follows figure 1 shown. This processing method specifically comprises the following steps:

[0034] (1) Mix and mix 10 kg of cement, 20 kg of lime, 80 kg of lead slag, 20 kg of lead soot, 200 kg of lead oxide ore, 10 kg of silver-containing slag, and 20 kg of iron oxide powder, and then make the mixture into balls Agglomerates or lumps to obtain lumps or pellets.

[0035] (2) After natural air-drying or drying of the block or pellet-like materials obtained in step (1), add them together with 50 kg of limestone, 10 kg of quartz stone and 80 kg of coke into an energy-saving and environment-friendly oxygen-enriched smelting furnace. Melting; the main chemical components contained in the added mixed material and their mass percentages are: Pb 30%, FeO 19%, CaO 12%,...

Embodiment 3

[0038]An embodiment of the process method of the present invention using an energy-saving and environment-friendly oxygen-enriched smelting furnace to process non-ferrous metal materials, the process flow chart is as follows figure 1 shown. This processing method specifically comprises the following steps:

[0039] (1) Mix and mix 10 kg of cement, 20 kg of lime, 200 kg of copper concentrate, 100 kg of copper slag, 20 kg of gold-containing slag, and 30 kg of iron oxide powder, and then make the mixture into a lump to obtain a lump shaped or pelletized materials.

[0040] (2) After natural air-drying or oven-drying of the block or pellet-like materials obtained in step (1), add them together with 40 kg of limestone, 10 kg of quartz stone and 70 kg of coke into an energy-saving and environment-friendly oxygen-enriched melting furnace for melting ; The main chemical components contained in the added mixed material and their mass percentages are: Cu 20%, FeO 20%, CaO 10%, SiO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com