Automatic packaging machine for reinforcing steel bar connecting sleeve

A technology of automatic packaging machine and steel bar connecting sleeve, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high labor intensity, time-consuming and laborious, low work efficiency, etc., to reduce labor intensity, speed up packaging, packaging fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

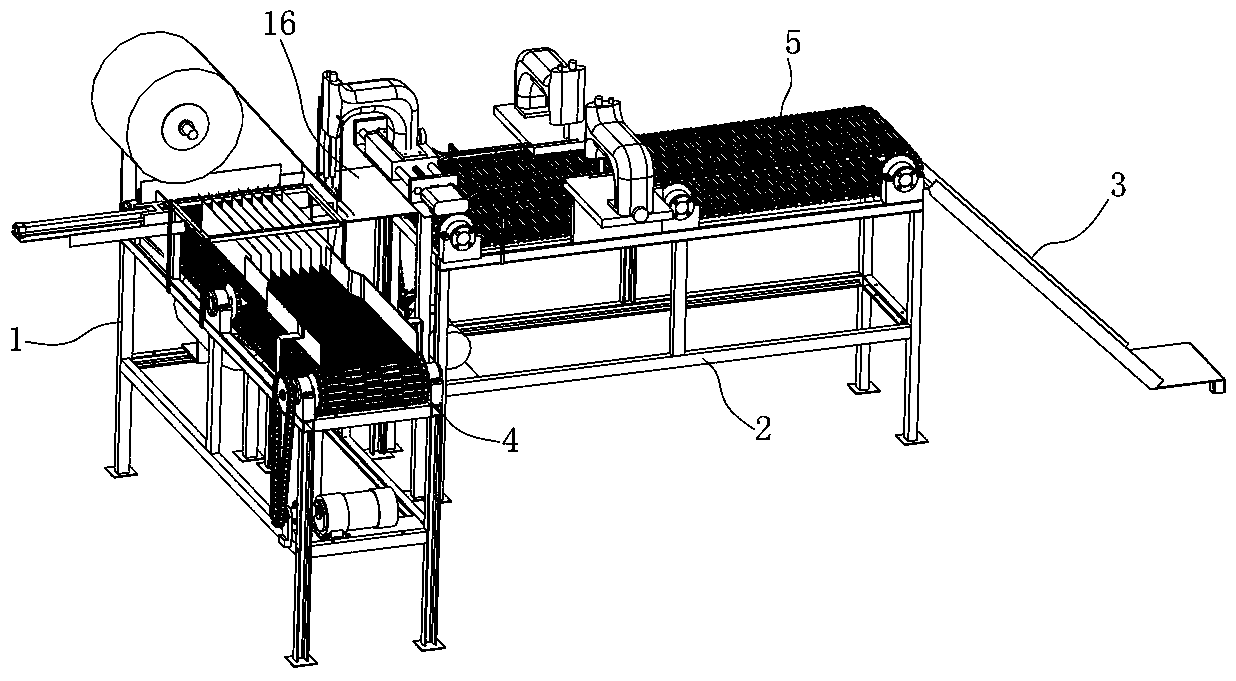

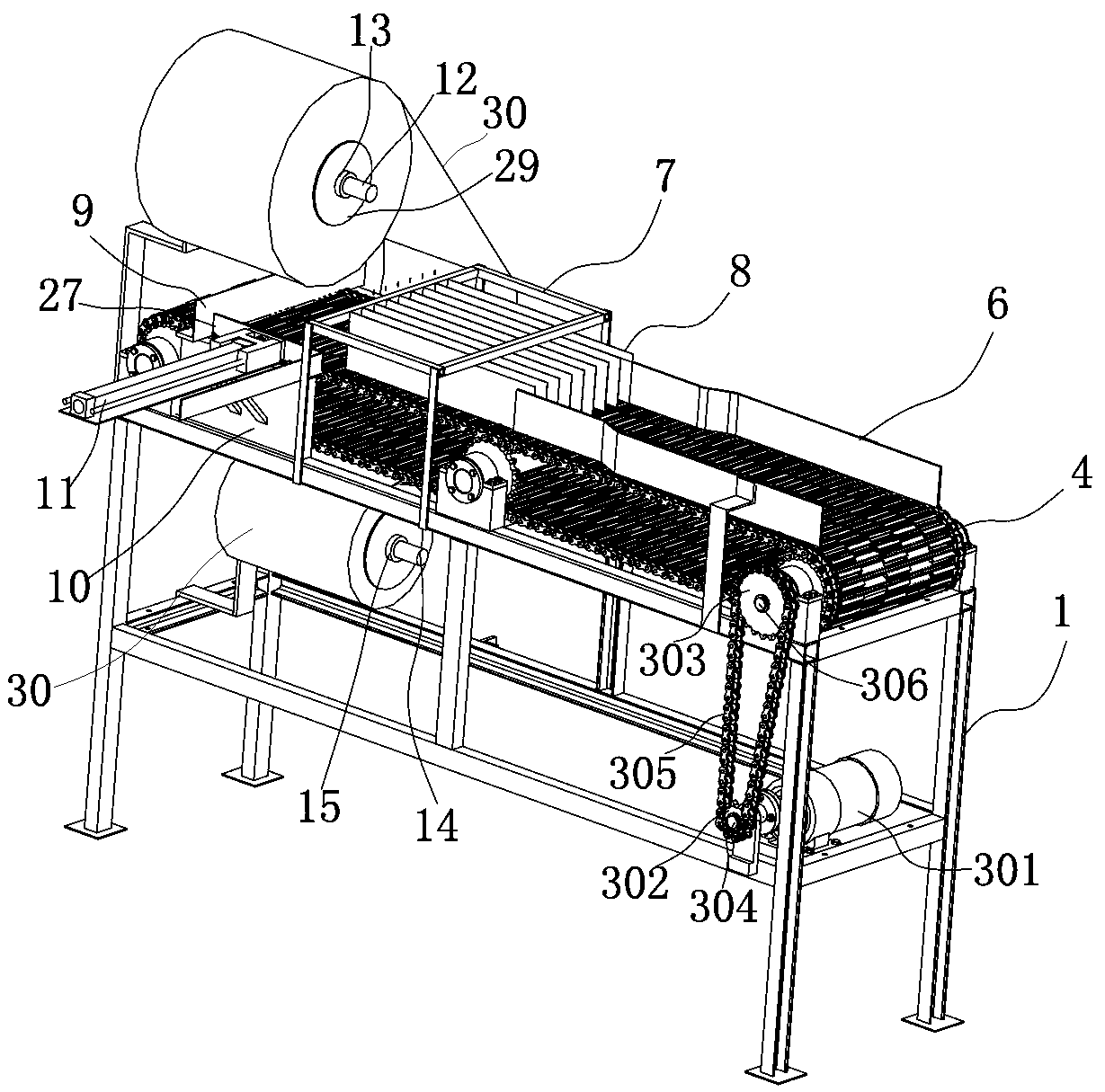

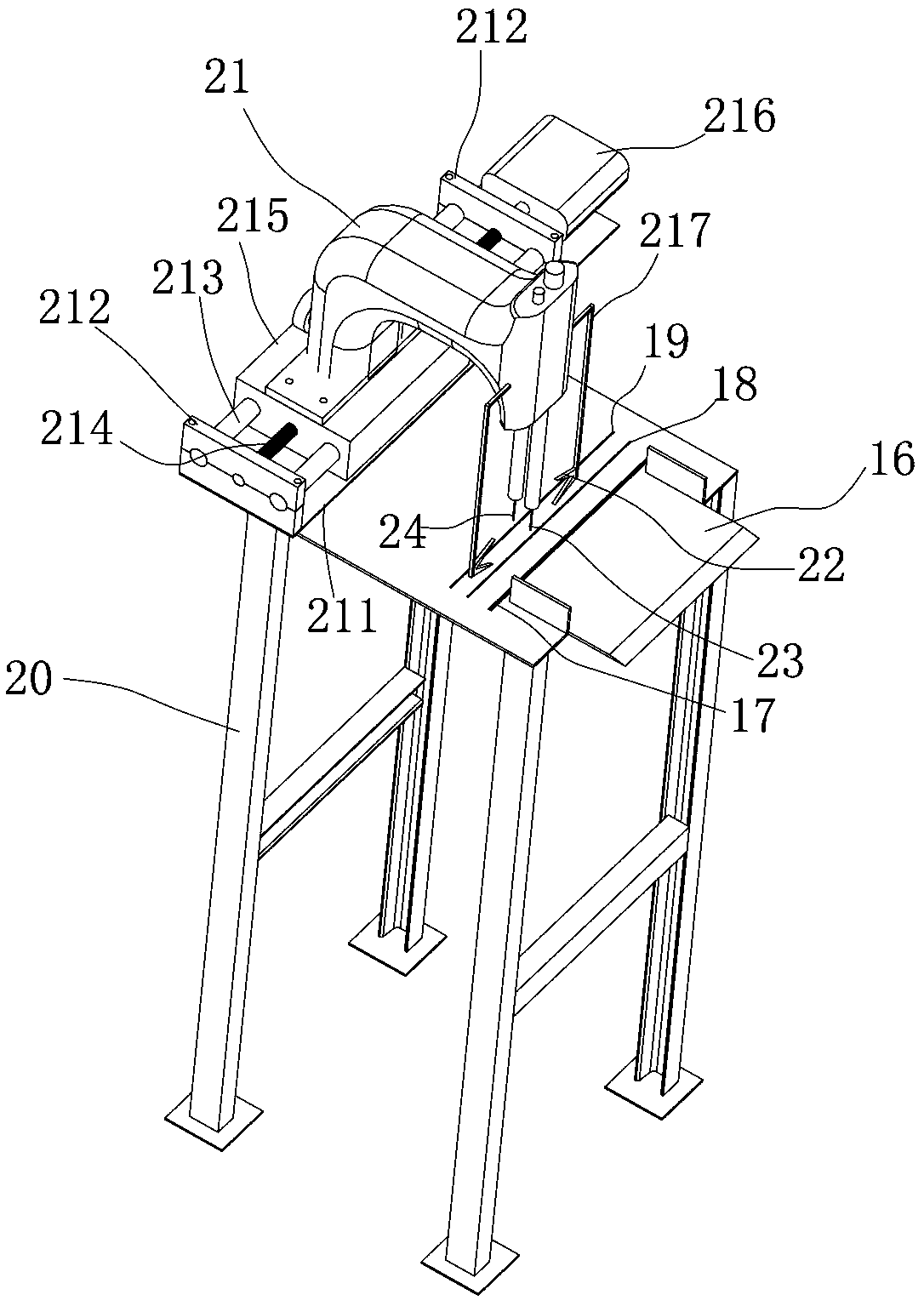

[0022] as attached Figure 1-5 As shown, the present invention includes a frame, a conveyor belt, a finishing device, a pushing device, a packaging device, a sealing device and an inclined slideway 3; Type PLC controller control; the frame includes a left frame 1 arranged vertically and a right frame 2 arranged horizontally outside the end of the left frame 1; The left conveyor belt 4 and the right conveyor belt 5 installed on the right frame 2, the left conveyor belt 4 and the right conveyor belt 5 are chain plate conveyor belts; the structure of the left conveyor belt 4 and the right conveyor belt 5 The same; the left conveyor belt 4 and the right conveyor belt 5 are respectively composed of geared motors, couplings, small sprockets, large sprockets, sprocket shafts, keys, chains, chain plate conveyor belts, chain plate shafts, rolling bearings and bearing seats. Drive, the deceleration motor drives the coupling to drive the sprocket shaft to rotate, the small sprocket is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com