Fruit packaging system for improving packaging efficiency

A packaging system and fruit technology, applied in the field of fruit packaging system, can solve the problems of unable to realize automatic packaging of foam net, high maintenance cost, low efficiency of apples, etc., achieve low production cost, low maintenance cost, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

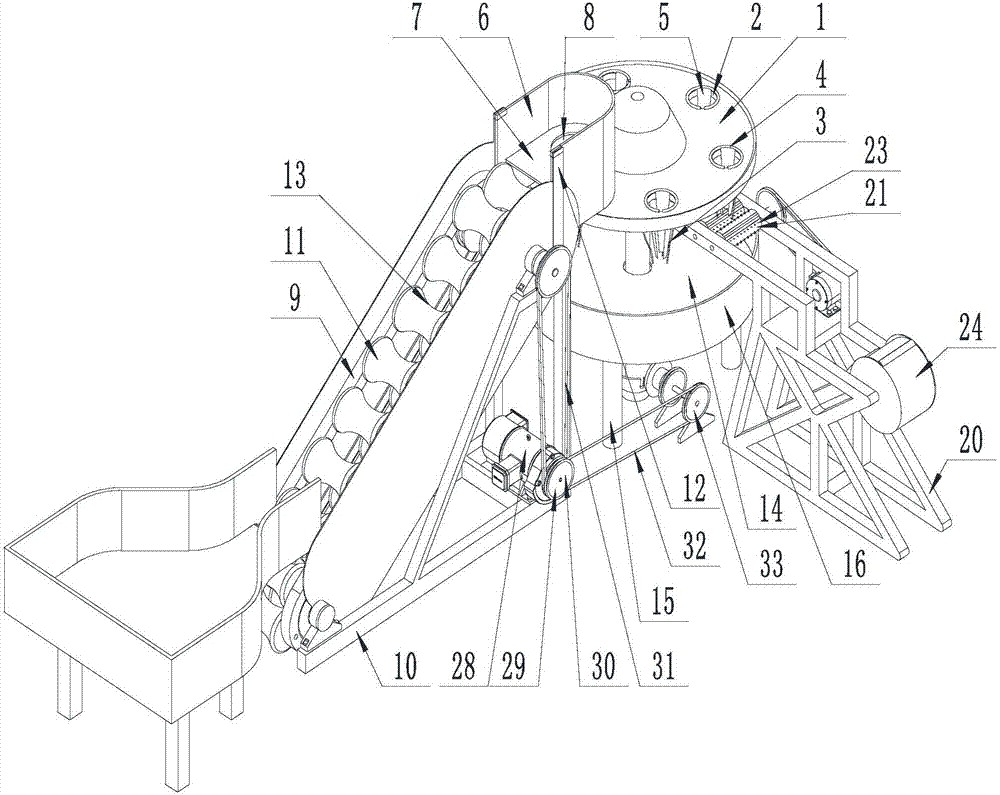

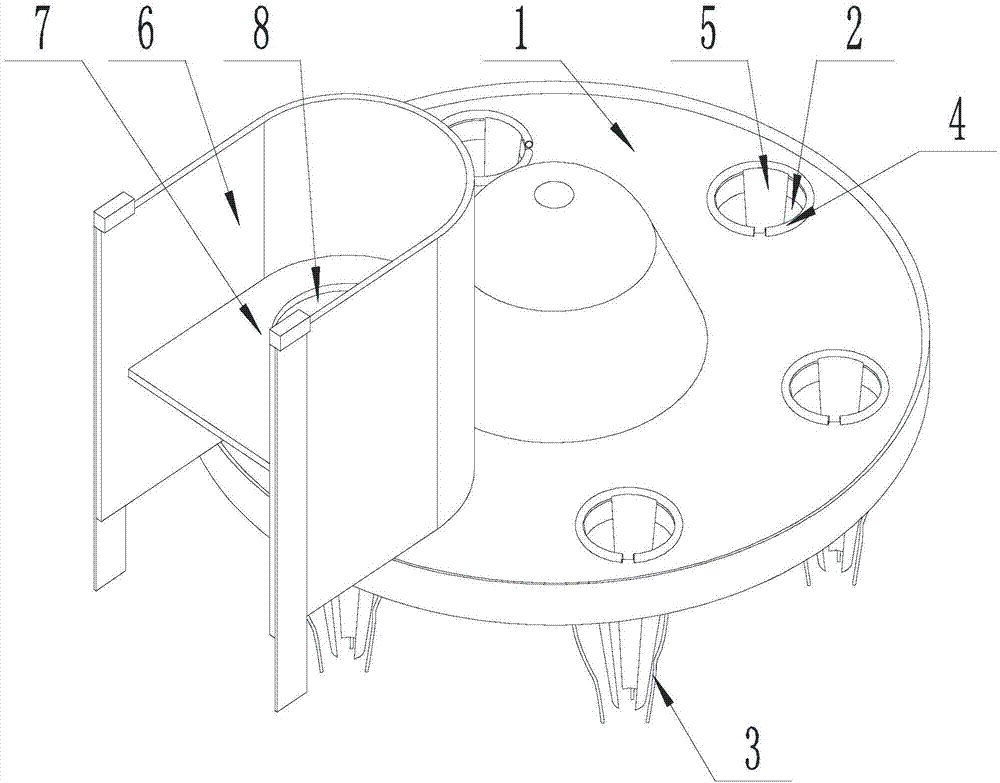

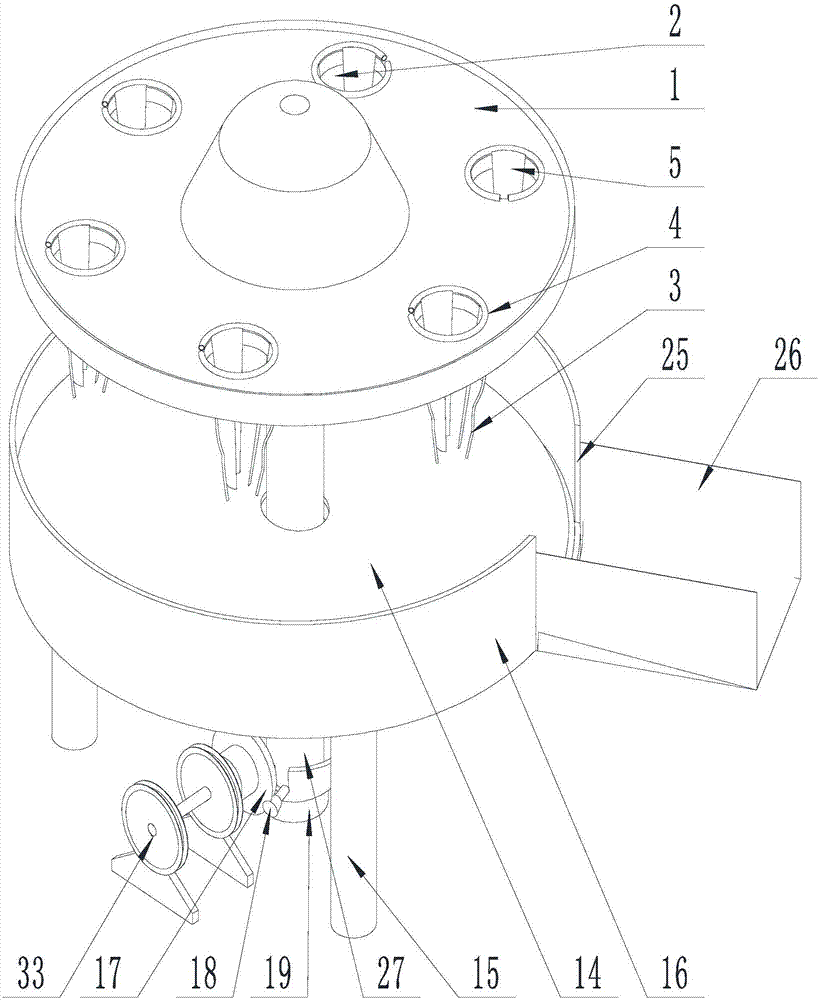

[0043] Such as Figure 1-Figure 4 As shown, the fruit packaging system for improving packaging efficiency of the present invention includes a conveying device, the distance between the discharge end of the conveying device and the ground is greater than the distance between the feeding end and the ground, and the discharging end of the conveying device is provided with Foaming mesh set-up mechanism, the set-up mechanism includes a turntable 1 connected in sequence and an intermittent drive mechanism, the intermittent drive mechanism drives the turntable 1 to rotate around its own axis; the turntable 1 is symmetrically arranged along its axis center Several fruit receiving holes 2 are provided with several support rods 3 on the end of the fruit receiving hole 2 close to the ground, and the distance between the support rods 3 on each fruit receiving hole 2 and the axis of the corresponding fruit receiving hole 2 increases with the distance from the receiving fruit hole 2. Fruit ...

Embodiment 2

[0047] This embodiment is based on the above embodiments to further illustrate the present invention.

[0048] Such as Figure 1-Figure 4 As shown, in the fruit packaging system for improving packaging efficiency of the present invention, a steel ring 4 is provided on the end of the fruit receiving hole 2 away from the ground, and the axis of the steel ring 4 coincides with the axis of the corresponding fruit receiving hole 2 . The steel ring 4 has a circular cross section with a smooth surface, and the radius of the inner surface of the steel ring 4 is consistent with the radius of the fruit-receiving hole 2 . The setting of the steel ring 4 prevents the sliding or rolling of the apples during long-term use, and wears the opening of the fruit receiving hole 2 .

[0049] Further, several rubber plates 5 are arranged on the hole wall of the fruit-receiving hole 2, and one end of the rubber plate 5 close to the ground extends out of the fruit-receiving hole 2, and with the exte...

Embodiment 3

[0055] This embodiment is based on the above embodiments to further illustrate the present invention.

[0056] Such as Figure 1-Figure 4 As shown, the present invention improves the packaging efficiency of the fruit packaging system. The conveying device includes a conveying belt 9 driven by a driving mechanism and a support I10 supporting the conveying belt 9. There are two conveying belts 9, and the conveying directions of the conveying belts 9 are parallel to each other. Between the two conveyor belts 9, there are several transmission rollers 11 evenly distributed along the extension direction of the conveyor belt 9, the two ends of the transmission rollers 11 are respectively connected with a conveyor belt 9, and the axes of the transmission rollers 11 are perpendicular to the conveyor belt 9 transmission directions;

[0057] Both ends of the limiting plate 6 are connected to the bracket I10 through the connecting arm 12 .

[0058] Annular grooves 13 are provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com