Extrusion forming feeding device for rebar connecting sleeve blank

A steel connection sleeve and extrusion molding technology, which is applied in the field of material conveying devices between stations, achieves the effects of reasonable layout, improved mechanization and automation, and increased economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

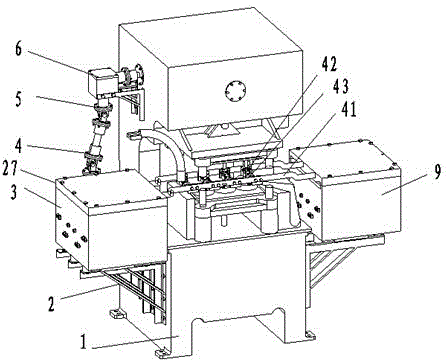

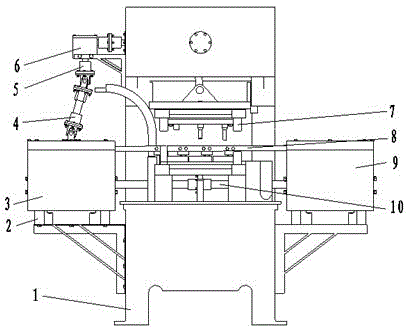

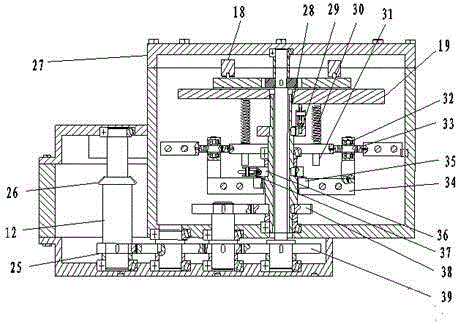

[0020] The invention is composed of a power transmission part, a mechanical transmission part and a manipulator execution part. The mechanical transmission part includes a left box body 3 and a right box body 9, the left box body 3 and the right box body 9 are respectively fixedly installed on both sides of the fuselage of the press 1, and the left box body 3 and the right box body 9 respectively have the same structure. Gear transmission mechanism, traverse transmission mechanism, lifting transmission mechanism, longitudinal clamping transmission mechanism.

[0021] The power of the press 1 is transmitted to the left box 3 and the right box 9 of the mechanical transmission part through the power transmission part. After the longitudinal clamping transmission mechanism drives the manipulator execution part to complete the clamping action of the blank workpiece, the lifting transmission mechanism drives the manipulator execution part After the clamping is completed, the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com