Mobile door removal electric equipment

An electric equipment, mobile technology, applied in metal processing equipment, vehicle parts, metal processing and other directions, can solve the problems of low work efficiency, high labor cost, hidden quality problems, etc., to achieve high work efficiency, high degree of automation, avoid quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

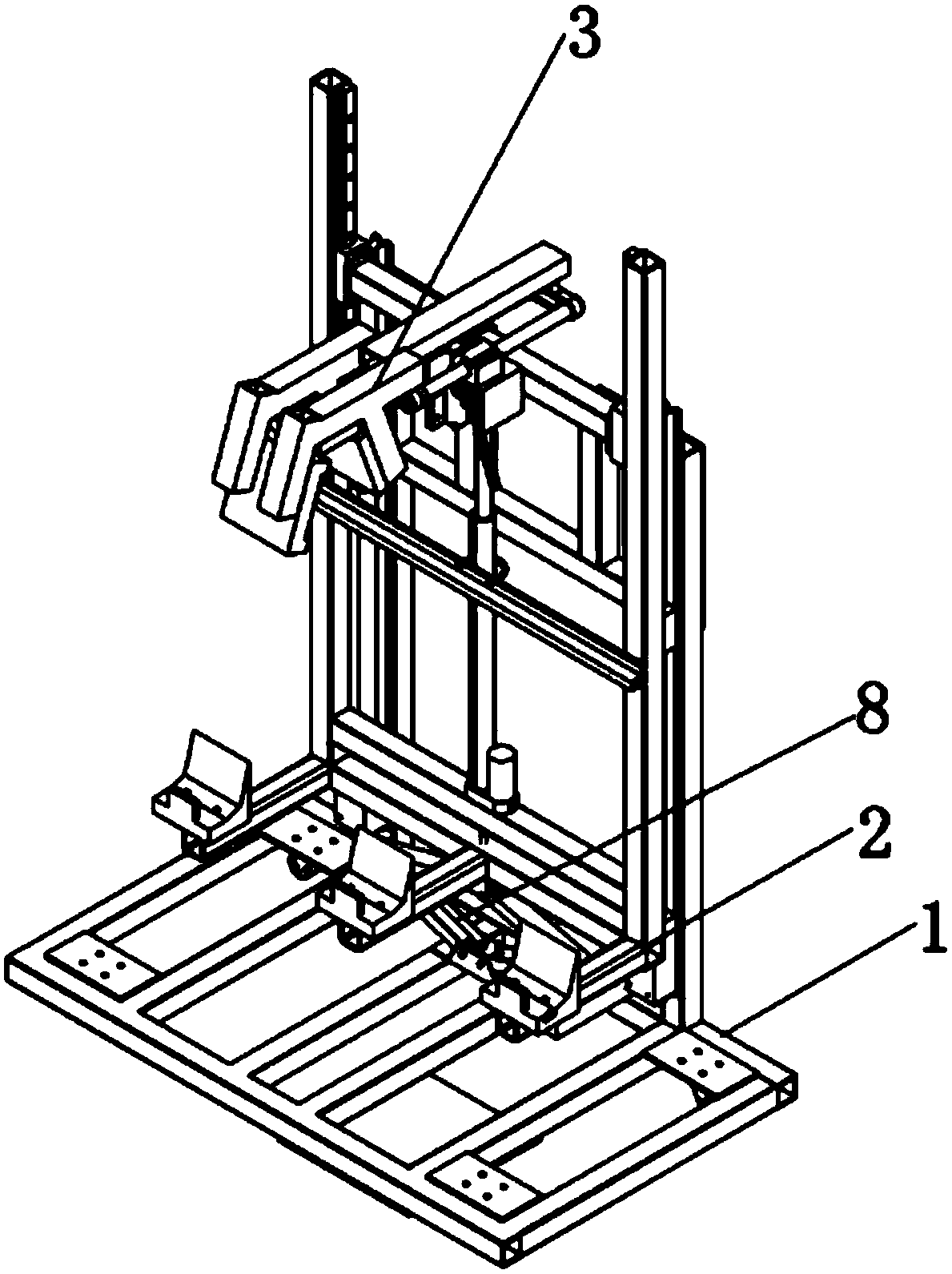

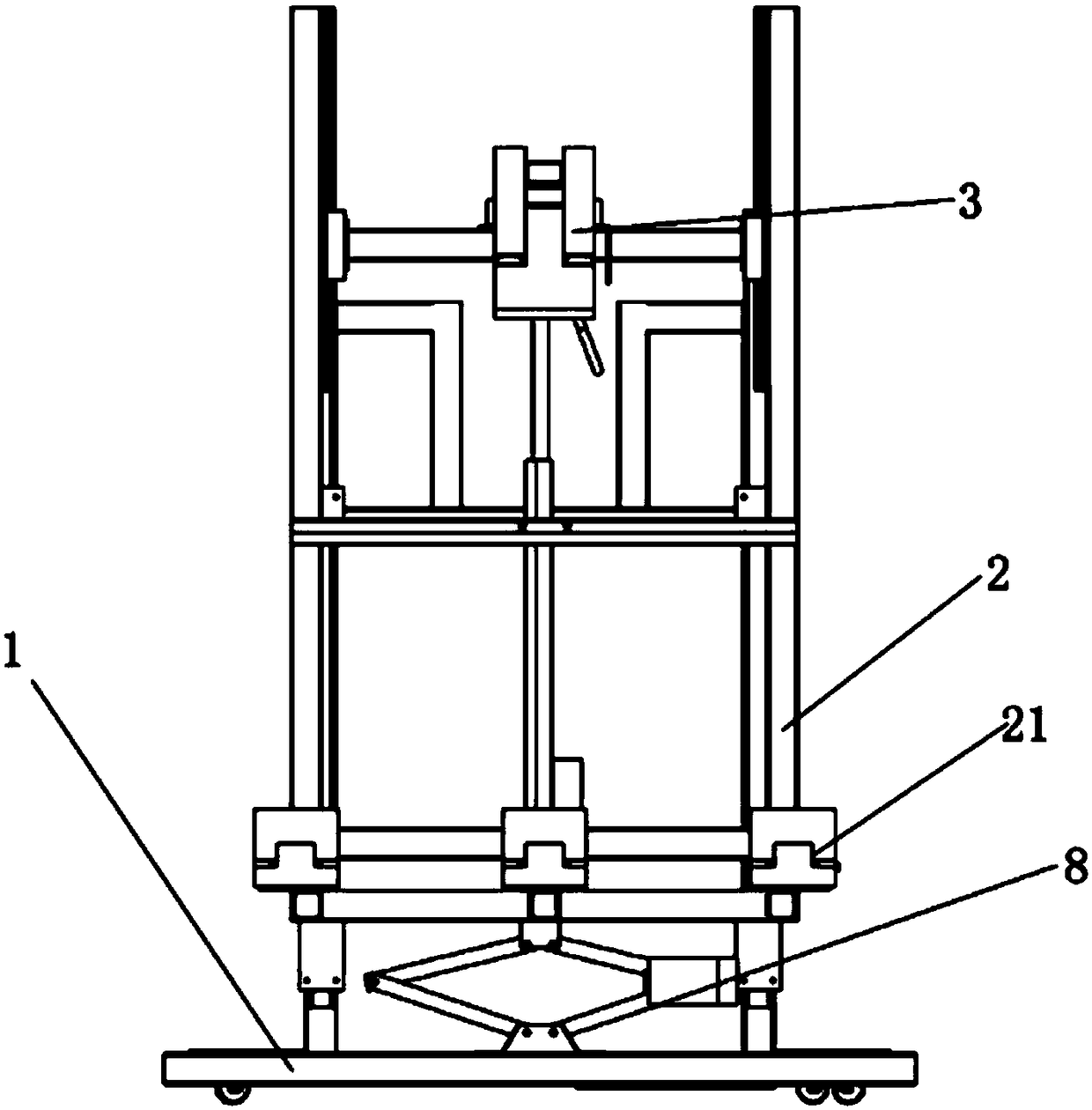

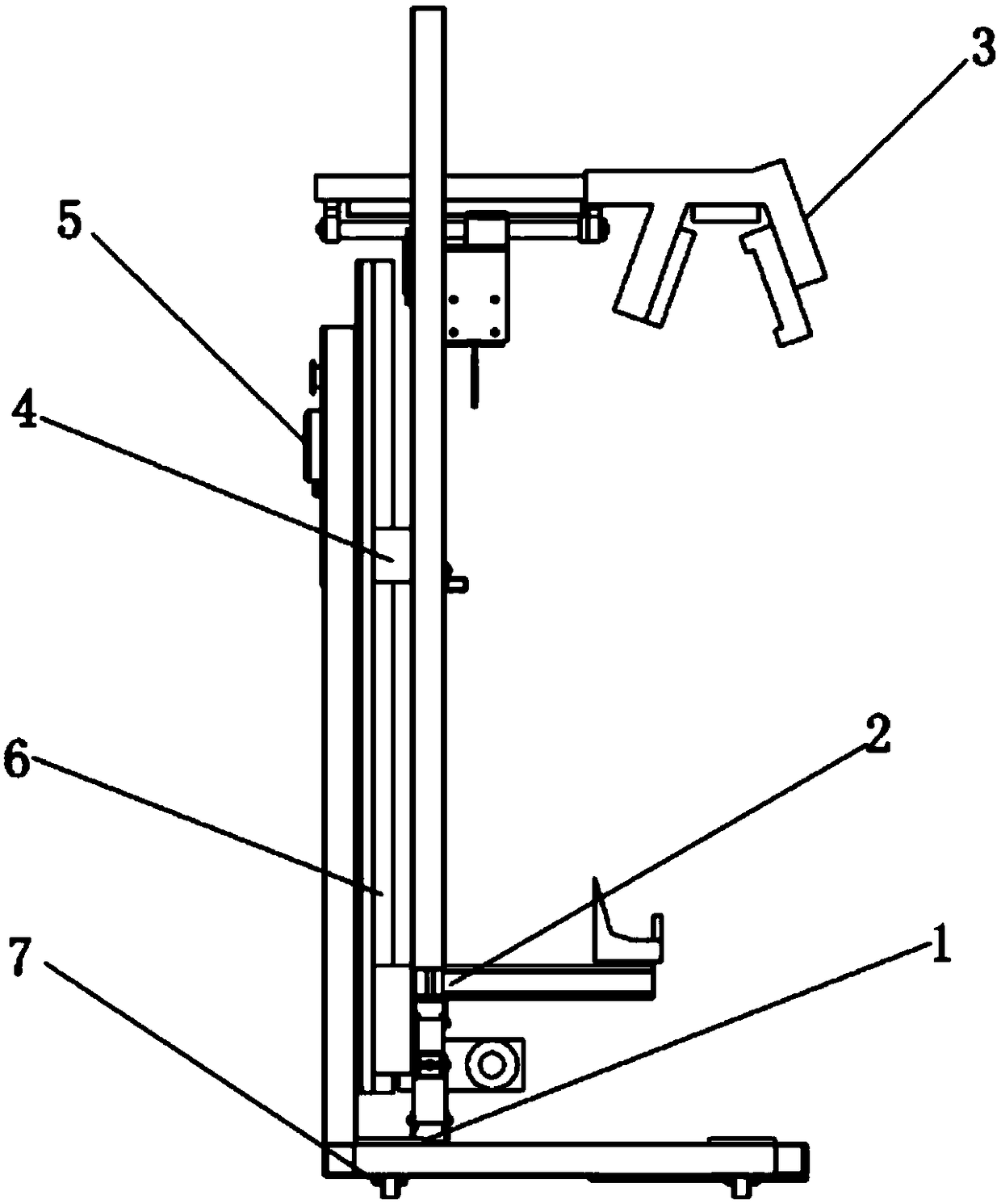

[0025] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

[0026] Such as Figure 1-Figure 7 As shown: the present invention provides a mobile door disassembly electric device, including a supporting frame 1, a lifting assembly 2 arranged on the supporting frame 1, a clamping arm assembly 3, and a power supply for controlling the lifting assembly 2 and the clamping arm assembly 3 Action control panel 5; lifting assembly 2 includes lower jaw 21 for clamping the lower part of the car door, clamp arm assembly 3 includes upper jaw 31 for clamping the upper part of the car door; The first drive mechanism for the claw 21 to rise and fall and the second drive mechanism for driving the upper jaw 31 to rise and fall.

[0027] In addition, the clamp arm assembly 3 also includes an adjustment mechanism 32 for adjusting the lateral position of the upper jaw 31, so as to improve the flexibility of the device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com