A Loose Handle Straightening Device for Recycling Waste Steel Wire Rope

A wire rope and loose handle technology, which is applied in the field of recycling waste steel wire rope equipment, can solve the problems of low automation, high labor intensity, and low operating efficiency, and achieve the effects of improved mechanization and automation, reasonable layout, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

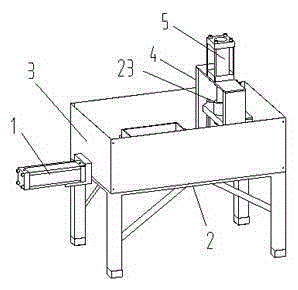

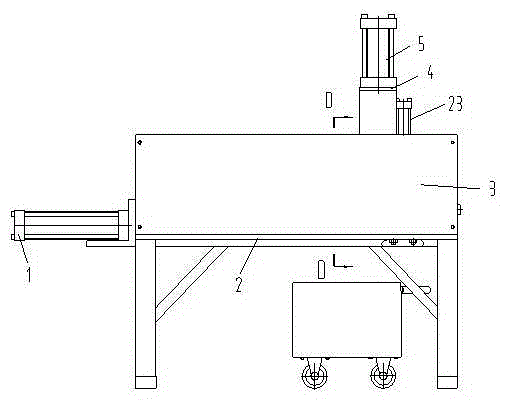

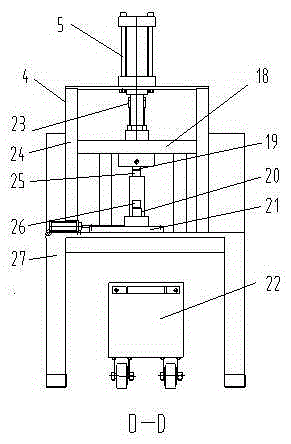

[0018] The present invention is composed of a body 27, a work surface 2, a traction rail 6, a feeding clamping mechanism, a clamping mechanism, a traction mechanism, a fixed-length cutting mechanism, and a blanking recovery device 22.

[0019] As shown in the figure, the feeding clamping mechanism is composed of a clamping cylinder 23 and a clamping slider 25. The clamping cylinder 23 is placed vertically, and the lower end of the cylinder push rod of the clamping cylinder 23 is connected with the clamping slider 25. After the wire rope passes through the inlet 26, the clamping cylinder 23 pushes the rod downward to push the clamping slider 25 with a sawtooth end to hold the wire rope. Adjust the working position of the clamping cylinder 23 and set the holding force to ensure that the wire rope advances under the traction force of the traction mechanism, while overcoming the radial torque of the traction mechanism, so that the wire rope does not twist.

[0020] As shown in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com